Table of Contents

Advertisement

Quick Links

Centroid Hickory CNC Controller Installation Manual

CNC Software version: CNC12 V.5.08+

Models: Hickory

Hickory CNC Installation Manual rev5 3-26-24 Copyright © 2021-24 CENTROID

www.centroidcnc.com

Hickory CNC

Installation Manual

Compatible EtherCat Drives

Hickory CNC Control Kit

Bench Test Hardware setup

Windows 10/11 config for CNC use

Communications Bench Testing

Spindle Bench Testing Procedure

Electrical Component Wiring

CNC12 Software Configuration

Absolute Encoder Setting Home Position

Appendix A Trouble Shooting Chart

Appendix B: Hickory LED Codes

Appendix C: Hickory Specifications Manual

6

Before you Begin

8

10

12

16

35

39

52

72

75

88

90

91

Advertisement

Table of Contents

Summary of Contents for Centroid Hickory CNC

- Page 1 Spindle Bench Testing Procedure Electrical Component Wiring CNC12 Software Configuration Absolute Encoder Setting Home Position Appendix A Trouble Shooting Chart Appendix B: Hickory LED Codes Appendix C: Hickory Specifications Manual Hickory CNC Installation Manual rev5 3-26-24 Copyright © 2021-24 CENTROID www.centroidcnc.com...

-

Page 2: Table Of Contents

6.4 Motor Software Setup..........................77 6.5 Spindle Setup.............................80 6.6 Configuring Overall Turns Ratio.........................83 6.7 Software Travel Limits..........................84 6.8 Performing the System Test........................86 CNC12 Configuration Backup..........................87 Chapter 7 Appendices............................85 Appendix A Troubleshooting..........................88 Appendix B LED Error Codes..........................90 Page 1 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24... -

Page 3: Introduction

As CNC control products from CENTROID can be installed on a wide variety of machine tools NOT sold or supported by CENTROID, you MUST consult and follow all safety instructions provided by your machine tool manufacture regarding the safe operation of your machine and unique application. - Page 4 Centroid warrants to the original purchaser that any part of its product purchased will be free of defects in workmanship and parts for a period of twelve (12) months from the date of delivery (hereinafter "Warranty Period").

- Page 5 When not in use, store the motor in a dry location between 0° to 40° C. Do not remove the nameplate from a motor. Never use a hammer or other impact device on the motor shaft for any reason. Page 4 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24...

- Page 6 Improper handling can lead to ESD (electrostatic discharge) which may damage the PCB, or shorten its lifespan. Keep the work area free from static generating materials such as Styrofoam, vinyl, plastic, and fabrics. Page 5 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24...

- Page 7 About This Manual This manual describes how to install and configure the Centroid CNC Hickory Ethercat-based Closed- Loop Controller. The Hickory system provides up to eight axes of motion control through fast and reliable EtherCat communication protocol, controlled by industry standard G-Codes.

- Page 8 Creating a photo album is a place for all your machine photos to be in one location that will always have the same link. Avoiding having photos scattered across multiple posts or emails. Etc.. A photo album will result in faster and better technical support response. Page 7 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24...

-

Page 9: Before You Begin

Additional troubleshooting resources are included in the Appendices. Useful Resources Hickory Schematics: Type in “Hickory” in the search bar. https://www.centroidcnc.com/centroid_diy/schematics/pbrowse.php Centroid’s YouTube Channel: Centroid CNC Technical Support https://www.youtube.com/user/CentroidSupport/videos Free Hickory CNC Support Forum https://centroidcncforum.com/viewforum.php?f=68 Centroid CNC Tech Bulletins: http://www.centroidcnc.com/centroid_diy/tech_bulletins/browse.php... - Page 10 When you post to the forum, your question will be seen by many users. Possibly getting you more than one solution to your problem. Your post can be helpful others in the f uture. Forum Posting Guidelines: https://centroidcncforum.com/viewtopic.php?f=60&t=1043 Factory Direct technical support is available in 1 hour blocks. Purchase here: https://shopcentroidcnc.com/centroid-factory-direct-11-technical-support/ Page 9 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24...

-

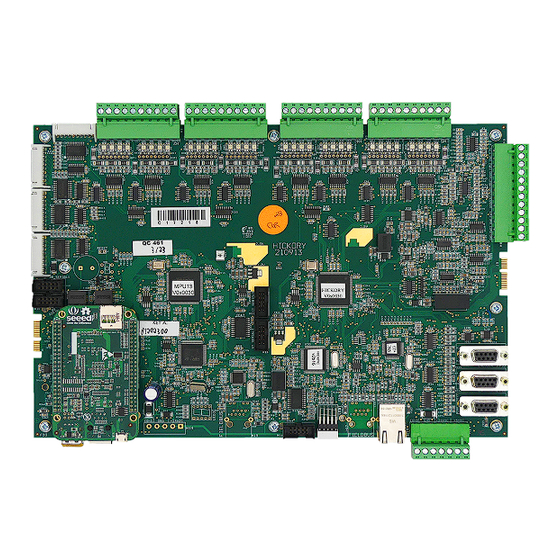

Page 11: Chapter 1 Hickory Controller

Make sure your kit is complete and has not been visibly damaged in shipment. Hickory only utilizes Centroid curated AC brushless servos with EtherCat communication protocol. Currently the Centroid curated drive list is: Yaskawa Sigma 7, Glentek Gamma series, Estun Summa, Leadshine EL7 and EL8, Inovance SV660N. - Page 12 • Full-sized Paper Wiring Schematic • Centroid CNC12 "FREE" version of CNC software. ◦ Pro and Ultimate Licenses may be purchased here: https://shopcentroidcnc.com/product- category/cnc-software/ Hickory Specifications Characteristic Min. Typ. Max. Unit 24 Volt Supply Current 5 Volt Supply Current Input Pullup Voltage (Vinp)

-

Page 13: Chapter 2 Bench Test Hardware Setup

Do not use fabric covered surfaces as it may cause ESD (electrostatic discharge) damage. A wooden surface is an ideal test bench location. • A PC or a Centroid console unit which comes with CNC12 installed. The PC must meet the specifications listed in Technical Bulletin #273, which can be found here: https://www.centroidcnc.com/dealersupport/tech_bulletins/uploads/273.pdf... -

Page 14: Hickory Communications Bench Setup

1. Wire the provided Logic power supply to Hickory following the bench test schematic. Leaving the Meanwell power supply disconnected from 110VAC, wire the power connections to H19 on the Hickory. Note: Included Power supply will also run on 240VAC. Page 13 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24... - Page 15 Figure 2.2.1. One part #7269 15ft Shielded Ethernet cable is included with the Hickory kit. Centroid also stocks part #6143 25ft Shielded Ethernet cable. Note: An unshielded cable can result in intermittent PC Data receive errors in the software due to electronic noise and interference.

- Page 16 Hickory is booted when you see the horizontal LED bar moving from top to bottom in a scrolling fashion on the display. This means all is good and Hickory is ready to connect to CNC12 software. Page 15 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24...

-

Page 17: Chapter 3 Cnc12 Software

Microsoft Windows, Mac OS, or Linux are not supported. 1. If you have purchased a console unit or computer from Centroid, it comes with Windows properly configured and the CNC12 software already installed. If you bought or built your own computer, it must meet the prerequisites listed on the Centroid Website here and to be configured for CNC use following the steps below. - Page 18 (https://www.centroidcnc.com/dealersupport/tech_bulletins/uploads/270.pdf If your corporate policy requires anti-virus software, a third-party firewall, or that certain Windows security features be enabled to connect to the network, then Centroid recommends that you keep any computers with CNC12 installed disconnected from the network. Before installing CNC12, Windows Update should be performed. Centroid CNC software relies on Microsoft .NET Framework tools.

-

Page 19: Cnc12 Software Installation

4 Windows 10/11 systems may pop up a Windows Defender SmartScreen showing “Microsoft Defender SmartScreen prevented an unrecognized app from starting (see image below). Running this app might put your PC at risk”. Click “More info”, Then Click “Run anyway”. Microsoft Defender Smartscreen Page 18 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24... - Page 20 5. Depending on your Windows settings you might also get a prompt asking if you want allow the application to make changes to your device. Click “Yes”. 6. Read the Centroid Disclaimer of Software Warranty and if you agree click on “I Agree”. Page 19 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt...

- Page 21 CNC setup where the PC power is turned on when machine power is turned on. Select “Next” to continue. 8. Select Hickory as the control option and then select “Next” to continue. Page 20 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24...

- Page 22 10. Choose between Imperial (Inches) and Metric (Millimeters) as the default units. This is to help with initial setup and can be changed at any time later in the software. Select “Install” to continue. Page 21 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24...

- Page 23 11. After seeing the “Setup was completed successfully.” screen select “Next” to continue. Page 22 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24...

- Page 24 Select the Ethernet option to automatically configure the IP address for CNC use and click “Next”. DO NOT select the Wi-Fi option. A prompt will appear asking if you want to change the IP address of the Ethernet adapter. Select “Yes”. Page 23 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24...

- Page 25 Windows 10/11 configurations are setup properly for CNC control use. NOTE: Centroid recommends using a computer with two Ethernet ports. Alternatively one Ethernet port and one Wi-Fi adapter is also acceptable. That way one Ethernet port is used for the Hickory, and the second wired Ethernet port can be used to access the internet or a LAN.

- Page 26 13. Confirm that the Ethernet selected is the correct one and select “Yes” to proceed. 14. Click “Finish” to complete CNC12 software installation. Page 25 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24...

- Page 27 15. The installer will prompt you if you want to install a PLC program. Click “Yes”. The PLC installer program will open. Use the “+” buttons to select either Mill or Lathe, then expand the _HICKORY section. Select _Centroid_Standard, then click either Install option at the bottom. Page 26 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24...

-

Page 28: Chapter 4 Bench Testing

Hickory License Installation Instructions: 1) Download and save the license.dat file emailed to you by Centroid to the CNC PC desktop using a Windows PC. (Note: Mac or any Apple computers, will corrupt the .dat file attached) 2) With Hickory powered up and running, start the CNC12 software. - Page 29 4.2 CNC12 Software Configuration Before starting the CNC12 software verify that the Hickory CNC control is powered on and the Ethernet cable connected to the CNC PC. The seven-segment LED on the Hickory will be a continuous scrolling sequence when it is in a ready state (if you see a number it is an error code). For a list of error codes see Appendix B.

- Page 30 Note: When running beta software this message will appear on start up. Click OK to continue. If you see this message, please STOP and download the latest released version of CNC12 found on our website. Do not use any BETA software versions on a production machine. Page 29 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24...

- Page 31 Set the units of the machine, change both the DRO display units and Machine units to either Inches or Millimeters using the space bar. b) Set Max Spindle to 3000 and Min Spindle to 0. c) Change “Machine home at power up” to the desired home configuration: Page 30 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24...

- Page 32 Use Ref Mark-HS when reference marks are used to set initial home position. This option is recommended for machines without home switches. Refer to TB127 for more details. d) If you wish to use the virtual control panel (VCP), select the “Virtual” Jog Panel Type option. Page 31 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24...

- Page 33 F10 – Shut Down → F9 – Exit CNC12. Right click on CNC12 desktop shortcut. Select properties. Click on the Compatibility tab. Check the box labeled “Run this program as an administrator”. Click “Apply”. Click “OK”. Start the CNC12 software and try again. Page 32 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24...

- Page 34 F3-Config → Password: 137 → F3-Parms. Use the arrow keys or F8 to navigate to Parameters 300-307. For each of these parameters that has a non-zero value, set it to 0. Press F10-Save to save the parameters and exit to the previous menu. Page 33 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24...

- Page 35 Power Off. Once the computer shuts down, cut power to the Hickory by shutting off your outlet strip. Wait 30 seconds, then power the Hickory back on and open CNC12. CNC12 is now ready for the communications bench test and the spindle analog voltage bench test. Page 34 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24...

-

Page 36: Hickory Communications Stress Test

3. Toggle the Reset button if you are using the VCP. If you are not using the VCP, you must toggle input 11 using the <Alt + i> PLC Diagnostic display. Press <Ctrl + Alt + i> to set input 11 red, then press it once again to turn it back to green. Page 35 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24... - Page 37 4. The DRO should be clear of any labeled axis. Because of this, the software should not require the home position to be set. If the DRO has any labeled axis, see Step 5 in the previous section on how to clear the axis labels. Page 36 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24...

- Page 38 5. Press F2-Load and navigate to the communications stress test program. The default location of the file is: C:\cncm\ncfiles. Note: cncm would be replaced by ‘cnct’ on lathes. stressTest.cnc will appear beside “Job Name:” 6. Press cycle start to run the communications stress test. Page 37 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24...

- Page 39 Review this information on solving communication errors: Review IP settings, Virus and Firewall. For complete guidance on this see this post. https://centroidcncforum.com/viewtopic.php?f=61&t=1451 and supported document Tech Bulletin 270 https://www.centroidcnc.com/dealersupport/tech_bulletins/uploads/270.pdf Page 38 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24...

-

Page 40: Hickory Analog Spindle Output Test "Spindle Bench Test

1. Load spindlebenchtest.cnc. From the main menu, press F2-Load and navigate to the spindlebenchtest.cnc file located in the ncfiles folder, then click “open”. 2. spindlebenchtest.cnc appears as the job name in the upper-right corner of the CNC12 window. Page 39 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24... - Page 41 H8 will work). d) Tighten down the screw terminals to firmly grasp the probes. 4. With spindlebenchtest.cnc loaded, press Cycle Start or the keyboard shortcut <Alt + s>to begin. The following screen will be displayed: Page 40 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24...

- Page 42 The program will exit and the status window will say “Job finished” after a successful completion. If the spindle bench test program fails, please contact support@centroidcnc.com with details about the failed test along with images of each failed voltage reading. Page 41 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24...

-

Page 43: Axis And Motor Setup

1. Label the Axes: From the main menu, press F1 – Setup → F3 – Config. The password is 137. Press F2 – Mach → F2 – Motor. Under “Label” configure the software for the correct number of axes and label them appropriately. Typical setups: Page 42 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24... - Page 44 302 = 3 Typical configuration for a 4-axis CNC: 300 = 1 301 = 2 302 = 3 303 = 4 Unused axes need to be set to zero, or errors will occur! Page 43 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24...

- Page 45 Parameter 34 = your spindle encoder counts/rev Parameter 35 = 8 (Spindle Axis number) Parameter 78 = 1 (Spindle Speed display and operation) Parameter 315 = 1 (Axis 8 encoder index) Page 44 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24...

- Page 46 For Hickory, this will be all of the axes. Press F10-Save to save the parameter values and exit to the previous menu. Page 45 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24...

- Page 47 → F2-Motor. Enter the counts into the “Encoder counts/rev” field corresponding to the axis’s encoder counts. Repeat for each used axis. After setting the values in this section, power cycle the Hickory and drives. Page 46 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24...

- Page 48 E-Stop input MUST be cycled in order to clear the fault. During the bench test we will trick the software into thinking the we cycled the E-Stop by toggling input 11. Page 47 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24...

- Page 49 Notice that as you toggle the E-Stop input to red, “406 Emergency stop detected” is displayed in the status window, followed by “2099 Message Cleared.” When the E-Stop input is toggled green, notice how “335 Emergency stop released” is displayed. Page 48 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24...

-

Page 50: Setup For Bench Testing Drives And Motors

2. Follow the schematic that shipped with your order to connect the drives to the Hickory. It is not necessary to use drives solely from the same manufacturer in a system. 3. Power up the Hickory and the drives. Ensure that the drives power on before applying power to the Hickory. Page 49 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24... - Page 51 Navigate using the arrow keys to parameter 64, then set the parameter to the value from the table below that corresponds to your machine’s configuration. Press F10 to save the parameter and exit the Parameter Menu. Page 50 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24...

- Page 52 For paired axis motors, ensure that the motors move simultaneously, and if the direction reversal field is set for one of the motors, ensure that the motors rotate opposite of one another. Now install the Page 51 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24...

-

Page 53: Chapter 5 Cabinet Wiring

This chapter of the manual will go into detail about how to wire the various systems into your cabinet. During cabinet wiring, it is important that you follow the schematic examples provided by Centroid. Schematic sets may be found here: https://www.centroidcnc.com/centroid_diy/schematics/pbrowse.php... - Page 54 8.000" (203.20mm) 7.400" (187.96mm) 4.050" (102.87mm) 0.500" (12.70mm) Pin 1 Pin 1 5.800" (147.32mm) Pin 1 Pin 1 12.000" (304.8mm) Pin 1 11.400" (289.56mm) Pin 1 3.000" (76.20mm) Page 53 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24...

- Page 55 We only carry the part if it has a Centroid part number on the schematic. Call Centroid for with the part # ready for pricing and availability.

- Page 56 Stranded wire in these gauges can be purchased from most home improvement centers in the electrical section and from automotive suppliers for automotive wiring. Common Wiring Problems The following information covered in Technical Bulletin #78 which can be found here: (http://www.centroidcnc.com/dealersupport/tech_bulletins/uploads/78.pdf) Page 55 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24...

-

Page 57: Hickory Digital Inputs

The Hickory is equipped with 32 optically-isolated inputs. Inputs can be wired for either sourcing or sinking. This is determined by wiring the common terminal for the bank to supply positive (sinking), or supply common (sourcing). Inputs are divided in banks of four. Page 56 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24... - Page 58 Voltages can be selected by installing the appropriate SIP. Without a SIP installed (default configuration when shipped from Centroid) the voltage is set to 24V. Optional SIPs can be installed to use 12V or 5V input voltage. VDC is supplied via Common (1-4, 5-8, 9-12, 13-16) on H2, H3, H4, and H5. These terminals are NOT connected internally.

-

Page 59: Hickory Analog Inputs

GND pin. Analog Input Bits Analog Input Input Bits 33 – 48 49 – 64 Internal Circuitry Analog Input +12 VDC Analog Input Analog Ground -12 VDC GROUND Analog Input Calculations Page 58 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24... -

Page 60: Hickory Outputs

5.4 Hickory Outputs The Hickory is equipped with a total of 32 relayed outputs via four (4) 8 relay boards. The relay boards come equipped with LEDs showing output status. Page 59 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24... -

Page 61: Hickory Analog Outputs

0 to 10 15 bits *Parameter 420 only sets the mode bits of Analog Out 1. Analog Output Bits Analog Output Output Bits Mode Bit A Mode Bit B 33 – 48 49 – 64 Page 60 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24... - Page 62 Internal Circuitry Analog Output +12 VDC Analog Output Analog Ground GROUND -12 VDC +5 VDC Generator PWM Output Analog Output Calculations Page 61 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24...

-

Page 63: Wiring Axis Drives

Hickory are Yaskawa Sigma7, Glentek Gamma Series, Estun Summa, Leadshine EL7 and EL8, and Inovance SV660N. Each Centroid curated drive has its own dedicated hookup schematic that was shipped with your order or search the Centroid Hookup Schematics page with “Hickory”... -

Page 64: Wiring E-Stop Circuit

A contactor is an electrically controlled switch. It can be thought of like a higher current relay. • These are used to turn on and off power to the main spindle and the axis drive. The Centroid recommendation for contactors is a 24VAC type, although 24VDC and 110VAC contactors are available. - Page 65 For smaller desktop machines with steppers and small spindle motors, The LC1K0610B7 24VAC Flood Contactor w/snubber (#14377 from Centroid) can be used. This contact is also useful on all machines for turning on and off accessories like spindle, pumps, vacuums and other high current accessories.

- Page 66 E-Stop is released (not tripped), and red when E-Stop is depressed. Note: A general guide to E-Stop wiring and motor power troubleshooting is contained in Technical Bulletin #286 which is located here. (https://www.centroidcnc.com/dealersupport/tech_bulletins/uploads/286.pdf) Page 65 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24...

-

Page 67: Wiring Limit Switches

Using normally-closed switches (and other devices) prevents noise from causing spurious faults because the signal is being electrically held at the operational level. Regular dry contact switches can be utilized as well as 3 wire proximity switches. Page 66 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24... - Page 68 4. If the limits are still inverted from bench testing, there will be a bar above inputs 1-6. Remove the inversion from these inputs by pressing <Ctrl + Alt + i> for each input 1-6. Page 67 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24...

- Page 69 5. Confirm that all limit switches are green when no switch is tripped. 6. Confirm that the correct input turns red when the switches are manually tripped. Page 68 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24...

-

Page 70: Wiring The Spindle

7 and 8 on the Hickory board. • This method is simple but prevents the Centroid CNC software from being able to control the speed of the spindle. When using contactors the spindle speed will have to be adjusted by mechanical methods. - Page 71 • All contactors need snubbers! Centroid recommends using the Quencharc snubber network (Centroid p/n 1819) on the coil of the contactor. This reduces electrical noise when the spindle is turned off and on. Wiring a VFD Wire the VFD according to the schematic for your system, the image below from...

- Page 72 Spindle Encoder: For spindle slaved movements such as rigid tapping, the spindle encoder needs to be connected to the Hickory. The spindle encoder must meet the Centroid encoder type requirements to be compatible with Hickory. See this post. https://centroidcncforum.com/viewtopic.php?f=63&t=921 When making your own cables or using your own encoders, make sure they adhere to the guidelines...

- Page 73 Encoder channel low level Encoder channel high level Centroid sells 2000 line encoders in multiple shaft sizes as well as encoder cables (plug and play between the encoder pigtail and the AcornSix) in 12’ and 16’ lengths. These encoders should be installed on a jack shaft and be protected from the environment.

-

Page 74: Chapter 6 Final Software Configuration

CNC12 keeps a log file containing all errors and faults, along with the time and date that these errors occurred at. You can access this log from the main menu by pressing F7-Utility → F9-Logs → F1- Errors. Page 73 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24... -

Page 75: Servo Drive Setup And Tuning

Yaskawa SGD7S EtherCat Setup and Tuning: TB 322 (https://www.centroidcnc.com/dealersupport/tech_bulletins/uploads/322.pdf) • Estun Summa Setup and Tuning: TB 317 (https://www.centroidcnc.com/dealersupport/tech_bulletins/uploads/317.pdf) • Glentek Gamma Setup and Tuning: Tech Bulletin in progress • Inovance SV660N Setup and Tuning: TB 329 (https://www.centroidcnc.com/dealersupport/tech_bulletins/uploads/329.pdf) Page 74 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24... -

Page 76: Setting Home Position With Absolute Encoders

Upon CNC12 start up you may see some warning dialogues related to the absolute encoders. If you see one about axis movement like below, this is not unexpected during initial setup and can be safely ignored. Page 75 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24... - Page 77 CNC12/Hickory system will save the absolute encoder position in non-volatile memory when an M26 is executed for that motor. - Never issue a M26 on a paired axis. For example: Never issue M26/Y when that axis is paired Page 76 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24...

-

Page 78: Motor Software Setup

After homing for the first time , double check for expected position and gantry squareness. It is a good idea to test this several times by moving to different positions and rebooting to verify that the positions are correct after homing. Page 77 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24... - Page 79 - It may be desirable to issue other commands as part of the homing procedure such as retracting the Z axis etc.. See Centroid’s Operator Manuals and Macro Programming guide for more information on creating custom home programs.

- Page 80 For axes that move the tool, axis motion is the same as the tool motion. In the figure below, if the tool moves up, it is moving in the +Z direction. Therefore, a +Z movement should move the tool up. Page 79 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24...

-

Page 81: Spindle Setup

(VFD). All spindle speeds entered in a CNC program are output to the PLC as percentages of this maximum value. If your machine is equipped with a dual range spindle, see the Parameters 65-67 section below. Page 80 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24... - Page 82 For example, if the machine is a mill with a dual range spindle, and the spindle in low range turns 1/10 the speed it turns in high range, then parameter 65 should be set to 0.1. Page 81 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24...

- Page 83 These parameters work in conjunction with the PLC program, which uses the states of inputs 13 (low range), 14 (medium range), and 15 (high range) to signal to the CNC12 software which range is in effect. Page 82 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24...

-

Page 84: Configuring Overall Turns Ratio

Refer to the setup shown in the image below. To reach the motor parameters screen to set Motor revs/in from the main menu, press F1-Setup → F3-Config → Password: 137 → F2-Mach → F2- Motor. Page 83 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24... -

Page 85: Software Travel Limits

Password: 137 → F2-Mach → F1-Jog. In the Jog Parameters menu, enter the DRO value of the noted positive position for the measured axis in the Travel (+) box. Do the same for the noted negative position in the Travel (-) box. Page 84 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24... - Page 86 7. Enter F3-MDI to issue a G-code that asks the software to move just beyond the software travel limit. Verify that the CNC12 status window throws the “907: _ axis travel exceeded” error. Page 85 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24...

-

Page 87: Performing The System Test

Do not start or use the System Test macro with Hickory or with a system that has software paired axes. The Centroid System Test was created to ensure OEM’s properly setup the CNC Controller and don’t drop ship a CNC machine Tool to an enduser that has not been properly configured. The System Test has been around for years and has not been updated for use with Hickory. -

Page 88: Cnc12 Configuration Backup

CNC configuration settings on a USB memory stick. This is easily accomplished with the Centroid “Create Report” feature found in the CNC12 Utility Menu. Keep making new report.zip files as you progress through the CNC control setup process. If a problem arises, you can simply use the “Restore Report”... -

Page 89: Chapter 7 Appendices

The control is in incremental jog mode. If the LED is lit on the INCR/CONT key, the control is set to incremental jog. Press the INCR/CONT key to toggle the LED off and attempt to jog. See TB 285 for more information: (http://www.centroidcnc.com/dealersupport/tech_bulletins/uploads/285.p Page 88 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24... - Page 90 PID menu of CNC12 and try moving again. Does the motor move as expected? Do you need to reverse the direction of the axis? • Quadrature Errors are either a problem with the encoder shield, grounds, or faulty wiring. Page 89 D:\centroid 2024\Hickory Install Manual\hickory_install_manual_rev5.odt 03/26/24...

-

Page 91: Appendix B Led Error Codes

Power was lost If error appears briefly at startup, it is normal, otherwise check for loose power connections Communication Data in and out are not Internal error, contact Centroid out of sync locked together in a synchronous relationship Too many counts Communication error or Cycle E-Stop to clear. - Page 92 HICKORY User Guide For Revision 240227 3/26/24 Overview The HICKORY is an integrated PLC and motion control processor. HICKORY uses an Ethernet based fieldbus to communicate with all accessories over RJ45 shielded twisted pair (Ethernet) cables. The new protocol and connection scheme are the defining features of HICKORY versus previous products such as Oak.

- Page 93 HICKORY Typical Connection Overview /hardware/HICKORY/190628/docs/HICKORY_MAN.doc...

- Page 94 PLC Section Digital Outputs 32 5 volt logic outputs are available on the HICKORY. The outputs are intended to be used with external 8 relay modules. The default (off) logic state is high. A low level will activate a relay on the external board. Internal Circuitry H1, H6, H7 and H9 Connector Outputs +5 VDC...

- Page 95 Internal Circuitry Analog Output +12 VDC Analog Output Analog Ground GROUND -12 VDC +5 VDC Generator PWM Output Analog Output Calculations PWM Output Calculations PWM output can be calculated using the following equation with one exception. Analog request of 65535 will output continuous 5VDC (100% duty cycle, not 99.998%).

- Page 96 Digital Inputs HICKORY has 32 optically isolated inputs. Inputs are divided into banks of four. Each bank is configurable for various voltages and sinking or sourcing polarity. Voltage may be selected by installing the appropriate value resistor pack or SIP into a socket for each bank. Without a SIP installed, input voltage is set to 24V. Optional SIPs may be installed to use 12V or 5V input voltage.

- Page 97 Analog Inputs Two analog inputs are available. The input range is -10 to 10 volts. The analog ground is connected internally to other HICKORY GND pins. However, for best wiring results, use the GND pin adjacent to the analog input pin for analog connections.

- Page 98 Jog panel, MPG, and probe devices always map to the same memory areas. These special cases allow for better compatibility with all PLC programs. The location of this I/O is always known. Only one Jog Panel, MPG, and probe expansion device may be used on a system because of the fixed locations for data. Currently, the only device on the fieldbus that fits these categories is the JOGBRD13 jog panel controller.

- Page 99 PLC I/O Map Input Specification Input Location Output Specification Output Location Number Function Type Connector Number Function Type Connector General Purpose General Purpose General Purpose General Purpose General Purpose General Purpose General Purpose General Purpose General Purpose General Purpose General Purpose General Purpose General Purpose General Purpose...

- Page 100 PLC I/O Map Continued Input Specification Input Location Output Specification Output Location Number Function Type Connector Number Function Type Connector Analog In 2 b0 Analog2 b0 Analog In 2 b1 Analog2 b1 Analog In 2 b2 Analog2 b2 Analog In 2 b3 Analog2 b3 Analog In 2 b4 Analog2 b4...

- Page 101 PLC I/O Map Continued Input Specification Input Location Output Specification Output Location Number Function Type Connector Number Function Type Connector Encoder 3 b0 Encoder 3 b1 Encoder 3 b2 Encoder 3 b3 Encoder 3 b4 Encoder 3 b5 Encoder 3 b6 Encoder 3 b7 Encoder 3 b8 Encoder 3 b9...

- Page 102 HICKORY Specifications Characteristic Min. Typ. Max. Unit 24 Volt Supply Current 5 Volt Supply Current Input Pullup Voltage (Vinp) Input On Voltage Vinp-1.25 Input Off Voltage 1.25 Input Operating current Analog Output Current Analog Output Voltage Analog Output Resolution bits Analog Output Error <...

- Page 103 LED1 Error Codes Error Number Meaning Cause Corrective Action *No LED codes are currently displayed by HICKORY LED1 Operation A 7 segment display (LED1) is used to display status. At startup, all number segments will light in a rotating pattern until initialization is complete. Initialization takes several seconds. After initialization, one segment will light if HICKORY is ready, but not enabled.

- Page 104 HICKORY Connections OUTPUT 25 OUTPUT 26 OUTPUT 27 OUTPUT 28 OUTPUT 29 OUTPUT 30 OUTPUT 31 OUTPUT 32 +5 VDC Pin 1 Ethernet Pin 1 Input 1 Input 2 Input 3 SIP4 Input 4 Common 1-4 Input 5 Input 6 Input 7 SIP3 Input 8...

- Page 105 HICKORY Mounting Dimensions 8.000" (203.20mm) 7.400" (187.96mm) 4.050" (102.87mm) 0.500" (12.70mm) Pin 1 Pin 1 5.800" (147.32mm) Pin 1 Pin 1 12.000" (304.8mm) Pin 1 11.400" (289.56mm) Pin 1 3.000" (76.20mm) /hardware/HICKORY/190628/docs/HICKORY_MAN.doc...

- Page 106 8 Relay Module Connections and Mounting Dimensions Out 1 NC Common Out 1 NO Out 2 NC Common Out 2 NO Out 3 NC Common Out 3 NO Out 4 NC Output 1 Common Output 2 Output 3 Out 4 NO 5.669"...

Need help?

Do you have a question about the Hickory CNC and is the answer not in the manual?

Questions and answers