Table of Contents

Advertisement

Quick Links

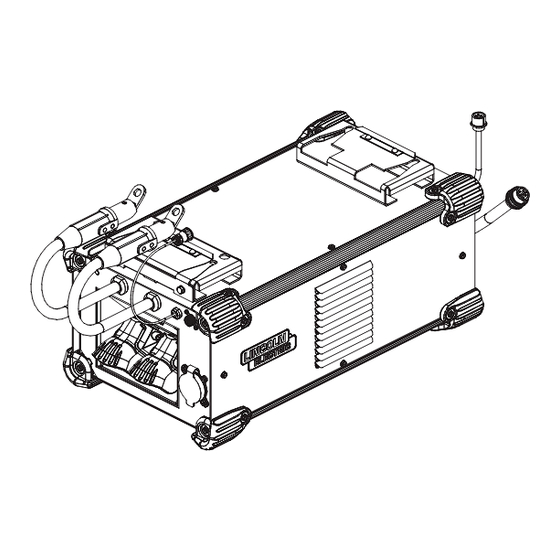

POWER WAVE ® ADVANCED MODULE

For use with machines having Code Numbers:

Power Wave Advanced Module: 11935,

12376

SERVICE MANUAL

SVM241-A

| Issue D ate 18-Oct

© Lincoln Global, Inc. All Rights Reserved.

NOTE: This manual will cover most of the troubleshooting and repair

procedures for the code numbers listed. Some variances may exist when

troubleshooting/repairing later code numbers.

Advertisement

Table of Contents

Troubleshooting

Subscribe to Our Youtube Channel

Summary of Contents for Lincoln Electric POWER WAVE 11935

- Page 1 NOTE: This manual will cover most of the troubleshooting and repair procedures for the code numbers listed. Some variances may exist when troubleshooting/repairing later code numbers. POWER WAVE ® ADVANCED MODULE For use with machines having Code Numbers: Power Wave Advanced Module: 11935, 12376 SERVICE MANUAL SVM241-A...

- Page 2 POWER WAVE ADVANCED MODULE SAFETY ® THANK YOU FOR SELECTING A QUALITY PRODUCT BY KEEP YOUR HEAD OUT OF THE FUMES. DON’T get too close to the arc. LINCOLN ELEC TRIC. Use corrective lenses if necessary to stay a reasonable distance away from the arc.

- Page 3 MAGNETIC FIELDS MAY W117.2-1974. A Free copy of “Arc Welding Safety” booklet BE DANGEROUS E205 is available from the Lincoln Electric Company, 22801 St. Clair Avenue, Cleveland, Ohio 44117-1199. 2.a. Electric current flowing through any conductor BE SURE THAT ALL INSTALLATION, OPERATION, causes localized Electric and Magnetic Fields (EMF).

- Page 4 POWER WAVE ADVANCED MODULE SAFETY ® SAFETY ELECTRIC SHOCK ARC RAYS CAN BURN. CAN KILL. 3.a. The electrode and work (or ground) circuits are 4.a. Use a shield with the proper filter and cover plates to protect your electrically “hot” when the welder is on. Do eyes from sparks and the rays of the arc when welding or not touch these “hot”...

- Page 5 POWER WAVE ADVANCED MODULE SAFETY ® SAFETY WELDING AND CUTTING CYLINDER MAY EXPLODE IF SPARKS CAN CAUSE DAMAGED. FIRE OR EXPLOSION. 7.a. Use only compressed gas cylinders containing the correct shielding gas for the process used 6.a. Remove fire hazards from the welding area. If and properly operating regulators designed for this is not possible, cover them to prevent the welding sparks the gas and pressure used.

- Page 6 POWER WAVE ADVANCED MODULE TABLE OF CONTENTS ® MASTER TABLE OF CONTENTS FOR ALL SECTIONS Page Safety ..........................................i-iv Installation, Operation, Accessories, Maintenance ................... See IM10149 Theory of Operation ................................Section E Troubleshooting and Repair ............................Section F Electrical Diagrams ................................Section G...

- Page 7 POWER WAVE ADVANCED MODULE THEORY OF OPERATION ® TABLE OF CONTENTS - THEORY OF OPERATION SECTION - Theory Of Operation ......................Section E Output ................... .E-2 AC Switch Control Board .

- Page 8 40VDC HIGH FREQUENCY DIFF TO BOARD STT AND AC ELECTRODE RECEPTACLE / PIGTAIL TERMINAL HIGH HIGH FREQUENCY FREQUENCY TRANSFORMER PULSE BACKGROUND CHOKE ELECTRODE AC SWITCH TERMINAL BACKGROUND CONTROL BOARD DIODE INPUT FROM BLOCKING WORK POWER DIODE THERMOSTAT – SUPPLY TERMINAL 40VDC ARCLINK ARCLINK CAN...

- Page 9 40VDC HIGH FREQUENCY DIFF TO BOARD STT AND AC ELECTRODE RECEPTACLE / PIGTAIL TERMINAL HIGH HIGH FREQUENCY FREQUENCY TRANSFORMER PULSE BACKGROUND CHOKE ELECTRODE AC SWITCH TERMINAL BACKGROUND CONTROL BOARD DIODE INPUT FROM BLOCKING WORK POWER DIODE THERMOSTAT – SUPPLY TERMINAL 40VDC ARCLINK ARCLINK CAN...

- Page 10 POWER WAVE ADVANCED MODULE THEORY OF OPERATION ® Figure E.4 - Tig welding and high frequency circuit 40VDC HIGH FREQUENCY DIFF TO BOARD STT AND AC ELECTRODE RECEPTACLE / PIGTAIL TERMINAL HIGH HIGH FREQUENCY FREQUENCY TRANSFORMER PULSE BACKGROUND CHOKE ELECTRODE AC SWITCH TERMINAL BACKGROUND...

-

Page 11: Table Of Contents

POWER WAVE ADVANCED MODULE TROUBLESHOOTING AND REPAIR ® TABLE OF CONTENTS - TROUBLESHOOTING AND REPAIR SECTION - Troubleshooting And Repair ....................Section F How To Use Troubleshooting Guide ..............F-2 PC Board Troubleshooting Procedures . -

Page 12: How To Use Troubleshooting Guide

HOW TO USE TROUBLESHOOTING GUIDE WARNING Service and repair should be performed by only Lincoln Electric Factory Trained Personnel. Unauthorized repairs performed on this equipment may result in danger to the technician and machine operator and will invalidate your factory warranty. For your safety and to avoid Electrical Shock, please observe all safety notes and precautions detailed throughout this manual. -

Page 13: Pc Board Troubleshooting Procedures

POWER WAVE ADVANCED MODULE TROUBLESHOOTING AND REPAIR ® PC BOARD TROUBLESHOOTING PROCEDURES 4. Test the machine to determine if the failure symptom has been WARNING corrected by the replacement PC board. NOTE: It is desirable to have a spare (known good) PC board available for PC board troubleshooting. -

Page 14: Troubleshooting Guide

Power Wave Advanced Module. See the Wiring Diagram. CAUTION If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. - Page 15 Power Wave power source. CAUTION If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877.

- Page 16 AC Switch Control Board Test. CAUTION If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877.

- Page 17 3. There may be a software problem. See Power Wave Manager. CAUTION If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877.

- Page 18 CAUTION If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877.

-

Page 19: Using The Status Led To Troubleshoot System Problems

Not applicable. BLINKING RED Not applicable. CAUTION If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. -

Page 20: Error Codes For The Advanced Module

Service Department. CAUTION If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. F-10... - Page 21 CASE COVER REMOVAL AND REPLACEMENT PROCEDURE WARNING Service and repair should be performed only by Lincoln Electric factory trained personnel. Unauthorized repairs performed on this equipment may result in danger to the technician or machine operator and will invalidate your factory warranty.

-

Page 22: Case Cover Removal And Replacement Procedure

POWER WAVE ADVANCED MODULE TROUBLESHOOTING AND REPAIR ® CASE COVER REMOVAL AND REPLACEMENT PROCEDURE (continued) Figure F.1 – Corner cap removal CORNER CAP SCREWS AND WASHERS REMOVAL PROCEDURE ROOF REMOVAL 1. Remove all corner caps and both case sides. 2. Using a 7/16” nutdriver, remove the two bolts and associated CORNER CAP REMOVAL washers securing the locking bracket to the front mounting bracket assembly. - Page 23 POWER WAVE ADVANCED MODULE TROUBLESHOOTING AND REPAIR ® CASE COVER REMOVAL AND REPLACEMENT PROCEDURE (continued) Figure F.2 – Case side removal CASE COVER MOUNTING SCREWS (4 ON EACH SIDE) Figure F.3 – Roof removal MOUNTING BRACKET BOL TS ROOF (4 SCREWS) MOUNTING MOUNTING SCREWS...

- Page 24 POWER WAVE ADVANCED MODULE TROUBLESHOOTING AND REPAIR ® CASE COVER REMOVAL AND REPLACEMENT PROCEDURE (continued) REPLACEMENT PROCEDURE RIGHT CASE SIDE REPLACEMENT 1. Carefully position the right case side onto the machine. 2. Using a 5/16” nutdriver, attach the four case cover mounting ROOF REPLACEMENT screws securing the right case side.

-

Page 25: High Frequency Transformer Test

HIGH FREQUENCY TRANSFORMER TEST WARNING Service and repair should be performed only by Lincoln Electric factory trained personnel. Unauthorized repairs performed on this equipment may result in danger to the technician or machine operator and will invalidate your factory warranty. For your safety and to avoid electrical shock, please observe all safety notes and precautions detailed throughout this manual. - Page 26 POWER WAVE ADVANCED MODULE TROUBLESHOOTING AND REPAIR ® HIGH FREQUENCY TRANSFORMER TEST (continued) Figure F.4 – High frequency transformer location HIGH FREQUENCY TRANSFORMER 10. Using a 7/16” wrench, attach the secondary leads. PROCEDURE 11. Attach the two primary leads to terminals B1 and B2. 1.

- Page 27 POWER WAVE ADVANCED MODULE TROUBLESHOOTING AND REPAIR ® HIGH FREQUENCY TRANSFORMER TEST (continued) Figure F.5 – High frequency transformer test points FERRITE SLUG SECONDARY COIL PRIMARY TURN SECONDARY F-17...

- Page 28 POWER WAVE ® ADVANCED MODULE NOTES F-18...

-

Page 29: Gas Solenoid Test

GAS SOLENOID TEST WARNING Service and repair should be performed only by Lincoln Electric factory trained personnel. Unauthorized repairs performed on this equipment may result in danger to the technician or machine operator and will invalidate your factory warranty. For your safety and to avoid electrical shock, please observe all safety notes and precautions detailed throughout this manual. - Page 30 POWER WAVE ADVANCED MODULE TROUBLESHOOTING AND REPAIR ® GAS SOLENOID TEST (continued) Figure F.6 – Gas solenoid location GAS SOLENOID 10. Connect the two previously removed leads (412 and 406) to the PROCEDURE gas solenoid. 1. Remove input power to the machine. Case Cover Replacement Procedure.

- Page 31 POWER WAVE ADVANCED MODULE TROUBLESHOOTING AND REPAIR ® GAS SOLENOID TEST (continued) Figure F.7 – Gas solenoid lead location GROUND TERMINAL F-21...

- Page 32 POWER WAVE ® ADVANCED MODULE NOTES F-22...

-

Page 33: Ac Switch Control Board Test

AC SWITCH CONTROL BOARD TEST WARNING Service and repair should be performed only by Lincoln Electric factory trained personnel. Unauthorized repairs performed on this equipment may result in danger to the technician or machine operator and will invalidate your factory warranty. For your safety and to avoid electrical shock, please observe all safety notes and precautions detailed throughout this manual. - Page 34 POWER WAVE ADVANCED MODULE TROUBLESHOOTING AND REPAIR ® AC SWITCH CONTROL BOARD TEST (continued) Figure F.8 – AC switch control board assembly location AC SWITCH CONTROL BOARD PROCEDURE 1. Remove input power to the machine. Case Cover Removal Procedure. 2. Perform the 3.

- Page 35 POWER WAVE ADVANCED MODULE TROUBLESHOOTING AND REPAIR ® AC SWITCH CONTROL BOARD TEST (continued) Figure F.9 – STT snubber resistor lead location STT SNUBBER RESISTORS AND LEADS Figure F.10 – Advance module test points NEGATIVE POSITIVE INPUT INPUT WORK ELECTRODE OUTPUT OUTPUT F-25...

- Page 36 POWER WAVE ADVANCED MODULE TROUBLESHOOTING AND REPAIR ® AC SWITCH CONTROL BOARD TEST (continued) Table F.3 – Advance module (DMM diode test function) With all output (weld) cables disconnected from the module and all input cables disconnected from the power source, perform the following tests at the specified locations: DEVICES TESTED ON RED PROBE...

- Page 37 POWER WAVE ADVANCED MODULE TROUBLESHOOTING AND REPAIR ® AC SWITCH CONTROL BOARD TEST (continued) Figure F.11 – AC switch control board test points and LED locations POSITIVE NEGATIVE X14 HEAT BUS BAR BUS BAR SINK LED3 LED1 5 LED13 LED1 4 LED6 LED5 LED11...

- Page 38 POWER WAVE ADVANCED MODULE TROUBLESHOOTING AND REPAIR ® AC SWITCH CONTROL BOARD TEST (continued) Table F.5 – Status LEDs function COLOR FUNCTION INDICATION GREEN H-BRIDGE Normal Status: ON STATUS Fault Condition: If the snubber capacitor voltage exceeds its threshold, the acceptable voltage across the switch is exceeded or the power supplies voltages are insufficient, the LED will be off.

-

Page 39: Background Diode Test

BACKGROUND DIODE TEST WARNING Service and repair should be performed only by Lincoln Electric factory trained personnel. Unauthorized repairs performed on this equipment may result in danger to the technician or machine operator and will invalidate your factory warranty. For your safety and to avoid electrical shock, please observe all safety notes and precautions detailed throughout this manual. - Page 40 POWER WAVE ADVANCED MODULE TROUBLESHOOTING AND REPAIR ® BACKGROUND DIODE TEST (continued) Figure F.12 – Background diode location BACKGROUND DIODE VIEWED FROM TOP PROCEDURE 1. Remove input power to the machine. Case Cover Removal Procedure. 2. Perform the 3. Locate the background diode. See Figure F.12. 4.

- Page 41 POWER WAVE ADVANCED MODULE TROUBLESHOOTING AND REPAIR ® BACKGROUND DIODE TEST (continued) Figure F.13 – Background diode test point locations CATHODE ANODE (TO AC SWITCH CONTROL BOARD) (FROM BACKGROUND CHOKE) LEAD B7 LEAD B1C CHOKE LEAD BACKGROUND DIODE F-31...

- Page 42 POWER WAVE ® ADVANCED MODULE NOTES F-32...

-

Page 43: Input Blocking Diode Test

INPUT BLOCKING DIODE TEST WARNING Service and repair should be performed only by Lincoln Electric factory trained personnel. Unauthorized repairs performed on this equipment may result in danger to the technician or machine operator and will invalidate your factory warranty. For your safety and to avoid electrical shock, please observe all safety notes and precautions detailed throughout this manual. - Page 44 POWER WAVE ADVANCED MODULE TROUBLESHOOTING AND REPAIR ® INPUT BLOCKING DIODE TEST (continued) Figure F.14 – Input blocking diode locations AC SWITCH CONTROL BOARD ASSEMBLY INPUT DIODE BUS BAR INPUT BLOCKING DIODES PROCEDURE 1. Remove input power to the machine. Case Cover Removal Procedure.

-

Page 45: Power Wave Advanced Module Functional Test

POWER WAVE ADVANCED MODULE FUNCTIONAL TEST WARNING Service and repair should be performed only by Lincoln Electric factory trained personnel. Unauthorized repairs performed on this equipment may result in danger to the technician or machine operator and will invalidate your factory warranty. - Page 46 POWER WAVE ADVANCED MODULE TROUBLESHOOTING AND REPAIR ® POWER WAVE ADVANCED MODULE FUNCTIONAL TEST (continued) Figure F.15 – Short circuit test K1543-XX K1543-XX FROM FROM FEEDER FEEDER S350 S500 K2230-1 PF-10M PROCEDURE OPEN CIRCUIT TEST Figure F.16) (See 1. With the output disabled, remove short from work and electrode SHORT CIRCUIT TEST studs of the advanced module.

- Page 47 POWER WAVE ADVANCED MODULE TROUBLESHOOTING AND REPAIR ® POWER WAVE ADVANCED MODULE FUNCTIONAL TEST (continued) Figure F.16 – Open circuit test K1543-XX TO STT MODULE K2230-1 PF-10M Table F.6 – Short circuit test VOLTAGE INDICATION / POSSIBLE CAUSE AC Switch Shorted: •...

- Page 48 POWER WAVE ADVANCED MODULE TROUBLESHOOTING AND REPAIR ® POWER WAVE ADVANCED MODULE FUNCTIONAL TEST (continued) Figure F.17 – Status LED locations LED3 LED15 LED13 LED14 LED6 LED5 LED1 LED9 LED1 LED7 LED4 LED8 LED2 LED10 G7103-1 AC/STT SWITCH Table F.7 – Status LEDs function COLOR FUNCTION INDICATION...

- Page 49 POWER WAVE ADVANCED MODULE TROUBLESHOOTING AND REPAIR ® POWER WAVE ADVANCED MODULE FUNCTIONAL TEST (continued) Table F.8 – Open circuit test VOLTAGE INDICATION / POSSIBLE CAUSE < 70 VAC AC Switch Shorted: • Faulty or disconnected differential I/O control signal (grey cable located at rear of module). - Verify cable connections (including those internal to the module and host power source).

- Page 50 POWER WAVE ® ADVANCED MODULE NOTES F-40...

-

Page 51: High Frequency Board Test

HIGH FREQUENCY BOARD TEST WARNING Service and repair should be performed only by Lincoln Electric factory trained personnel. Unauthorized repairs performed on this equipment may result in danger to the technician or machine operator and will invalidate your factory warranty. For your safety and to avoid electrical shock, please observe all safety notes and precautions detailed throughout this manual. - Page 52 POWER WAVE ADVANCED MODULE TROUBLESHOOTING AND REPAIR ® HIGH FREQUENCY BOARD TEST (continued) Figure F.18 – High frequency board location HIGH FREQUENCY BOARD VIEWED FROM TOP PROCEDURE 1. Perform the Case Cover Removal Procedure. 2. Locate the high frequency board. See Figure F.18. 3.

- Page 53 POWER WAVE ADVANCED MODULE TROUBLESHOOTING AND REPAIR ® HIGH FREQUENCY BOARD TEST (continued) Figure F.19 – High frequency board LED and test point locations HIGH FREQ CAP DISCHARGE OCI2 SCR1 G7372-1 5. If the LEDs are lit and high frequency is not present at the torch, 14.

- Page 54 POWER WAVE ® ADVANCED MODULE NOTES F-44...

-

Page 55: Stt Snubber Resistors Assembly Removal And Replacement Procedure

REMOVAL AND REPLACEMENT PROCEDURE WARNING Service and repair should be performed only by Lincoln Electric factory trained personnel. Unauthorized repairs performed on this equipment may result in danger to the technician or machine operator and will invalidate your factory warranty. For your safety and to avoid electrical shock, please observe all safety notes and precautions detailed throughout this manual. - Page 56 POWER WAVE ADVANCED MODULE TROUBLESHOOTING AND REPAIR ® STT SNUBBER RESISTORS ASSEMBLY REMOVAL AND REPLACEMENT PROCEDURE (continued) Figure F.20 – STT snubber resistors and mounting screw locations STT SNUBBER RESISTORS ASSEMBLY DANGER MOUNTING SCREWS REMOVAL PROCEDURE 1. Remove input power to the machine. Case Cover Removal Procedure.

- Page 57 POWER WAVE ADVANCED MODULE TROUBLESHOOTING AND REPAIR ® STT SNUBBER RESISTORS ASSEMBLY REMOVAL AND REPLACEMENT PROCEDURE (continued) Figure F.21 – STT snubber resistors leads STT WORK STT NEG B STT NEG A STT WORK POS B STT ELECTRODE POS A STT ELECTRODE REPLACEMENT PROCEDURE 1.

- Page 58 POWER WAVE ® ADVANCED MODULE NOTES F-48...

-

Page 59: Fan Assembly Removal And Replacement Procedure

FAN ASSEMBLY REMOVAL AND REPLACEMENT PROCEDURE WARNING Service and repair should be performed only by Lincoln Electric factory trained personnel. Unauthorized repairs performed on this equipment may result in danger to the technician or machine operator and will invalidate your factory warranty. - Page 60 POWER WAVE ADVANCED MODULE TROUBLESHOOTING AND REPAIR ® FAN ASSEMBLY REMOVAL AND REPLACEMENT PROCEDURE (continued) Figure F.22 – Fan assembly, plug J52 and fan bracket mounting screw locations PLUG J52 FAN BRACKET MOUNTING SCREWS REMOVAL PROCEDURE 1. Remove input power to the machine. Case Cover Removal Procedure.

- Page 61 POWER WAVE ADVANCED MODULE TROUBLESHOOTING AND REPAIR ® FAN ASSEMBLY REMOVAL AND REPLACEMENT PROCEDURE (continued) Figure F.23 – Fan assembly screw locations FAN BRACKET FAN ASSEMBLY MOUNTING SCREWS REPLACEMENT PROCEDURE 4. Lower the top front extrusion assembly securing the fan in place then using a 5/16”...

- Page 62 POWER WAVE ® ADVANCED MODULE NOTES F-52...

-

Page 63: High Frequency Transformer Removal And Replacement Procedure

REMOVAL AND REPLACEMENT PROCEDURE WARNING Service and repair should be performed only by Lincoln Electric factory trained personnel. Unauthorized repairs performed on this equipment may result in danger to the technician or machine operator and will invalidate your factory warranty. For your safety and to avoid electrical shock, please observe all safety notes and precautions detailed throughout this manual. - Page 64 POWER WAVE ADVANCED MODULE TROUBLESHOOTING AND REPAIR ® HIGH FREQUENCY TRANSFORMER REMOVAL AND REPLACEMENT PROCEDURE (continued) Figure F.24 – High frequency transformer location HIGH FREQUENCY TRANSFORMER NOTE: A slotted screwdriver may be necessary if a nutdriver cannot REMOVAL PROCEDURE access the mounting screws. 1.

- Page 65 POWER WAVE ADVANCED MODULE TROUBLESHOOTING AND REPAIR ® HIGH FREQUENCY TRANSFORMER REMOVAL AND REPLACEMENT PROCEDURE (continued) Figure F.25 – High frequency transformer mounting bolt and screws MOUNTING SCREWS VIEWED FROM TOP LEAD TO TIG OUTPUT TERMINAL Figure F.26 – Heavy black lead connection point DANGER HEAVY BLACK LEAD CONNECTION POINT...

- Page 66 POWER WAVE ADVANCED MODULE TROUBLESHOOTING AND REPAIR ® HIGH FREQUENCY TRANSFORMER REMOVAL AND REPLACEMENT PROCEDURE (continued) REPLACEMENT PROCEDURE 1. Carefully position the new high frequency transformer into the machine. 2. Using a 5/16” nutdriver, attach the two screws securing the high frequency transformer to the base of the machine.

-

Page 67: High Frequency Board Removal And Replacement Procedure

REMOVAL AND REPLACEMENT PROCEDURE WARNING Service and repair should be performed only by Lincoln Electric factory trained personnel. Unauthorized repairs performed on this equipment may result in danger to the technician or machine operator and will invalidate your factory warranty. For your safety and to avoid electrical shock, please observe all safety notes and precautions detailed throughout this manual. - Page 68 POWER WAVE ADVANCED MODULE TROUBLESHOOTING AND REPAIR ® HIGH FREQUENCY BOARD REMOVAL AND REPLACEMENT PROCEDURE (continued) Figure F.27 – High frequency board location HIGH FREQUENCY BOARD VIEWED FROM TOP 9. The high frequency board can now be removed and replaced. REMOVAL PROCEDURE 1.

- Page 69 POWER WAVE ADVANCED MODULE TROUBLESHOOTING AND REPAIR ® HIGH FREQUENCY BOARD REMOVAL AND REPLACEMENT PROCEDURE (continued) Figure F.28 – High frequency board leads, plugs and mounting nut locations HIGH FREQ CAP DISCHARGE OCI2 SCR1 G7372-1 MOUNTING NUTS REPLACEMENT PROCEDURE Case Cover Replacement Procedure.

- Page 70 POWER WAVE ® ADVANCED MODULE NOTES F-60...

-

Page 71: Background Choke Removal And Replacement Procedure

BACKGROUND CHOKE REMOVAL AND REPLACEMENT PROCEDURE WARNING Service and repair should be performed only by Lincoln Electric factory trained personnel. Unauthorized repairs performed on this equipment may result in danger to the technician or machine operator and will invalidate your factory warranty. - Page 72 POWER WAVE ADVANCED MODULE TROUBLESHOOTING AND REPAIR ® BACKGROUND CHOKE REMOVAL AND REPLACEMENT PROCEDURE (continued) Figure F.29 – Background choke location BACKGROUND CHOKE REMOVAL PROCEDURE 1. Remove input power to the machine. Case Cover Removal Procedure. 2. Perform the 3. Locate the background choke. See Figure F.29. STT Snubber Resistors Removal 4.

- Page 73 POWER WAVE ADVANCED MODULE TROUBLESHOOTING AND REPAIR ® BACKGROUND CHOKE REMOVAL AND REPLACEMENT PROCEDURE (continued) Figure F.30 – Choke lead connected to input diode bus bar AC SWITCH INPUT DIODE CONTROL BOARD BUS BAR HEAVY BLACK LED3 (POSITIVE) LEAD LED15 LED13 LED14 LED6...

- Page 74 POWER WAVE ADVANCED MODULE TROUBLESHOOTING AND REPAIR ® BACKGROUND CHOKE REMOVAL AND REPLACEMENT PROCEDURE (continued) Figure F.32 – Background choke mounting nut location MOUNTING NU TS REPLACEMENT PROCEDURE 1. Carefully position the new background choke into the machine. 2. Using a 3/8” nutdriver, attach the two mounting nuts securing the background choke to the machine.

-

Page 75: Gas Solenoid Removal And Replacement Procedure

GAS SOLENOID REMOVAL AND REPLACEMENT PROCEDURE WARNING Service and repair should be performed only by Lincoln Electric factory trained personnel. Unauthorized repairs performed on this equipment may result in danger to the technician or machine operator and will invalidate your factory warranty. - Page 76 POWER WAVE ADVANCED MODULE TROUBLESHOOTING AND REPAIR ® GAS SOLENOID REMOVAL AND REPLACEMENT PROCEDURE (continued) Figure F.33 – Gas solenoid location GAS SOLENOID REMOVAL PROCEDURE 1. Remove input power to the machine. Case Cover Removal Procedure. 2. Perform the 3. Locate the gas solenoid. See Figure F.33. Fan Assembly Removal Procedure.

- Page 77 POWER WAVE ADVANCED MODULE TROUBLESHOOTING AND REPAIR ® GAS SOLENOID REMOVAL AND REPLACEMENT PROCEDURE (continued) Figure F.34 – Gas solenoid leads GROUND TERMINAL Figure F.35 – Gas solenoid mounting nut MOUNTING NUT AND WASHER F-67...

- Page 78 POWER WAVE ADVANCED MODULE TROUBLESHOOTING AND REPAIR ® GAS SOLENOID REMOVAL AND REPLACEMENT PROCEDURE (continued) Case Cover Replacement Procedure. 6. Perform the REPLACEMENT PROCEDURE 1. Carefully position the new gas solenoid into the case back of the machine. 2. Carefully tighten nut and washer securing the gas solenoid to the case back.

-

Page 79: Background Diode Removal And Replacement Procedure

BACKGROUND DIODE REMOVAL AND REPLACEMENT PROCEDURE WARNING Service and repair should be performed only by Lincoln Electric factory trained personnel. Unauthorized repairs performed on this equipment may result in danger to the technician or machine operator and will invalidate your factory warranty. - Page 80 POWER WAVE ADVANCED MODULE TROUBLESHOOTING AND REPAIR ® BACKGROUND DIODE REMOVAL AND REPLACEMENT PROCEDURE (continued) Figure F.36 – Background diode location BACKGROUND DIODE VIEWED FROM TOP REMOVAL PROCEDURE 1. Remove the input power to the machine. Case Cover Removal Procedure. 2.

- Page 81 POWER WAVE ADVANCED MODULE TROUBLESHOOTING AND REPAIR ® BACKGROUND DIODE REMOVAL AND REPLACEMENT PROCEDURE (continued) Figure F.37 – Background diode leads LEAD B7 LEAD B1C CHOKE LEAD Figure F.38 – Background diode mounting screws MOUNTING SCREWS F-71...

- Page 82 POWER WAVE ADVANCED MODULE TROUBLESHOOTING AND REPAIR ® BACKGROUND DIODE REMOVAL AND REPLACEMENT PROCEDURE (continued) REPLACEMENT PROCEDURE 1. Carefully position the new background diode into the machine. Note background diode polarity. See Wiring Diagram. 2. Using a 7/64” allen wrench, attach the two screws and washers securing the background diode to the base of the machine.

-

Page 83: Ac Switch Control Board Removal And Replacement Procedure

REMOVAL AND REPLACEMENT PROCEDURE WARNING Service and repair should be performed only by Lincoln Electric factory trained personnel. Unauthorized repairs performed on this equipment may result in danger to the technician or machine operator and will invalidate your factory warranty. For your safety and to avoid electrical shock, please observe all safety notes and precautions detailed throughout this manual. - Page 84 POWER WAVE ADVANCED MODULE TROUBLESHOOTING AND REPAIR ® AC SWITCH CONTROL BOARD REMOVAL AND REPLACEMENT PROCEDURE (continued) Figure F.39 – AC switch control board location AC SWITCH CONTROL BOARD REMOVAL PROCEDURE 11. Label and disconnect leads B5, B6, B7, 401 and 402 (401 & 402 1.

- Page 85 POWER WAVE ADVANCED MODULE TROUBLESHOOTING AND REPAIR ® AC SWITCH CONTROL BOARD REMOVAL AND REPLACEMENT PROCEDURE (continued) Figure F.40 – Heatsink bracket removal TORX TORX SCREW SCREW WASHERS TOP HEATSINK MOUNTING BRACKET INSULATORS MOUNTING TOP HEATSINK SCREWS BRACKET TO HEATSINK 16.

- Page 86 POWER WAVE ADVANCED MODULE TROUBLESHOOTING AND REPAIR ® AC SWITCH CONTROL BOARD REMOVAL AND REPLACEMENT PROCEDURE (continued) Figure F.41 – AC switch control board plug locations LED3 LED15 LED13 LED14 LED6 LED5 LED11 LED9 LED1 LED7 LED4 LED8 LED2 LED10 G7103-1 AC/STT SWITCH Figure F.42 –...

- Page 87 POWER WAVE ADVANCED MODULE TROUBLESHOOTING AND REPAIR ® AC SWITCH CONTROL BOARD REMOVAL AND REPLACEMENT PROCEDURE (continued) Figure F.43 – AC switch control board base mounting AC SWITCH CONTROL BOARD INSULATO R ( 2) BASE INSULATO R ( 2) MOUNTING SCREW (2) BUTT O N PLUG (2)

- Page 88 POWER WAVE ® ADVANCED MODULE NOTES F-78...

- Page 89 POWER WAVE ADVANCED MODULE DIAGRAMS ® TABLE OF CONTENTS - DIAGRAMS SECTION - Diagrams ..........................Section G Wiring Diagram ................. . . G-2 Dimension Print .

- Page 90 POWER WAVE ADVANCED MODULE DIAGRAMS ®...

- Page 91 POWER WAVE ADVANCED MODULE DIAGRAMS ® 8.48 11.51 10.49 24.80 13.94 25.42 3.97 6.00 3.97 2.48 18.35 3.98 A.01 L15814-2...

Need help?

Do you have a question about the POWER WAVE 11935 and is the answer not in the manual?

Questions and answers