Table of Contents

Advertisement

Quick Links

MODEL NUMBERS:

UH15B045, UH15B070, UH15B096,

UH15B120, UH15B145, UH15B175,

UH15B195, UH15B245, UH15B295

An ISO 9001-2008 Certified Company

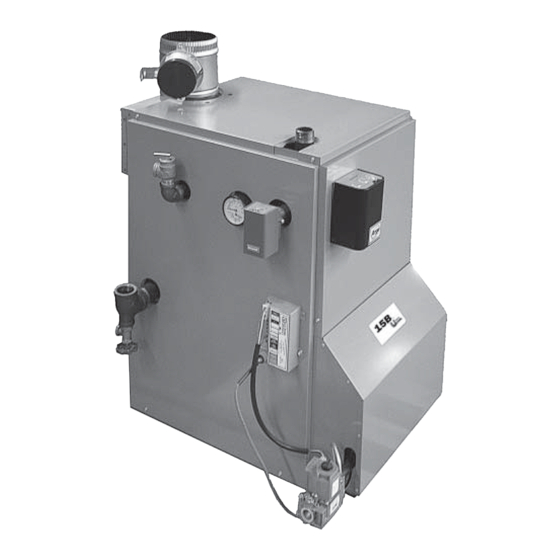

Cast Iron Gas Fired Boilers

For Forced Hot Water

INSTALLATION, OPERATION &

MAINTENANCE MANUAL

UTICA HEATING

2201 Dwyer Avenue, Utica NY 13501

web site: www.ecrinternational.com

UH15B SERIES

P/N 1305026UH, Rev. F [08/2011]

Advertisement

Table of Contents

Summary of Contents for ECR UTICA HEATING UH15B Series

- Page 1 UH15B SERIES Cast Iron Gas Fired Boilers For Forced Hot Water INSTALLATION, OPERATION & MODEL NUMBERS: UH15B045, UH15B070, UH15B096, MAINTENANCE MANUAL UH15B120, UH15B145, UH15B175, UH15B195, UH15B245, UH15B295 UTICA HEATING 2201 Dwyer Avenue, Utica NY 13501 web site: www.ecrinternational.com An ISO 9001-2008 Certified Company P/N 1305026UH, Rev.

-

Page 2: Table Of Contents

INSTALLATION MANUAL AND OPERATING INSTRUCTIONS IMPORTANT: Read the following instructions COMPLETELY before TABLE OF CONTENTS installing!! Ratings & Data - Natural Gas & Propane Gas ...3 Installation Procedure .........4 WARNING Ventilation & Combustion Air ......5 Keep boiler area clear and free from combustible materials, gasoline and other Connecting Supply &... -

Page 3: Ratings & Data - Natural Gas & Propane Gas

RATINGS & DATA - NATURAL GAS & PROPANE GAS Heating Net I=B=R Water Input AFUE Elect. AFUE Stdg. No. Of Recommended Air Capacity Rating Water Content Model No. Ign. Pilot Burners Cushion Tank (Gals.) 15B045 82.0% 80.0% 15B070 82.0% 80.0% 15B096 82.0% 80.0% 15B120 82.0% 80.0% 15B145 82.0% 80.0% 15B175 80.5%... -

Page 4: Installation Procedure

INSTALLATION PROCEDURE FOR INSTALLATION ON NON-COMBUSTIBLE WARNING FLOORS ONLY - For installation on combustible fl ooring special base must be used. (See Replacement Improper installation, adjustment, alteration, Parts Section.) Boiler can not be installed on service or maintenance can cause injury. carpeting. -

Page 5: Ventilation & Combustion Air

VENTILATION & COMBUSTION AIR Known Air Infi ltration Rate. See Table 1 for WARNING space with boiler only. Use equation for multiple appliances. Do not use an air infi ltration rate Air openings to combustion area must not (ACH) greater than 0.60. be obstructed. Following instructions below, adequate combustion air can be maintained. -

Page 6: Connecting Supply & Return Piping

CONNECTING SUPPLY & RETURN PIPING • Individual boiler discharge piping shall be Hydronic Piping - General independent of other discharge piping. • Install piping in accordance with authority having juris- • Size and arrange discharge piping to avoid reducing diction. safety relief valve relieving capacity below minimum •... - Page 7 CONNECTING SUPPLY & RETURN PIPING WARNING To avoid burns, scalding, or water damage due to discharge of steam and/or hot water during operation, a discharge line shall be installed to relief valve outlet connection. Discharge line shall: • connect to relief valve outlet and piped down to safe point of disposal. Check local codes for maximum distance from fl...

- Page 8 CONNECTING SUPPLY AND RETURN PIPING IMPORTANT: Circulators in following illustrations are mounted on system supply side, but mounting on system return side is also acceptable practice. Figure 2 PRESSURE REDUCING VALVE GATE VALVE SUPPLY PIPING TO HEATING AND COOLING ELEMENT CIRCULATOR PROPER BACKFLOW WATER PROTECTION EXPANSION FEED...

- Page 9 CONNECTING SUPPLY AND RETURN PIPING Figure 3 - BYPASS PIPING -AUTOMATIC MIXING VALVE TO SYSTEM FROM SYSTEM WATER INLET EXPANSION TANK BOILER ALTERNATE CIRCULATOR LOCATION PRESSURE BALL VALVE AIR SEPARATOR CIRCULATOR REDUCER VALVE Figure 4 - BYPASS PIPING - FIXED LOW TEMP ONLY FROM SYSTEM TO SYSTEM SYSTEM CIRCULATOR...

- Page 10 CONNECTING SUPPLY AND RETURN PIPING Figure 5 - Single Zone System With DHW Priority CH CIRCULATOR WATER INLET EXPANSION TANK CIRCULATOR BOILER PRIORITY ZONE PRESSURE BALL VALVE CIRCULATOR HOSE BIB REDUCER VALVE AIR SEPARATOR FLOW CONTROL SHUT-OFF ZONE VALVE CHECK VALVE VAVLE VALVE Figure 6 - Multi-zone System with Circulators and DHW Priority ZONE 4 CIRC 4 ZONE 3...

- Page 11 CONNECTING SUPPLY AND RETURN PIPING Figure 7 - Mult i-zone System With Zone Valves And DHW Priority (With Circulator) ZONE 4 ZONE 3 *USE FULL PORT ZONE VALVE. ZONE 2 CIRCULATOR ZONE 1 (PRIORITY ZONE) WATER INLET CIRCULATOR BOILER EXPANSION TANK PRESSURE BALL VALVE AIR SEPARATOR CIRCULATOR REDUCER VALVE...

-

Page 12: Vent Installation

VENT INSTALLATION Vent connectors serving appliances vented by natural WARNING draft shall not be connected into any portion of mechanical draft systems operating under positive All installations of boilers and venting should pressure. be done only by a qualifi ed expert and in Connect fl... -

Page 13: Vent Damper Installation & Instructions

VENT DAMPER INSTALLATION & INSTRUCTIONS Figure 9 - DAMPER INSTALLATION Figure 10 - DAMPER LOCATION CLOSE-UP OF UN-ACCEPTABLE INSTALLER LOCKNUT DAMPER LOCATIONS CHIMNEY HOOK-UP HARNESS REFER TO DAMPER MANUFACTURER'S CONN. INSTALLATION INSTRUCTIONS FOR POSITION OF DAMPER CONTROL BOX DAMPER MOTOR DAMPER CONN. VENT ACCEPTABLE VENT DAMPER DAMPER LOCATIONS VENT... -

Page 14: Connecting Gas Service

CONNECTING GAS SERVICE Use piping materials and joining methods acceptable WARNING to authority having jurisdiction. In absence of such requirements: Do not use an open fl ame. • National Fuel Gas Code, ANSI Z223.1/NFPA 54 Figure 11 Ground joint union should be installed for easy removal of gas control for servicing. -

Page 15: Wiring Diagram

WIRING DIAGRAM Figure 12 - 24V Standing Pilot... - Page 16 WIRING DIAGRAM Figure 13 - 24V Intermittent Ignition...

- Page 17 WIRING DIAGRAM Figure 14 - 24V Standing Pilot with LWCO...

- Page 18 WIRING DIAGRAM Figure 15 - 24V Interim Ignition With LWCO...

-

Page 19: Lighting Instructions

LIGHTING INSTRUCTIONS Do not use this appliance if any part has been WARNING under water. Immediately call a qualifi ed service technician to inspect the appliance and to replace If you do not follow these instructions exactly, any part of the control system and any gas control a fi... - Page 20 LIGHTING INSTRUCTIONS Lighting procedure for boiler with continuous pilot Figure 18 For Your Safety, Read Before Lighting! Read warning at beginning of " Lighting Instructions" on previous page. This appliance has a pilot which must be lighted by hand. When lighting the pilot, follow these instructions exactly.

-

Page 21: Normal Sequence Of Operation

NORMAL SEQUENCE OF OPERATION On call for heat, thermostat will actuate, completing Figure 19 the circuit to control. Completed circuit to control will fi rst activate the circulator and damper which will close an end switch inside the damper. This action will complete the circuit to the ignition system and ignition will take place. - Page 22 GENERAL INSTRUCTIONS When cleaning process is complete, restore boiler Figure 20 components to their original position. Use IS-808 GE silicone (available from a distributor) to seal around fl ue collector and boiler castings. Visual check of main burner and pilot fl ames should be made at start of heating season and again in mid-season.

-

Page 23: Checking Gas Input Rate To Boiler

CHECKING GAS INPUT RATE TO BOILER Gas input to boiler can be adjusted by removing Figure 23 protective cap on pressure regulator (Figures 16- 18) and turning screw clockwise to increase input and counterclockwise to decrease input. Manifold pressures are taken at outlet side of gas valve. -

Page 24: Replacement Parts

REPLACEMENT PARTS BOILER EXPLODED VIEW Item Description Item Description Item Description Jacket Front Lower 13 Draft Hood 25 Pipe Nipple Control 14 Restrictor 26 Pilot Spark Control Jacket Front Upper 15 Jacket Back 27 Temperature-Pressure Gauge Jacket Side Right 16 Right End Section 28 High Limit Control Left End Section 17 Jacket Side Left... - Page 25 REPLACEMENT PARTS BOILER BASE Item Part No. Description QTY. Item Part No. Description Qty. Burner Tube 1½” (045) 240006794 Manifold (120, 145) Burner Tube 1½” (070, 096) 240006795 Manifold (175, 195) Burner Tube 1½” (120, 145) 240006796 Manifold (245) 240005543 Burner Tube 1½” (175, 195) 240006797 Manifold (295) Burner Tube 1½”...

- Page 26 REPLACEMENT PARTS HEAT EXCHANGER Fully Assembled Heat Exchangers 912000001 Heat Exchanger (2 Section) Heat Exchanger (3 Section) 912000002 Heat Exchanger (4 Section) 912000003 Heat Exchanger (5 Section) 912000004 912000005 Heat Exchanger (6 Section) 912000006 Heat Exchanger (7 Section) PIPING & CONTROLS Item Part No.

- Page 27 REPLACEMENT PARTS BOILER JACKET Description Part No. Description Qty. Item Qty. Item Part No. 240006936 4” Damper (045) 34620501 Flue Collector (045) 240006937 5” Damper (070, 096) 109008571 Flue Collector (070, 096) 240006938 6” Damper (120, 145) 109008554 Flue Collector (120, 145) 240006939 7”...

- Page 28 REPLACEMENT PARTS STANDING PILOT Spark Pilot Kit - Natural Gas 550001911 Spark Pilot Kit - LP/Propane 550001912 Item Description Qty. PILOT BRACKET ASSEMBLY BRACKET SCREW SPARK CABLE PILOT TUBING, 1/8" x 24" PILOT SHIELD IGNITER CONTINUOUS PILOT Continuous Pilot Kit - Natural Gas 550001926 Continuous Pilot Kit - LP/Propane 550001927 Item Description...

-

Page 29: Conversion Kits

CONVERSION KITS ROLLOUT & SPILL SWITCH ITEM PART NO. DESCRIPTION QTY.* 32611001 2 Section Temp. Sensor Bracket 3161202 3 Section Temp. Sensor Bracket 109008517 4 Section Temp. Sensor Bracket 109008518 5-7 Section Temp. Sensor Bracket Control - Fixed Temperature Thermostat AQ02101 (Rollout Switch) HW06501 Screw - #6 x 1/4”... - Page 30 NOTES...

- Page 32 UTICA HEATING 2201 Dwyer Avenue, Utica NY 13501 web site: www.ecrinternational.com...

Need help?

Do you have a question about the UTICA HEATING UH15B Series and is the answer not in the manual?

Questions and answers