Table of Contents

Advertisement

Quick Links

INSTRUCTIONS–PARTS LIST

Model PPM 100

Precision Pulse Volumetric

Fluid Flow Meter

Functions to display instantaneous flow, batch total flow, and cumulative total flow

20.7 bar (300 psi) Maximum Fluid Working Pressure

Flow Range is 30 cc/min. (1.0 oz/min.) to 1000 cc/min. (34 oz/min.)

Part No. 224–877, Series A

Intrinsically Safe for Class , Division 1, Group D

Hazardous Indoor locations

ENTITY PARAMETERS

Vmax

14 VDC

Imax

150 mA

Ci

6.3 F

Li

0 mH

Hazard of Using Fluids Containing Halogenated Hydrocarbons

Never use 1,1, 1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids contain-

ing such solvents in this equipment. Such use could result in a serious chemical reaction, with the possibility of

explosion, which could cause death, serious injury and/or substantial property damage.

Consult your fluid suppliers to ensure that the fluids being used are compatible with aluminum parts.

Refer to the Technical Data on page 15 for "Wetted Parts" information.

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

This manual contains important

warnings and information.

READ AND RETAIN FOR REFERENCE

COPYRIGHT 1992 GRACO INC.

WARNING

308–205

Rev. E

Supersedes D

01033

Advertisement

Table of Contents

Summary of Contents for Graco PPM 100

- Page 1 Consult your fluid suppliers to ensure that the fluids being used are compatible with aluminum parts. Refer to the Technical Data on page 15 for “Wetted Parts” information. GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441 COPYRIGHT 1992 GRACO INC.

- Page 2 Repair or replace worn or damaged parts immediately. 3. Follow the Pressure Relief Procedure for your fluid Use only Graco replacement parts. system dispensing device. IMPORTANT United States Government safety standards have been adopted under the Occupational Safety and Health Act. These stan-...

-

Page 3: Table Of Contents

See Data, page 15, for recommended barrier module. Accessories for Graco cable seal, part no. 110–458. For your safety , be sure to understand and follow Hazardous Location Wiring of Intrinsically Safe The purpose of such sealing or venting is to prevent Circuits instructions, below. -

Page 4: Installation Drawing For Csa Approval

Installation Drawing for CSA Approval Part No. 224–877 Intrinsically Safe For Class , Division 1, Group D Hazardous Location NOTE: This installation drawing is for use of the PPM100 with a remote monitor . A barrier module is not required if the PPM100 is used as a stand-alone meter (i.e. -

Page 5: Control Drawing For Fm Approval

Control Drawing for FM Approval Part No. 224–877 Intrinsically Safe For Class , Division 1, Group D Hazardous Location NOTE: This installation drawing is for use of the PPM100 with a remote monitor . A barrier module is not required if the PPM100 is used as a stand-alone meter (i.e. - Page 6 Cable Wiring and Dip Switch Settings When Using PPM 100 Flow Meter with PPD 200 Remote Display 235–616 (PPM 100 Meter used in Class , Division 1 Hazardous Location) Remote Display Dip Switch Tab Positions (Located on bottom of the control)

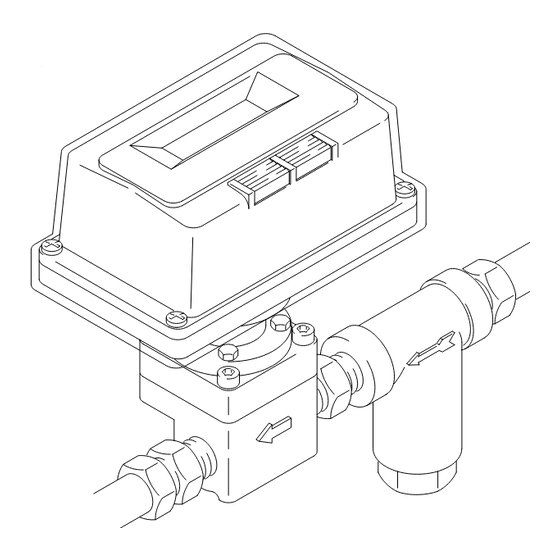

- Page 7 Installation Flow Meter Attach ground lug under screw Fluid Shutoff Valve Fluid Filter Fluid Shutoff Valve on outlet side on inlet side 01063 Fig. 2 Dust and Foreign Matter Flow Meter Location NOTE: Flow volume can only be measured at the lo- Avoid allowing dust or foreign matter from entering the flow meter by taking the following precautions: cation where the flow meter is installed.

-

Page 8: Operation

Operation WARNING When used with low viscosity fluids, such as sol- vent, the flow meter will not be accurate at low flow Pressure Relief Procedure rates under 50 cc/min (1.69 oz/min). See graph, To reduce the risk of serious injury, including page 16. - Page 9 10. If the flow meter accuracy is outside of your No Flow Volume Display acceptable limit, return the meter to Graco for recalibration or parts replacement. If there is no flow volume display, check the following:...

-

Page 10: Maintenance

Maintenance WARNING Cleaning the Meter Chamber Pressure Relief Procedure 1. Follow the Pressure Relief Procedure Warning, Before checking, cleaning, or servicing the meter, at left. always follow this procedure to reduce the risk of serious injury, including splashing fluid in the eyes 2. - Page 11 Maintenance 01034 01036 Connector Connector Power Pack Power Pack STEP 1: STEP 3: Remove the covers and connect the Install the new power pack in the me- new power pack. Do not disconnect the old power ter and install the covers. pack until the new power pack is connected.

-

Page 12: Parts

Parts M4 x 12 M5 x 25 Permanently bonded to meter 01031... -

Page 13: Graco Phone Numbers

187–570 LABEL, warning 110–504 FITTINGS, 3/8 npt(m) TO PLACE AN ORDER , contact your Graco distribu- tor, or call Graco: 1–800–328–0211 Toll Free Replacement W arning labels are available at no cost. FOR TECHNICAL ASSIST ANCE , service repair infor- Changing the rotor may effect the meter accuracy . - Page 14 Part No. Length ft (m) 208–630 1/2 npt(m) x 3/8 npt(f); carbon steel and PTFE ; for non-corrosive fluids 235–790 PPM 100 235–616 25 (7.63) 210–071 3/8 npt(m) x 3/8 npt(f); stainless steel and 235–791 PPM 100 235–616 50 (15.25)

-

Page 15: Dimensions

Dimensions Weight: 672 g (24 oz.) 147 mm (5.8 in.) M6 x 8 thread 130 mm 5.1 in. 76 mm (3.0 in.) 20 mm (0.787 in.) 01134 Technical Data Maximum Fluid Working Pressure. 20.7 bar (300 psi) Fluid Viscosity Range . -

Page 16: Performance Chart

Graco distributor to the original purchaser for use. As purchaser’s sole remedy for breach of this warranty, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment proven defec- tive.

Need help?

Do you have a question about the PPM 100 and is the answer not in the manual?

Questions and answers