Summary of Contents for WhisperPower M-SQ Pro

- Page 1 User Manual Marine Diesel Generator M-SQ Pro E n j o y G r e e n E n e r g y 15 kVA | 18 kVA | 1800 RPM | 240/120 VAC | 60Hz | Split phase whisperpower.com...

-

Page 2: Table Of Contents

M-SQ PRO 15/18 kVA 60 Hz Marine Diesel Generator CONTENTS INTRODUCTION ....................4 General ........................4 Service and maintenance ..................4 Guarantee ......................4 Liability ........................5 1.5 Identification ......................5 1.5.1 General ........................5 1.5.2 Identification plate ....................5 INFORMATION ....................6 Safety ........................ - Page 3 M-SQ PRO 15/18 kVA 60 Hz Marine Diesel Generator 2.5.25 Lay out control wiring M-SQ PRO 18 3-Phase Kubota ........27 2.5.26 Lay out control wiring M-SQ PRO 18 3-Phase Kubota ........28 2.5.27 Lay out control wiring M-SQ PRO 18 3-Phase Kubota ........29 OPERATION ....................30 General ........................30 3.2 Operating Instructions ................... 30 3.2.1 Summarized operating instructions (daily use) ............. 30 3.2.2 Extended operating instructions ................30 MAINTENANCE ....................32 4.1 Alternator ....................... 32 4.2 Engine ........................

-

Page 4: Introduction

M-SQ PRO 15/18 kVA 60 Hz Marine Diesel Generator 1 INTRODUCTION Guarantee General WhisperPower guarantees that this generating set has been built according to good workmanship, according to the spec- The M-SQ Pro 15 and M-SQ Pro 18 Marine Diesel Generating sets ifications in this manual and according to European Commu- are manufactured and marketed by WhisperPower. nity safety regulations. It is important to read this manual before installing and operating During production and prior to delivery, all of our generating the generating set. Both safety and durability rely very much on sets are tested and inspected. the correct identification, installation and a good understanding of ratings, features, design, maintenance and operation proce- This generating set’s correct operation is subject to guar- dures. antee. The period and conditions of this guarantee are laid down in the general conditions of delivery as registered with The information, specifications, illustrations and statements con- the Chamber of Commerce and Industries for the North of tained within this publication are given with our best intentions the Netherlands number 01120025. The guarantee period and are believed to be correct at the time of going to press. is two years, limited to 1000 running hours. Some aspects of our guarantee scheme are given here in more detail: All of the specifications, provisions and instructions contained in this manual apply solely to standard versions of the M-SQ Pro 15 Guarantee does not cover failures that are caused by misuse, and M-SQ Pro 18 generating set. -

Page 5: Liability

Made in The Netherlands Manufacturer: WhisperPower b.v. Kelvinlaan 82, 9207 JB Drachten, The Netherlands Tel. +31 (0)512-571550 WhisperPower cannot be held responsible for damage caused by the unattended running generator using the auto-start/stop mode or interval mode. Identification 1.5.1 General Fig.2: Location identification plate... -

Page 6: Information

M-SQ PRO 15/18 kVA 60 Hz Marine Diesel Generator 2.1.2 Electrical safety VOLTAGE. This shows the nominal voltage. This voltage should be within the specified tolerance at This warning sign indicates parts which could be live. the nominal frequency. The Generator can be connect- The voltage of 230V or 240/120VAC generated by this ed for different voltages in split phase or three phase. generating set is dangerous and if instructions and The nameplate indicates the connection as made in the procedures are not strictly observed may result in factory. electrical shock which will result in severe personal FREQUENCY. This is shown in Hz and is determined by injury or loss of life. the speed of the engine (RPM). 60 Hz correlates with 1800 rpm. • Check all wiring at least once a year. Defects, such as CURRENT. This shows the maximum current that is ac- loose connections, burned cables etc. must be repaired ceptable at the specified frequency, voltage and power immediately. factor. When connected in three phase the indicated • Do not work on the electrical system if it is still connect- current is the current between two phases that can be ed to a current source. Only allow changes in your elec- taken off three times. trical system to be carried out by qualified electricians. -

Page 7: Installation

M-SQ PRO 15/18 kVA 60 Hz Marine Diesel Generator 2.1.4 Installation • Avoid refilling the fuel tank while the engine is running. Whisper generating sets are not self-contained and have to be When oil or fuel is leaking do not use the generating properly installed in enclosed areas such as a machine room. set. • Do not run the engine close to explosives or gases. Installation includes measures to be taken to outlet • Hydrogen gas generated by charging batteries is exhaust fumes which contain carbon monoxide and are explosive. Take measures for proper ventilation. Do extremely dangerous. not smoke or allow sparks, flames, or other sources of ignition around batteries. Carbon monoxide (CO) is an invisible odorless gas. Inhalation pro- • Keep a fire extinguisher on hand. duces headache, nausea or death. Installation includes measures • Poor electrical connections or using wiring which is not for proper ventilation, safe electric connections, safe installation suited for the rated currents can cause overheating and of the starting battery, proper fitting of the cooling system and possibly fire. fuel pipes etc. See the installation manual. 2.1.7 Chemicals 2.1.5 Operation... -

Page 8: M-Sq Pro 15 And M-Sq Pro 18

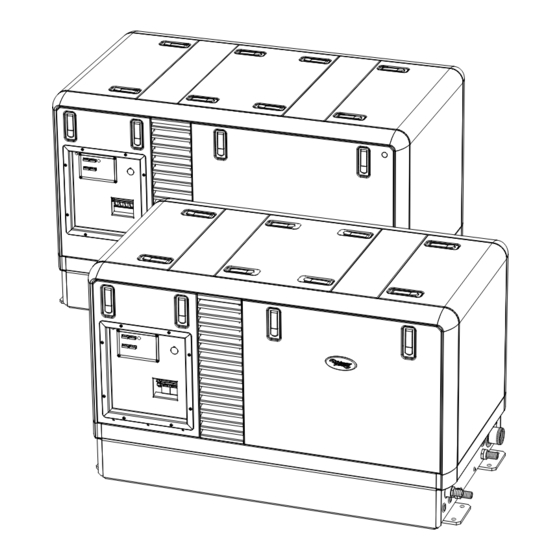

M-SQ PRO 15/18 kVA 60 Hz Marine Diesel Generator M-SQ Pro 15 and M-SQ Pro 18 2.3.1 Features This generating set includes a 4 cylinder diesel engine which is connected by close coupling to a one or tree phase synchronous alternator in a sound attenuated capsule. The set is mounted on a steel base frame and mounted securely on anti-vibration mounting pads to the capsule base. The complete set is again on rubber mountings. All cables and hoses are guided through the capsule’s sides. The set is not self-contained and is only operable after proper installation using additional accessories and installa- tion materials. Installation accessories are listed in the installation manual and are available through the supplier of the generating set. The full automatic Digital Control is based on microprocessor technology. Several automatic start/stop functions can be programmed and monitored (see Digital Diesel Control user manual). 2.3.2 Remote control The full automatic remote control panel including 15 mtr cable comes as standard with the Whisper generating M-SQ Pro 15 / 18. 2.3.3 Documentation Included in the delivery are: •... -

Page 9: Components

M-SQ PRO 15/18 kVA 60 Hz Marine Diesel Generator Components 2.4.1 Main components to identify 19. Air filter Battery "black" 35mm² SQ- Pro 15 20. Oil fill Battery "red" 35mm² 21. Lifting eye Air inlet 22. V-belt Earth lug M10 23. - Page 10 M-SQ PRO 15/18 kVA 60 Hz Marine Diesel Generator Air filter Battery "black" 35mm SQ- Pro 18 Oil fill Battery "red" 35mm Accelerator Air inlet Waterpump Earth lug M10 13 (8x) V-belt AC cable 3G 10mm (1phase) Oil filter AC cable 4G 6mm (2phase)

-

Page 11: Generator Control Panel

M-SQ PRO 15/18 kVA 60 Hz Marine Diesel Generator 2.4.2 Generator control panel Technical Information 2.5.1 AC alternator Start / Stop The synchronous alternator is directly coupled, one bearing, Internal fuel pump Digital Diesel Control brushless, rotating field design, 12 wire, four pole (1800 RPM) Fuse 3A Fuse 3A Remove fuse and regulated by an Automatic Voltage regulator (AVR). before maintenance The exciter stator has a residual magnetism, which guarantees self-exciting of the generator on start-up (that thereby generates Auxiliary External Fuel Pump a residual voltage of about 10% nominal voltage). -

Page 12: Battery Charger

M-SQ PRO 15/18 kVA 60 Hz Marine Diesel Generator 2.5.9 Hour counter Diesel Control user’s manual. The microprocessor unit of the Digital Diesel Control is located The remote control offers several timer functions that help to next to the alternator. schedule maintenance. 2.5.4 Battery charger 2.5.10 Load indicator On the engine is an alternator generating 40 Amp 12V. This On the remote control the load will be indicated on the display current is rectified to charge the battery. The voltage is regulated and by the LED-bar. The load is measured by current transform- at approx. 14.4V. ers on the alternator. All phases are monitored and overload of all phases or just one or two phases will provoke an alarm or 2.5.5 Alarms and shut down even shut down when the alarm is ignored. 2.5.11 Fuel specification In case of malfunctioning this will be indicated by the failure light, details will be shown on the display and the engine will be shut down. There are three functions guarded: oil pressure, oil The engine must only be used with diesel fuel oil which conforms temperature and exhaust temperature. -

Page 13: Cooling Liquid

M-SQ PRO 15/18 kVA 60 Hz Marine Diesel Generator 2.5.13 Cooling liquid The engine is cooled by cooling liquid. The capacity is: 4,0 ltr. for SQ Pro 15 / 8,1 ltr. for SQ Pro 18 A lways use coolant which is compatible with alumini- um components of the cooling system. Do not mix coolants with different kinds of chemical compound, as this may cause the refrigerant to freeze. In case of doubt refresh the content of the entire cooling system. Use only long-life type G12+ cooling liquid in order to minimize maintenance. We recommend not using water but cooling liquid that is market- ed for the use in combustion engines. Cooling liquid protects the engine against frost to minus 25° C. Also it protects the engine block against corrosion. One can fill the engine via the filling cap on the exhaust manifold. Fill up till the fluid is leveled with the indicator in the manifold (see fig 7 ). When the engine is on temperature the liquid will expand and the redundant liquid will be pressed into the expansion tank. This tank has to be filled up till the mark. When cooling liquid is not available clean fresh water could be used with an additive of anti-freeze. When using water with anti- freeze the right mixture has to be calculated according to the information of the supplier of the anti-freeze. When the cooling is based on keel cooling or radiator cooling the capacity of these coolers and piping has to be taken into account calculating the right mixture. The cooling liquid in the engine is pressurized and has a boiling point above 100° C. The temperature switch in the thermostat housing switches at 110° C. When keel cooling is applied the cooling system is not pressurized. There should be a special cap... -

Page 14: Technical Data

M-SQ PRO 15/18 kVA 60 Hz Marine Diesel Generator 2.5.14 Technical data M-SQ Pro 15 M-SQ Pro 18 GENERAL 1800 rpm 1800 Alternator 1 phase or 3 phase synchronous (air cooled) Engine Kubota diesel, model V1505 BG V2203 BG Number of cylinders Displacement 1498 cm3 2197 cm3 Bore X stroke 78,0 x 78,4 mm 87 x 92,4 mm Combustion air consumption 1,5 m³/min. 1,52 m³/min Continuous power 50 Hz 12 kW electric power 14 kW electric power Cooling system indirect cooling by raw water, 20-25 l/min. -

Page 15: Wiring Codes And Colors

M-SQ PRO 15/18 kVA 60 Hz Marine Diesel Generator 2.5.15 WIRING CODES AND COLORS WIRING COLOURS W-SQ Pro 15 Split Phase Origin Wire number Destination Section Color code -M1:+ -G3:+ 10 (mm²) -M1:+ 35 (mm²) -M1:+ -J1:+ 6 (mm²) -M1:+ -P1:J4 2.5 (mm²) -

Page 16: Lay Out Control Wiring M-Sq Pro 15 1-Phase Kubota

M-SQ PRO 15/18 kVA 60 Hz Marine Diesel Generator 2.5.16 Lay out control wiring M-SQ PRO 15 Split Phase Kubota... - Page 17 M-SQ PRO 15/18 kVA 60 Hz Marine Diesel Generator 2.5.17 Lay out control wiring M-SQ PRO 15 Split Phase Kubota...

-

Page 18: Lay Out Control Wiring M-Sq Pro 15 1-Phase Kubota

M-SQ PRO 15/18 kVA 60 Hz Marine Diesel Generator 2.5.18 Lay out control wiring M-SQ PRO 15 Split Phase Kubota Fig.8: Terminal modes... - Page 19 M-SQ PRO 15/18 kVA 60 Hz Marine Diesel Generator 2.5.19 Lay out control wiring M-SQ PRO 18 Split Phase Kubota Origin Origin Wire number Destination Section Color code Wire number -G1:BL - EXC - -J4:F- 1.5 (mm²) -Q1:1 L1-1 -G1:YL - EXC + -J4:F+ 1.5 (mm²)

-

Page 20: Lay Out Control Wiring M-Sq Pro 18 3-Phase Kubota

M-SQ PRO 15/18 kVA 60 Hz Marine Diesel Generator 2.5.20 Lay out control wiring M-SQ PRO 18 3-Phase Kubota Origin or code Wire number Destination Section Color code -Q1:1 -G1:L1 16 (mm²) L1-1 -J2:AC2 -X4:3 10 (mm²) L1-2 -Q1:3 -G1:L2 16 (mm²) - Page 21 M-SQ PRO 15/18 kVA 60 Hz Marine Diesel Generator 2.5.21 Lay out control wiring M-SQ PRO 18 Split Phase Kubota...

- Page 22 M-SQ PRO 15/18 kVA 60 Hz Marine Diesel Generator 2.5.22 Lay out control wiring M-SQ PRO 18 Split Phase Kubota...

- Page 23 M-SQ PRO 15/18 kVA 60 Hz Marine Diesel Generator 2.5.23 Lay out control wiring M-SQ PRO 18 Split Phase Kubota...

-

Page 24: Operation

M-SQ PRO 15/18 kVA 60 Hz Marine Diesel Generator 3 OPERATION Stopping generator: Switch off all electrical devices (consumers). If the generat- General ing set has been running under full load for a longer period, do not shut it down abruptly. Reduce the electrical load The generating set is operational after full installation and filling to about 30% of the rated load and let it run for approx. 5 minutes. up with: fuel, engine lubricating oil and cooling liquid, filling the starter battery with acid (WhisperPower batteries do not need to Press the STOP button. be filled up and are sealed), connecting the remote control panel. Close the inlet sea water cock. Switch to another 240/120VAC power source, if available. If a WhisperPower Switch is installed, this is done automat- ically. 3.2.2 Extended operating instructions Check when starting the first time or after a longer period of rest: If there is any damage caused by transport or installation. Check if installation conforms to the installation instruc- tions. Ensure the generating set is free to turn without obstruc- tion. Check all hoses and hose connections for leaks. - Page 25 M-SQ PRO 15/18 kVA 60 Hz Marine Diesel Generator In the event of starting problems (numerous attempts Do not run the generator for very long periods at no load or are made), close the sea-water inlet cock while at very low load. When this is necessary do load the gener- cranking to prevent the outlet system and engine to ator at least one hour in 10 hours for minimum 70%. Long fill up with water. term running at too low load will cause the exhaust to be During the starting process, the cooling water pump is driven choked by carbon. with the engine. The cooling water is discharged to the exhaust outlet, because the engine does not run, the exhaust pressure is N ever remove the battery while the engine is not high enough to expel this water. running or any electrical cable while the battery is connected in the circuit. Only disconnect the Open the valve immediately when the engine starts in order to battery with the engine stopped and all switches prevent damaging the impeller. in “OFF” position. Water in the cylinders will cause serious damage to the engine. Stopping the generating set: For instance; a bent piston rod or a cracked cylinder head. In fact water in the cylinder is the main cause for engine damage in pleasure craft. Avoid stopping of the generator abruptly after a long period of operation at high load! Doing so, you avoid unnecessary...

-

Page 26: Maintenance

M-SQ PRO 15/18 kVA 60 Hz Marine Diesel Generator 4 MAINTENANCE Alternator The alternator does not require any maintenance. Periodic in- spection and cleaning is recommended, depending on environ- mental conditions.However when the alternator has been idle for a long period attention to winding condition is recommended. The condition of windings can be assessed by measurement of insulation resistance to earth. (See 5.3.5 Meggering) The alternator bearing is greased for life and is therefore not regreasable. Engine Injection pump air bleeding screw Hand operated fuel lift pump 4.2.1 Preliminary instructions UNLESS OTHERWISE SPECIFIED: Fig.11: Bleeding fuel lines CHAMFER SHARP EDGES GENERAL TOLERANCE NEN ISO 2768-m... -

Page 27: Tensioning V-Belt

M-SQ PRO 15/18 kVA 60 Hz Marine Diesel Generator A smear of oil has to be put on the seal of the filter before fitting the filter. The filter should be fastened manually: when the rub- ber touches the metal turn 3/4 further. 4.2.6 Tensioning V-belt The alternator bracket allows for readjust of the V-belt. Deflec- tions should be 13 mm (see Fig. 15) DETAIL A Engine oil filter SCALE 1 : 3 Fig.15: Tension V-belt TOLERANCE PRINCIPE FINISH: UNLESS OTHERWISE SPECIFIED: DO NOT SCALE DRAWING ISO 8015 CHAMFER SHARP EDGES... -

Page 28: Maintenance Schedule

M-SQ PRO 15/18 kVA 60 Hz Marine Diesel Generator AFTER FIRST 50 HOURS: EVERY 2000 HOURS: • Change oil and replace the oil filter. • Check lubricating oil pressure. Have the engine run until it is on temperature and stop • Clean and check or replace fuel injector nozzles and it. Replace the filter. Drain oil by the sump pump into check injection pressure. a suitable retainer and fill up with fresh oil. Start the • Check the air cleaner element: engine again and have it run for 5 minutes. Stop the • The air is taken from the section between the alternator engine again and pause for a few minutes to let the oil and the engine gather in the crankcase. Check the level again and add • Check the cooling system: oil when necessary. • Check and tighten nuts, bolts, and unions, paying partic- The engine cooling liquid is indirectly cooled by ular attention to the fuel system. -

Page 29: Taking Out Of Service

M-SQ PRO 15/18 kVA 60 Hz Marine Diesel Generator 4.3.2 Taking out of service When not using the generating set for a longer period it is recommended to execute an engine preservation procedure. Clean the engine. Loosen the fuel suction pipe and fuel return and put them in a can with preservation diesel fuel. Start the en- gine and run the engine warm. Drain the hot engine oil and refill with preservation oil. Stop the engine and take loose the inlet of the raw water pump. Drain the water from the water lock. Crank the... -

Page 30: Troubleshooting

M-SQ PRO 15/18 kVA 60 Hz Marine Diesel Generator 5 TROUBLESHOOTING out measurements to investigate the cause of the failure. Alternator/ electrical faults Check if the engine is running correctly at 1800 RPM (50 Hz) CAUTION according to its settings and does as well under load. A RPM Remove 3 Amp. Fuse in the control panel while drop of 3% at full load is acceptable. Therefore a no load setting working on the generator to prevent the engine to should be at 1545 RPM = 51.5 Hz. Under no circumstances start. should the RPM under full load be below 1485 RPM = 49.5 Hz. When the problem is in the RPM refer to the engine fault finding paragraph. DANGER! Take care for parts which are live! Digital Diesel Control system will help to indicate failures and display causes. 5.1.1 General CAUTION If any problem should occur, check basic conditions and examine If the voltage is set any higher than its maximum limit, all external wiring, switch gear and circuit breakers. Also check the generator may be damaged. if measuring instruments give the correct value. If in doubt, measure directly on the alternator terminals with an indepen- dent instrument. This should only be carried out by an expe- rienced electrician. If during these measurements the engine... - Page 31 M-SQ PRO 15/18 kVA 60 Hz Marine Diesel Generator Tabel ECU signal pattern, these patterns can be read out on the red light of Fig. 17 & 18...

-

Page 32: Troubleshooting Table

M-SQ PRO 15/18 kVA 60 Hz Marine Diesel Generator 5.1.2 Troubleshooting table PROBLEM CAUSE SOLUTION • Circuit breaker “off” or faulty main Check switches and fuses and measure directly on the alternator to exclude external fuse causes. Check fuse of the AVR • Faulty fuse of the AVR • Loss of residual magnetism Check the residual magnetism, temporally increase RPM with 15%. Try to and flash the alternator (see special procedures) No output (Voltage) at all • Low engine RPM. Check the engine RPM and adjust (see special procedures). • Faulty RPM. Check by independent excitation if the problem is in the AVR or in the windings and replace if necessary (see special procedures). • Engine is not reaching the rated See special procedures to readjust RPM. -

Page 33: Engine Faults

M-SQ PRO 15/18 kVA 60 Hz Marine Diesel Generator Engine faults CAUTION! When the engine is cranking, well starting problems almost Remove 3 Amp. fuse in the control panel while working always originate from lack of fuel or air bubbles in the fuel pipes. on the generator to prevent the engine from starting. CAUTION! W hen the engine does not start instantly, prolonged 5.2.1 General cranking can fill up the exhaust system with cooling water because of the water injected exhaust. When Most electrical problems relating to Voltage or Frequency are the water enters the cylinder through the valves this will bring due to wrong engine speed. severe damage to the engine. When the engine does not start and repeated cranking is necessary shut off the seawater inlet. Note that RPM and Hz are basically the same. Open the valve immediately after the engine has started. Use the problem solving table to find the cause of a wrong A failure code is displayed when a hardware failure at the engine speed. When there is no obvious cause one can adjust the generator is detected. RPM (see special procedures). When the engine is not cranking well, starting problems almost always originate from battery problems or poor battery cable connections. Failure code... -

Page 34: Troubleshooting Table

M-SQ PRO 15/18 kVA 60 Hz Marine Diesel Generator 5.2.2 Troubleshooting table PROBLEM CAUSE SOLUTION Check on water in the cylinder and further • Almost certainly this is an electrical damage by cranking. When there is water in problem. One other possibility is the cylinder, then deactivate the control sys- that the engine is locked by water tem, disconnect the battery, remove the glow in the cylinders or there is other plugs. Crank the engine to remove the water Diesel engine fails to crank, it severe damage. Display will indicate through the opening of the glow plugs. Check does not react at all, or the start- oil on the presence of water and change oil. “low battery voltage”. er makes clicking noises, or the Find out how the water did enter the cylinder engine cranks very slowly (check the air vent). Take precautions to pre- vent it from happening again. When there is no mechanical malfunction the problem must be an electric malfunction. • Starter battery switched “OFF”. - Page 35 M-SQ PRO 15/18 kVA 60 Hz Marine Diesel Generator • Air in the fuel pipes Bleed air from fuel system (see maintenance section). • Blocked injector. Have the necessary injector tested and cleaned if necessary Engine runs irregularly. • Wrong valve clearance. Adjust valve clearance. • Temporarily hunting (this will disap- pear when engine has run in). • Too much oil. Drain oil to proper level. • Lack of fuel. Check fuel supply system: fuel pump and filter. • Lack of intake air. Check air intake. • Choked exhaust system, exhaust Check exhaust system.

- Page 36 M-SQ PRO 15/18 kVA 60 Hz Marine Diesel Generator • Generator is being overloaded. Check electrical load and switch off some consumers Digital Diesel Control will indicate “overload”. • Insufficient intake air. Check intake air paths and filter, clean and replace if necessary. • Choked air cleaner. • Fuel injector faulty. Replace injector. Sooty, black exhaust. • Valve clearance incorrect. Readjust valve clearance • Poor fuel quality. Use better quality diesel. • Poor quality lubricating oil. Use better quality oil. • Continuous running with very low Increase load and have the engine run for a few hours load. • Wrong measurement. Check if the load is measured correctly. Does the Amp meter...

-

Page 37: Warnings

M-SQ PRO 15/18 kVA 60 Hz Marine Diesel Generator 5.2.3 Warnings CAUTION! Generator must be shut off immediately if: • Motor RPM suddenly rises or drops. • Unusual noise comes from generating set. • Exhaust gases suddenly colour dark. • Engine failure warning light is on. 5.2.4 Service address If you cannot correct a problem with the aid of the mal- function table, contact your WhisperPower Service Centre or Whisper- Power Netherlands, tel: INT+31-512-571555. www.whisperpower.com. Fig.19: Automatic Voltage Regulator (AVR) Special procedures alternator Setting the bottom speed at 50 (60)Hz: start up rotation of the generating set adjusting it to obtain a frequency of 46 (56) Hz. 5.3.1 Automatic Voltage Regulator (AVR) Turn trimmer “Hz” until the voltage begins to drop. Restore... -

Page 38: Testing Rotary Rectifier Diodes

M-SQ PRO 15/18 kVA 60 Hz Marine Diesel Generator 5.3.4 Winding resistant values When using the starter battery fuse it and limit the current with a 30 Ohm resistor. Flashing can be done while the engine is run- If after establishing and correcting any fault on the AVR and ning and the wiring is connected. When a variac (variable power diodes, and output is still low when separately excited, then supply) is available one should be able to control the voltage the main rotor, stator auxiliary and exciter stator winding manually. resistance should be checked as the fault must be in one of these windings. The respective leads must be disconnected before taking the readings. Resistance values should be within 10% of the values given in the CAUTION table below: If the starter set battery is used for exciting one must take care. A short circuit can cause heavy sparking, fire Resistance M-SQ Pro 15/18 and injuries. Alternator Winding SQ Pro 15 SQ Pro 15 SQ Pro 18... -

Page 39: Adjusting Valve Clearance And Retightening The Cylinder Head Bolts

M-SQ PRO 15/18 kVA 60 Hz Marine Diesel Generator 5.4.2 Adjusting valve clearance and retightening the cylinder head bolts Both procedures have to be executed with a cold engine. When After adjusting the valves of cylinder 1 adjust the valve clearance both procedures are executed be sure to retighten the cylinder of the remaining cylinders in firing order 1-3-4-2 Turn the crank- head bolts before adjusting the valve clearance. When retight- shaft 180º clockwise from the T.D.C of cylinder 1 to the T.D.C of ening the cylinder head bolts, drain the coolant by removing the cylinder 3. Adjusts the valves of cylinder 3 and turn the crank- coolant drain plug shaft further clockwise to the T.D.C of cylinder 4 and finally to 2. 5.4.3 Measuring exhaust backpressure Loosen the bolts slightly, remove the rocker assembly (the rocker arms, shaft, and stays) and then retighten the bolts to the speci- fied torque in the numerical order illustrated (ref. to Fig.22). The exhaust system must be of adequate size - 1 1/2”/ 50 mm - and maximal length (see installation manual). When V1505 any doubt, backpressure has to be measured. An easy way to... -

Page 40: Disassembling Instructions

M-SQ PRO 15/18 kVA 60 Hz Marine Diesel Generator 5.4.4 Disassembling instructions It could be necessary for repair or checks to disassemble the generating set. Following instructions will help: The design of the M-SQ Pro 15/18 makes it possible to do most repairs on the spot. The heat exchang- er is accessible and can be removed. The connections of the alternator are very accessible as well. The sound shield canopy can be disassembled according to exploded view below. Fig.25: Exploded view soundshield Exploded view sound shield SQ Pro 15 / 18... - Page 41 To take the generating set out of the canopy all hose and cable connections have to be taken off. The set is fixed to its base by four rubber mountings and can be loosened by removing the four bolts of these mountings. The easiest way to get the generator out of its capsule is by lifting the set with the aid of the lifting eyes Taking the generator set from its mounting, or to replace a mounting can be done according to the drawing below Reassembling the generating set one should take care of alignment, cleaning the surfaces between engine and alter- nator and tighten the bolts crosswise and gradually. Test the generating set first outside its capsule and check very carefully for leakages before putting it back in its enclosure. DETAIL D SCALE 1 : 3 TOLERANCE PRINCIPE FINISH: UNLESS OTHERWISE SPECIFIED: DO NOT SCALE DRAWING ISO 8015 CHAMFER SHARP EDGES GENERAL TOLERANCE SHEET FORMAT: PROJECTION : THIRD ANGLE NEN ISO 2768-m UNITS : mm FORM AND PLACE TOLERANCES...

-

Page 42: Spare Parts

Oil filter GV15 / GV3 PLUS / SQ15 - K 40403138 Gasket Thermostat housing GV2/SQ15 PRO K 40201634 Gasket Injector GV15 / GV3 PLUS / SQ Pro 15 50212170 Plug fuse 10A 32V ROOD 50212154 Plug fuse 3A 32V VIOLET 40406120 V belt SQ Pro 15 50209243 Temperature switch 110ºC M16X1.5 NC assy 40201645 Thermostat GV15 / GV3 PLUS / SQ Pro 15 42401360 Spare Parts Kit-A SQ Pro 18 Article no. Description Quantity Quantity unit 40209030 Fuel Filter WP 40406121 Oil filter D1703/V2203 50212170 Plug fuse 10A 32V ROOD 50212154 Plug fuse 3A 32V VIOLET 40408120 V belt SQ Pro 18 You can find a more extensive Parts List on our website: whisperpower.com (fast moving parts) -

Page 43: 40201670 Raw Water Pump Sq Pro 15

40201670 Raw Water Pump SQ Pro 15... -

Page 44: 42401870 Raw Water Pump Sq Pro 18

42401870 Raw Water Pump SQ Pro 18... -

Page 45: Maintenance Log

7 MAINTENANCE LOG First Service After 50 Hours: Hour Counter: Remarks: Next Service (Every 150 Hours): Hour Counter: Remarks:... - Page 46 E n j o y G r e e n E n e r g y WhisperPower BV Kelvinlaan 82, 9207 JB Drachten The Netherlands www.whisperpower.com sales@whisperpower.com...

Need help?

Do you have a question about the M-SQ Pro and is the answer not in the manual?

Questions and answers