Table of Contents

Advertisement

Quick Links

1

2

3

22/02/23

03/03/23

XX/XX/23

Sonia

Sonia

NAME

EN ORIGINAL INSTRUCTIONS

IMPORTANT - These instructions are for your safety.

Please read through them thoroughly prior to handling

the product and retain them for future reference.

V10323_3663602627913_MAND1_2223

3663602627913_MNL_IN_V02.indd 1

4

5

XX/XX/23

XX/XX/23

Impala Ref: PRJ27468

NAME

NAME

EAN: 3663602627913

Page Size: A5

KNG: KNG-2208-0029

EN Electric Chain Saw

2000W

TTL758CHN-A

5059340880709

NMCS2000

5063022106209

5063022106568

3/3/2023 2:42 PM

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Kingfisher TTL758CHN-A

- Page 1 NAME NAME NAME KNG: KNG-2208-0029 EN Electric Chain Saw 2000W TTL758CHN-A 5059340880709 EN ORIGINAL INSTRUCTIONS IMPORTANT - These instructions are for your safety. Please read through them thoroughly prior to handling NMCS2000 the product and retain them for future reference.

- Page 2 EN You will need EN Contents Product description Safety Technical specification Before you start Functions & Settings Operation Care and maintenance Guarantee 3663602627913_MNL_IN_V02.indd 2 3663602627913_MNL_IN_V02.indd 2 3/3/2023 2:42 PM 3/3/2023 2:42 PM...

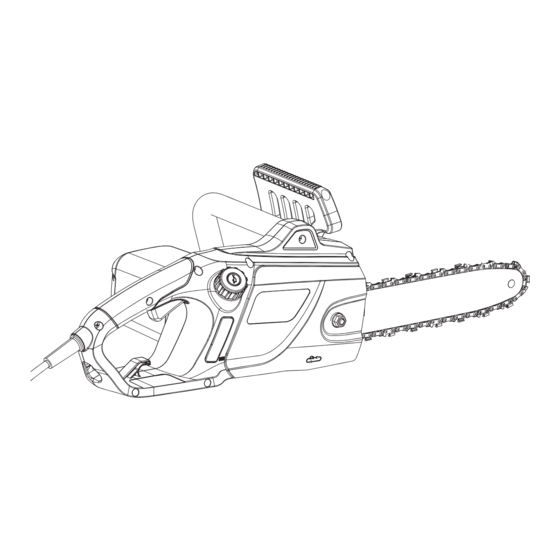

- Page 3 EN Product description 1. Front handle 12. Drive sprocket 2. Front hand guard 13. On/off switch (Chain brake lever) 14. Lock-off button 3. Saw chain 15. Rear handle 4. Guide bar 16. Power cord with plug 5. Sprocket wheel 17. Cable strain relief 6.

-

Page 4: General Power Tool Safety Warnings

EN Safety Safety warnings 1. Children should be supervised to ensure that they do not play with the product. General power tool safety warnings WARNING! RWARNING Read all safety warnings, instructions, illustrations and specifications provided with this power tool. Failure to follow all instructions listed below may result in electric shock, fire and/or serious injury. -

Page 5: Personal Safety

2. Avoid body contact with earthed or grounded surfaces, such as pipes, radiators, ranges and refrigerators. There is an increased risk of electric shock if your body is earthed or grounded. 3. Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of electric shock. - Page 6 5. Do not overreach. Keep proper footing and balance at all times. This enables better control of the power tool in unexpected situations. 6. Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and gloves away from moving parts. Loose clothes, jewellery or long hair can be caught in moving parts.

-

Page 7: Chain Saw Safety Warnings

7. Use the power tool, accessories and tool bits etc. in accordance with these instructions, taking into account the working conditions and the work to be performed. Use of the power tool for operations different from those intended could result in a hazardous situation. 8. -

Page 8: Causes And Operator Prevention Of Kickback

6. Always keep proper footing and operate the chain saw only Slippery or unstable surfaces such as ladders may cause a loss of balance or control of the chain saw. 7. When cutting a limb that is under tension be alert for spring back. - Page 9 Either of these reactions may cause you to lose control of the saw which could result in serious personal injury. Do not rely exclusively upon the safety devices built into your saw. As a chain saw user, you should take several steps to keep your cutting jobs free from accident or injury.

-

Page 10: Vibration And Noise Reduction

Vibration and noise reduction To reduce the impact of noise and vibration emission, limit the time of operation, use low-vibration and low-noise operating modes as well as wear personal protective equipment. Take the following points into account to minimize the vibration and noise exposure risks: 1. - Page 11 1. Health defects resulting from vibration emission if the product is being used over longer period of time or not adequately managed and properly maintained. 2. Injuries and damage to property to due to broken accessories or hidden objects that are suddenly dashed. 3.

- Page 12 The product complies with the applicable European directives and an evaluation method of conformity for these directives was done. yyWxx Manufacturing date code; year of manufacturing (20yy) and week of manufacturing (Wxx) UK Conformity Assessed. NMCS2000 NM-No name, CS- Chain Saw TTL758CHN-A TTL-TITAN, CHN-Chain Saw 3663602627913_MNL_IN_V02.indd 12 3/3/2023 2:42 PM...

- Page 13 General : TTL758CHN-A: CS2000: > Rated voltage : 220-240 V~, 50 Hz : 220-240 V~, 50 Hz > Rated input power : 2000 W : 2000 W > Rated no load speed : 8000 /min : 8000 /min > Oil tank volume...

-

Page 14: You Will Need

EN Before you start Unpacking 2. Remove all packing materials and shipping devices if applicable. or show damage do not use the product but contact your dealer. Using an incomplete or damaged product represents a hazard to people and property. 4. - Page 15 Fig. 1a Fig. 1b 6. Align the guide bar (4) and saw chain (3) assembly with the drive sprocket (12) and bolt (10). Lay the saw chain around the drive sprocket (12) and then lower the guide bar (4) to install it to the bolt (Figs. 1c, 1d). Fig.

-

Page 16: Saw Chain Tensioning

8. Pre-tighten the saw chain (3) turning the tension screw (9a) clockwise with the multitool (23). 9. Replace the cover (7) and slightly tighten the retaining nut (6) (Fig. 1f). Fig. 1f NOTE: Fix the retaining nut finger tight only at this stage. The chain tension cannot be adjusted with the retaining nut tightened - it must be loosened first. - Page 17 1. Place the product on a suitable flat surface. 2. Lift up the tip of the guide bar (4) and keep it there as you adjust the tension (Fig. 2a). Fig. 2a 3. Turn the tension screw (9a) until the chain ‘tie straps’ are just touching the bottom edge of the guide bar (4) (Fig.

-

Page 18: Chain Lubrication

Chain lubrication WARNING! The product is not filled with chain oil. It is essential to fill the product with chain oil before using it! Never operate the product without chain oil as this will result in extensive damage to the product! Operating the saw chain dry or with too little chain oil will decrease cutting efficiency, shorten the product life span and cause rapid wear to the saw chain and guide bar from overheating! - Page 19 4. Check the oil level window (20) prior to start-up and regularly during operation. Refill oil when the oil level is lower than "MIN" marking (Fig. 3c). Fig. 3c 5. Wipe up spilled lubricant with a soft cloth and refit the oil tank cap (21). NOTE: Always dispose of lubricant, used oil and objects contaminated with them in accordance with local regulations.

-

Page 20: Connection To The Power Supply

Connection to the power supply WARNING! For your safety, it is required that the plug attached to this product is always connected to an extension cord! The extension cord must be suitable for outdoor use with sockets protected against water splashing! Ensure the extension cord is of the proper size and type for your product (≥... -

Page 21: Intended Use

EN Functions & Settings Intended use 1. This electric chain saw TTL758CHN-A/NMCS2000 is designated with a rated input of 2000 Watts. The product is intended cutting logs with a thickness of max. 350 mm. It must not be used for cutting other materials, such as plastic, stone, metal or wood that contains foreign objects. -

Page 22: Switching On/Off

Switching on/off 1. Make sure the chain brake is disengaged (see above). 2. Ensure the saw chain (3) does not come into contact with anything before starting the product. 3. Grip the product with both hands, your left hand holding the front handle (1) (do not hold the front hand guard) and your right hand holding the rear handle (15). - Page 23 4. Only use the product with a secure stance. Hold the product at the right-hand side of your body (Fig. 7a). Fig. 7a 5. Check the proper lubrication as described in section “Before you start - Chain lubrication” before performing any cut 6.

- Page 24 10. Optimum sawing is achieved if the chain speed remains constant during cutting. 11. Be careful when reaching the end of the cut. The weight of the product may change unexpectedly as it cuts free from the wood. This can cause accidents to the legs and feet. Always remove the product from a wood cut while the product is running.

-

Page 25: Felling A Tree

To avoid kickback: • Saw with guide bar at a flat angle. • Never work with a loose, widely stretched or the heavily worn out saw chain. • Ensure the saw chain is sharpened correctly. • Never saw above shoulder height. •... -

Page 26: Limbing And Pruning

Notching undercut Make the notch (Fig. 9b, B) 1/3 the diameter of the tree, perpendicular to the direction of fall (Fig. 9b). Make the lower horizontal notching cut first. This will help to avoid pinching either the saw chain or the guide bar when the second notch is being made. -

Page 27: Bucking A Log

Warning! Never climb into a tree to limb or prune! Do not stand on ladders, platforms, logs, or in any position which may cause you to lose the balance or next to main limp or trunk until you have cut off the limb further out to reduce the weight! This prevents stripping the bark from the main member! Warning! If the limbs to be pruned are above chest height, hire a professional to perform the pruning! -

Page 28: After Use

3. When the log is supported on both ends (Fig. 12c), cut 1/3 the diameter from the top (overbuck). Then make the finished cut by underbucking the lower 2/3 to meet the first cut. Fig. 12c 4. When bucking on a slope always stand on the uphill side of the log (Fig. -

Page 29: General Cleaning

EN Care and maintenance The golden rules for care WARNING! Always switch the product off, disconnect it from the power supply and let the product cool down before performing inspection, maintenance and cleaning work! 1. Keep the product clean. Remove debris from it after each use and before storage. 2. - Page 30 Guide bar and saw chain maintenance non-standard cutter and depth gauge settings are the causes of most guide bar problems, primarily resulting in uneven bar wear. As the bar wears unevenly, the rails widen, which may cause the chain to clatter and make a saw chain which is too tight, this will contribute to rapid bar wear.

- Page 31 Saw chain sharpening NOTE: Never saw with a blunt chain. The saw chain is blunt if you have to push the product into the tree and the chips are very small. 1. Have the saw chain (3) sharpened professionally at an authorised service centre or sharpen the chain yourself by using a proper sharpening kit.

-

Page 32: Spare Parts

The following parts of this product may be replaced by the consumer. Spare parts are available at an authorised dealer or through our customer service. Description Saw chain OREGON Oregon 91PJ056X (TTL758CHN-A) Oregon 91PJ057X (NMCS2000) Guide bar OREGON 160SDEA041 3663602627913_MNL_IN_V02.indd 32... -

Page 33: Power Cord

Power cord If the replacement of the supply cord is necessary, this has to be done by the manufacturer or his agent in order to avoid a safety hazard Plug replacement (for UK only) IMPORTANT: The wires in the mains lead are coloured in accordance with the following code: Blue - Neutral Brown - Live... -

Page 34: Troubleshooting

Troubleshooting Suspected malfunctions are often due to causes that the users can fix themselves. Therefore check the product using this section. In most cases the problem can be solved quickly. WARNING! Only perform the steps described within these instructions! All further inspection, maintenance and repair work must be performed by an authorised service centre or a similarly qualified specialist if you cannot solve the problem yourself! - Page 35 EN Guarantee We take special care to select high quality materials and use manufacturing techniques that allow us to create products incorporating design and durability. This product has a manufacturer’s guarantee of 2 years against manufacturing defects, from the date of purchase (if bought in store) or date of delivery (if bought online), at no additional cost for normal (non-professional or commercial) household use.

-

Page 36: Availability Of Spare Parts

A better way to repair your tools Kingfisher takes special care in creating high-quality garden power tools that are designed to last. But if a fault develops with your garden power tool and you need to claim under the guarantee, the Customer Care and Technical Helpline can support with technical assistance or if required, arrange a free courier collection from your home, assess your garden power tool for fault, repair it, and return it. - Page 37 Product Electrical chainsaw 2000W TTL758CHN-A Serial number range 000001 to 999999 Name and address of the manufacturer or his authorised representative: Kingfisher International Products Limited 1 Paddington Square London W2 1GG United Kingdom This declaration of conformity is issued under the sole responsibility of the manufacturer.

- Page 38 Nazwa i adres producenta lub jego upoważnionego przedstawiciela: Denumirea și adresa producătorului sau a reprezentantului său autorizat: Nombre y dirección del fabricante o de su representante autorizado: Nome e endereço do fabricante ou do respetivo mandatário: Kingfisher International Products B.V., Rapenburgerstraat 175E, 1011 VM Amsterdam, The Netherlands This declaration of conformity is issued under the sole responsibility of the manufacturer.

- Page 39 Authorised signatory and technical file holder/signataire et responsable de la documentation technique authorisé/ podmiot uprawniony do wystawienia i adres prezechowywania dokumentacji technicznej/semnatar autorizat și deținător al dosarului tehnic/firmante autorizado y titular del expediente tecnico/ signatário autorizado e detentor da ficha técnica Kingfisher International Products B.V., Rapenburgerstraat 175E, 1011 VM Amsterdam,...

- Page 40 Manufacturer: EN www.diy.com www.screwfix.com UK Manufacturer: www.screwfix.ie Kingfisher International Products Limited, To view instruction manuals online, 1 Paddington Square, London, W2 1GG, visit www.kingfisher.com/products United Kingdom EU Manufacturer: Kingfisher International Products B.V. Rapenburgerstraat 175E 1011 VM Amsterdam The Netherlands 3663602627913_MNL_IN_V02.indd 37 3663602627913_MNL_IN_V02.indd 37...

Need help?

Do you have a question about the TTL758CHN-A and is the answer not in the manual?

Questions and answers