Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for AND AD-4401A

- Page 1 AD-4401A Weighing Indicator INSTRUCTION MANUAL 1WMPD4003050F...

- Page 2 No part of this publication may be reproduced, transmitted, transcribed, or translated into any language in any form by any means without the written permission of A&D Company, Limited. The contents of this manual and the specifications of the instrument covered by this manual are subject to change for improvement without notice.

-

Page 3: Table Of Contents

9.5. Check Weighing Functions ..................32 10. Control I/O ........................33 10.1. Pin Assignment ....................33 10.2. Connection Diagram..................... 34 10.3. Control Input Method ................... 35 11. Setpoint Input ......................36 11.1. Pin Assignment ....................36 11.2. Connection Diagram..................... 39 Page 3 AD-4401A... - Page 4 13. Option-01 BCD Output ....................44 13.1. Pin Assignment ....................44 13.2. Connection Diagram..................... 45 13.3. Data Output Timing ..................... 46 13.4. Data Output Logic and Strobe Output Logic ............. 46 14. Option-03 RS-422/485 ....................47 14.1. Terminal Assignment.................... 47 14.2. Connection Diagram..................... 47 14.3.

- Page 5 21.8. Standard Serial Output Functions ............... 91 21.9. BCD Output Functions..................91 21.10. RS-422/485, RS-232C Functions ..............92 21.11. Setpoint Input Functions ..................93 21.12. Analog 4-20 mA Output Functions ..............93 21.13. Modbus TCP Functions ..................93 22. Specifications ......................94 Page 5 AD-4401A...

-

Page 6: Safety Precautions

1. Safety Precautions For safe and correct usage, read the following precautions carefully before using the indicator. Precautions on designing WARNING ● Provide an external safety circuit to the indicator so that the safety of the whole system can be secured even if errors occur in the external power supply or in the indicator. -

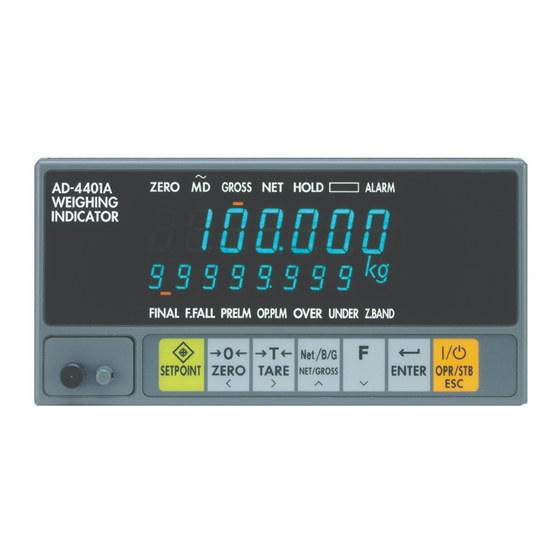

Page 7: Part Names

Underweight Hi-Hi Near-zero (Z.BAND) Near-zero (Z.BAND) Attach the accessory status label when performing loss-in-weight batching or check weighing. CAL (Calibration) key SETPOINT ZERO TARE Key Switches NET/GROSS Function (FncF-02) ENTER ON/OFF Rating label (Accessory) Other Sealing cover Page 7 AD-4401A... -

Page 8: Rear Panel

Terminal block cover 1074005384-4 Terminal block cover securing screw 11702FN-S3X6 1JI361J016-AG Connector Connector for the CONTROL I/O 1JI360C016-B Connector cover Connector for the SER.OUT 1JATCP0576 Panel mount packing 1064004213A Rubber foot 110NO.5837 Rating label 1084028304 Status label 1083001699 AD-4401A Page 8... -

Page 9: Installation To Control Panel

Make a hole in a control panel as shown below. Panel thickness: 1.6 to 3.2 Unit: mm Remove the slide rails on both sides and insert the AD-4401A with the accessory panel mount packing through the hole into the panel. AD-4401A... -

Page 10: Connection To Power Supply

Use a solderless terminal with a width of 6.2 mm or less. Terminal No. Symbol Description Ground terminal AC power input (Neutral) Earthed conductive part AC power input (Live) Unearthed conductive part 4.2. Connection Diagram Live Neutral AD-4401A Page 10... -

Page 11: Connection To Load Cell

Symbol Description EXC+ Load cell excitation voltage + SEN+ Sensing input + SEN- Sensing input - EXC- Load cell excitation voltage - SIG+ Load cell signal input + SIG- Load cell signal input - SHLD Frame ground Page 11 AD-4401A... -

Page 12: Connection Diagram

Load cell excitation voltage - Sensing - Load cell signal - ●4-wire connection As shown in the figure below, short-circuit the pins No.1 and No.2, and pins No.3 and No.4. Shield Load cell excitation voltage + Load cell signal +... -

Page 13: Calibration

6. Calibration Calibrates the AD-4401A to convert the signal from the load cell to a mass value correctly. 6.1. Calibration Setting Set the following calibration functions which are required for calibration using calibration weights. For the function setting procedure, refer to "21.1. -

Page 14: Calibration Using Calibration Weights

Zero calibration Press the ENTER key when the STABLE (MD) status is turned OFF. Dashes are displayed in the sub-display and zero calibration is performed. Note: When the Function key is pressed, the AD- 4401A proceeds to the span calibration without performing zero calibration. - Page 15 The load cell signal voltage at zero calibration is less than 0 mV/V. Check if load cell connections of SIG+ and SIG- are not reversed. The calibration weight value that is set in the span calibration exceeds the maximum capacity.

-

Page 16: Basic Weighing Functions

When the AD-4401A is powered ON, all the segments of the display turn ON and OFF for checking the display. Then the AD-4401 is in the normal mode and starts weighing. If the AD-4401A is powered OFF in the OFF mode (with the display OFF), the AD-4401A is in the OFF mode when powered ON. - Page 17 The NET status turns ON when the net value is displayed. Operation: NET/GROSS key, Control input ●Zero Center of zero is detected and the ZERO status turns ON when the gross value is within 1/4 of the minimum division. ●Stable Stability is detected when the weight value is maintained within the stability detection width (CALF-09) during the stability detection time (CALF-08).

- Page 18 Data is output from the standard serial output or options (BCD, RS-232C, RS-422/485). Operation: Function key (FncF-02), Control input ●Accumulation The net value is accumulated on the total weight and the number of accumulations is updated. Operation: Function key (FncF-02), Control input ●Total clear The total weight and the number of accumulations are cleared.

-

Page 19: Batch Weighing Functions

When the small flow comparison disable time (Sq F-12) has passed and the net value has exceeded the free fall value, the small flow output turns OFF. When the judging delay time (Sq F-13) has passed and the net value is stable (Sq F-07), the net value is judged. - Page 20 ●Near-zero When the weight value is compared with the setpoint and the condition is met, the control output turns ON. Condition Control output Near-zero Gross value ≤ Near-zero Timing chart Judge Overweight Final weight Free fall Underweight Preliminary Optional Preliminary...

- Page 21 When the net value is judged to be underweight, the small flow output turns ON. When the correction flow ON time (Sq F-16) has passed, the small flow output turns OFF. When the correction flow OFF time (Sq F-17) has passed and the net value is stable (Sq F-07), the net value is judged.

-

Page 22: Loss-In-Weight Batching

When the small flow comparison disable time (Sq F-12) has passed and the – net value has exceeded the free fall value, the small flow output turns OFF. When the judging delay time (Sq F-13) has passed and the net value is stable (Sq F-07), the net value is judged. - Page 23 Medium flow output Small flow output Weighing end output OK/Over/Under output T1: Weighing start input delay time T2: Medium flow comparison disable time T3: Small flow comparison disable time T4: Judging delay time T5: Weighing end output time Page 23 AD-4401A...

- Page 24 When the net value is judged to be underweight, the small flow output turns ON. When the correction flow ON time (Sq F-16) has passed, the small flow output turns OFF. When the correction flow OFF time (Sq F-17) has passed and the net value is stable (Sq F-07), the net value is judged.

-

Page 25: Sequential Weighing Functions

(Si F-02) or options (bCdF-02, rS F-02). ●Emergency stop The large flow, medium flow and small flow outputs turn OFF, the weighing sequence error output turns ON and the indicator waits for the next weighing start input. Operation: Function key (FncF-02), Control input ●Flow timeout error/Discharge timeout error... - Page 26 Starts the correction flow. Turns the small flow output ON for correction. Waits for the correction flow ON time to pass and turns the small flow output OFF. Waits for the correction flow OFF time to pass. Judges the correction flow value.

-

Page 27: Simple Comparison Normal Batching

8.4. Simple Comparison Normal Batching When the weight value is compared with the setpoint and the condition is met, the control output turns ON. Condition Control output Near-zero Gross value ≤ Near-zero Net value ≥ Final - Optional preliminary Large flow Net value ≥... -

Page 28: Simple Comparison Loss-In-Weight Batching

●Automatic print When the weight value is five times the minimum division or more and the large flow, medium flow and small flow outputs turn ON, data is output once from the standard serial output or options. To output again, wait for the –weight value to be four times the minimum division or less. -

Page 29: Check Weighing Functions

6: Check weighing 2 7: Check weighing 3 8: Check weighing 4 9.1. Check Weighing 1 When the weight value is compared with the setpoint and the condition is met, the control output turns ON. Condition Control output Gross value ≤ Near-zero Near-zero Net value >... -

Page 30: Check Weighing 2

9.2. Check Weighing 2 When the weight value is compared with the setpoint and the condition is met, the control output turns ON. Condition Control output Near-zero Gross value ≤ Near-zero Net value > Target + Hi-Hi limit Hi-Hi Target + Hi-Hi limit ≥ Net value > Target + Hi limit Target + Hi limit ≥... -

Page 31: Check Weighing 3

9.3. Check Weighing 3 When the weight value is compared with the setpoint and the condition is met, the control output turns ON. Condition Control output Near-zero Gross value ≤ Near-zero Net value > Hi-Hi limit Hi-Hi Net value > Hi limit Hi limit ≥... -

Page 32: Check Weighing 4

●Automatic print When the weight value is five times the minimum division or more and is stable, data is output once from the standard serial output or options. To output again, wait for the weight value to be four times the minimum division or less. -

Page 33: Control I/O

Pin No. Description Description Pin No. Control input Control output Control input Control output Control input Control output Control input Control output Control input Control output Control input Control output Input common Control output Output common Control output Page 33 AD-4401A... -

Page 34: Connection Diagram

- OFF current: 1 mA or less Internal Circuit 3.3 kΩ Control output - Maximum load voltage: 30 VDC - Maximum load current: 50 mA/point - Voltage drop at ON: 1 V or less - Leakage current at OFF: 0.1 mA or less AD-4401A Page 34... -

Page 35: Control Input Method

10.3. Control Input Method Two methods of control input are available; edge detection and level detection. Edge detection Control input is performed when the control input is turned ON (short-circuit) from the OFF state (open- circuit). The pulse width is 50 ms or more. -

Page 36: Setpoint Input

Connector cover: OTAX N360C024B (A&D Part No.: 1JI360C024-B) The connector is not provided and must be prepared by the user. The descriptions of the pin Nos. depend on the weighing mode (CALF-14) and the setpoint setting method (SP F-01) settings. - Page 37 Lo limit 10^0 BCD input 8 Lo limit 10^1 Target 10^0 Lo limit 10^2 Target 10^1 Lo limit 10^3 Target 10^2 Lo limit 10^4 Target 10^3 Target 10^4 Hi limit 10^0 Hi limit 10^1 Hi limit 10^2 Shield Page 37 AD-4401A...

- Page 38 Hi-Hi limit 10^0 Lo-Lo limit 10^0 Hi-Hi limit 10^1 Lo-Lo limit 10^1 Hi-Hi limit 10^2 Lo-Lo limit 10^2 Hi-Hi limit 10^3 Lo-Lo limit 10^3 Hi limit 10^0 Hi limit 10^1 Hi limit 10^2 Hi limit 10^3 Shield AD-4401A Page 38...

-

Page 39: Connection Diagram

- Voltage drop at ON: 1 V or less - Leakage current at OFF: 0.1 mA or less Key scan input - ON voltage: 1 V or less - ON current: 3 mA or more - OFF current: 1 mA or less Page 39 AD-4401A... -

Page 40: Standard Serial (Current Loop) Output

Signal level Current loop 0 to 20 mA Baud rate (Si F-03) 600, 2400 bps Character bit length 7 bits Parity Even Star bit length 1 bit Stop bit length 1 bit Code ASCII Terminator CR LF AD-4401A Page 40... -

Page 41: Output Data

5: Gross value + Net value + Tare value 6: Total weight 7: Number of accumulations 8: Total weight and number of accumulations 12.4. Communication Type Select a communication Type (Si F-02) from the following: 1: Interval output at the display update rate (FncF-03) (default) -

Page 42: Output Data Format

+ SP SP SP SP . SP SP Positive overload - SP SP SP SP . SP SP Negative overload SP SP None SP g Unit (CALF-01) SP t No unit is added when the number of accumulations is output. SP: space AD-4401A Page 42... - Page 43 Positive overload - SP SP SP SP SP SP SP . SP SP Negative overload SP SP None SP g Unit (CALF-01) SP t No unit is added when the number of accumulations is output. SP: space Page 43 AD-4401A...

-

Page 44: Option-01 Bcd Output

(For USA only) Strobe output Hold input Common Common Frame ground Frame ground When the weight value is overloaded and the data output logic (bCdF-03) is set to negative logic (default), all of the output data is turned ON. AD-4401A Page 44... -

Page 45: Connection Diagram

- Voltage drop at ON: 1 V or less - Leakage current at OFF: 0.1 mA or less Hold input - ON voltage: 1 V or less - ON current: 3 mA or more - OFF current: 1 mA or less Page 45 AD-4401A... -

Page 46: Data Output Timing

Update will stop within 50 ms after the hold input turns ON. Then, update will restart within 50 ms after the hold input turns OFF. 13.4. Data Output Logic and Strobe Output Logic Select a data output logic (bCdF-03) and a strobe output logic (bCdF-04) from the following: 1: Positive logic 2: Negative logic (default) -

Page 47: Option-03 Rs-422/485

Disable the terminal resistor Short-circuited to No. 4 Enable the terminal resistor Signal ground 14.2. Connection Diagram 14.2.1. RS-422 AD-4401A Master 1 Send data + 2 Send data - 3 Receive data + 4 Receive data - 5 Terminal resistor 100 Ω... - Page 48 14.2.2. 2-wire RS-485 Short-circuit the terminals No.1 and No.3, and the terminals No.2 and No.4 as shown below. Terminal resistors must be installed on both ends of the circuit. When a multidrop connection is required, refer to “Multidrop connection” in “14.9. Format When Communication Type (rS F-02) is 4”.

-

Page 49: Communication Specifications

3: In synchronization with manual print 4: Write data or read setpoint values by commands from the master 5: Interval output of comparison result and gross value at 100 times/s. 6: Interval output of comparison result and net value at 100 times/s. -

Page 50: Format When Communication Type (Rs F-02) Is 1, 2, 3 Or 7

+ SP SP SP SP . SP SP Positive overload - SP SP SP SP . SP SP Negative overload SP SP None SP g Unit (CALF-01) SP t No unit is added when the number of accumulations is output. SP: space AD-4401A Page 50... - Page 51 Positive overload - SP SP SP SP SP SP SP . SP SP Negative overload SP SP None SP g Unit (CALF-01) SP t No unit is added when the number of accumulations is output. SP: space Page 51 AD-4401A...

-

Page 52: Format When Communication Type (Rs F-02) Is 5 Or 6

Small flow/Lo-Lo Discharge Weighing end *2: The gross value and the net value are converted from a signed decimal number into a 6-digit hexadecimal number. Negative numbers are represented by the two's complement. A decimal point is not included. Decimal Hexadecimal …... -

Page 53: Format When Communication Type (Rs F-02) Is 8

+ 0 0 0 0 0 0 0 (rS F-01) + SP SP SP SP . SP SP Positive overload - SP SP SP SP . SP SP Negative overload A decimal point is not added to the output weight value. Page 53 AD-4401A... -

Page 54: Format When Communication Type (Rs F-02) Is 4

Data format is the same as that when communication type (rS F-02) is 1, 2, 3 or 7. Refer to “14.6. Format When Communication Type (rS F-02) is 1, 2, 3 or 7” for the weight data format. AD-4401A Page 54... - Page 55 Optional preliminary/Full/Lo limit 0 1 8 0 0 0 18.000 kg Overweight/Lo-Lo limit 0 0 0 0 2 0 0.020 kg Underweight 0 0 0 0 2 0 0.020 kg Near-zero 0 0 0 2 0 0 0.200 kg Page 55 AD-4401A...

- Page 56 (rS F-09) is assigned to each AD-4401A. When the master sends a command by adding the slave address (@ 0 1 to @ 9 9) at the beginning, the AD-4401A with the matching slave address sends a response by adding the slave address (@ 0 1 to @ 9 9) at the beginning.

- Page 57 M N : Display net value in the main display B B : Weighing start B D : Discharge start H B : Emergency stop When the command above is sent, the command is echoed back and is executed. Master Command AD-4401A...

-

Page 58: Modbus-Rtu When Communication Type (Rs F-02) Is 9

2-wire RS-485 RS-422/485 electrical specifications For the 2-wire RS-485 connection method, refer to the connection diagram in "14.2.2. 2-wire RS-485". Select a baud rate and a slave address from the following: Setting value rS F- Item Default 5: 9600 bps... - Page 59 Reserved internally 000301-000400 Reserved internally 000401 Zero calibration 000402 Span calibration*2 000403-000500 Reserved internally *1: When "1" is written, the operation is executed. *2: Before span calibration, set CALF-23 Calibration weights at span calibration via Modbus (400145-400146). Page 59 AD-4401A...

- Page 60 *1: "Double Word" word order is low word first (L/H). *2, *4: For the detailed description, refer to the next page. *3: This function is available for the software version 1.08 or later *5: Refer to "21. FUNCTION LIST". AD-4401A Page 60...

- Page 61 HOLD 400010.01 Function □ (FncF-05) 400010.00 ALARM *3: During an internal write cycle / Write result Write success Write failure 2-8: Calibration error (C Err) Refer to "6.2. Calibration Using Calibration Weights". During an internal write cycle Page 61 AD-4401A...

-

Page 62: Option-04 Rs-232C

15. Option-04 RS-232C 15.1. Pin Assignment The applicable connector is a D-sub 25-pin male connector. The locking screw is M2.6. The connector is not provided and must be prepared by the user. Pin No. Description 9 to 19 21 to 25... -

Page 63: Connection Diagram

Start bit length 1 bit Stop bit length (rS F-06) 1, 2 bits Code ASCII Terminator (rS F-07) CR LF, CR 15.4. Output Data, Communication Type Refer to “14. OPTION-03 RS-422/485” for output data and communication type. Page 63 AD-4401A... -

Page 64: Option-07 Analog 4-20Ma Output

Analog current output - SHLD Frame ground When the optional analog 4-20mA output is not installed, the pins No.8 and No.9 are vacant. Check the 07 column of the option list on the side of the indicator casing. 16.2. Connection Diagram... -

Page 65: Output Specifications

3: Net value ●Output adjustment Output characteristic is represented by the straight line obtained by connecting between the weight value at 4 mA output (An F-02) and the weight value at 20mA output (An F-03). Output current 20mA Weight value... -

Page 66: Option-23 Modbus-Tcp

The connector is not provided and must be prepared by the user. Note on the appearance change Due to some discontinued main components for the AD-4401A-23, the appearance is changed as shown below. After this change, the connectors cannot be inserted or disconnected with the terminal block cover attached. -

Page 67: Ip Address, Subnet Mask, Default Gateway

17.3. IP Address, Subnet mask, Default gateway Consult with the network administrator for the IP address, subnet mask, and default gateway setting. EthF Item Setting Value Default IP address XXX. XXX. XXX. 0.0.0.0 192.168.0.2 255.255.255.255 Subnet mask 255. 255. XXX. -

Page 68: Setpoint Setting

Normal mode SETPOINT key Goes to the item selection mode. Item selection Selects the blinking item in the lower status display and goes to the inputting ENTER key mode of the item. TARE key Shifts the blinking item in the lower status display to the right. - Page 69 Normal mode Select an item Save Cancel Input a setting value Page 69 AD-4401A...

-

Page 70: Setpoint Values List

Weighing mode: Check weighing 1/2/3/4 Attach the accessory status label on the lower status display. Status display Item Setting value Blinking Z.BAND Near-zero Blinking Lo-Lo Lo-Lo Blinking Lo -999999 to 9999999 Blinking Go Blinking Hi Blinking Hi-Hi Hi-Hi AD-4401A Page 70... -

Page 71: Operation Checking

19. Operation Checking Operations are checked in the checking mode. Select an operation to be checked and press the ENTER key. Select an operation to be checked Key switches Software version Control input/output Standard serial output Load cell input BCD output... -

Page 72: Checking Key Switches

When the NET/GROSS key or Function key is pressed, the corresponding pin No. of the control output B1 to B6 turns ON. A6 A5 A4 A3 A2 A1 B1 to B6 19.3. Checking Standard Serial Output When the ENTER key is pressed, “123” is sent. The communication specifications comply with the standard serial output specifications. AD-4401A Page 72... -

Page 73: Checking Bcd Output

19.4. Checking BCD Output When the hold input turns ON, “0” turns to “1” and the output of the displayed pin No. turns ON. Press the NET/GROSS key or Function key to switch pin Nos. Hold input Pin No. 19.5. Checking RS-422/485, RS-232C When the ENTER key is pressed, “123”... -

Page 74: Checking Analog 4-20 Ma Output

Press the NET/GROSS key or Function key to increase or decrease the current value. 2 mA Output 20 mA Output 19.8. Checking Load Cell Input The load cell signal voltage (mV/V) is displayed in the sub-display. 19.9. Checking Software Version The AD-4401A software version is displayed in the sub-display. AD-4401A Page 74... -

Page 75: Checking The Load Cell Connection With A Digital Multimeter

The value may exceed 2 V when a long cable is used. EXC- SEN- cell cable For the 4-wire connection, it is 0 V. Load cell middle point Normally 4.5 to 5 V, half of the load cell excitation SIG- EXC- voltage voltage. Page 75 AD-4401A... -

Page 76: Check List

19.11. Check List If the AD-4401A operates improperly, contact your local A&D dealer. Use the chart below to write necessary items before contacting your dealer. Checking item Example Weighed product Plastic pellet, livestock feed Capacity of the weighing instrument 20.00 kg Minimum division of the weighing instrument 0.01 kg... -

Page 77: Initialization

With the display shown to the left, press the ENTER key. With the display shown to the left, hold the ENTER key for three seconds or more to initialize the parameters described in 19.1. and general functions. Page 77 AD-4401A... -

Page 78: All Data Initialization

When “CAL Set” is displayed, press the Function key. When “initAll” is displayed, press the ENTER key. With the display shown to the left, hold the ENTER key for three seconds or more to initialize the parameters described in 19.1., general functions and calibration functions AD-4401A Page 78... -

Page 79: Function List

When “CAL" is displayed, press the ENTER key. When “CAL SEt” is displayed, press the NET/GROSS key. When “CAL Fnc” is displayed, the indicator has entered the calibration function mode. Press the ENTER key to go to the item selection mode. Page 79 AD-4401A... - Page 80 Operation in the calibration function mode: Item selection ENTER key Selects the displayed item and goes to the inputting mode of the item. TARE key Shifts the blinking item to the right. ZERO key Shifts the blinking item to the left.

-

Page 81: General Function Setting

21.2. General Function Setting Set the general functions in the general function mode. Select a function to be set and press the ENTER key to go to the item selection mode. Select a function to be set Basic function Reserved internally... - Page 82 Operation: Item selection ENTER key Selects the displayed item and goes to the inputting mode of the item. TARE key Shifts the blinking item to the right. ZERO key Shifts the blinking item to the left. NET/GROSS key Increases the blinking digit by one.

-

Page 83: Calibration Functions

Stability detection time 400116 0.1 to 5.0 s 400117 0: Not used Stability detection width 400118 1 to 9 d 400119 Tare and zero setting at 0: Disable 400120 unstable weight 1: Enable 400121 0: Disable Tare at negative gross value 400122... - Page 84 ±10% of the maximum capacity. 400141 0: Disable Zero clear 400142 1: Enable Zero calibration, Span 400143 0: Disable calibration and Calibration 400144 1: Enable function setting via Modbus(*) 400145 Calibration weights at span 0 to 999999 20000 400146 calibration via Modbus.(*) Available for the software version 1.03 or later...

-

Page 85: Basic Functions

4: Final weight 5: Total weight 6: Number of accumulations 7: Weighing sequence error None During discharge 400309 Condition to turn the When zero tracking is enabled 400310 FUNCTION status ON In weighing sequence Normal batching (/loss-in-weight batching) Page 85 AD-4401A... - Page 86 11.0 Hz 8.0 Hz digit: 5.6 Hz Post-digital filter cutoff 4.0 Hz frequency 2.8 Hz 2.0 Hz Pre-digital filter and 1.4 Hz post-digital filter are 1.0 Hz 400311 connected in series. 0.7 Hz 400312 101: 11.0 Hz (HPDF) 102: 8.0 Hz (HPDF)

-

Page 87: Weighing Sequence Functions

400442 1: Enable value 400443 Add the final weight to 0: Disable 400444 the full setpoint value 1: Enable 400445 Reserved internally 400446 Simple comparison 400447 1: Positive logic large/medium/small flow 400448 2: Negative logic output logic Page 87 AD-4401A... - Page 88 400452 the near-zero value 3: Net value 4: |Net value| Comparison target 400453 1: Gross value excluding the near-zero 400454 2: Net value and full values 400455 Automatic tare at 0: Disable 400456 weighing start 1: Enable AD-4401A Page 88...

-

Page 89: Control Input Functions

Net value display ON=Display gross value OFF=Display net value Weighing restart Pause Forced weighing end Forced discharge end Error clear ON=Select loss-in-weight batching OFF=Select normal batching Manual correction flow (One-shot small flow) ON=Checking weighing start OFF=Checking weighing stop Page 89 AD-4401A... -

Page 90: Control Output Functions

When zero setting fails 400616 Overload Reserved internally When tare fails When zero setting or tare fails Total weight / number of accumulations overflow When the judgment result is OK Hold ON = loss-in-weight batching / Off = Normal batching AD-4401A Page 90... -

Page 91: Standard Serial Output Functions

400701 Gross value + Net value + Tare value Output weight value 400702 Total weight Number of accumulations Total weight and number of accumulations Interval output at the display update rate (FncF-03) 400703 In synchronization with automatic print Data output timing... -

Page 92: Rs-422/485, Rs-232C Functions

In synchronization with automatic print In synchronization with manual print Response to command Interval output of comparison result 400903 Communication type and gross value at 100 times/s 400904 Interval output of comparison result and net value at 100 times/s. In synchronization with automatic/manual accumulation... -

Page 93: Setpoint Input Functions

EthF Modbus Item Setting Value Default User setting IP address XXX. XXX. XXX. XXX 0.0.0.0 192.168.0.2 255.255.255.255 Subnet 255. 255. XXX. mask Available only to 255.255.0.0 255.255.255.0 255.255.255.0 Default XXX. XXX. XXX. XXX gateway 0.0.0.0 0.0.0.0 255.255.255.255 Page 93 AD-4401A... -

Page 94: Specifications

22. Specifications Dimensions 144 (W) x 72 (H) x 197 (D) mm -10 °C to 40 °C Operating temperature and humidity range Less than 85%RH, non-condensing When the indicator is secured to the control panel: IP rating Outside of the control panel: IP65... - Page 95 External dimensions パネルカット寸法 Panel cutout dimensions Panel cutout dimensions 板厚 1.6~3.2 Panel thickness: 1.6 to 3.2 Panel thickness: 1.6 to 3.2 Unit: mm Page 95 AD-4401A...

- Page 96 MEMO AD-4401A Page 96...

- Page 97 MEMO Page 97 AD-4401A...

- Page 98 MEMO AD-4401A Page 98...

- Page 99 THIS PAGE INTENTIONALLY LEFT BLANK...

- Page 100 Back cover: A&D Global A&D Company, Limited 3-23-14 Higashi-Ikebukuro, Toshima-ku, Tokyo 170-0013, JAPAN Telephone: [81] (3) 5391-6132 Fax: [81] (3) 5391-1566 A&D ENGINEERING, INC. 47747 Warm Springs Blvd, Fremont, California 94539, U.S.A. Tel: [1] (800) 726-3364 Weighing Support:[1] (888) 726-5931 Inspection Support:[1] (855) 332-8815 A&D INSTRUMENTS LIMITED...

Need help?

Do you have a question about the AD-4401A and is the answer not in the manual?

Questions and answers