Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for ARB Airlocker RD152

- Page 1 RD152 TOYOTA 9.5”, 32 SPLINE AIR OPERATED LOCKING DIFFERENTIAL INSTALLATION GUIDE...

- Page 2 No liability is assumed for damages resulting in the use of the information contained herein. ARB AIR LOCKER Locking Differentials and AIR LOCKER are trademarks of ARB Corporation Limited. Other product names used herein are for identification purposes only and may be trademarks of their respective owners.

-

Page 3: Table Of Contents

Table of Contents: 1 Introduction 1.1 Pre-Installation Preparation 1.2 Tool-Kit Recommendations 2 Removing the Existing Differential 2.1 Vehicle Support 2.2 Differential Fluid Drain 2.3 Removing the Axles 2.4 Marking the Bearing Caps 2.5 Checking the Current Backlash Amount 2.6 Removing the Differential Carrier 3 Installing the Air Locker 3.1 Mounting the Ring Gear 3.2 Installing the Carrier Bearings... -

Page 5: Introduction

Although your ARB Air Locker comes complete with all the step by step instructions you will need to supplement your vehicle manufacturer’s service manual and install your new differential, ARB recommends that you have your Air Locker installed by a trained professional. -

Page 6: Tool-Kit Recommendations

A gasket sealant or replacement gasket for your third member. A sufficient volume of differential oil to completely refill your housing. (See the ARB Air Locker Operating and Service Manual for recommended lubricants) A soap and water mixture to test for air leaks. -

Page 7: Removing The Existing Differential

Any misalignment of the axle tubes may result in excessive wear and/or failure of your differential and axle shafts. ARB strongly recommends that you have your axle assembly inspected for concentricity and straightness before... -

Page 8: Marking The Bearing Caps

2 Removing the Existing Differential Marking the Bearing Caps Using a small pointed center punch, gently mark the bearing caps in a way that will enable you to know which cap is ‘LEFT’ and which cap is ‘RIGHT’, which way is ‘UP’ and which way is ‘DOWN’. (Fig.1.) ... -

Page 9: Checking The Current Backlash Amount

2 Removing the Existing Differential Checking the Current Backlash Amount IMPORTANT: This step is a precautionary measure recommended by ARB due to the fact that some after market ring and pinion sets have been manufactured to run with different backlash settings than those specified by your vehicle manufacturer. -

Page 10: Removing The Differential Carrier

2 Removing the Existing Differential Removing the differential carrier Remove the adjuster nut locking tabs. Remove the bearing caps from the third member. Remove the adjuster nuts. Carefully remove the differential carrier from the third member. ... -

Page 11: Installing The Air Locker

3 Installing the Air Locker Mounting the Ring Gear Remove the bolts that hold the ring gear in place. Using a plastic or copper hammer, tap in a circle around the ring gear to separate it from the differential carrier. ... - Page 12 3 Installing the Air Locker Figure 4.

-

Page 13: Installing The Carrier Bearings

3 Installing the Air Locker Installing the Carrier Bearings Apply a thin film of high pressure grease to the bearing journals of the Air Locker, then press the bearing cones onto the bearing journals as shown in Figure 5. Figure 5. -

Page 14: Drilling And Tapping The Bulkhead Port

3 Installing the Air Locker Drilling and Tapping the Bulkhead Port In order to route the seal housing tube correctly, a hole needs to be drilled through the housing at the base of the bearing cap, and an air line port must be drilled and tapped through the differential housing to mount the bulkhead fitting into. - Page 15 3 Installing the Air Locker Figure 7. Figure 8.

- Page 16 3 Installing the Air Locker Cover the drive pinion area with a rag to protect it from metal filings. Secure the differential housing to the work bench. Drill an 8mm [5/16”] diameter hole through the housing at the base of the bearing cap, as per Figure 6.

-

Page 17: Setting Up The Bulkhead Fitting

3 Installing the Air Locker Setting up the Bulkhead Fitting Apply thread sealant to the outside threads of the bulkhead body. Screw the bulkhead body into the tapped hole, and lightly tighten using a 14mm [9/16”] spanner. Wipe the area clean of any excess thread sealant (inside and outside of the housing). - Page 18 3 Installing the Air Locker From the outside of the housing, assemble one of the small O-rings over the top of the short length of seal housing tube protruding through the bulkhead fitting. Install the brass spacer. Install the second small O-ring after the spacer. ...

-

Page 19: Final Air Locker Assembly

3 Installing the Air Locker Final Air Locker Assembly Clean all parts of the differential assembly, paying particular attention to the seal housing journal. Place the Air Locker into the differential housing and install the bearing caps. NOTE : Be sure to check that the bearing caps are on the correct sides of the third member and are correctly aligned. -

Page 20: Checking The Backlash

3 Installing the Air Locker Checking the Backlash Set a depth indicator on one of the ring gear teeth. (Fig.11.) While supporting the pinion gear by holding the drive shaft flange, rotate the differential in both directions while observing the maximum variation in depth from the indicator (i.e., the highest value minus the lowest value). -

Page 21: Installing The Seal Housing

3 Installing the Air Locker Installing the Seal Housing Make sure the grooves and airway of the seal housing are clean and free from any contaminants (e.g. water, dirt, metal filings, etc.). Inspect the seal housing O-rings (supplied) for dirt, damage or other conditions which might cause leaks. - Page 22 3 Installing the Air Locker Figure 12. Figure 13.

- Page 23 3 Installing the Air Locker Figure 14. Install the spring clip by first hooking both ends of the clip into the small aligned cutouts of the seal housing and the adjuster nut, and then snapping the clip into the groove of the seal housing using a screwdriver.

- Page 24 3 Installing the Air Locker Check that the seal housing is now secured from rotating and that it is still sitting flat against the adjuster nut. IMPORTANT: In order for the seal housing to float and self center on the bearing journal, the seal housing tube must not be pulling against the seal housing.

-

Page 25: Bench Testing The Air Locker

NOTE : An accurate way to test for air leaks is to fit a shut-off valve to an air pressure gauge (Available as ARB part #ALTG01). Charge with shop air until 620 KPA [90 PSI] is reached, shut the valve off, disconnect the air hose, and watch to see if there is any drop in pressure. -

Page 26: Reinstalling The Differential & Axles

3 Installing the Air Locker Reinstalling Differential and Axles Replace the paper gasket on the axle housing flange. Reinstall the third member to the differential housing according to your vehicle service manual. Reinstall the drive shaft. Replace the axle seals if necessary and fit to the axles. ... -

Page 27: Installing The Air System

4 Installing the Air System Mounting the Solenoid Connection to an ARB Air Compressor (Fig.17.) 4.1.1 Remove one of the 1/8” BSP plugs from its port in the compressor tank. Apply Teflon paste to the 1/8” BSP nipple on the solenoid and insert it into the port and tighten. - Page 28 For ease of installation, quality of air supply, and a high level of dependability from your Air Locker(s), ARB strongly recommends use of a genuine ARB Air Compressor, however, the Air Locker air system can be operated on any alternate air source that meets each of the following guidelines: ...

-

Page 29: Running & Securing The Air Line

4 Installing the Air System Running and Securing the Air Line The path taken by the air line from your air source (i.e., compressor) to your Air Locker is unique to your vehicle and the position of your air source. Plan ahead carefully when running the air line and always follow these guidelines: ... -

Page 30: Connection To The Bulkhead Fitting

4 Installing the Air System NOTE : To remove the air line from the push-in fitting; push the air line as far into the fitting as possible and hold, push inward on the flange, and then pull the air line free of the fitting. - Page 31 4 Installing the Air System Push the airline into the compression fitting body and screw the outer nut down onto it. Using a 12mm spanner, tighten the outer nut onto the compression fitting body. NOTE : Some force is required to crush the ferrule, however the outer compression nut will tighten against a stop.

-

Page 32: Mounting & Connecting The Electrical System

Switch(es) should not be mounted where they will be exposed to water (e.g., in the lower section of an inner door panel). ARB recommends that you apply the Air Locker Warning Sticker (ARB part # 210101) within close visual proximity of the switch location. -

Page 33: Wiring The Actuator System

Connection to an ARB AIR COMPRESSOR 5.2.1 When wiring the Air Locker actuator switch(es) and solenoid(s) to an ARB Air Compressor, all connections can easily be set up directly from the supplied wiring loom. (Fig.20.) NOTE : 180409 model loom shown for reference only. Refer to your ARB Air Compressor Installation Guide for details on configuring your installation. - Page 34 5 Mounting & Connecting the Electrical System SWITCH TERMINAL IDENTIFICATION Figure 21. Connection to an Alternate Air Source 5 .2.2 When connecting the actuation switch to an alternate air source, the switch(es) should be wired according to figures 22. and 23. depending on whether one or two Air Lockers will be installed in the vehicle.

- Page 35 5 Mounting & Connecting the Electrical System Dual Air Locker System 5.2.2.2 If two Air Lockers are to be installed in the system, ARB recommends that the switches and solenoids be wired according to figure 23. For safety reasons, this configuration allows SOLENOID 2 to be actuated only if SOLENOID 1 is already on.

-

Page 36: Testing & Final Assembly

6 Testing & Final Assembly Leak Testing With the vehicle parked and the engine off, turn the compressor on and wait until the air system is fully charged. NOTE : With the Air Locker(s) disengaged, the air source (i.e., compressor) should not have to recharge over time. -

Page 37: Filling The Differential

Rotate the same wheel. The wheels should again rotate in opposite directions. Filling the Differential NOTE : Consult the ARB Air Locker Operating & Service Manual for recommendations on differential lubricant specifications. Refill the differential until level with the filler hole. -

Page 38: Post-Installation Check List

6 Testing & Final Assembly Post-Installation Check List Now that the Air Locker installation has been completed, ARB recommends that you take the time to complete the following check list just to insure that you haven’t missed any of the vital steps. -

Page 39: Parts List

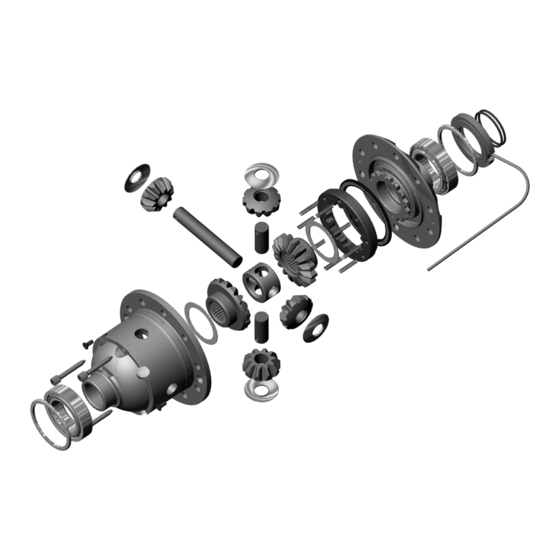

7 Parts List Toyota 9.5”,32 SPL RD152 Exploded Assembly Diagram (See itemized parts list overleaf) Figure 24. Specifications 32 tooth, Ø34.8mm [1.37”] Axle Spline Ratio Supported 150.0mm [5.91”] Ring Gear ID 241mm [9.5”] Ring Gear OD 12 bolts on Ø174mm [6.85”] Ring Gear Bolts Ring Gear Torque 95Nm [70 ft-lb]... -

Page 40: Itemized Parts List

For replacement O-rings use only Viton BS136 For replacement Bearings use Timken Bearing #32010X (ARB# 160116). Available only as complete 6 gear set # 728H201 Available only as complete thrust washer kit #730H01 All diffs produced before serial #17070001 came with 5mm air connection system.

Need help?

Do you have a question about the Airlocker RD152 and is the answer not in the manual?

Questions and answers