Summary of Contents for CMO VALVES AT Series

- Page 1 C O F F E R D A M G A T E - A T S E R I E S INSTRUCTIONS AND MAINTENANCE MANUAL manufacturing the valve you need...

-

Page 2: Purpose And Scope

(base and sides) or 4-sided (base, sides and lintel) seals to work with clean liquids or liquids loaded with solids, as is their designated use. Any other uses must be consulted and approved in writing by CMO Valves. CMO Valves shall not be liable for any damage arising from applications deviating from the intended use or as a result of improper installation, commissioning or operation of the gate. -

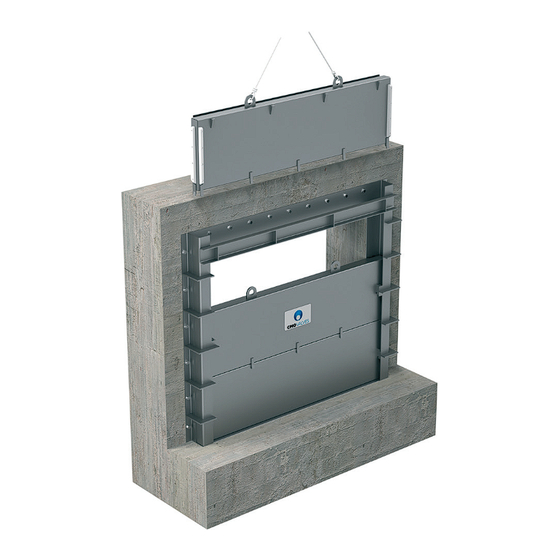

Page 3: Transport And Handling

To prevent damage, especially to the anticorrosive protection, it is recommended to use soft straps to lift CMO Valves co erdam gates. These straps must be secured around the side profi les in the top part of the body, or in the lifting lugs in the top of the leaf. -

Page 4: Installation

COFFERDAM GATE - AT SERIES COFFERDAM GATE - AT SERIES INSTALLATION Adhere to the following instructions in order to prevent personal and/or material damage (to the facilities, the gate, etc.): • Before installation, inspect the gate to ensure no damage has occurred during transport or storage •... - Page 5 COFFERDAM GATE - AT SERIES COFFERDAM GATE - AT SERIES ASSEMBLY CHANNEL ASSEMBLY The following procedures and instructions, which serve as general installation guidelines, should be consulted and observed, along with specifi c notes on approval drawings and other order and project documentation.

- Page 6 COFFERDAM GATE - AT SERIES COFFERDAM GATE - AT SERIES In order to assemble the gate using chemical or expansion anchors (fi g. 3), follow these steps: • Start by placing the gate in the channel in the required location. In this case, it is also particularly important for the leaves to be on the downstream side (in unidirectional only).

- Page 7 COFFERDAM GATE - AT SERIES COFFERDAM GATE - AT SERIES In order to mount the gate using chemical or expansion anchors (fi g. 4), follow these steps: • The concrete surface where the frame is mounted must be smooth and level.

- Page 8 Once the gate has been installed, check that all the nuts and bolts have been tightened correctly. All CMO Valves gates are tested at its facilities before shipping. Before assembling the gate, ensure its di erent parts and components have not been damaged or deformed during transport, handling or storage. Any incident must be corrected prior to assembly.

- Page 9 fi nish. CMO Valves' standard colour is blue RAL-5015. Opening and closing is carried out manually from the top section. MECHANICAL LOCKING DEVICE This system allows the gate to be mechanically locked in open or closed position.

- Page 10 COFFERDAM GATE - AT SERIES COFFERDAM GATE - AT SERIES LIFTING BEAM (fi g. 13 and 14) The lifting beam is used to lift or lower co erdam gates installed in di cult access areas (deep drainage systems, inlets, etc). It is fi tted with a mechanical device that allows the leaf to be secured or released. The steps to follow in order to position and extract the leaf are: Lower the leaf and the lifting beam guided by the body.

-

Page 11: Maintenance

COFFERDAM GATE - AT SERIES MAINTENANCE CMO Valves will not be liable if the gates su er damage due to improper handling or lack of proper authorisation, or due to incorrect assembly and commissioning. Manipulating or modifying the gate is forbidden unless expressly authorised by CMO Valves. - Page 12 COFFERDAM GATE - AT SERIES COFFERDAM GATE - AT SERIES Taking into account the recommendations indicated, below are the maintenance operations for this type of equipment: REPLACING THE SEALING JOINT (fi g. 15) Remove the leaf (2) from the body to make it eas- ier to change the seal.

-

Page 13: Components List

HD-500 HD-500 BOLTS Table. 2 *Note: As a reference, this table shows the materials and fi nishes in the most standard co erdam implementations. Check all materials against approval drawings and order information. If in doubt, contact CMO Valves. www.cmovalves.com... -

Page 14: Spare Parts

ENVIRONMENTAL ASPECTS: DISPOSAL AND RECYCLABILITY To minimise the environmental impact during the life cycle of the AT series co erdam gate, users are given the following environmental guidelines and should consult the relevant standards and directives before disposal. •... - Page 15 SOUTH AMERICA SOUTH AMERICA SOUTH AMERICA SOUTH AMERICA SOUTH AMERICA SOUTH AMERICA SOUTH AMERICA SOUTH AMERICA CMO VALVES CMO VALVES CMO VALVES HEADQUARTERS MAIN MADRID FRANCE OFFICES & FACTORY Amategi Aldea, 142 C / Romania, 5 - D5 (PE Inbisa) 5 chemin de la Brocardière...

Need help?

Do you have a question about the AT Series and is the answer not in the manual?

Questions and answers