Advertisement

Quick Links

INSTALLATION MANUAL

KCIS-52 DR11

KUE-52 DVN10

KUE-52 DVR11

KCIS-71 DR11

KUE-71 DVN10

KUE-71 DVR11

KCIS-90 DN10

KUE-90 DVN10

KCIS-105 DR11

IMPORTANT NOTE:

Read this manual carefully before installing or operating your new air

conditioning unit. Make sure to save this manual for future reference.

If used as MULTI unit, please refer to the Installation & operation manuals

packed with outdoor unit.

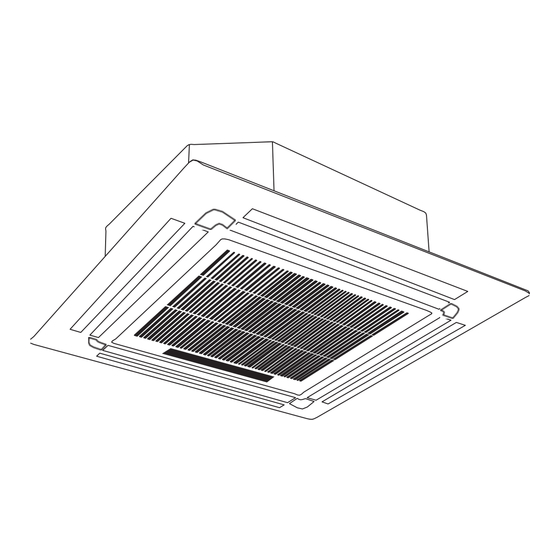

Super-Slim Four-Way Cassette

KUE-105 DVN10

KUE-105 DTN10

KUE-105 DTR11

KUE-105 DVR11

KCIS-125 DN10

KUE-125 DVN10

KCIS-125 DN10

KUE-125 DTN10

KCIS-140 DR11

KUE-140 DTR11

KUE-140 DVN10

KCIS-140 DR11

KUE-140 DTN10

KCIS-160 DR11

KUE-160 DTN10

KUE-160 DTR11

Advertisement

Subscribe to Our Youtube Channel

Summary of Contents for Kaysun KCIS-52 DR11

- Page 1 INSTALLATION MANUAL Super-Slim Four-Way Cassette KCIS-52 DR11 KUE-105 DVN10 KUE-140 DTR11 KUE-52 DVN10 KUE-105 DTN10 KUE-140 DVN10 KUE-52 DVR11 KUE-105 DTR11 KCIS-140 DR11 KCIS-71 DR11 KUE-105 DVR11 KUE-140 DTN10 KUE-71 DVN10 KCIS-125 DN10 KCIS-160 DR11 KUE-71 DVR11 KUE-125 DVN10 KUE-160 DTN10...

- Page 2 Table of Contents Installation Manual Accessories ............ Safety Precautions ........Installation Overview ....... Indoor Unit Installation ......Indoor Unit Parts ......... 09 Indoor Unit Installation Instructions .... Outdoor Unit Installation ......Outdoor Unit Installation Instructions ... Drain Joint Installation ......... Notes on Drilling Hole in Wall .......

- Page 3 Refrigerant Piping Connection ....Notes on Pipe Length and Elevation ....Refrigerant Piping Connection Instructions ...20 Wiring ..........Outdoor Unit Wiring ....... Indoor Unit Wiring ......Power Specifications ......Air Evacuation ..........Evacuation Instructions ........ 27 Note on Adding Refrigerant......Panel Installation .............

- Page 4 The air conditioning system comes with the following accessories. Use all the installation parts and accessories to install the air conditioner. Improper installation may result in water leakage, electrical shock and fire, or cause the equipment to fail. Name Shape Quantity Indoor unit Installation paper template...

- Page 5 Read Safety Precautions Before Installation Incorrect installation due to ignoring instructions can cause serious damage or injury. The seriousness of potential damage or injuries is classified as either a WARNING or CAUTION. Failure to observe a warning may result in serious injuries. The appliance must be installed in accordance with national regulations.

- Page 6 WARNING • The appliance disconnection must be incorporated with an all-pole disconnection device in the fixed wiring in accordance with the wiring rules. • Any person who is involved with working on or breaking into a refrigerant circuit should hold a current valid certificate from an industry-accredited assessment authority, which authorizes their competence to handle refrigerants safely in accordance with an industry recognized assessment specification.

- Page 7 Note about Fluorinated Gasses 1. This air-conditioning unit contains fluorinated gasses. For specific information on the type of gas and the amount, please refer to the relevant label on the unit itself. 2. Installation, service, maintenance and repair of this unit must be performed by a certified technician. 3.

- Page 8 Installation Overview INSTALLATION ORDER Install the indoor unit Install the outdoor unit Install the drainpipe (Page 9) (Page 12) (Page 15) Evacuate the refrigeration system Connect the refrigerant pipes Connect the wires (Page 25) (Page 22)

-

Page 9: Indoor Unit Installation

Indoor Unit Installation Indoor Unit Parts Drain pump (within indoor unit) Air outlet Air inlet Fig. 4.1 Safety Precautions CAUTION WARNING • Securely install the indoor unit on a •... -

Page 10: Indoor Unit Installation Instructions

Indoor Unit Installation Instructions CAUTION NOTE: Panel installation should be done after DO NOT install the unit in the following piping and wiring. locations: In areas with oil drilling or fracking Step 1: Select installation location In coastal areas with high salt content in the air The indoor unit should be installed in a location that meets the following requirements: In areas with caustic gases in the air, such... - Page 11 Step 2: Hang indoor unit. 1. Use the included paper template to cut a rectangular hole in the ceiling, leaving at least 1m (39”) on all sides. The cut hole size should be 4cm (1.6”) larger than the body size(See Fig. 4.3). Be sure to mark the areas where ceiling hook holes will be drilled.

- Page 12 5. Mount the indoor unit. You will need two NOTE: Ensure that the indoor unit is level. The people to lift and secure it. Insert suspension unit is equipped with a built-in drain pump and bolts into the unit’s hanging holes. Fasten float switch.

- Page 13 Outdoor Unit Installation √ The area must be free of combustible gases Outdoor Unit Installation Instructions and chemicals. √ The pipe length between the outdoor and Step 1: Select installation location. indoor unit may not exceed the maximum The outdoor unit should be installed in the allowable pipe length.

- Page 14 Vertical Discharge Type Outdoor Unit Split Type Outdoor Unit (Refer to Fig 5.7, 5.8, 5.9 and Table 5.2) (Refer to Fig 5.4, 5.5, 5.6, 5.10 and Table 5.1) (Wall or obstacle) Air Outlet >152.4cm / 60” Fig. 5.4 Fig. 5.7 Fig.

- Page 15 NOTE: The minimum distance between the 2. Insert the drain joint into the hole in the base outdoor unit and walls described in the pan of the unit. installation guide does not apply to airtight 3. Rotate the drain joint 90° until it clicks in place rooms.

-

Page 16: Drainpipe Installation

Drainpipe Installation The drainpipe is used to drain water from the NOTE ON DRAINPIPE INSTALLATION unit. Improper installation may cause unit and When using an extended drainpipe, tighten • property damage. the indoor connection with an additional protection tube to prevent it from pulling CAUTION loose. - Page 17 3. Using a 65-mm (2.5”) core drill, drill a hole in the wall. Make sure that the hole is drilled at a slight downward angle, so that the outdoor end of the hole is lower than the indoor end by about 12mm (0.5”). This will ensure proper water drainage (See Fig.

- Page 18 Refrigerant Piping Connection Safety Precautions Notes On Pipe Length and Elevation Ensure that the length of the refrigerant pipe, the number of bends, and the drop height between WARNING the indoor and outdoor units meets the • All field piping must be completed by a requirements shown in Table 7.1: licensed technician and must comply with Table 7.1: The Maximum Length And Drop...

- Page 19 CAUTION CAUTION • Oil traps If the outdoor unit is installed higher than the indoor unit: If the indoor unit is installed higher than the outdoor unit: -It is recommended that vertical suction risers not be upsized. Proper oil return to the -If oil flows back into the outdoor unit’s compressor should be maintained with suction compressor, this might cause liquid...

- Page 20 Table 7.2 Permitted length Total piping length 18K+18K 30/98’ L+Max 90° (L1, L2) Oblique Rough Warped 24K+24K 50/164’ 30K+30K Piping length (farthest distance from 15/49’ L1, L2 the line pipe branch) (farthest distance from 10/32.8’ L1-L2 the line pipe branch) ...

- Page 21 1. When connecting the flare nuts, apply a 4. Remove PVC tape from ends of pipe when thin coat of refrigeration oil to the flared ready to perform flaring work. ends of the pipes. 2. Align the center of the two pipes that you 5.

- Page 22 NOTE ON MINIMUM BEND RADIUS Carefully bend the tubing in the middle according to the diagram below. DO NOT bend the tubing more than 90° or more than 3 times. Bend the pipe with thumb min-radius 10cm (3.9”) Fig. 7.12 6.

- Page 23 Wiring Follow these instructions to prevent distortion Safety Precautions when the compressor starts: WARNING • The unit must be connected to the main outlet. Normally, the power supply must have a low output impedance of 32 ohms. • No other equipment should be connected to the same power circuit.

- Page 24 Indoor Unit Wiring Table 8.2: Other Regions 1. Prepare the cable for connection Rated Current of Nominal Cross-Sectional a. Using wire strippers, strip the rubber jacket Appliance (A) Area (mm²) from both ends of signal cable to reveal 6 0.75 about 15cm (5.9”) of the wires inside.

- Page 25 CAUTION While connecting the wires, please strictly follow the wiring diagram. • The refrigerant circuit can become very hot. Keep the interconnection cable away from • the copper tube. 5. Clamp down cable with the designated cable clamp to secure it in place. The cable should not be loose, and should not pull on the u-lugs.

- Page 26 Independent Power Supply Specifications 18K MODEL(Btu/h) 19K~24K 25K~36K 37K~48K 49K~60K PHASE 1 Phase 1 Phase 1 Phase 1 Phase 1 Phase POWER (indoor) 208-240V 208-240V 208-240V 208-240V 208-240V VOLT CIRCUIT BREAKER/ 15/10 15/10 15/10 15/10 15/10 FUSE(A) PHASE 1 Phase 1 Phase 1 Phase 1 Phase...

- Page 27 Air Evacuation 4. Turn on the vacuum pump to evacuate the Safety Precautions system. 5. Run the vacuum for at least 15 minutes, or until the Compound Meter reads -76cmHG CAUTION (-1x105Pa). • Use a vacuum pump with a gauge reading 6.

- Page 28 Note On Adding Refrigerant CAUTION • Refrigerant charging must be performed after wiring, vacuuming and the leak test. DO NOT exceed the maximum allowable quantity of refrigerant or overcharge the system. • Doing so can damage or impact the unit’s function. •...

- Page 29 Panel Installation Step 3: Install the panel CAUTION Align the front panel to the main body, considering the position of the piping and drain DO NOT place the panel face down on the floor, sides.

- Page 30 5. Close the front grille. 2. Remove foam stops from inside the fan. 6. Fasten the installation covers at all four 3. Attach the side of the front grille to the corners by pushing them inwards. panel. (See Fig.10.6) 4. Connect the display panel cable to the corresponding wire on the main body.

- Page 31 f. Check to see that the drainage system is Before Test Run unimpeded and draining smoothly. A test run must be performed after the entire g. Ensure there is no vibration or abnormal system has been completely installed. Confirm noise during operation.

- Page 32 Users in European Countries may be required to properly dispose of this unit. This appliance contains refrigerant and other potentially hazardous materials. When disposing of this appliance, the law requires special collection and treatment. DO NOT dispose of this product as household waste or unsorted municipal waste.

- Page 33 Impedance Information (Applicable to Middle East Countries only) NOTE: To be in compliance with EN61000-3-11, the product MCDT4-36CRN1-QC5W shall be connected only to a supply of the system impedance: Zsys = 0.020 K or less. Before connecting the product to public power network, please consult your local power supply authority to ensure the power network meet above requirement.

- Page 34 (Required for the units adopt R32 Refrigerant only) 1. Checks to the area Prior to beginning work on systems containing flammable refrigerants, safety checks are necessary to ensure that the risk of ignition is minimized. For repair to the refrigerating system, the following precautions shall be complied with prior to conducting work on the system.

- Page 35 the charge size is in accordance with the room size within which the refrigerant containing ⚫ parts are installed; the ventilation machinery and outlets are operating adequately and are not obstructed; ⚫ if an indirect refrigerating circuit is being used, the secondary circuits shall be checked ⚫...

- Page 36 11. Repair to intrinsically safe components Do not apply any permanent inductive or capacitance loads to the circuit without ensuring that this will not exceed the permissible voltage and current permitted for the equipment in use. Intrinsically safe components are the only types that can be worked on while live in the presence of a flammable atmosphere.

- Page 37 When the final OFN charge is used, the system shall be vented down to atmospheric pressure to enable work to take place. This operation is absolutely vital if brazing operations on the pipe-work are to take place. Ensure that the outlet for the vacuum pump is not closed to any ignition sources and there is ventilation available.

- Page 38 18. Labelling Equipment shall be labelled stating that it has been de-commissioned and emptied of refrigerant. The label shall be dated and signed. Ensure that there are labels on the equipment stating the equipment contains flammable refrigerant. 19. Recovery When removing refrigerant from a system, either for service or decommissioning, it is recommended good practice that all refrigerants are removed safely.

- Page 39 QSQ4-001I(D) 16122700000122 20171108 The design and specifications are subject to change without prior notice for product improvement. Consult with the sales agency or manufacturer for details.

Need help?

Do you have a question about the KCIS-52 DR11 and is the answer not in the manual?

Questions and answers