Subscribe to Our Youtube Channel

Summary of Contents for Flowserve SEM-100

- Page 1 I N S TA L L AT I O N O P E R AT I O N M A I N T E N A N C E SEM-100 and SEM-100FT Electronic Flow Meter PUIOM000650-00 (ENGLISH, REV 08-2022) Experience In Motion...

-

Page 2: Table Of Contents

SEM-100 and SEM-100FT User Instructions Contents 1. Introduction and safety....3 4. Installation and operation.....9 1.1 General ........3 4.1 Unpacking the meter ....9 1.2 Disclaimer ........4 4.2 Installation ........9 1.3 Copyright ........4 4.3 Calibration and operation ..10 1.4 Duty conditions ......5 5. -

Page 3: Introduction And Safety

These instructions must always be kept close to the product’s operating location or directly with the product. Flowserve products are designed, developed and manufactured with state-of-the-art technologies in modern facilities. The unit is produced with great care and commitment to continuous quality control, utilizing sophisticated quality techniques and safety requirements. -

Page 4: Disclaimer

1.2 Disclaimer Information in these User Instructions is believed to be reliable. In spite of all the efforts of Flowserve to provide sound and all necessary information, the content of this manual may appear insufficient and is not guaranteed by Flowserve as to its completeness or accuracy. -

Page 5: Duty Conditions

The product must not be operated beyond the parameters specified for the application. If there is any doubt as to the suitability of the product for the application intended, contact Flowserve for advice, quoting the serial number. 1.5 Safety 1.5.1 Summary of safety markings: These User Instructions contain specific safety markings where non-observance of an instruction would cause hazards. -

Page 6: Transport And Storage

Immediately after receipt of the equipment, it must be verified for contents and inspected for damages in transportation. Any shortage and/or damage must be reported immediately to distributor/Flowserve Scienco and must be received within 10 days of receipt of the equipment. Later claims cannot be accepted. -

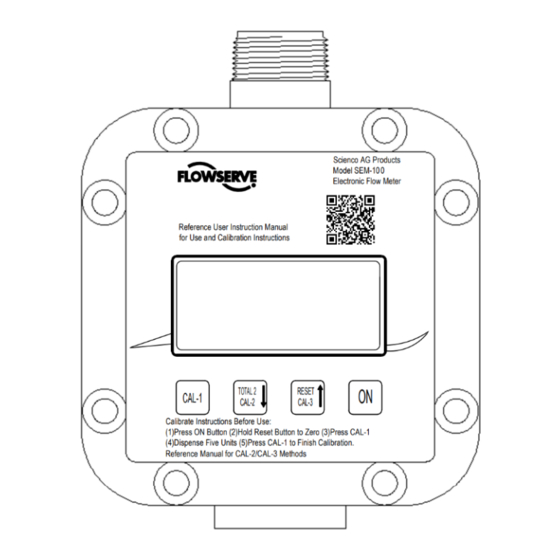

Page 7: Description

The SEM-100 flow meter line features a large LCD display, an anti-glare screen with back light, large positive touch buttons, and simple one-touch operation, making the meters easy to read and easy to use in both high light and low light settings. -

Page 8: Operating Parameters

• Pressures up to 4 bar (60 psi) 3.3 Available equipment and accessories The SEM-100 and SEM-100FT electronic flow meters are available individually or in packages with the CT6 chemical transfer pump in multiple configurations, each with varying equipment and accessories, including: •... -

Page 9: Materials Of Construction

SEM-100 and SEM-100FT User Instructions 3.4 Materials of construction The SEM-100 and SEM-100FT electronic flow meters are resistant to corrosion from typical ag-chem and light industrial chemicals. Wetted materials include: • Fluid Housing/Form Cover ------- Nylon or Polypropylene • Meter Chamber... -

Page 10: Installation And Operation

Flow can be metered in either direction through SEM-100 and SEM-100FT flow meters. SEM-100: Thread the meter inlet into the female discharge port of the pump. Using an elbow or coupling, screw the discharge hose onto the other port of the meter. Use thread sealant tape or pipe dope to seal thread connections as necessary. -

Page 11: Calibration And Operation

Push to enter into the three calibration modes, starting with CAL-1. 4.3.1 Calibration The SEM-100 / SEM-100FT Flow Meter has three calibration options, CAL-1, CAL-2, and CAL-3. The flow meter can be calibrated in any unit desired (i.e. gallons, liters, pounds, acres, pints, etc.). CAL-1 requires pumping 5 units of fluid. - Page 12 SEM-100 and SEM-100FT User Instructions CAL-1 Calibration: 1. Press “ON” button to wake up meter. 2. Press and hold the “Reset” button to zero (“.00”) the Current Total screen 3. Press “CAL-1” to enter calibration sequence. 4. Pump process liquid into a calibrated container that holds five units (gallons, liters, etc.)

- Page 13 SEM-100 and SEM-100FT User Instructions 7. Press “UP” and “DOWN” arrow keys to enter the amount of fluid that was pumped in the desired units. Note: The display will return to the Current Total screen and read the previous total.

- Page 14 SEM-100 and SEM-100FT User Instructions 4.3.2 Operation TO METER FLUID: With the pump and meter properly installed, the meter will wake up automatically and begin to display the Current Total as fluid is pumped. TO DISPLAY CURRENT TOTAL: Press “ON” button.

-

Page 15: Maintenance

SEM-100 and SEM-100FT User Instructions 5. Maintenance It is the final operator’s responsibility to ensure that all maintenance steps are carried out by authorized and qualified personnel who have adequately familiarized themselves with the subject matter by studying this manual in detail. -

Page 16: Meter Chamber Removal

SEM-100 and SEM-100FT User Instructions Place the gasket and electronic assembly onto the meter assembly. Reinstall the 8 screws (PH-13) to secure the electronic assembly to the meter assembly. Tighten the screws to 32-36 inch-pounds in a star pattern to avoid any leakage. -

Page 17: Parts List And Parts Diagram

SEM-100 Polypropylene Fluid Housing S10-05N SEM-100 Nylon Fluid Housing S10-10 SEM-100FT Nylon Fluid Housing S10-10P SEM-100FT Polypropylene Fluid Housing Note: All parts are common to the SEM-100 and SEM-100FT except for the fluid housing PUIOM000650-00-UIM (EN/HL) August 2022 Flowserve.com 17... - Page 18 SEM-100 and SEM-100FT User Instructions PH-13 S10-11 S10-12 PH-03 S10-02 S10-03 (VITON) S10-07 S10-14 SFM10000-02 SFM10000-03A SFM10000-01 S10-04 (VITON) S10-03 S10-10 S10-10P PUIOM000650-00-UIM (EN/HL) August 2022 Flowserve.com 18...

- Page 19 SEM-100 and SEM-100FT User Instructions 7. Troubleshooting guide Problem: Meter reads high or low. Solution: Check for the following: • Ensure lines are full and there is no trapped air in the system before calibrating. • Pump may be sucking air due to low fluid level or bad pump inlet connection.

- Page 20 SEM-100 and SEM-100FT User Instructions Problem: No liquid will pass through the meter or the meter will not register flow. Solution: Foreign material is in the metering cartridge and is obstructing flow or preventing the nutating disk from moving freely. Remove the meter cartridge and clean.

- Page 21 WARRANTY OF MERCHANTABILITY OR FITNESS FOR PURPOSE, SHALL APPLY. Flowserve is not responsible for repairs or alterations made by others without manual written agreement between the Company and Buyer. The Company does not warrant the Equipment or any repair/replacement part against the effects of erosion, corrosion, or normal wear and tear due to operation or the environment.

- Page 22 5215 North O’Connor Blvd. designed to perform its intended function safely during its useful life. However, the purchaser or user of Flowserve products should be aware that Flowserve Suite 700 products might be used in numerous applications under a wide variety of industrial service conditions.

Need help?

Do you have a question about the SEM-100 and is the answer not in the manual?

Questions and answers