Summary of Contents for Miller Fusion 160

- Page 1 OM-279105H 2022-09 Processes Stick (SMAW) Welding Description Engine Driven Welder/Generator Fusion 160 OWNER’S MANUAL For product information, Owner’s Manual translations, and more, visit www.MillerWelds.com...

- Page 2 We know you don’t have time to do it any other way. That’s why when Niels Miller first started building arc welders in 1929, he made sure his products offered long-lasting value and superior quality.

-

Page 3: Table Of Contents

TABLE OF CONTENTS SECTION 1 – SAFETY PRECAUTIONS – READ BEFORE USING..............1 Symbol Usage . - Page 4 TABLE OF CONTENTS Reorienting Recoil Starter ................... 39 SECTION 10 –...

-

Page 5: Section 1 - Safety Precautions - Read Before Using

SECTION 1 – SAFETY PRECAUTIONS – READ BEFORE USING Protect yourself and others from injury—read, follow, and save these important safety precautions and operating instructions. 1-1. Symbol Usage DANGER! – Indicates a hazardous situation which, if not avoided, will result in death or serious injury. The possible hazards are shown in the adjoining symbols or explained in the text. - Page 6 Accidental contact of electrode to metal objects can cause sparks, ex- FLYING METAL OR DIRT can injure plosion, overheating, or fire. Check and be sure the area is safe be- eyes. fore doing any welding. � Welding, chipping, wire brushing, and grinding �...

-

Page 7: Engine Hazards

� Install cylinders in an upright position by securing to a stationary � Turn face away from valve outlet when opening cylinder valve. Do support or cylinder rack to prevent falling or tipping. not stand in front of or behind the regulator when opening the valve. -

Page 8: Compressed Air Hazards

1-4. Compressed Air Hazards � Reinstall doors, panels, covers, or guards when servicing is fin- COMPRESSED AIR EQUIPMENT can ished and before starting unit. injure or kill. � If ANY air is injected into the skin or body seek medical help immediately. - Page 9 � Follow the guidelines in the Applications Manual for the Revised HIGH PRESSURE FLUIDS can injure NIOSH Lifting Equation (Publication No. 94-110) when manually or kill. lifting heavy parts or equipment. � Engine fuel system components can be under high OVERHEATING can damage motors.

-

Page 10: California Proposition 65 Warnings

� If notified by the FCC about interference, stop using the equipment � Be sure all equipment in the welding area is electromagnetically at once. compatible. � Have the installation regularly checked and maintained. � To reduce possible interference, keep weld cables as short as �... -

Page 11: Section 2 - Consignes De Sécurité - Lire Avant Utilisation

SECTION 2 – CONSIGNES DE SÉCURITÉ - LIRE AVANT UTILISATION Pour écarter les risques de blessure pour vous-même et pour autrui — lire, appliquer et ranger en lieu sûr ces consignes relatives aux précautions de sécurité et au mode opératoire. 2-1. - Page 12 � Ne pas toucher aux portes-électrodes qui sont raccordés à deux bien ventilé, et en portant un respirateur à alimentation d’air. Les machines à souder en même temps, car cela entraîne la présence revêtements et tous les métaux renfermant ces éléments peuvent d’une tension de circuit-ouvert double.

-

Page 13: Dangers Existant En Relation Avec Le Moteur

� Ne pas souder là où l’air ambiant pourrait contenir des poussières, � Les porteurs d’implants médicaux doivent consulter leur médecin gaz ou émanations inflammables (vapeur d’essence, par et le fabricant du dispositif avant de s’approcher de la zone où se exemple). -

Page 14: Dangers Liés À L'air Comprimé

� Ne pas placer l’appareil sur, au-dessus ou à proximité de surfaces � Ne pas toucher aux pièces chaudes, utiliser les outils recomman- inflammables. dés et porter des gants de soudage et des vêtements épais pour éviter les brûlures. � Tenir à distance les produits inflammables de l’échappement. LA VAPEUR ET LE LIQUIDE DE Les PIÈCES MOBILES peuvent REFROIDISSEMENT CHAUD peuvent... -

Page 15: Symboles De Dangers Supplémentaires En Relation Avec L'installation, Le Fonctionnement Et La Maintenance

L’AIR COMPRIMÉ risque de Les PIÈCES MOBILES peuvent provoquer des blessures ou même la causer des blessures. mort. � S’abstenir de toucher des parties mobiles telles � Avant d’intervenir sur le circuit d’air comprimé, que des ventilateurs, courroies et rotors. couper l’alimentation électrique, verrouiller etéti- �... - Page 16 � Utiliser uniquement des équipements adéquats pour un fonction- � Régler les commandes de charge de batterie sur la position d’arrêt nement avec une alimentation de 50/60 ou de 60 Hz. avant de brancher la batterie. Veiller à ce que les pinces de charge ne se touchent pas.

-

Page 17: Proposition Californienne 65 Avertissements

� Effectuer l’installation, l’entretien et toute intervention selon les LE SOUDAGE À L’ARC risque de manuels d’utilisateurs, les normes nationales, provinciales et de provoquer des interférences. l’industrie, ainsi que les codes municipaux. � L’énergie électromagnétique risque de provoquer LE RAYONNEMENT HAUTE des interférences pour l’équipement électronique FRÉQUENCE (H.F.) risque de sensible tel que les ordinateurs et l’équipement... - Page 18 les porteurs d’implants médicaux doivent être prises: par exemple, 5. Connecter la pince sur la pièce aussi près que possible de la des restrictions d’accès pour les passants ou une évaluation indivi- soudure. duelle des risques pour les soudeurs. Tous les soudeurs doivent ap- 6.

-

Page 19: Section 3 - Definitions

� Complete Parts List is available at www.MillerWelds.com SECTION 3 – DEFINITIONS Become trained and read the instructions before working on the Become trained and read the instructions before working on the machine or heating. machine or heating. 3-1. Additional Safety Symbol Definitions Safe85 2012 06 Safe85 2012 06 �... - Page 20 � Complete Parts List is available at www.MillerWelds.com Power Single Phase Suitable For Weld- Internal Protection ing In An Environ- Rating ment With An Increased Risk Of Electric Shock Reduced Rated No- Percent Load Voltage Line Connection Hertz OM-279105 Page 16...

-

Page 21: Section 4 - Specifications

Information About Default Weld Parameters And Settings NOTICE – Each welding application is unique. Although certain Miller Electric products are designed to determine and default to certain typical welding parameters and settings based upon specific and relatively limited application variables input by the end user, such default settings are for reference purposes only;... -

Page 22: Dimensions, Weights, And Operating Angles

A complete Parts List is available at www.MillerWelds.com A complete Parts List is available at www.MillerWelds.com � Complete Parts List is available at www.MillerWelds.com 1-3. Dimensions, Weights, And Operating Angles 4-7. Dimensions, Weights, And Operating Angles 1-3. Dimensions, Weights, And Operating Angles Dimensions Engine End Height... -

Page 23: Volt-Ampere Curve

� Complete Parts List is available at www.MillerWelds.com 4-9. Volt-Ampere Curve The volt-ampere curve shows the minimum and maximum voltage and amperage output capabilities of the welder/generator. Curves of all other settings fall between the curves shown. DC AMPERES 279102-A DC AMPERES 279102-A 1-6. -

Page 24: 4-11. Fuel Consumption

1-7. Fuel Consumption � Complete Parts List is available at www.MillerWelds.com A. Fuel Consumption While Welding 4-11. Fuel Consumption A. Fuel Consumption While Welding 1.00 Fuel Consumption While Welding 1.00 0.80 0.80 0.60 0.60 0.40 IDLE 0.40 IDLE 0.20 0.20 0.00 0.00 DC WELD AMPERES AT RATED DUTY CYCLE... -

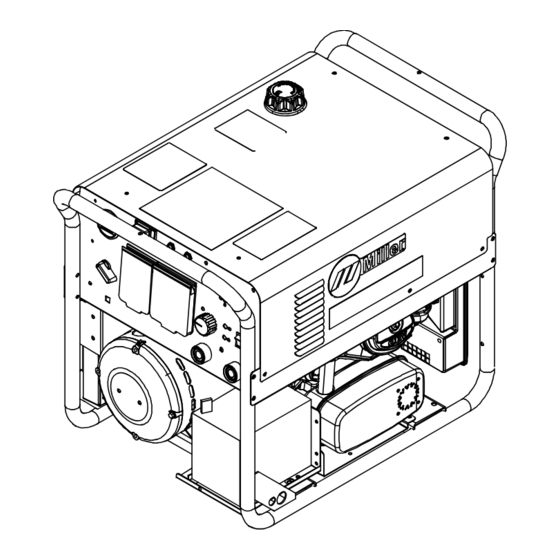

Page 25: Section 5 - Installation For Engine Power

� Complete Parts List is available at www.MillerWelds.com SECTION 5 – INSTALLATION FOR ENGINE POWER 5-1. Installing Welder/Generator 1-1. Installing Welder/Generator 1-1. Installing Welder/Generator Lifting Handles Use handles to lift unit. Lifting Handles 1 Lifting Handles Movement Hand Cart Use handles to lift unit. Use cart or similar device to move Use handles to lift unit. -

Page 26: Grounding Generator To Truck Or Trailer Frame

� Complete Parts List is available at www.MillerWelds.com 5-2. Grounding Generator to Truck or Trailer Frame 1-1. Grounding Generator To Truck Or Trailer Frame GND/PE Bed liners, shipping skids, and 1 Equipment Grounding Terminal (On Always ground generator frame to some running gear insulate the Front Panel) vehicle frame to prevent electric... -

Page 27: Fuel Valve Positions

� Complete Parts List is available at www.MillerWelds.com 5-4. Fuel Valve Positions 1 Fuel Valve � Always close fuel valve after stopping unit. Moving unit may cause carburetor flooding and make starting difficult. 268 699 / 267 206 5-5. Connecting The Battery Turn Engine Switch to Off. -

Page 28: Engine Prestart Checks

� Complete Parts List is available at www.MillerWelds.com 5-6. Engine Prestart Checks Check all fluids daily. Engine must be cold and on a level surface. Unit is shipped with 10W-50 synthetic engine oil. 1 Fuel Valve Open valve. � Close fuel valve before moving unit or carburetor may flood and make starting difficult. -

Page 29: Weld Output Terminals

A complete Parts List is available at www.MillerWelds.com � Complete Parts List is available at www.MillerWelds.com Weld Output Terminals 5-7. Weld Output Terminals Stop engine before connecting to weld output terminals. Do not use worn, damaged, under- sized, or repaired cables. 1 Positive (+) Weld Output Terminal 2 Negative (-) Weld Output Terminal Direct... -

Page 30: Section 6 - Installation For Utility Power

� Complete Parts List is available at www.MillerWelds.com A complete Parts List is available at www.MillerWelds.com SECTION 6 – INSTALLATION FOR UTILITY POWER SECTION 2 INSTALLATION FOR UTILITY POWER 6-1. Selecting A Location 2-1. Selecting A Location Do not move or operate unit where dimension and weight and rating la- Movement it could tip. -

Page 31: Multi-Voltage Plug (Mvp) Connection

� Complete Parts List is available at www.MillerWelds.com 6-2. Multi-Voltage Plug (MVP) Connection Selecting Plug Connecting Plug To Power Cord Ref. 803812-C Ref. 803812-C 2 Plug - NEMA Type 5-15P Connecting Plug To Power Cord Do not cut off power cord connector and rewire. -

Page 32: Electrical Service Guide

� Complete Parts List is available at www.MillerWelds.com 6-3. Electrical Service Guide Failure to follow these electrical service guide recommendations could create an electric shock or fire hazard. These recommen- dations are for an individual branch circuit sized for the rated output and duty cycle of one welding power source. In individual branch circuit installations, the National Electrical Code (NEC) allows the receptacle or conductor rating to be less than the rating of the circuit protection device. -

Page 33: Connecting 120 Volt Input Power

� Complete Parts List is available at www.MillerWelds.com 6-5. Connecting 120 Volt Input Power For 120 volts AC input power, a 15 or 20 am- 2 Plug From Unit Installation must meet all National pere individual branch circuit protected by and Local Codes —... -

Page 34: Connecting 1-Phase Input Power

� Complete Parts List is available at www.MillerWelds.com A complete Parts List is available at www.MillerWelds.com 6-6. Connecting 1-Phase Input Power Connecting 1-Phase Input Power For 240 VAC Installation must meet all National and Local Codes—have only quali- fied persons make this installation. Disconnect and lockout/tagout in- put power before connecting input conductors from unit. -

Page 35: Section 7 - Operation

SECTION 3 OPERATING THE WELDER/GENERATOR � Complete Parts List is available at www.MillerWelds.com SECTION 7 – OPERATION 3-1. Front Panel Controls 7-1. Front Panel Controls 279652-B 1 Engine Control Switch dig threshold is lowered, resulting in less dig � Always close fuel valve after stopping current added and a softer arc. -

Page 36: Section 8 - Operating Auxiliary Equipment

� A complete Parts List is available at www.MillerWelds.com Complete Parts List is available at www.MillerWelds.com SECTION 8 – OPERATING AUXILIARY EQUIPMENT SECTION 4 OPERATING AUXILIARY EQUIPMENT 8-1. Generator Power Panel Receptacles 4-1. Generator Power Panel Receptacles 279652-B 2 Supplementary Protectors CB2 and CB3 RC1 supplies 60 Hz single-phase power at Use GFCI protection when operating weld/power speed. -

Page 37: Gfci Receptacle Information, Resetting, And Testing

� Complete Parts List is available at www.MillerWelds.com 8-2. GFCI Receptacle Information, Resetting, And Testing Use GFCI protection when operating If a ground fault is detected, the GFCI Reset Resetting GFCI Receptacles auxiliary equipment. If unit does not button pops out, and the circuit opens to dis- If a GFCI fault occurs, stop engine and dis- have GFCI receptacles, use GFCI- connect power to the faulty equipment. -

Page 38: Section 9 - Maintenance

� Complete Parts List is available at www.MillerWelds.com SECTION 9 – MAINTENANCE his flowchart is intended as a general guide only. Al- ways read and follow the safety information and specific 9-1. Routine Maintenance nstructions given elsewhere in this Technical Manual. Complete Parts List available at www.MillerWelds.com ways perform the following basic manufacturer. -

Page 39: Maintenance Label

� Complete Parts List is available at www.MillerWelds.com 9-2. Maintenance Label OM-279105 Page 35... -

Page 40: Servicing Air Cleaner

� Complete Parts List is available at www.MillerWelds.com 9-3. Servicing Air Cleaner Complete Parts List available at www.MillerWelds.com 8-3. Stop engine. Let cool. Stop engine. Let cool Complete Parts List available at www.MillerWelds.com NOTICE – Do not run engine without air NOTICE Do not run engine with- cleaner element or with dirty element. -

Page 41: Changing Oil

� 3X longer oil change interval. 300-hour oil change interval for Miller Electric Engine Drives with KOHLER gas engines. � Engineered exclusively for Kohler air cooled engines. (This oil is not available from other manufacturers.) � Full synthetic oil formulated specifically for extended oil change intervals in air-cooled engines �... -

Page 42: Adjusting Engine Speed

� Complete Parts List is available at www.MillerWelds.com 9-7. Adjusting Engine Speed tools/ PAPR allen_set flathead philips head wrench crescent wrench Respirator needlenose knife steelbrush nutdriver chippinghammer Phillips #2 bit nlee knockout punch PAPR Grinder right heavy-duty workclamp light-duty workclamp wirecutter frontcutter stripcrimp... -

Page 43: Reorienting Recoil Starter

� Complete Parts List is available at www.MillerWelds.com 9-8. Reorienting Recoil Starter Removing Recoil Starter 1 Recoil Starter 2 Screws 3 Blower Housing Remove screws securing starter to blower housing. Remove starter assembly. Orient starter in desired position. Installing Starter Install retractable starter onto blower hous- ing, leaving screws slightly loose. -

Page 44: Section 10 - Troubleshooting

Internal temperature of welder has exceeded the Wait for unit to cool down. If the fan is not run- maximum limit. ning, contact Miller Electric Mfg. LLC service department. Overtemp LED blinks 2 times. Primary voltage is above 310 volts. - Page 45 The primary boost has not successfully been Cycle power to clear error. If this error persists established. after a power cycle, contact Miller Electric Mfg. LLC service department. Overtemp LED blinks 9 times. The two microcontrollers on the control board Cycle power to clear error.

- Page 46 � Complete Parts List is available at www.MillerWelds.com Trouble Remedy Have Factory Authorized Service Agent check low oil level shutdown switch. Engine stopped during normal Check fuel level (see Section 5-6). operation. Open fuel valve (see Section 5-6). Close fuel valve before moving unit or carburetor may flood and make starting difficult.

-

Page 47: Section 11 - Parts List

� Complete Parts List is available at www.MillerWelds.com SECTION 11 – PARTS LIST 11-1. Recommended Spare Parts Item No. Dia. Mkgs. Part No. Description Quantity 268467 Spark Plug, Kohler (CH440) 268468 Filter, Air (Kohler CH440) 246110 Filter, Fuel In-line .250 Kohler 75um 290693 Kohler Pro 10W-50 (Quart) (300 Hour) 021718... -

Page 48: Section 12 - Electrical Diagrams

SECTION 12 – ELECTRICAL DIAGRAMS Figure 12-1. Circuit Diagram For Welder/Generator OM-279105 Page 44... - Page 49 OM-279105 Page 45...

-

Page 50: Section 13 - Generator Power Guidelines

SECTION 13 – GENERATOR POWER GUIDELINES � The views in this section are intended to be representative of all engine-driven welder/generators. Your unit may differ from those shown. 13-1. Selecting Equipment 1 Generator Power Receptacles – Neutral Bonded To Frame 2 3-Prong Plug From Case Grounded Equipment 3 2-Prong Plug From Double Insulated... - Page 51 13-3. Grounding When Supplying Building Systems 1 Equipment Grounding Terminal 2 Grounding Cable GND/PE Use #8 AWG or larger insulated copper wire. 3 Ground Device � Use ground device as stated in electri- cal codes. Ground generator to system earth ground if supplying power to a premises (home, shop, farm) wir- ing system.

- Page 52 13-5. Approximate Power Requirements For Industrial Motors Industrial Motors Rating Starting Watts Running Watts Split Phase 1/8 HP 1/6 HP 1225 1/4 HP 1600 1/3 HP 2100 1/2 HP 3175 Capacitor Start-Induction Run 1/3 HP 2020 1/2 HP 3075 3/4 HP 4500 1400 1 HP...

- Page 53 Farm/Home Equipment Rating Starting Watts Running Watts Refrigerator or Freezer 3100 Shallow Well Pump 1/3 HP 2150 1/2 HP 3100 1000 Sump Pump 1/3 HP 2100 1/2 HP 3200 1050 13-7. Approximate Power Requirements For Contractor Equipment Contractor Equipment Rating Starting Watts Running Watts Hand Drill...

- Page 54 13-8. Power Required To Start Motor 1 Motor Start Code 2 Running Amperage 3 Motor HP 4 Motor Voltage AC MOTOR VOLTS AMPS Step 1: Find code and use table to find kVA/ CODE HP. If code is not listed, multiply running am- PHASE perage by six to find starting amperage.

- Page 55 13-10. Typical Connections To Standby Power 1. Utility Electrical 2. Transfer Switch 3. Fused Disconnect 4. Welder/Generator Service Switch (If Required) Output 5. Essential Loads Have only qualified persons perform 1 Utility Electrical Service 4 Welder/Generator Output these connections according to all 2 Transfer Switch (Double-Throw) Generator output voltage and wiring must applicable...

- Page 56 13-11. Selecting Extension Cord (Use Shortest Cord Possible) A. Cord Lengths For 120 Volt Loads Use GFCI protection when operating auxiliary equipment. If unit does not have GFCI receptacles, use GFCI-protected extension cord. Do not use GFCI receptacles to power life support equipment. Maximum Allowable Cord Length In ft (m) for Conductor Size In AWG (mm Current (Amperes)

-

Page 57: Section 14 - Stick Welding (Smaw) Guidelines

SECTION 14 – STICK WELDING (SMAW) GUIDELINES tools/ 14-1. Stick Welding Procedure wrench crescent wrench allen_set flathead philips head wrench crescent wrench Weld current starts when electrode Tools Needed: touches workpiece. Weld current can damage elec- tronic parts in vehicles. Discon- nect both battery cables before welding on a vehicle. - Page 58 14-2. Electrode And Amperage Selection Chart 6010 DEEP 3/32 MIN. PREP, ROUGH HIGH SPATTER 6011 DEEP 6010 5/32 & 6013 EP,EN GENERAL 3/16 6011 7/32 SMOOTH, EASY, 7014 EP,EN FAST 1/16 LOW HYDROGEN, 7018 5/64 STRONG 3/32 FLAT SMOOTH, EASY, 7024 EP,EN 6013...

- Page 59 14-4. Positioning Electrode Holder 1 End View Of Work Angle Groove Welds 2 Side View Of Electrode Angle After learning to start and hold an arc, prac- tice running beads of weld metal on flat 10 -30 10 -30 plates using a full electrode. Hold the electrode nearly perpendicular to the work, although tilting it ahead (in the di- rection of travel) will be helpful.

- Page 60 14-7. Conditions That Affect Weld Bead Shape Electrode Angle � Weld bead shape is affected by elec- trode angle, arc length, travel speed, and thickness of base metal. 1 Angle Too Small 2 Correct Angle 3 Drag 4 Angle Too Large 5 Too Short 6 Normal Arc Length...

- Page 61 14-9. Welding Lap Joints 1-1. Welding Lap Joints 1 Electrode 2 Single-Layer Fillet Weld 1-1. Welding Lap Joints Move electrode in circular motion. 3 Multi-Layer Fillet Weld Weld a second layer when a heavier fillet is needed. Remove slag before making anoth- er weld pass.

- Page 62 14-11. Welding T-Joints 1-3. Welding T-Joints 1/16 in. (1.6 mm) 1 Electrode 2 Fillet Weld Keep arc short and move at definite rate of speed. Hold electrode as shown to provide fusion into the corner. Square edge of the weld surface. For maximum strength weld both sides of up- 1-3.

- Page 63 Excessive Spatter - scattering of molten metal particles that cool to solid form near weld bead. Possible Causes Corrective Actions Amperage too high for electrode. Decrease amperage or select larger electrode. Arc length too long or voltage too high. Reduce arc length or voltage. Incomplete Fusion - failure of weld metal to fuse completely with base metal or a preceding weld bead.

- Page 64 Distortion - contraction of weld metal during welding that forces base metal to move. Illustration: Base metal moves in the direction of the weld bead. Possible Causes Corrective Actions Excessive heat input. Use restraint (clamp) to hold base metal in position. Make tack welds along joint before starting welding operation.

- Page 65 Notes...

- Page 66 Notes...

- Page 67 Effective January 1, 2022 (Equipment with a serial number preface of NC or newer) This limited warranty supersedes all previous Miller warranties and is exclusive with no other guarantees or war- ranties expressed or implied. � Field Options (NOTE: Field options are cov-...

- Page 68 Appleton, WI 54914 USA tact your distributor and/or equipment manu- facturer’s Transportation Department. International Headquarters–USA USA Phone: 920-735-4505 USA & Canada FAX: 920-735-4134 International FAX: 920-735-4125 For International Locations Visit www.MillerWelds.com ORIGINAL INSTRUCTIONS – PRINTED IN USA © Miller Electric Mfg. LLC 2022-09...

Need help?

Do you have a question about the Fusion 160 and is the answer not in the manual?

Questions and answers

How do you disconnect engine from generator on a miller 160 fusion

To disconnect the engine from the generator on a Miller Fusion 160, remove the spark plugs or injectors to prevent the engine from kicking back or starting. Then block the flywheel so it cannot turn while working on generator components.

This answer is automatically generated