Summary of Contents for Nyle e360

- Page 1 NOT TO BE USED FOR INSTALLATION NOT TO BE USED FOR INSTALLATION NOT FINAL DRAFT NOT FINAL DRAFT Rev. IM-E360-051223...

- Page 3 BMS systems. Nyle’s e-Series units are not intended for primary space conditioning, nor for multi-pass water heating configurations. When installed in suitable conditioned spaces, they can provide supplemental cooling and/or dehumidification benefits.

-

Page 4: Table Of Contents

Required Tools & Materials....................Rough-In Checklist........................Transportation, Placement, Mounting................Water Piping..........................Condensate Piping........................Power Wiring..........................Control Wiring..........................Optional Ducting & Ventilation................... Configuration..........................Pre-Startup Checklist........................Startup Procedure..........................Initial Troubleshooting........................Routine Maintenance......................... Warranty..............................HeatWater.com | WaterService@nyle.com | (800) 777-6953 | Rev. IM-E360-060523... -

Page 5: Safety Information

This product contains a chemical known to the State of California to cause cancer, birth defects, or other reproductive harm. This appliance can cause low level exposure to some substances listed in the Act. HeatWater.com | WaterService@nyle.com | (800) 777-6953 | Rev. IM-E360-060523... - Page 6 1. External fire. the water heater. 2. Damage. 3. Running without water . HeatWater.com | WaterService@nyle.com | (800) 777-6953 | Rev. IM-E360-060523...

-

Page 7: General Description

HeatWater.com | WaterService@nyle.com | (800) 777-6953 | Rev. IM-E360-060523... - Page 8 Please refer to the Performance Specifications for appropriate operating ranges and requirements. If more detailed information is required than is available in this manual, please contact Nyle Water Heating Systems for additional assistance. HeatWater.com | WaterService@nyle.com | (800) 777-6953 | Rev. IM-E360-060523...

-

Page 9: Performance Specifications & Requirements

****Minimum Tank Cycle Volume is the min volume between tank sensor and and heat pump inlet pipe, in the storage tank. *****Sound Pressure measured 3’ away 3’ from ground, at max and quiet mode fan speeds, with ductless cowl installed. HeatWater.com | WaterService@nyle.com | (800) 777-6953 | Rev. IM-E360-060523... - Page 10 Do not install e-Series heat pumps such that they would need to be operated in conditions outside of these performance specifications. Units may stop compressor operation outside of ambient temperature limits. In cold climates, freeze protection measures will remain active when the compressor is turned off. HeatWater.com | WaterService@nyle.com | (800) 777-6953 | Rev. IM-E360-060523...

-

Page 11: Expanded Performance Data

202 kBTU/hr 10.5 GPM 70 Deg. F. 287 kBTU/hr 242 kBTU/hr 12.3 GPM 80 Deg. F. 333 kBTU/hr 282 kBTU/hr 14.0 GPM 90 Deg. F. 351 kBTU/hr 327 kBTU/hr 15.9 GPM HeatWater.com | WaterService@nyle.com | (800) 777-6953 | Rev. IM-E360-060523... -

Page 12: Physical Specifications & Clearances

AIR FLOW 8 " 8 " O.D. 8 " O.D. 2 " 8 " 7" FRONT 7" LEFT 8 " 40" 72" 36" 36" 3/4" CONDENSATE DRAIN REAR 8 " REAR HeatWater.com | WaterService@nyle.com | (800) 777-6953 | Rev. IM-E360-060523... - Page 13 Top clearance required for fan installation/removal. If fans are installed prior to mounting and unit can be moved to replace fans in the event of failure, this can reduce to 1” clearance. HeatWater.com | WaterService@nyle.com | (800) 777-6953 | Rev. IM-E360-060523...

- Page 14 Pounds Net Weight (Shipping) 2,400 Pounds Net Weight (Filled, w/Fans) 2,604 Pounds Fan Unit Net Weight (Each) Pounds Refrigerant Charge 60.0 Pounds Refrigerant Oil Charge 158.4 Ounces Internal Water Volume Gallons HeatWater.com | WaterService@nyle.com | (800) 777-6953 | Rev. IM-E360-060523...

-

Page 15: Before Ordering Your Heat Pump

The manual has been organized to follow the general sequence of most installations. If any details are not clear or questions are not answered contact your Nyle representative to resolve them ahead of time. Review performance specifications against your intended installed environment and water temperature requirements, and ensure the unit will perform appropriately for your conditions. -

Page 16: Cold Climate Installation Considerations

It is recommended that this tracing be thermostatically activated to run as needed, not always on. Self regulating cable is recommended. HeatWater.com | WaterService@nyle.com | (800) 777-6953 | Rev. IM-E360-060523... - Page 17 Do not install vents or condensate pumps outside. 5. If filling the system in cold weather, ensure the 120v power circuit is active BEFORE filling the circuit. See Pre-Startup and Startup procedures in this manual for more information. HeatWater.com | WaterService@nyle.com | (800) 777-6953 | Rev. IM-E360-060523...

-

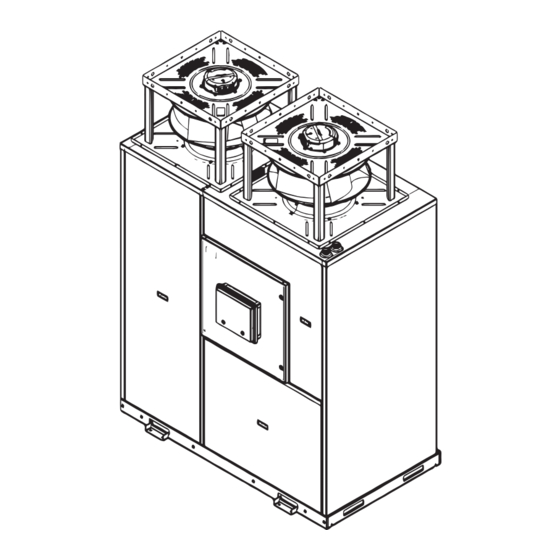

Page 18: Unit Diagram & Key Components

THE INFORMATION CONTAINED IN THIS DRAWN DRAWING IS THE SOLE PROPERTY OF NYLE SYSTEMS LLC. ANY REPRODUCTION CHECKED IN PART OR AS A WHOLE WITHOUT THE WRITTEN PERMISSION OF NYLE SYSTEMS LLC IS PROHIBITED. EDITED HeatWater.com | WaterService@nyle.com | (800) 777-6953 | Rev. IM-E360-060523... -

Page 19: Required Tools & Materials

• Ohms up to 2,000,000 ohms. • Continuity. • Amperage up to 200 amps. 5. Anemometer or other airflow measuring device. 6. Magnahelic or other pressure measuring device capable of reading 0.1” to 2” w.c.g. HeatWater.com | WaterService@nyle.com | (800) 777-6953 | Rev. IM-E360-060523... -

Page 20: Rough-In Checklist

Condensate drain lines, including pipe insulation and heat tracing as necessary. Ducting to or from remote locations, including insulation as necessary. Control wiring for alarms, BMS interface, and external accessories. Nyle recommends running a minimum of two 18/8 control wires and a CAT-5e/6 wire to ensure that all likely accessories and control functions could be utilized. -

Page 21: Transportation, Placement, Mounting

1-½” or smaller shank forks will fit the available lifting holes in the base of the unit. See dimensional drawings for size and spacing of forklift access holes. Follow all standards and best pactices for lifting and load stabilization. HeatWater.com | WaterService@nyle.com | (800) 777-6953 | Rev. IM-E360-060523... - Page 22 Installation: Transportation, Placement, Mounting D3-Handling HeatWater.com | WaterService@nyle.com | (800) 777-6953 | Rev. IM-E360-060523...

- Page 23 HeatWater.com | WaterService@nyle.com | (800) 777-6953 | Rev. IM-E360-060523...

- Page 24 IN PART OR AS A WHOLE WITHOUT THE WRITTEN PERMISSION OF NYLE SYSTEMS EDITED LLC IS PROHIBITED. MOUNTING RAILS BOTTOM 45" UNLESS OTHERWISE SPECIFIED: TITLE: HeatWater.com | WaterService@nyle.com | (800) 777-6953 | Rev. IM-E360-060523 E360 MOUNTING RAIL SPECIFICATIONS DIMENSIONS ARE IN INCHES TOLERANCES:...

- Page 25 Installation: Transportation, Placement, Mounting D8-Center of Gravity Diagram 16 " 16 " 16 " HeatWater.com | WaterService@nyle.com | (800) 777-6953 | Rev. IM-E360-060523...

- Page 26 2. Take care to line up the fan base plates with the supplied mounting holes for bolt attachment with the supplied bolts. 3. Affix all attachment points securely. 4. Attach Fan wiring in accordance with the next section. HeatWater.com | WaterService@nyle.com | (800) 777-6953 | Rev. IM-E360-060523...

- Page 27 DIMENSIONS ARE IN INCHES TOLERANCES: FRACTIONAL 1/16" DECIMAL 0.02" PART REVISION: DEPT: SECTION: ANGULAR MACH 1/2° HeatWater.com | WaterService@nyle.com | (800) 777-6953 | Rev. IM-E360-060523 UNLESS OTHERWISE SPECIFIED: TITLE: FAN PREP(2) E360 MANUAL ANGULAR BEND 1° DIMENSIONS ARE IN INCHES NAME DATE...

- Page 28 11. Connect control wires to the control terminals in each enclosure. 12. Tighten the cable fittings on the fans and on the heat pump. 13. Close the fan enclosures. D10-Fan Wiring Connections HeatWater.com | WaterService@nyle.com | (800) 777-6953 | Rev. IM-E360-060523...

-

Page 29: Water Piping

Installation: Water Piping All information in this manual is superseded by all applicable local codes and regulations. Where codes and guidance from Nyle are in conflict, advise Nyle or your local manufacturer’s representative of the conflict. e-Series heat pump water heaters are designed to be piped directly to tank water storage in a “Single-Pass”... - Page 30 <70 HCO3/SO4 >1 Conductivity 10-500 μS/cm 7.5-10 Ammonium <2 Chlorides <100 Free Chlorine <1 Hydrogen Sulfide <0.05 Free CO2 <5 Total Hardness 60-120 Nitrate <100 Iron <0.2 Aluminum <0.2 Manganese <0.1 HeatWater.com | WaterService@nyle.com | (800) 777-6953 | Rev. IM-E360-060523...

- Page 31 Ensure the air vent is installed in an interior, protected space. 10. Expansion devices must be located on the swing tank side of the primary storage to swing tank/distribution system check valves. HeatWater.com | WaterService@nyle.com | (800) 777-6953 | Rev. IM-E360-060523...

- Page 32 3. Pressure testing the water side components with air to a pressure less than 150 PSI or the pressure rating on the storage tank pressure relief valves. Nyle recommends testing to 80-100 PSI or 1.25x the standing pressure of the system, whichever is higher, for a minimum of two continuous hours.

-

Page 33: Condensate Piping

Nyle recommends all condensate lines be piped to drain. Failure to control condensate can result in slip/fall conditions, site erosion, water damage, and/or damage to the heat pump water heater itself;... - Page 34 7. Any drain connection to septic requires an indirect connection and trap. Pay special attention to all local codes and ordinances if connecting to septic. 8. When multiple units are connected to the same condensate piping, Nyle recommends the use of isolation valves to allow blowing out of individual lines when necessary.

-

Page 35: Power Wiring

6. Follow manufacturer’s torque specifications for all power wire equipment by others. 7. Install service disconnects on incoming power feeds at the heat pump location. 8. All power wiring to the unit must be rated for 600v. HeatWater.com | WaterService@nyle.com | (800) 777-6953 | Rev. IM-E360-060523... - Page 36 6. Connect power wires to their terminals. Use the torque specifications in Table 5. All power distribution terminals are located in the upper right corner of the electrical enclosure. 7. Close the electrical enclosure box. HeatWater.com | WaterService@nyle.com | (800) 777-6953 | Rev. IM-E360-060523...

- Page 37 1-1/2’ Female Thread Backup Circuit Power Input 120/1/60 120/1/60 Volt/Phase/Hz 120v Power Wire Min. Size Volts 120v Power Cable Voltage Rating 120v Power Block Line Side Torque 17.7 in-lbs D9-Power Feed Connections HeatWater.com | WaterService@nyle.com | (800) 777-6953 | Rev. IM-E360-060523...

-

Page 38: Control Wiring

Nyle recommends running enough conductors to use all available contacts if the installation site would make wire retrofits challenging, even if those contacts are not intended for use during the initial installation. This allows changes and reconfiguration to happen seamlessly in the future. - Page 39 CT12 CT13 Stranded/Shielded Service Mode* 24Vdc *Service Mode enables access to Diagnose and Configure screens. Jump terminals for access **Reserved terminals used by optional accessories and/or internal wiring. See accessory instructions. HeatWater.com | WaterService@nyle.com | (800) 777-6953 | Rev. IM-E360-060523...

- Page 40 D12 - Tank Sensor Installation DHW Out From Heat Pump Tank sensor or Aquastat Min. Cycle Volume To Heat Pump HeatWater.com | WaterService@nyle.com | (800) 777-6953 | Rev. IM-E360-060523...

-

Page 41: Optional Ducting & Ventilation

Ducting can significantly reduce freeze risks, and it can simplify maintenance access and/or provide superior protection to many potential outdoor locations. HeatWater.com | WaterService@nyle.com | (800) 777-6953 | Rev. IM-E360-060523... - Page 42 4. Dampers: in very cold climates, motorized dampers or louvers can reduce freeze risks significantly, preventing cold outside air from migrating to the unit in between heating cycles. Louver/damper motor speeds need to be 30 seconds or less. Insulated dampers are recommended. HeatWater.com | WaterService@nyle.com | (800) 777-6953 | Rev. IM-E360-060523...

- Page 43 1440 sq. in. Note 1: Discharge min. temp rating is wintertime outdoor ambient design temp, minus 15. If ducts are fully within conditioned space, this can be limited to zero degrees fahrenheit. HeatWater.com | WaterService@nyle.com | (800) 777-6953 | Rev. IM-E360-060523...

-

Page 44: Configuration

Following is guidance for the setup and configuration of the heat pump water heater for its standard modes of operation. HeatWater.com | WaterService@nyle.com | (800) 777-6953 | Rev. IM-E360-060523... - Page 45 Target outlet water temp from the heat pump* Temp *In Single-Pass applications, Target outlet temp cannot be set lower than Target Tank Temp. Typically, these will be set to equal values. HeatWater.com | WaterService@nyle.com | (800) 777-6953 | Rev. IM-E360-060523...

- Page 46 Note that the heat pump will allow itself to exceed the target outlet temperature if incoming water is too hot, flow is too low, and/or during high capacity conditions, up to its maximum operating temperature for the current ambient conditions. HeatWater.com | WaterService@nyle.com | (800) 777-6953 | Rev. IM-E360-060523...

-

Page 47: Pre-Startup Checklist

Ensure all power feeds are powered down for this testing. Damage to the compressor due to startup with visible leak indications is not covered by warranty. HeatWater.com | WaterService@nyle.com | (800) 777-6953 | Rev. IM-E360-060523... - Page 48 Exterior condensate piping is insulated, freeze protected, pitched toward drain points. Pour several gallons of water slowly into the condensate pan, and verify the drain is clear and operational. Condensate pump, if used, is plugged in and operational. HeatWater.com | WaterService@nyle.com | (800) 777-6953 | Rev. IM-E360-060523...

- Page 49 QR Code in the “Startup Procedure” portion of this manual. Turn on main and 120v power to allow the heat pump to warm up. DO NOT engage any functions on the control interface. HeatWater.com | WaterService@nyle.com | (800) 777-6953 | Rev. IM-E360-060523...

-

Page 50: Startup Procedure

Send the completed form to waterservice@nyle.com Before starting the Startup Procedure, ensure that the Pre-Startup Checklist has been fully completed! A standalone copy of the Startup Procedure is available here: https://www.heatwater.com/startup-procedure-checklist/ PDF Download HeatWater.com | WaterService@nyle.com | (800) 777-6953 | Rev. IM-E360-060523... - Page 51 Startup Procedure Startup Procedure and Checklist. Verify 120v and primary power have been on for at least 12 hours before running the unit. Using the “Configuration” section of this manual and project documentation, set the configuration options for this project on the control interface. Verify incoming voltage is +/- 5% of ratings and +/-2% across phases with your service tools.

- Page 52 Startup Procedure At this point if all Pre-Startup and Startup procedures and checks have been completed, it is safe to turn the heat pump “on” at the control interface. Doublecheck that all configuration options on the control interface are set as required for this project.

-

Page 53: Initial Troubleshooting

In the rare event that major components end up damaged or defective, you MUST obtain assistance and approval from your rep or from Nyle to authorize warranty replacement, BEFORE the components are removed from service. - Page 54 Ambient is cold enough to make frost. Frost, ice, or snow is visible on coil. Defrost On Defrost function is active All Fan Fault checks are good. Defrost sensor and wiring good. HeatWater.com | WaterService@nyle.com | (800) 777-6953 | Rev. IM-E360-060523...

- Page 55 Drain Pan Drain pan has sensed Hold water for some time Condensate piping is clear and pitched. Condensate pumps, if used, are functional. Condensate piping is trapped and vented after trap. HeatWater.com | WaterService@nyle.com | (800) 777-6953 | Rev. IM-E360-060523...

- Page 56 Incoming water temp is Entering water temp sensor and wiring are Water too high good. It is the correct time for Quiet Mode. Quiet Mode Quiet Mode is active Programmed schedule is correct. HeatWater.com | WaterService@nyle.com | (800) 777-6953 | Rev. IM-E360-060523...

-

Page 57: Routine Maintenance

Inspect and clear any louvers or grilles in attached ducting. Isolate, inspect, and clean any wye strainers on the heat pump piping. Inspect all attached piping and ducting for water leaks and/or uncontrolled condensation. HeatWater.com | WaterService@nyle.com | (800) 777-6953 | Rev. IM-E360-060523... - Page 58 Ducted Systems: confirm airflow through the evaporator using the “max fan” button on the control interface, and taking static pressure readings as described in the startup procedure checklist section of this manual. HeatWater.com | WaterService@nyle.com | (800) 777-6953 | Rev. IM-E360-060523...

-

Page 59: Warranty

Limited Warranty Limited Warranty Nyle Water Heating Systems, the warrantor, extends the following LIMITED WARRANTY to the original owner of this commercial heat pump water heater subject to the terms, conditions and disclaimers stated below: 1. COMPRESSOR If the 5-Year Extended Compressor Warranty is purchased, and if within FIVE... - Page 60 Some states do not allow limitations on how long an implied warranty lasts, so the above limitation may not apply to you. HeatWater.com | WaterService@nyle.com | (800) 777-6953 | Rev. IM-E360-060523...

- Page 61 Service Log Service Log Issue Description Date Servicer HeatWater.com | WaterService@nyle.com | (800) 777-6953 | Rev. IM-E360-060523...

- Page 62 Notes Notes HeatWater.com | WaterService@nyle.com | (800) 777-6953 | Rev. IM-E360-060523...

- Page 63 © 2023 Nyle Water Heating Systems e360 Manual Version 060523...

- Page 65 Nyle Systems, LLC 12 Stevens Rd Brewer ME, 04412...

Need help?

Do you have a question about the e360 and is the answer not in the manual?

Questions and answers

Start up on model C90A

To start up the Nyle e360 model C90A, follow these steps:

1. Ensure the heat pump has active power for at least 12 hours before pressing the "ON" button. This prevents compressor damage.

2. Activate both the main and 120V power feeds.

3. Keep the system “off” at the control interface during the 12-hour warm-up period.

4. Complete the Startup Procedure form, which must be filled out by a factory-authorized commissioning agent.

5. Submit the completed form to WaterService@nyle.com to activate the unit’s warranty and access factory tech support.

For detailed voltage measurements and additional startup requirements, refer to the official Startup Procedure checklist.

This answer is automatically generated