Advertisement

Quick Links

Advertisement

Summary of Contents for Comet HPP H-100/2 SAP

- Page 1 REPAIR MANUAL H-100/2 SAP GENERATION...

- Page 3 INDEX ASSEMBLING THE H-100 PUMP POWER END ASSEMBLING THE SAP G-IV PLUNGER KIT (FROM P-18 TO P-30) ASSEMBLING THE SAP G-IV PLUNGER KIT (FROM P-32 TO P-40) ASSEMBLING THE SAP G-IV PUMP HEAD POWER END PARTS CONNECTING RODS OIL SEAL CAGE PUMP HEAD PLUNGER KIT (P-18) PLUNGER KIT (P-20)

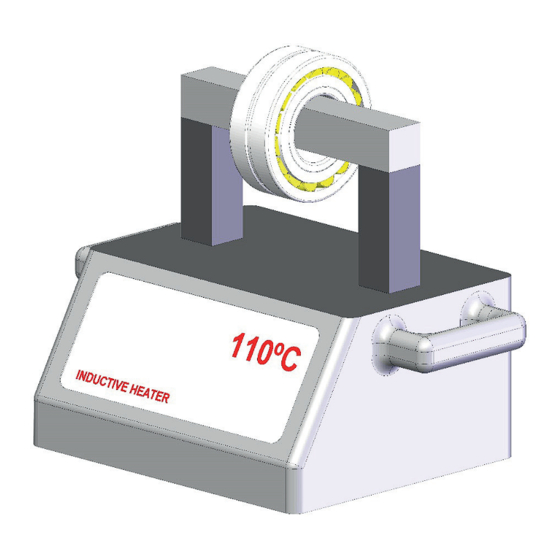

- Page 4 ASSEMBLING THE H-100 PUMP POWER END HEAT THE FIRST BEARING OF THE GEAR SHAFT FOR 10 MINUTES AT 110°C. Fig. 01 MOUNT THE FIRST BEARING IN THE GEAR SHAFT WHILE IT IS WARM. Fig. 02...

- Page 5 ASSEMBLING THE H-100 PUMP POWER END INSERT THE GEAR SHAFT INTO THE HOUSING. Fig. 03 MOUNT THE SECOND BEARING. IT WILL BE NECESSARY TO HEAT THE BEARING FOR 10 MINUTES AT 110°C BEFORE MOUNTING (SEE FIG. 01). Fig. 04...

- Page 6 ASSEMBLING THE H-100 PUMP POWER END MOUNT THE OIL SEAL ON THE GEAR SHAFT FLANGE AND ENSURE THAT THE SEAL APERTURE IS INWARDS. Fig. 05 USE COPPER GREASE TO COVER THE THREAD OF THE M10 SCREWS FIXING THE ALIGNMENT CRANKCASE FLANGE. TIGHT TO “X” TO TORQUE OF 64 Nm. Fig.

- Page 7 ASSEMBLING THE H-100 PUMP POWER END INSERT THE SHAFT EXTENSION WITH ITS KEY AND FIX IT ON THE SHAFT. Fig. 07 INSERT THE BEARING AND THE SEEGER RING. Fig. 08...

- Page 8 ASSEMBLING THE H-100 PUMP POWER END MOUNT THE BUSHING AND THE BEARING SHELLS INTO THE CONNECTING ROD. ATTENTION: MOUNT THE PAIR OF BEARING SHELLS CONTAINED IN THE BOX. Fig. 09 ASSEMBLE THE GUIDE PISTON WITH THE CONNECTING ROD USING THE PIN AND SEEGER RINGS.

- Page 9 ASSEMBLING THE H-100 PUMP POWER END INSERT THE KIT INTO THE HOUSING. REPEAT THE PROCESS FOR THE OTHER 2 KITS. Fig. 11 HEAT THE PAIR OF CRANKSHAFT BEARINGS AT 115°C FOR 10 MINUTES. Fig. 12...

- Page 10 ASSEMBLING THE H-100 PUMP POWER END MOUNT THE BEARINGS ON THE CRANKSHAFT WHILE THEY ARE STILL WARM. Fig. 13...

- Page 11 ASSEMBLING THE H-100 PUMP POWER END MOUNT THE CRANKSHAFT KEY. Fig. 14 HEAT THE CROWN GEAR AT 120°C FOR 10 MINUTES. Fig. 15...

- Page 12 ASSEMBLING THE H-100 PUMP POWER END MOUNT THE CROWN GEAR IN THE CRANKSHAFT WHILE IT IS WARM WITH THE THREADS FACING OUT. Fig. 16 MOUNT THE SEEGER RING. Fig. 17...

- Page 13 ASSEMBLING THE H-100 PUMP POWER END LIFT THE CRANKSHAFT USING LIFTING EYES APPLIED ON THE APPROPRIATE THREADS. THE GEAR CROWN MUST BE POSITIONED FACING THE SHAFT GEAR SIDE. Fig. 18 MOUNT O-RINGS (APPLY “ROCOL” TYPE GREASE TO SEAL) AND THE BEARING FLANGES WITH THE “HALF-MOON”...

- Page 14 ASSEMBLING THE H-100 PUMP POWER END MOUNT BEARINGS ON BOTH CRANKSHAFT SIDES. Fig. 20 MOUNT THE SLEEVE ON THE CRANKSHAFT (PINION SIDE). APPLY LOCTITE 577 ON THE THREAD OF THE M16 SCREWS TO A TORQUE OF 232 Nm. Fig. 21...

- Page 15 ASSEMBLING THE H-100 PUMP POWER END MOUNT THE O-RING (USE “ROCOL” TYPE GREASE TO SEAL) AND FIX THE CRANKSHAFT COVER (PINION SIDE). APPLY GREASE ON THE THREAD OF THE M10 SCREWS. TIGHT “X” TO A TORQUE OF 64 Nm. Fig. 22 MOUNT THE O-RING AND THE BEARING SEAT ON THE CRANKSHAFT.

- Page 16 ASSEMBLING THE H-100 PUMP POWER END MOUNT THE ROTO GLYD AND ITS COVER ON THE BEARING SEAT. TIGHT THE M6 SCREWS TO A TORQUE OF 13 Nm. (PAY ATTENTION: DO NOT USE GREASE OR ANYTHING SIMILAR). Fig. 24 MOUNT THE O-RING (APPLY “ROCOL” TYPE GREASE TO SEAL) AND FIX THE CRANKSHAFT COVER (SHAFT SIDE).

- Page 17 ASSEMBLING THE H-100 PUMP POWER END MOUNT THE ADAPTOR, THE O-RING AND THE ROTO GLYD ALIGNMENT IN THE CRANKSHAFT COVER. TIGHT THE ADAPTOR TO A TORQUE OF 60 Nm. (PAY ATTENTION: DO NOT USE GREASE OR ANYTHING SIMILAR). Fig. 26 MOUNT THE FIRST ROD CAP (PINION SIDE).

- Page 18 ASSEMBLING THE H-100 PUMP POWER END MOUNT THE FIRST BEARING CAP (PINION SIDE). TIGHT THE M16 SCREWS TO A TORQUE OF 232 Nm. (PAY ATTENTION: DO NOT USE GREASE OR ANYTHING SIMILAR). TURN THE SHAFT TO ENSURE A PERFECT FIX BETWEEN COMPONENTS. REPEAT THE PROCESS FOR THE OTHER 2 BEARINGS, ALWAYS TURNING THE SHAFT AND CHECKING THE ASSEMBLY.

- Page 19 ASSEMBLING THE SAP G-IV PLUNGER KIT PLUNGER KIT – ASSEMBLY STEPS – SAP IV (FROM P-18 TO P-30) ARRANGE ALL PLUNGER KIT COMPONENTS ON SEPARATE ALL SUPPORT FLANGE COMPONENTS THE WORK BENCH. ON THE WORK BENCH. Fig. 01 Fig. 02 INSERT THE SLIDING BUSH INTO THE SUPPORT OVERLAP THE O-RING.

- Page 20 PLUNGER KIT – ASSEMBLY STEPS – SAP IV (FROM P-18 TO P-30) INSERT THE LOW PRESSURE SEAL WITH THE OPENED SIDE TURNED TO THE SUPPORT FLANGE (APPLY “ROCOL” TYPE GREASE TO SEAL). Fig. 05 INSERT THE SPACER AND THE SEEGER RING TO INSERT THE O-RING INTO THE SUPPORT FIX THE ASSEMBLED PARTS.

- Page 21 PLUNGER KIT – ASSEMBLY STEPS – SAP IV (FROM P-18 TO P-30) INSERT THE GUIDE PIN INTO THE SLEEVE MOUNT THE SUPPORT FLANGE ON THE SLEEVE. (SOME MODELS COULD BE SUPPLIED WITH PIN ALREADY MOUNTED). Fig. 09 Fig. 08 CHECK HOLE ALIGNMENT. INSERT THE ALLEN SCREW WITHOUT HEAD AND FIX IT.

- Page 22 PLUNGER KIT – ASSEMBLY STEPS – SAP IV (FROM P-18 TO P-30) APPLY “ROCOL” TYPE GREASE ON THE THREAD OF THE M10 SCREWS THAT FIX THE SUPPORT ARRANGE THE PLUNGER, THE BACK RING, FLANGE WITH THE SLEEVE, TIGHT “X” TO A THE O-RING AND THE G-IV SELF-CENTERING TORQUE OF 60Nm.

- Page 23 PLUNGER KIT – ASSEMBLY STEPS – SAP IV (FROM P-18 TO P-30) INSERT THE SECOND BACK RING ON THE INSERT THE G-IV SELF-CENTERING ADAPTER ON PLUNGER. THE SET. Fig. 16 Fig. 17 Fig. 05 INSERT THE SLEEVE ASSEMBLED WITH THE ARRANGE THE SEALING KIT ON THE FLANGE INTO THE PLUNGER UNTIL IT ...

- Page 24 PLUNGER KIT – ASSEMBLY STEPS – SAP IV (FROM P-18 TO P-30) INSERT THE LOWER SUPPORTING RING (WITH THE CHANFER FACING DOWN) AND USE A NYLON TOOL AND A HAMMER TO PUSH IT UNTIL IT REACHES THE BOTTOM. Fig. 20...

- Page 25 PLUNGER KIT – ASSEMBLY STEPS – SAP IV (FROM P-18 TO P-30) INSERT THE FIRST SCRAPER RING AND USE THE NYLON TOOL AND A HAMMER TO PUSH IT TO THE BOTTOM. Fig. 21...

- Page 26 PLUNGER KIT – ASSEMBLY STEPS – SAP IV (FROM P-18 TO P-30) INSER THE KEVLAR SEALING AND USE THE NYLON TOOL AND A HAMMER TO PUSH IT TO THE BOTTOM. Fig. 22...

- Page 27 PLUNGER KIT – ASSEMBLY STEPS – SAP IV (FROM P-18 TO P-30) INSERT THE BRAIDED SEALING PAYING ATTENTION TO KEEP ITS CHANFER AT A 180° WITH RESPECT TO THE KEVLAR SEALING. USE THE NYLON TOOL AND A HAMMER TO PUSH IT TO THE BOTTOM.

- Page 28 PLUNGER KIT – ASSEMBLY STEPS – SAP IV (FROM P-18 TO P-30) INSERT THE SECOND SCRAPER RING AND USE THE NYLON TOOL TO PUSH IT TO THE BOTTOM. Fig. 24...

- Page 29 PLUNGER KIT – ASSEMBLY STEPS – SAP IV (FROM P-18 TO P-30) INSERT THE UPPER SUPPORTING RING AND USE THE NYLON TOOL TO PUSH IT TO THE BOTTOM. Fig. 25...

-

Page 30: Table Of Contents

PLUNGER KIT – ASSEMBLY STEPS – SAP IV (FROM P-18 TO P-30) ARRANGE THE COMPONENTS FOR PACKING INSERT THE PACKING SPRING ALREADY SPRING ASSEMBLY. ASSEMBLED. Fig. 26 Fig. 27 Fig. 05 INSERT THE LOWER METAL RING WITH THE ASSEMBLE THE FRONTAL SLEEVE ON THE RADIUS FACING DOWNWARDS. -

Page 31: Fig. 32

PLUNGER KIT – ASSEMBLY STEPS – SAP IV (FROM P-18 TO P-30) PRESS IT UNTIL IT REACHES THE BOTTOM AND INSERT THE O-RING ON THE FRONTAL SLEEVE. ROTATE 90° TO LOCK THE FRONTAL Fig. 30 Fig. 31 Fig. 05 SLEEVE IN THE RIGHT POSITION. INSERT THE UPPER METAL RING WITH THE TIGHT COOLING SYSTEM CONNECTIONS. - Page 32 ASSEMBLING THE SAP G-IV PLUNGER KIT PLUNGER KIT – ASSEMBLY STEPS – SAP IV (FROM P-32 TO P-40) ARRANGE ALL THE PLUNGER KIT COMPONENTS MOUNT THE SUPPORT FLANGE WITH THE ON THE WORK BENCH. SLEEVE. Fig. 01 Fig. 02 CHECK HOLE ALIGNMENT. INSERT THE ALLEN SCREW WITHOUT HEAD AND FIX IT.

-

Page 33: Fig. 05

PLUNGER KIT – ASSEMBLY STEPS – SAP IV (FROM P-32 TO P-40) INSERT THE SLIDING BUSH INTO THE SLEEVE. OVERLAP THE O-RING. Fig. 05 Fig. 06 INSERT THE LOW PRESSURE SEAL WITH THE OPENED SIDE TURNED TO THE SUPPORT FLANGE (APPLY “ROCOL” TYPE GREASE TO SEAL). Fig. - Page 34 PLUNGER KIT – ASSEMBLY STEPS – SAP IV (FROM P-32 TO P-40) USE THE SPACER AND THE SEEGER RING TO FIX ARRANGE THE PLUNGER, THE BACK RINGS, THE ASSEMBLED PARTS. THE O-RING AND THE G-IV SELF-CENTERING ADAPTER. Fig. 08 Fig. 09 INSERT FIRST BACK RING ON THE PLUNGER.

- Page 35 PLUNGER KIT – ASSEMBLY STEPS – SAP IV (FROM P-32 TO P-40) INSERT SECOND BACK RING ON THE PLUNGER. INSERT THE G-IV SELF-CENTERING ADAPTER ON THE PLUNGER. Fig. 12 Fig. 13 INSERT THE SLEEVE ASSEMBLED WITH FLANGE ARRANGE THE SEALING KIT ON THE INTO THE PLUNGER UNTIL IT REACHES WORK BENCH.

- Page 36 PLUNGER KIT – ASSEMBLY STEPS – SAP IV (FROM P-32 TO P-40) INSERT THE LOWER SUPPORTING RING (WITH THE CHANFER FACING DOWN) AND USE A NYLON TOOL AND A HAMMER TO PUSH IT UNTIL IT REACHES THE BOTTOM. Fig. 16...

- Page 37 PLUNGER KIT – ASSEMBLY STEPS – SAP IV (FROM P-32 TO P-40) INSERT THE FIRST SCRAPER RING AND USE THE NYLON TOOL AND A HAMMER TO PUSH IT TO THE BOTTOM. Fig. 17...

- Page 38 PLUNGER KIT – ASSEMBLY STEPS – SAP IV (FROM P-32 TO P-40) INSER THE KEVLAR SEALING AND USE THE NYLON TOOL AND A HAMMER TO PUSH IT TO THE BOTTOM. Fig. 18...

- Page 39 PLUNGER KIT – ASSEMBLY STEPS – SAP IV (FROM P-32 TO P-40) INSERT THE BRAIDED SEALING PAYING ATTENTION TO KEEP ITS CHANFER AT A 180° WITH RESPECT TO THE KEVLAR SEALING. USE THE NYLON TOOL AND A HAMMER TO PUSH IT TO THE BOTTOM.

- Page 40 PLUNGER KIT – ASSEMBLY STEPS – SAP IV (FROM P-32 TO P-40) INSERT THE SECOND SCRAPER RING AND USE THE NYLON TOOL TO PUSH IT TO THE BOTTOM. Fig. 20...

- Page 41 PLUNGER KIT – ASSEMBLY STEPS – SAP IV (FROM P-32 TO P-40) INSERT THE UPPER SUPPORTING RING AND USE THE NYLON TOOL TO PUSH IT TO THE BOTTOM. Fig. 21...

-

Page 42: Arrange The Components For Packing Spring Assembly

PLUNGER KIT – ASSEMBLY STEPS – SAP IV (FROM P-32 TO P-40) ARRANGE THE COMPONENTS FOR PACKING INSERT THE PACKING SPRING ALREADY SPRING ASSEMBLY. ASSEMBLED. Fig. 22 Fig. 23 INSERT THE LOWER METAL RING WITH THE ASSEMBLE THE FRONTAL SLEEVE ON THE RADIUS FACING DOWNWARDS. - Page 43 PLUNGER KIT – ASSEMBLY STEPS – SAP IV (FROM P-32 TO P-40) PRESS AND ROTATE 90° TO LOCK THE FRONTAL MOUNT THE O-RING ON THE FRONTAL SLEEVE. SLEEVE IN THE RIGHT POSITION. Fig. 26 Fig. 27 INSERT THE UPPER METAL RING WITH THE TIGHT COOLING SYSTEM CONNECTIONS.

- Page 44 ASSEMBLING THE SAP G-IV PUMP HEAD ARRANGE THE INTELLIVALVES. Fig. 01 PUT THE MANIFOLD ON SUPPORTING SHIMS. Fig. 02...

- Page 45 ASSEMBLING THE SAP G-IV PUMP HEAD BEFORE INSERTING THE INTELLIVALVE IN THE HOLE, APPLY “ROCOL” TYPE GREASE ON ALL SEAL RINGS TO AVOID DAMAGE DURING ASSEMBY. Fig. 03 FIX THE INTELLIVALVE MANUALLY IN THE HOLE. Fig. 04...

- Page 46 ASSEMBLING THE SAP G-IV PUMP HEAD CHECK THE INTELLIVALVE ASSEMBLY: ITS OUTSIDE SURFACE MUST BE A LITTLE BIT FURTHER IN COMPARISON WITH THE PUMP HEAD SURFACE. CHECK IF THE VALVE IS COMPLETELY Fig. 05 MOUNTED. REPEAT THE PROCESS FOR THE OTHER TWO INTELLIVALVES. Fig.

- Page 47 ASSEMBLING THE SAP G-IV PUMP HEAD APPLY COPPER GREASE ON THE THREAD OF THE M24 SCREWS THAT FIX THE ASSEMBLED HEAD WITH THE FORK. TIGHT “X” WITH 100Nm, 250Nm AND 400Nm TORQUE STEPS. PAY ATTENTION! IN ORDER TO SIMPLIFY THE DRAWING, ON FIG. 8, 9, 10, 11, 12 AND 13 THE FORK AND THE PUMP CRANKCASE ARE NOT SHOWN.

- Page 48 ASSEMBLING THE SAP G-IV PUMP HEAD WITH THE PLUNGER KIT ALREADY ASSEMBLED, APPLY “ROCOL” TYPE GREASE TO AVOID SEALS BEING DAMAGED DURING ASSEMBLY. INSERT THE PLUNGER KIT INTO THE MANIFOLD (CHECK CONNECTION PARTS SIDE) AND INSERT SCREWS (APPLY COPPER GREASE ON THREADS). Fig.

- Page 49 ASSEMBLING THE SAP G-IV PUMP HEAD REPEAT THE PROCESS FOR THE OTHER TWO PLUNGERS. Fig. 10 ASSEMBLE THE O-RING ON THE FRONT FLANGE (APPLY “ROCOL” TYPE GREASE ON THE SEAL). Fig. 11...

- Page 50 ASSEMBLING THE SAP G-IV PUMP HEAD APPLY COPPER GREASE ON THE THREAD OF THE M12 SCREWS THAT FIX THE FRONT FLANGE WITH THE MANIFOLD. TIGHT “X” TO A TORQUE OF 100Nm. Fig. 12 REPEAT THE PROCESS FOR THE OTHER TWO FLANGES. Fig.

- Page 52 POWER END PARTS (see codes on the next page)

- Page 53 POWER ENDS - H100/2 CODE DESCRIPTION Q2310100110812 H100/2 HORIZONTAL POWER END 1800 RPM (60 Hz) Q2310100110811 H100/2 HORIZONTAL POWER END 1500 RPM (50 Hz) POWER END PARTS ITEM CODE DESCRIPTION QTY. Q231300005350 OIL SEAL Q231110010990 AXIS TRASMISSION FLANGE Q231200005500 ALLEN SCREW M8X20mm Q231300001110 O-RING Q231700001160...

- Page 54 POWER END PARTS ITEM CODE DESCRIPTION QTY. Q231300003810 O-RING Q231200003620 SEEGER Q231110010760 1800 RPM (60 Hz) CROWN H100/2 – H150/3 Q231110016630 1500 RPM (50 Hz) CROWN H100/2 – H150/3 Q231200001780 Q231010007710 CRANKSHAFT H100/2 – H150/3 Q231700001500 BEARING Q231300005360 O-RING Q231110011010 BUSHING Q231300005020 ROTO GLYD...

- Page 55 POWER END PARTS ITEM CODE DESCRIPTION QTY. Q231300001060 O-RING Q231200001070 LOCK WASHER M8 Q232320018110 COUPLING AC16 X 3/4" UNF ON REQUEST HOSE ON REQUEST HOSE Q232320018680 COUPLING AC16 X 7/8" UNF Q231200001400 ALLEN SCREW M10x25mm Q231200001030 LOCK WASHER M10 Q231300005820 O-RING Q231200008260 SEEGER I-52...

- Page 56 CONNECTING RODS - CODE Q231010011120 BOLT TORQUE: 110 N 3 SETS PER PUMP ITEM CODE DESCRIPTION QTY. Q231110022250 ARM OF CONNECTING ROD Q231110022260 BEARING OF CONNECTING ROD Q231200001870 HEX BOLT M12x70 Q231200001900 TOOTHED WASHER M12 Q231200008810 ELASTIC GUIDE BUSHING ATTENTION! ASSEMBLE WITH NUMBERS FACING THE SAME SIDE Attention!

- Page 57 OIL SEAL CAGE - CODE Q231010010971 ITEM CODE DESCRIPTION QTY. Q231200001070 WASHER * Note: Common wear parts or disposable Q231110044260 OIL SEAL CAGE Q231300011340 OIL SEAL Q231300011210 SLIDING RING Q231300001910 O-RING Q231200001540 SEEGER RING Q231200007960 SCREW M8X20mm Q231300001170 O-RING...

- Page 58 PUMP HEAD - CODE Q231010 018140...

- Page 59 PUMP HEAD - CODE Q231010 0181400 ITEM CODE DESCRIPTION QTY. Q231010018150 INTELLIVALVE SAP IV Q231110034610 SAP IV HEAD ASSEMBLY Q231200009410 ALLEN SCREW M24x200mm Q231200003630 LOCK WASHER M24 Q231200009980 ALLEN SCREW M24x180mm Q231300001790 O-RING 24 x 2 (90 SHORE) Q231110036020 FLANGE FRONTAL SAP IV Q231200002930 ALLEN SCREW M12x35mm Q231300001930...

- Page 60 PLUNGER KIT (P-18) - CODE Q231010022060 SEAL KIT (P-18) CODE Q231020002187...

- Page 61 Ø Nominal Appropriate Critical Change -0,01 -0,07 18 mm -0,1 -0,06 -0,09 ANALYSE PLUNGER DIMENSIONS WHEN CHANGING THE SEALS OR EVERY 500 HOURS RESPECT THE WEAR LIMIT. PLUNGER KIT (P-18) - CODE Q231010022060 ITEM CODE DESCRIPTION QTY. Q231010022070 HARD METAL PLUNGER P-18 Q231200011130 SEEGER I-30 Q231110037680...

- Page 62 PLUNGER KIT (P-20) - CODE Q231010020520 SEAL KIT (P-20) CODE Q231020002203...

- Page 63 Ø Nominal Appropriate Critical Change -0,01 -0,07 20 mm -0,1 -0,06 -0,09 ANALYSE PLUNGER DIMENSIONS WHEN CHANGING THE SEALS OR EVERY 500 HOURS RESPECT THE WEAR LIMIT. PLUNGER KIT (P-20) - CODE Q231010020520 ITEM CODE DESCRIPTION QTY. Q231010020730 HARD METAL PLUNGER P-20 Q231200010580 SEEGER I-32 Q231110037690...

- Page 64 PLUNGER KIT (P-22) - CODE Q231010020530 SEAL KIT (P-22) CODE Q231020002221...

- Page 65 Ø Nominal Appropriate Critical Change -0,01 -0,07 22 mm -0,1 -0,06 -0,09 ANALYSE PLUNGER DIMENSIONS WHEN CHANGING THE SEALS OR EVERY 500 HOURS RESPECT THE WEAR LIMIT. PLUNGER KIT (P-22) - CODE Q231010020530 ITEM CODE DESCRIPTION QTY. Q231010020200 HARD METAL PLUNGER P-22 Q231200010580 SEEGER I-32 Q231110037700...

- Page 66 PLUNGER KIT (P-24) - CODE Q231010020540 SEAL KIT (P-24) CODE Q231020002241...

- Page 67 Ø Nominal Appropriate Critical Change -0,01 -0,07 24 mm -0,1 -0,06 -0,09 ANALYSE PLUNGER DIMENSIONS WHEN CHANGING THE SEALS OR EVERY 500 HOURS RESPECT THE WEAR LIMIT. PLUNGER KIT (P-24) - CODE Q231010020540 ITEM CODE DESCRIPTION QTY. Q231010020210 PLUNGER P-24 G IV Q231200010600 SEEGER I-36 Q231110037710...

- Page 68 PLUNGER KIT (P-26) - CODE Q231010019980 SEAL KIT (P-26) CODE Q231020002261...

- Page 69 Ø Nominal Appropriate Critical Change -0,01 -0,07 26 mm -0,1 -0,06 -0,09 ANALYSE PLUNGER DIMENSIONS WHEN CHANGING THE SEALS OR EVERY 500 HOURS RESPECT THE WEAR LIMIT. PLUNGER KIT (P-26) - CODE Q231010019980 ITEM CODE DESCRIPTION QTY. Q231010020220 PLUNGER P-26 G IV Q231200003270 ALLEN SCREW PLAN HEAD Q231110008580...

- Page 70 PLUNGER KIT (P-28) - CODE Q231010019990 SEAL KIT (P-28) CODE Q231020002281...

- Page 71 Ø Nominal Appropriate Critical Change -0,01 -0,07 28 mm -0,1 -0,06 -0,09 ANALYSE PLUNGER DIMENSIONS WHEN CHANGING THE SEALS OR EVERY 500 HOURS RESPECT THE WEAR LIMIT. PLUNGER KIT (P-28) - CODE Q231010019990 ITEM CODE DESCRIPTION QTY. Q231010020230 PLUNGER P-28 G IV Q231200003270 ALLEN SCREW PLAN HEAD Q231110008590...

- Page 72 PLUNGER KIT (P-30) - CODE Q231010020000 SEAL KIT (P-30) CODE Q231020002301...

- Page 73 Ø Nominal Appropriate Critical Change -0,01 -0,07 30 mm -0,1 -0,06 -0,09 ANALYSE PLUNGER DIMENSIONS WHEN CHANGING THE SEALS OR EVERY 500 HOURS RESPECT THE WEAR LIMIT. PLUNGER KIT (P-30) - CODE Q231010020000 ITEM CODE DESCRIPTION QTY. Q231010020240 PLUNGER P-30 G IV Q231200003270 ALLEN SCREW PLAN HEAD Q231110008600...

- Page 74 PLUNGER KIT (P-32) - CODE Q231010020490 SEAL KIT (P-32) CODE Q231020002321...

- Page 75 Ø Nominal Appropriate Critical Change -0,01 -0,07 32 mm -0,1 -0,06 -0,09 ANALYSE PLUNGER DIMENSIONS WHEN CHANGING THE SEALS OR EVERY 500 HOURS RESPECT THE WEAR LIMIT. PLUNGER KIT (P-32) - CODE Q231010020490 ITEM CODE DESCRIPTION QTY. Q231010004340 HARD METAL PLUNGER P-32 Q231110036010 FLANGE G IV Q231200003270...

- Page 76 PLUNGER KIT (P-35) - CODE Q231010018200 SEAL KIT (P-35) CODE Q231020002351...

- Page 77 Ø Nominal Appropriate Critical Change -0,01 -0,07 35 mm -0,1 -0,06 -0,09 ANALYSE PLUNGER DIMENSIONS WHEN CHANGING THE SEALS OR EVERY 500 HOURS RESPECT THE WEAR LIMIT. PLUNGER KIT (P-35) - CODE Q231010020490 ITEM CODE DESCRIPTION QTY. Q231010004060 HARD METAL PLUNGER P-35 Q231110036010 FLANGE G IV Q231200003270...

- Page 78 PLUNGER KIT (P-40) - CODE Q231010020010 SEAL KIT (P-40) CODE Q231020002404...

- Page 79 Ø Nominal Appropriate Critical Change -0,01 -0,07 40 mm -0,1 -0,06 -0,09 ANALYSE PLUNGER DIMENSIONS WHEN CHANGING THE SEALS OR EVERY 500 HOURS RESPECT THE WEAR LIMIT. PLUNGER KIT (P-40) - CODE Q231010020010 ITEM CODE DESCRIPTION QTY. Q231010006260 PLUNGER P-40 GIII Q231110036010 FLANGE G IV Q231200003270...

- Page 80 SELF CENTERING G-IV (FROM P-18 TO P-45) - CODE Q231010020080 ITEM CODE DESCRIPTION QTY. Q231200004230 ALLEN SCREW M14x40 Q231110036110 CONNECTION BUSHING (G-IV) Q231110036090 SPHERICAL RING (G-IV) Q231110036080 SPHERICAL RING (G-IV) Q231110010280 NYLON CYLINDER Q231110036130 BACK UP RING (G-IV) Q231300010240 O-RING Q231110036100 SELF CENTERING RING (G-IV)

- Page 81 NOTES:...

- Page 82 NOTES:...

- Page 84 Comet S.p.a. - Via G. Dorso, 4 42124 Reggio Emilia - ITALY Tel. +39 0522 386111 Export: e-mail: export@comet.re.it › fax 0039 0522 386280 Italia: e-mail: vendite@comet.re.it › fax 0039 0522 386300 www.comet-spa.com...

Need help?

Do you have a question about the HPP H-100/2 SAP and is the answer not in the manual?

Questions and answers