Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Nyle e360

- Page 1 For units produced from 12/2/23 to: – IM-e360-122023...

-

Page 2: Table Of Contents

Water Piping ............19 Service Log ............43 Water Temperature Control ........19 Water Quality Specifications ........19 Tank Selection ............19 Typical Water Side Piping ......... 20 Typical Process for Installing Water Piping ....21 HeatWater.com | WaterService@nyle.com | (800) 777-6953 IM-e360-122023... -

Page 3: Introduction

BMS systems. Nyle’s e-Series units are not intended for primary DANGER space conditioning, nor for multi-pass water heating configurations. When installed in suitable conditioned... -

Page 4: Precautions

HeatWater.com | WaterService@nyle.com | (800) 777-6953 IM-e360-122023... -

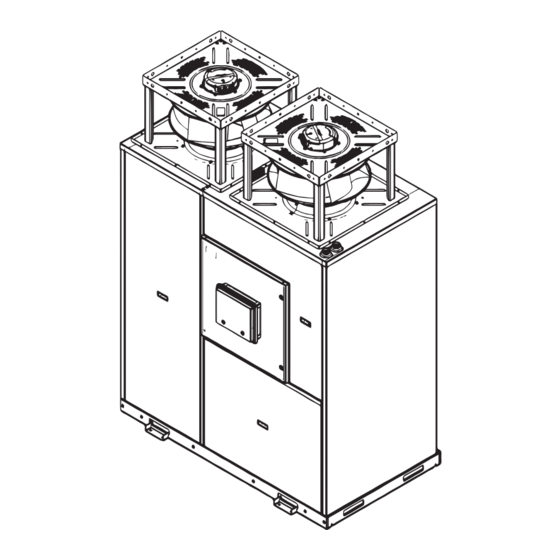

Page 5: Purpose

Refer to the Performance Specifications for appropri- preserve this stratification. ate operating ranges and requirements. If more de- tailed information is required contact Nyle Water Heat- Ease of Installation ing Systems for additional assistance. The enclosure is designed to minimize its footprint, and to simplify placement considerations for mul- tiple-unit installations. -

Page 6: Performance Specifications And Requirements

Performance Specifications and Requirements Table 1: e360 – Performance Specifications 287,000 BTUs / hr Heating Capacity at 70°F 98,000 BTUs / hr Heating Capacity at 10°F Cooling Capacity at 70°F 211,000 BTUs / hr Recovery Rate 380 Gallons / hr Outdoor Temperature Operating Range 10-120°F... -

Page 7: Electrical Specifications

Electrical Specifications Table 2: e360 – Electrical Specifications Electrical Specifications Standard Power Package Unified Power Package Voltage (Volt/Phase/Hz) 208-230/3/60 460/3/60 208-230/3/60 460/3/60 Wire and Disconnect Sizing MOCP Running Load Amps (RLA) Power Factor 0.86 0.86 Short Circuit Current Rating (SCCR) -

Page 8: Expanded Performance Data - 140°F Lwt

H2O flow rate (gpm) H2O Inlet Temperature 70°F Ambient DB °F Heating capacity (kbtu/h) Cooling capacity (kbtu/h) Unit heating COP H2O flow rate (gpm) 10.0 10.0 Note: All conditions are at 50% relative humidity. HeatWater.com | WaterService@nyle.com | (800) 777-6953 IM-e360-122023... -

Page 9: Expanded Performance Data - 120°F Lwt

H2O Inlet Temperature 70°F Ambient DB °F Heating capacity (kbtu/h) Cooling capacity (kbtu/h) Unit heating COP H2O flow rate (gpm) 10.5 12.3 14.0 15.9 15.9 Note: All conditions are at 50% relative humidity. IM-e360-122023 HeatWater.com | WaterService@nyle.com | (800) 777-6953... -

Page 10: Physical Specifications And Clearances

Free discharge (unpiped) condensate applications are not generally rec- ommended. See “Condensate Piping” beginning on page 21 for more in- formation about piped and free discharge condensate applications. HeatWater.com | WaterService@nyle.com | (800) 777-6953 IM-e360-122023... -

Page 11: Dimensions

AIR FLOW 8 " 8 " O.D. 8 " 2 " 7" 7" 8 " 40" 72" 36" 3/4" CONDENSATE DRAIN FRONT 8 " REAR LEFT 4 " 2 " 8 " BOTTOM IM-e360-122023 HeatWater.com | WaterService@nyle.com | (800) 777-6953... -

Page 12: Before Ordering Your Heat Pump

Review performance specifications against your support and ongoing system maintenance. If intended installed environment and water tem- this is in question, contact your local Nyle repre- perature requirements, and ensure the unit will sentative to discuss support options. perform appropriately for your conditions. -

Page 13: Considerations For Exterior Applications In Cold Climates

Discharge Air Outlet Water Inlet Water Outlet Flow Control Valve Electronic Expansion Valve Circulator Pump Evaporator (Heat Exchanger) (Air to Refrigerant) Condenser Condensate Pan with Heat Trace Receiver Manual Dump Valve (Behind Accumulator) Accumulator Compressor IM-e360-122023 HeatWater.com | WaterService@nyle.com | (800) 777-6953... -

Page 14: Installation

Nyle recommends running a minimum of two 18/8 control wires and a CAT- 5e/6 wire to ensure that all likely accessories and control functions could be utilized. Site prep for mounting the heat pump. HeatWater.com | WaterService@nyle.com | (800) 777-6953 IM-e360-122023... - Page 15 Figure 5: Handling and Rigging IM-e360-122023 HeatWater.com | WaterService@nyle.com | (800) 777-6953...

-

Page 16: Placement Considerations For The Heat Pump

Figure 6: Rail Positions and Widths MOUNTING RAILS " MIN. 3 1 4 " MIN. MOUNTING 43 1 " RAILS BOTTOM BOTTOM 36" HeatWater.com | WaterService@nyle.com | (800) 777-6953 IM-e360-122023... -

Page 17: Seismic Mounting

All non-ducted applications must enclose the fans and direct air away from the intake (back) of the unit. A duct- less fan shroud accessory is available for this purpose. IM-e360-122023 HeatWater.com | WaterService@nyle.com | (800) 777-6953... -

Page 18: Fan Wiring

12. Tighten the cable fittings on the fans and on the TOP VIEW heat pump. 13. Close the fan enclosures. 4X 3/8" Serrated Locknut Figure 10: Fan Wire Locations Diagram 1: Fan Wiring Connections Wire Whip Entry Wire Whip Entry TOP VIEW HeatWater.com | WaterService@nyle.com | (800) 777-6953 IM-e360-122023... -

Page 19: Water Piping

Where codes and guid- potable water usage and suitable for temperatures in ance from Nyle are in conflict, advise Nyle or your local excess of 160 degrees fahrenheit on the water piping manufacturer’s representative of the conflict. -

Page 20: Typical Water Side Piping

Air venting is recommended on high point of the hot water supply piping from the water heater. Use only air vents suitable for open systems. Ensure the air vent is installed in an interior, protected space. 10. Expansion devices must be located on the swing tank side of the primary storage to swing tank/distribution system check valves. HeatWater.com | WaterService@nyle.com | (800) 777-6953 IM-e360-122023... -

Page 21: Typical Process For Installing Water Piping

See “Unit Diagram and Key Compo- Nyle recommends testing to 80-100 PSI or 1.25x nents” on page 13 to identify this drain valve. the standing pressure of the system, whichever is higher, for a minimum of two continuous hours. -

Page 22: Condensate Piping Requirements

8. When multiple units are connected to the same 5. All traps require a vent immediately downstream condensate piping, Nyle recommends the use of from the trap. Vents should extend to a point higher isolation valves to allow blowing out of individual than the drain pan of the heat pump. -

Page 23: Power Wiring

7. Close the electrical enclosure box. 7. Install service disconnects on incoming power feeds at the heat pump location. 8. All power wiring to the unit must be rated for 600V. IM-e360-122023 HeatWater.com | WaterService@nyle.com | (800) 777-6953... - Page 24 120V Secondary / Control Power Field Supplied Terminal Block Exterior Disconnects Field Installed Wiring 120V 120V Secondary Fuse Field Installed Wiring Neutral Neutral Field Installed Wiring Ground Ground Electrical Enclosure Backboard Main Power HeatWater.com | WaterService@nyle.com | (800) 777-6953 IM-e360-122023...

-

Page 25: To Wire For Single Point Power On 208V Systems

120 Volt Secondary / Control Power Terminal Block Ground Lug Field Installed Wiring Ground 120V Secondary Fuse Neutral IN Field Installed Wiring WHT #14 Neutral GRN #14 Ground Electrical Enclosure Backboard Neutral Main Power IM-e360-122023 HeatWater.com | WaterService@nyle.com | (800) 777-6953... -

Page 26: Control Wiring

7. Close the electrical enclosure box. Nyle recommends running enough conductors to use all available contacts if the installation site would CAUTION make wire retrofits challenging, even if those contacts are not intended for use during the initial installation. - Page 27 From Heat Pump ture, or defrost. Backup heat sources can use this as an enable trigger. Tank Sensor or Aquastat Min. Cycle Volume To Heat Pump IM-e360-122023 HeatWater.com | WaterService@nyle.com | (800) 777-6953...

-

Page 28: Optional Ducting And Ventilation

Louver/damper motor speeds need to be 30 seconds or less. Insu- lated dampers are recommended. HeatWater.com | WaterService@nyle.com | (800) 777-6953 IM-e360-122023... - Page 29 1920 sq. in. Discharge Ducting +2 In. See Note 1 Summer Ambient 1440 sq. in. Note Discharge minimum temperature rating is wintertime outdoor design temperature minus 15, or 0 degree Fahrenheit, whichever is higher. IM-e360-122023 HeatWater.com | WaterService@nyle.com | (800) 777-6953...

-

Page 30: Configuration

Whenever 120V power is avail- able, the controller will be active. There are 4 primary screens that may be used during installation and typ- ical operation. Diagram 5: Configuration Screen HeatWater.com | WaterService@nyle.com | (800) 777-6953 IM-e360-122023... -

Page 31: Tank Sensor Mode Configuration

In Single-Pass applications, Target Outlet Temperature cannot be set lower than Target Tank Temperature. Typically, these will be set to equal values. The e360 requires a 45 degree delta between entering and leaving water temperatures. Do not initiate heat demands above 115 EWT. -

Page 32: Additional Parameter Configuration

Note: The heat pump will allow itself to exceed the target outlet temperature if incoming water is too hot, flow is too low, and/or during high capacity conditions, up to its maximum operating temperature for the current ambient conditions. HeatWater.com | WaterService@nyle.com | (800) 777-6953 IM-e360-122023... -

Page 33: Pre-Startup Checklist

Water and Piping Checks Exterior water piping is insulated, freeze protect- ed, pitched toward drain points. All water piping has been pressure tested and verified leak free. IM-e360-122023 HeatWater.com | WaterService@nyle.com | (800) 777-6953... -

Page 34: Startup Procedure

12 hours before running the unit. tures. Below 16 GPM, confer with the project en- gineer and/or your Nyle representative. Ideally, Using the “Configuration” section of this manu- al and project documentation, set or confirm the... - Page 35 Note: At this point if all Pre-Startup and Startup procedures and checks have been completed, it is safe to turn the heat pump “ON” via the control interface, which will enable nor- mal compressor operation. IM-e360-122023 HeatWater.com | WaterService@nyle.com | (800) 777-6953...

- Page 36 Measured Amps (Compressor) ______________ L3 ______________ Amps ______________ L1 ______________ L2 Contactor B (230V Units Only) ______________ L3 ______________ Amps Measured Amps (Secondary 120V) L1______________ Amps Commissioning Agent Signature _________________________ Date _______ /_______ /________ HeatWater.com | WaterService@nyle.com | (800) 777-6953 IM-e360-122023...

-

Page 37: Initial Troubleshooting

Note: In the rare event that major components end up damaged or defective, you MUST obtain assistance and approval from your rep or from Nyle to authorize warranty replacement, BEFORE the components are removed from service. Problem Check 120V power is active at breaker and input terminals. - Page 38 No evidence of oil around compressor base. Ambient is cold enough to make frost. Frost, ice, or snow is visible on coil. Defrost On Defrost function is active All Fan Fault checks are good. Defrost sensor and wiring good. HeatWater.com | WaterService@nyle.com | (800) 777-6953 IM-e360-122023...

- Page 39 Tank Sensor Fault Tank sensor missing or out of range Ensure “tank“ is the correct mode for this install. Electrical or temperature problem with M Protection Power Monitor and wiring are good. compressor IM-e360-122023 HeatWater.com | WaterService@nyle.com | (800) 777-6953...

- Page 40 High Inlet Water Incoming water temp is too high Entering water temperature sensor and wiring are good. It is the correct time for Quiet Mode. Quiet Mode Quiet Mode is active Programmed schedule is correct. HeatWater.com | WaterService@nyle.com | (800) 777-6953 IM-e360-122023...

-

Page 41: Routine Maintenance

Inspect and clear any louvers or grilles in at- tached ducting. Isolate, inspect, and clean any wye strainers on the heat pump piping. Inspect all attached piping and ducting for water leaks and/or uncontrolled condensation. IM-e360-122023 HeatWater.com | WaterService@nyle.com | (800) 777-6953... -

Page 42: Limited Warranty

Limited Warranty (6) sized in accordance with proper sizing techniques for commercial heat pump water Nyle Water Heating Systems, the warrantor, extends heaters. the following LIMITED WARRANTY to the original own- er of this commercial heat pump water heater subject... -

Page 43: Service Log

Service Log Issue Description Date Servicer IM-e360-122023 HeatWater.com | WaterService@nyle.com | (800) 777-6953... - Page 44 690 Maine Ave Bangor, ME 04401 1-800-777-6953 Nyle Water Heating Systems engages in continuous improvement. Sequences, features and capabilities can change without notice at any time. Refer to most current documentation prior to installation or commissioning of all equipment.

Need help?

Do you have a question about the e360 and is the answer not in the manual?

Questions and answers