Summary of Contents for TYROLIT Hydrostress DME32MW

- Page 1 OPERATING INSTRUCTIONS DME32MW l DME32UW DME26MW l DME26UW DME23UW Index 000 Translation of the original operating instructions 11005436 en | 20/03/2024...

- Page 2 All repairs must be performed by trained specialist personnel only. Our Customer Service is at your disposal to help keep your Tyrolit Hydrostress equipment in perfect condition. We wish you smooth, trouble-free working.

-

Page 3: Table Of Contents

Contents Contents 1. About these instructions 1.1. Symbols in these instructions 2. Safety 2.1. General safety information 2.2. Protection devices and signs on the equipment 2.3. Spare parts and modifications 2.4. Danger zone and work area 2.5. Product-specific hazards 2.6. Residual risks 3. -

Page 4: About These Instructions

About these instruCtions About these instructions This instruction manual is just part of the documentation for the power tool. This booklet is only complete together with the “core drilling safety manual/system description”. This booklet together with the “Core drilling safety manual/system description” is part of the equipment. -

Page 5: Safety

sAfety Safety Core drilling systems may only be used by authorised personnel. You can find information on authorised personal in the “Core drilling safety manual/system description”. General safety information WARNING Read all safety information and instructions. Failure to comply with the safety information and instructions may cause electric shock, fire and/or serious injury. - Page 6 sAfety 2.1.3 Personal safety • When operating the power tool, be attentive, pay attention to what you are doing and use common sense. Do not operate power tools when you are tired or under the influence of drugs, alcohol or medication. A moment of carelessness when operating the power tool can lead to serious injury.

-

Page 7: Protection Devices And Signs On The Equipment

sAfety 2.1.5 Service • Only have your tool repaired by qualified specialists, and only with genuine spare parts. This guarantees that the safety of the power tool is maintained. 2.1.6 Safety instructions for drilling machines • Wear ear protection when using drilling machines. Exposure to noise can cause hearing loss. -

Page 8: Spare Parts And Modifications

Personal protective equipment (PPE) Spare parts and modifications Only use genuine spare parts from Tyrolit Hydrostress. Otherwise, personal injury, damage to the equipment and other material damages can occur. Do not install attachments on or convert the equipment without the written consent of Tyrolit Hydrostress. -

Page 9: Product-Specific Hazards

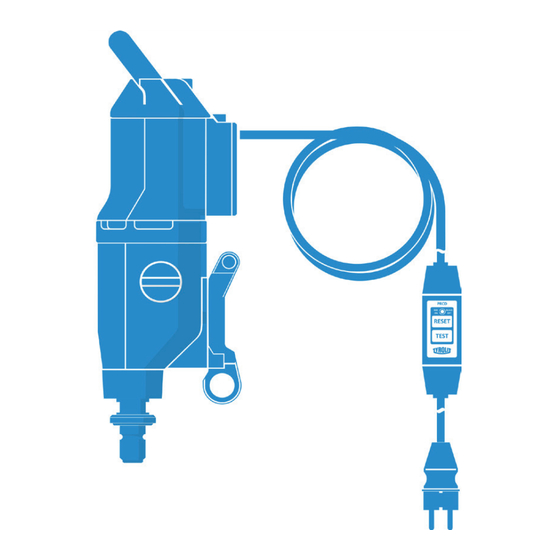

sAfety 2.4.2 Workstation danger zone INFORMATION You can find information on the workstation danger zone in the “Core drilling safety manual/system manual”. Product-specific hazards 2.5.1 Personal residual current protection device (PRCD, GFCI) – 230 V only Only work with a functional personal residual current protection device (PRCD, GFCI). Personal residual current protection device DANGER There is a risk of death or serious injury if this is not observed. - Page 10 sAfety 2.6.5 Harmful vapours and aerosol Inhaling harmful vapours and aerosols can lead to respiratory problems. Inhaling water spray emanating from the machine is hazardous to health. ►Wear a respirator mask. ►Make sure that closed rooms have adequate ventilation. 2.6.6 Poor physical condition ►Do not work under the influence of alcohol, drugs or medication.

-

Page 11: Product Description

Manipulating or modifying the device, drill rig and accessories is not permitted. Always use genuine Tyrolit Hydrostress accessories and suitable tools to avoid the risk of injuries. Scope of delivery • Drill motor •... -

Page 12: Technical Data And Main Dimensions

ProduCt desCriPtion Technical data and main dimensions 3.4.1 Technical data Drill motors DME32MW / UW DME26MW / UW DME23 UW Voltage 230 V/115 V 230 V/115 V 230 V 230 V/50 Hz 230 V/50 Hz Frequency 50 Hz 115 V/60 Hz 115 V/60 Hz Drill –... -

Page 13: Fluids And Lubricants

ProduCt desCriPtion Vibrations (EN ISO 5349) Parameter Value Whole-body vibration a < 2.5 m/s 3.4.2 Dimensions Dimensions in mm Fluids and lubricants Fluids and lubricants Parameter Value Transmission oil ISO 100 (Tyrolit No. 11008515 / 450ml) -

Page 14: Drilling Range

ProduCt desCriPtion Drilling range Example: DME32 | DRA400 Drilling range DME32 | DRA400... - Page 15 ProduCt desCriPtion Example: DME32 | DRA500 Drilling range DME32 | DRA500...

-

Page 16: Type Plate

ProduCt desCriPtion Type plate The type designation and serial number are marked on the type plate of your power tool. Type plate... -

Page 17: Design And Function

design And funCtion Design and function Design Design 1 Electric motor Module drill plate 2 Transmission Universal mounting plate 3 Quick release element Circuit breaker 4 Control panel Function 4.2.1 Functional description The drill spindle of the power tool is driven by means of an electric motor via a mechanical transmission. -

Page 18: Controls And Display Elements

design And funCtion Controls and display elements 4.3.1 Controls Controls 1 Handle (two mounting options) Main switch on/off 2 Rotary switch/gears Circuit breaker 3 Tap Drilling mode button 4 Easy release element... - Page 19 design And funCtion 4.3.2 Display elements Display elements 1 - 4 Light-emitting diodes Horizontal spirit level Vertical spirit level Display PRCD ON / OFF Gears marking LED colour code Power display at standstill LED 1+2 illuminates green Power tool is ready (normal mode) LED 1 illuminates green Power tool is ready (drilling mode) LED 2 illuminates green...

-

Page 20: Assembly/Disassembly

Assembly/disAssembly 5. 5. Assembly/disassembly Drill rig interface 5.1.1 Assembly 9 Tool SW 19 Open-end wrench Tyrolit No. 973784 Drill rig interface... -

Page 21: Cutting Tool Interface

Assembly/disAssembly Cutting tool interface 5.2.1 Assembly 9 Tool Allen key 6 mm Tyrolit No. 973792 Open-end wrench Tyrolit No. 973776 SW32 Open-end wrench Tyrolit No. 973779 SW41 Cutting tool interface... -

Page 22: Power Supply

Assembly/disAssembly Power supply INFORMATION • The mains voltage must match the specifications on the type plate. • Protect the connecting cables against heat, oil and sharp edges. • Only use the connecting cables for their intended purpose. • Never carry the power tool by the connecting cable. •... -

Page 23: Water

Assembly/disAssembly Water 5.4.1 Water connection Water connection 5.4.2 Cooling water Cooling water Parameter Value Hollow drill dia. in mm 52-152 162-202 212-300 350-450 Cooling water in l/min 2.5-3.0 Water connection max. 3 bar at max 25°C 5.4.3 Dry drilling INFORMATION Special Tyrolit diamond tools must be used for dry drilling. - Page 24 Assembly/disAssembly 5.4.4 Blowing out water Blowing out water Proceed as follows: ►Pull out the mains plug. ►Detach all water lines. ►Connect purge pump to the water coupling. ►Blow out water until all coolant has been removed. ►Remove the pump. INFORMATION Use the Tyrolit purge pump No.

-

Page 25: Operation

oPerAtion Operation DANGER • Never work without suitable PPE. • Always wear ear protection during work. • Remove adjustment and assembly tools before switching on the power tool. • Do not work on ladders. • Keep children away from the power tool and the working area. •... -

Page 26: Select Drilling Mode

oPerAtion Select drilling mode Mode Display Normal mode Normal mode Monitoring, inspections 6.4.1 Residual current circuit breaker ►Switch on and inspect the PRCD residual current circuit breaker. Inspection process: ►Insert the mains plug of the power tool into a socket outlet with an earth connection. ►Press the reset button on the residual current circuit breaker PRCD (display must illuminate). -

Page 27: Troubleshooting

Troubleshooting Troubleshooting Problem Possible cause Remedy Power tool will not start Mains cable is faulty Contact Tyrolit Hydrostress AG Customer Service Power supply faulty Check the power supply Electric motor or electron- Contact Tyrolit Hydrostress AG ics defective Customer Service... -

Page 28: Servicing And Maintenance

Recycling waste materials INFORMATION Tyrolit Hydrostress power tools are manufactured using a large proportion of recyclable materials. Proper material separation is a prerequisite for recycling. In many countries, Tyrolit has already set up arrangements for returning your old equipment for recycling. Ask... -

Page 29: Ec Declaration Of Conformity

Conformity EC Declaration of Conformity Designation Electric drill motor Type designation DME32MW l DME32UW DME26MW l DME26UW DME23UW We declare under our sole responsibility that this product complies with the following directives and standards: Applicable directives 2006/42/EC... - Page 30 TYROLIT CONSTRUCTION PRODUCTS GMBH Swarovskistraße 33 | 6130 Schwaz | Austria Tel +43 5242 606-0 | Fax +43 5242 63398 Our worldwide subsidiary companies can be found on our website at www.tyrolit.com...

Need help?

Do you have a question about the DME32MW and is the answer not in the manual?

Questions and answers