Advertisement

Telephone: 269-945-9501 Technical Services: 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com

1. DESCRIPTION

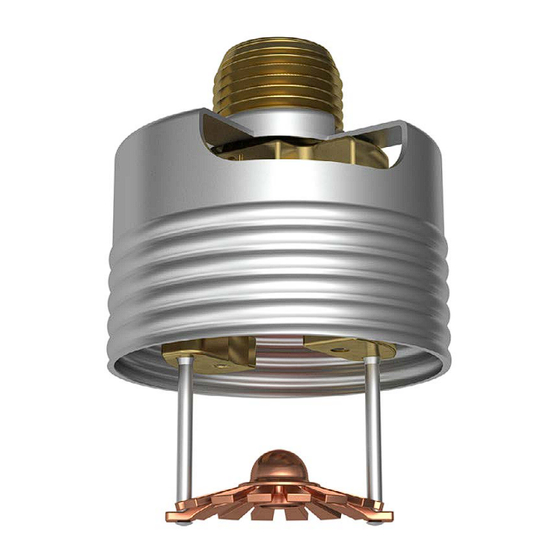

Viking Mirage

Standard Response Concealed Pendent sprinkler VK492 is a

®

thermosensitive glass-bulb spray sprinkler designed for installation on concealed

pipe systems where the appearance of a smooth ceiling is desired.

The sprinkler is pre-assembled with a threaded adapter for installation with a low-

profile cover assembly that provides up to ½" (13 mm) of vertical adjustment. The

two-piece design allows installation and testing of the sprinkler prior to installation of

the cover plate. The The "push-on" and "thread-on" designs of the concealed cover

plate assemblies allow easy installation of the cover plate after the system has been

tested and the ceiling finish has been applied. The cover assembly can be removed

and reinstalled, allowing temporary removal of ceiling panels without taking the

sprinkler system out of service or removing the sprinkler.

2. LISTINGS AND APPROVALS

cULus Listed: Category VNIV

FM Approval: Class 2015

China Approval: Approved according to China GB standard.

Refer to the Approval Charts and Design Criteria listing and approval requirements

that must be followed.

3. TECHNICAL DATA

Specifications:

Product release: 2016

Pressure: 7 psi (0.5 bar)

Maximum Working Pressure: 175 psi (12 bar)

Factory tested hydrostatically to 500 psi (34.5 bar)

Thread size: 1/2" (15 mm) NPT

Nominal K-Factor: 5.6 U.S. (80.6 metric

Glass-bulb fluid temperature rated to -65°F (-55°C)

Patents Pending

* Metric K-factor measurement shown is when pressure is measured in Bar. When pressure is

measured in kPa, divide the metric K-factor shown by 10.0.

Material Standards:

Sprinkler Body: Brass UNS-C84400

Deflector: Copper UNS-C19500

Deflector Pins: Stainless Steel Alloy

Bulb: Glass, nominal 5 mm diameter

Pip Cap and Insert Assembly: Copper UNS-C11000 and Stainless Steel UNS-S30400

Button: Brass UNS-C36000

Screws: 18-8 Stainless Steel

Belleville Spring Sealing Assembly: Nickel Alloy, coated on both sides with PTFE tape

Yoke: Phosphor Bronze UNS-C51000

Cover Adapter: Cold Rolled Steel UNS-G10080, Finish: Clear Chromate over zinc plating

Cover Assembly Materials:

Cover: Copper UNS-C11000

Base: Brass UNS-C26000 or UNS-C26800

Springs: Nickel Alloy

Solder: Eutectic

Ordering Information: The sprinkler and cover plate must be ordered separately. Refer to Tables 1 and 2.

4. INSTALLATION

Refer to appropriate NFPA Installation Standards.

5. OPERATION

During fire conditions, when the temperature around the sprinkler approaches its operating temperature, the cover plate detaches.

Continued heating of the exposed sprinkler causes the heat-sensitive liquid in the glass bulb to expand and the bulb to shatter,

Form No. F_101615

Rev 02

TECHNICAL DATA

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

Visit the Viking website for the latest edition of this technical data page.

)

*

September 2023

MIRAGE

STANDARD

®

RESPONSE CONCEALED

PENDENT SPRINKLER VK492

(K5.6)

Replaces Form No. F_101615 Rev 01

(Updated 135F cover plate temp. to 139F.)

Page 1 of 6

Advertisement

Table of Contents

Summary of Contents for Viking MIRAGE VK492

- Page 1 (K5.6) The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058 Telephone: 269-945-9501 Technical Services: 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com Visit the Viking website for the latest edition of this technical data page. 1. DESCRIPTION Viking Mirage Standard Response Concealed Pendent sprinkler VK492 is a ®...

-

Page 2: Technical Data

Refer to NFPA 25 for Inspection, Testing and Maintenance requirements. 7. AVAILABILITY Viking Sprinklers VK492 are available through a network of domestic and international distributors. See The Viking Corporation web site for the closest distributor or contact The Viking Corporation. - Page 3 Part number shown is the base part number. For complete part number, refer to current Viking price list schedule. Where a dash (-) is shown in the Finish suffix designation, insert the desired Temperature Rating suffix. See example above.

- Page 4 Footnotes Part number shown is the base part number. For complete part number, refer to current Viking price list schedule. Metric K-factor measurement shown is when pressure is measured in Bar. When pressure is measured in kPa, divide the metric K-factor shown by 10.0.

- Page 5 FM Approval Requirements: Viking Concealed Pendent Sprinkler VK492 is FM Approved as a standard response Non-Storage concealed pendent sprinkler as indicated in the FM Approval Guide. For specific application and installation requirements, reference the latest applicable FM Loss Prevention Data Sheets (including Data Sheet 2-0).

- Page 6 The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058 Telephone: 269-945-9501 Technical Services: 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com Visit the Viking website for the latest edition of this technical data page. 1/2” (15 mm) NPT 2-9/16” (65 mm) 2-1/16”...

- Page 7 Refer to the appropriate technical data page and NFPA standards for complete care, handling, installation, and maintenance instructions. For additional product and system information Viking data pages and installation instructions are available on the Viking Web site at www.vikinggroupinc.com.

- Page 8 * Refer to the appropriate current technical data pages for complete care, handling, and installation instructions. Data pages are included with each shipment from Viking or Viking distributors. They can also be found on the Web site at www. vikinggroupinc.com.

- Page 9 • while ceiling finish work is being completed. Use only the designated Viking recessed sprinkler wrench (refer to the appropriate sprinkler data page) to install these sprinklers. NOTE: The protective cap is • temporarily removed during installation and then placed back on the sprinkler for protection until finish work is completed.

- Page 10 Take care not to crack the wax coating on the units. • For touching up the wax coating after installation, wax is available from Viking in bar form. Refer to Table 1 below. The coating MUST be repaired after •...

-

Page 11: Listings And Approvals

1. DESCRIPTION Viking fire sprinklers consist of a threaded frame with a specific waterway or orifice size and a deflector for distributing water in a specified pattern. A closed or sealed sprinkler refers to a complete assembly, including the thermosensitive operating element. An open sprinkler does not use an operating element and is open at all times. - Page 12 TECHNICAL DATA SPRINKLER OVERVIEW The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058 Telephone: 269-945-9501 Technical Services: 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com VERTICAL SIDEWALL (VSW) SPRINKLER: A sprinkler intended for installation near the wall and ceiling. The deflector provides a water spray pattern outward in a quarter-spherical pattern and can be installed in the upright or pendent position with the flow arrow in the direction of discharge.

- Page 13 Refer to NFPA 25 for Inspection, Testing and Maintenance requirements. 7. AVAILABILITY Viking sprinklers are available through a network of domestic and international distributors. See The Viking Corporation web site for the closest distributor or contact The Viking Corporation. 8. GUARANTEE For details of warranty, refer to Viking’s current list price schedule or contact Viking directly.

-

Page 14: Installation

STANDARD RESPONSE, QUICK RESPONSE, EXTENDED COVERAGE, AND DRY SPRINKLERS Viking thermosensitive spray sprinklers consist of a small frame and either a glass bulb or a fusible operating element. Available styles include pendent, flush pendent, concealed pendent, upright, horizontal sidewall, vertical sidewall, or conventional, depending on the particular sprinkler model selected. - Page 15 C. Installation Instructions - Dry Sprinklers WARNING: Viking dry sprinklers are to be installed in the 1” outlet (for dry and preaction systems), or run of malleable, ductile iron, or Nibco CPVC* threaded tee fittings (for wet systems) that meet the dimensional requirements of ANSI B16.3 (Class 150), or cast iron threaded tee fittings that meet the dimensional requirements of ANSI B16.4 (Class 125), even at branch line ends.

-

Page 16: Operation

4. After installation, the entire sprinkler system must be tested. The test must be conducted to comply with the installation stand- ards. Viking high pressure sprinklers may be hydrostatically tested at a maximum of 300 psi (20.7 bar) for limited periods of time (two hours), for the purpose of acceptance by the Authority Having Jurisdiction. - Page 17 Refer to the Authority Having Jurisdiction for minimum replacement requirements. 7. AVAILABILITY Viking sprinklers are available through a network of domestic and international distributors. See The Viking Corporation web site for the closest distributor or contact The Viking Corporation.

-

Page 18: Warranty Terms And Conditions

For more information, go to www.P65Warnings.ca.gov 2. WARRANTY TERMS AND CONDITIONS For details of warranty, refer to Viking’s current list price schedule at www.vikinggroupinc.com or contact Viking directly. New Bulletin Form No. F_111218 18.11.15...

Need help?

Do you have a question about the MIRAGE VK492 and is the answer not in the manual?

Questions and answers