Table of Contents

Advertisement

Quick Links

Register at www.Toro.com.

Original Instructions (EN)

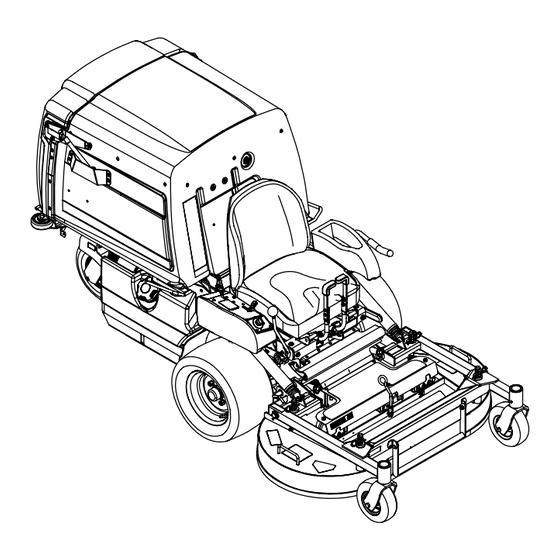

Z Master

®

Mower

With 42in and 48in Cutting Unit

Model No. 74314—Serial No. 400000000 and Up

Model No. 74316—Serial No. 400000000 and Up

Model No. 74318—Serial No. 400000000 and Up

Model No. 74319—Serial No. 400000000 and Up

Form No. 3466-575 Rev A

8000 Series Riding

*3466-575*

Advertisement

Table of Contents

Need help?

Do you have a question about the 74314 and is the answer not in the manual?

Questions and answers