GEDA AB 450 Operating Manual

Rope winch for incorporation in a machine

Hide thumbs

Also See for AB 450:

- Operating manual (64 pages) ,

- Assembly and operating manual (52 pages) ,

- Assembly and operating manual (96 pages)

Subscribe to Our Youtube Channel

Summary of Contents for GEDA AB 450

- Page 1 Assembly and Instruction Manual Rope winch for incorporation in a machine Original operating manual...

- Page 3 ® Rope winch GEDA AB 450 / AB 650 BL094 GB Edition 03/2016 3 / 72 Assembly and Instruction Manual...

- Page 4 ® Rope winch GEDA AB450 / AB 650 Assembly and Instruction Manual 4 / 72 BL094 GB Edition 03/2016...

-

Page 5: Table Of Contents

Technical data ...................... 20 Operating and environmental conditions ............20 Rope winch GEDA AB 450 Item No. 24100 ..........21 Rope winch GEDA AB 450 Item No. 23152 ..........22 Rope winch GEDA AB 650 Item No. 23100 ..........23 Wire rope ...................... -

Page 6: Chapter Page

® Rope winch GEDA AB450 / AB 650 Chapter Page Maintenance - Checking - Cleaning ..............37 Inspections ..................... 37 8.1.1 Documenting the results ................38 8.1.2 Checks before initial operation ..............38 8.1.3 Checks after assembly / daily before starting operation ......38 8.1.4... -

Page 7: General Information

® Rope winch GEDA AB 450 / AB 650 General information Information about the instruction manual This instruction manual is an essential aid to operating the machine successfully and hazard-free. This instruction manual contains important instructions on how to operate the machine safely, correctly and efficiently. Compliance with these instructions helps to avoid hazards and increases the reliability and service life of the machine. - Page 8 ® Rope winch GEDA AB450 / AB 650 The structural elements in this instruction manual appear as follows and have the following meaning: Health and safety symbol This symbol is found next to all safety instructions where there is danger of injury or a fatality. Observe these instructions and be very...

-

Page 9: Abbreviations

® Rope winch GEDA AB 450 / AB 650 Abbreviations The following abbreviations may be used in the manual. max. maximum Newton metre min. minimum km/h kilometres per hour mins. minutes miles per hour etc. et cetera incl. including poss. -

Page 10: Information About The Machine

® Rope winch GEDA AB450 / AB 650 Information about the machine ® Machine model Rope winch GEDA AB450 Serial number: (400 V) 23152 ________________ (230 V) 24100 ________________ (400 V) 24340 ________________ (for side suspension and rope winding) ®... -

Page 11: Name And Address Of The Manufacturer

Violations are an offence and incur an obligation to pay compensation. All rights to exercise industrial property rights are reserved by GEDA. BL094 GB Edition 03/2016 11 / 72... -

Page 12: Instructions For The Operating Company

Any replacement and wearing parts that are used must correspond to the technical requirements stipulated by GEDA. This is guaranteed with original replacement parts. Only employ qualified and/or trained personnel for the tasks described in this manual. -

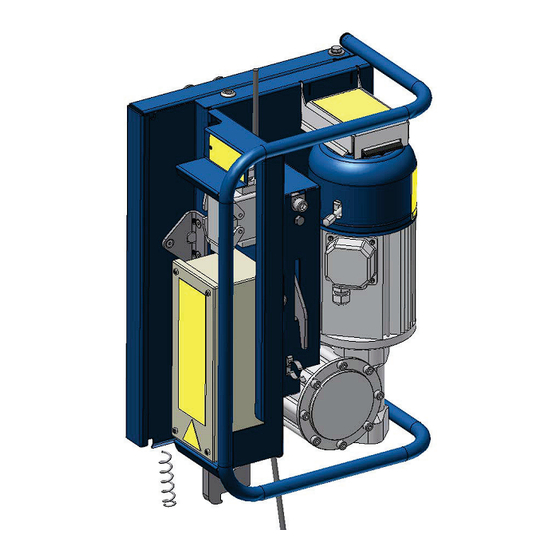

Page 13: Intended Use

Rope winch GEDA AB 450 / AB 650 Intended use The rope winches GEDA AB 450 and GEDA AB 650 constitute incomplete machines and are intended only for incorporation into a complete machine. An incomplete machine constitutes an entirety nearly forming a machine but which in itself is not able to meet a specific function. -

Page 14: Requirements Of Assembly Personnel

1.7.2 Improper use The rope winch GEDA AB 450 / AB 650 must not be operated without incorporation into a complete machine. must not be operated by people who have not been briefed on the machine, who are not familiar with the instruction manual or by children. -

Page 15: General Safety Information

® Rope winch GEDA AB 450 / AB 650 General safety information The incomplete machine has been designed and built according to the latest standards of technology and recognised safety-related rules. Nevertheless, hazards for personnel or third parties and/or damage to machinery and other tangible assets can occur during use, e.g. -

Page 16: Safety Instructions For Transport

® Rope winch GEDA AB450 / AB 650 Safety instructions for transport Immediately report transport damage and/or missing parts to the supplier. During transport work, wear a safety helmet, safety footwear and safety gloves! Never step under suspended loads! Only use appropriate, standardised and tested lifting gear, forklifts, cranes) and sling gear (round slings, lifting straps, rope slings, chains) for transport at the assembly site. -

Page 17: Safety Instructions For Servicing, Maintenance And Troubleshooting

® Rope winch GEDA AB 450 / AB 650 Safety instructions for servicing, maintenance and troubleshooting Operating personnel must be informed about how to carry out special work and maintenance work before they start. Deadlines that are stipulated or stated in the instruction manual for recurring tests/inspections must be adhered to. - Page 18 ® Rope winch GEDA AB450 / AB 650 Before starting servicing/repair tasks clean the machine, in particular connections and screw connections, from oil, operating fluids, contamination and maintenance products. Abrasive cleaning agents must not be used. Loosened screw connections during servicing and...

-

Page 19: Safety Whilst Working On The Electrics

® Rope winch GEDA AB 450 / AB 650 Safety whilst working on the electrics In the event of malfunctions of the electrical installations on the machine, immediately stop it by disconnecting the mains plug! Work on the electrical equipment of the machine must only be carried... -

Page 20: Technical Data

Technical data CAUTION General overhaul of the rope winches The rope winches GEDA AB 450 / AB 650 must undergo general overhaul every 500 hours of operation! The general overall must only be performed by the manufacturer or by a person authorised by the manufacturer. -

Page 21: Rope Winch Geda Ab 450 Item No. 24100

® Rope winch GEDA AB 450 / AB 650 Rope winch GEDA AB 450 Item No. 24100 Electrical connected loads Operating voltage 230 V/50 Hz / 1 Ph/N/PE Inline fuse 1 x 16 A (slow-blow) Control voltage 48 V Capacity 1.4 kW... -

Page 22: Rope Winch Geda Ab 450 Item No. 23152

® Rope winch GEDA AB450 / AB 650 Rope winch GEDA AB 450 Item No. 23152 Electrical connected loads Operating voltage 400 V/50 Hz / 3 Ph+N+PE Inline fuse 3 x 16 A slow-blow Control voltage 48 V Capacity 1.4 kW Current consumption (I 3.0 A... -

Page 23: Rope Winch Geda Ab 650 Item No. 23100

® Rope winch GEDA AB 450 / AB 650 Rope winch GEDA AB 650 Item No. 23100 Electrical connected loads Operating voltage 400 V/50 Hz / 3 Ph+N+PE Inline fuse 3 x 16 A slow-blow Control voltage 48 V Capacity 1.4 kW... -

Page 24: Wire Rope

51 kN Real breaking strength 53 kN WARNING Danger to life The rope winches GEDA AB 450 / AB 650 must only be operated using original GEDA ropes. Rope reel Drive Operating voltage 400 V / 50 Hz / 3 Ph +PE Capacity 0.18 kW... -

Page 25: Transport

® Rope winch GEDA AB 450 / AB 650 Transport WARNING Risk of injury The rope winch must be transported by experienced and competent persons. Inspection on receiving the scaffolding lift Check the shipment for transport damage and for completeness according to the purchase order. -

Page 26: Assembly

® Rope winch GEDA AB450 / AB 650 Assembly Assembly personnel, refer to Chapter 1.7.1 Mounting of the rope winch to the machine is described in the instruction manual of the finished machine! Mounting the rope winch Fastening points 2 x bolts for fastening the winch... -

Page 27: Mounting On The C-Clamp

® Rope winch GEDA AB 450 / AB 650 Examples for fastening 5.1.1 Mounting on the C-clamp Hook the traction hoist (1) into the latch (1A) and fold it up vertically. Now lower it. Pin the traction hoist (1) using a socket pin (2) and secure with a spring cotter (2A). -

Page 28: Mounting To The Winch Retainer

® Rope winch GEDA AB450 / AB 650 5.1.2 Mounting to the winch retainer Position the traction hoist (1) horizontally on the winch retainer (4) and swing upwards. Hook the traction hoist (1) on both bolts (1B) on the mounting sheet of the winch retainer (4). -

Page 29: Electrical Connection Of The Winch

® Rope winch GEDA AB 450 / AB 650 Electrical connection of the winch For electrical power supply requirements of the traction hoists, see Chapters 3.2, 3.3 and 3.4 (technical data). Special controls are available for the traction hoist for different applications in the machines. - Page 30 ® Rope winch GEDA AB450 / AB 650 EMERGENCY LIMIT limit switch for C clamp Plug in the connection line (3) to the EMERGENCY LIMIT limit switch. EMERGENCY LIMIT limit switch at winch retainer Plug in the connection line (3) to the EMERGENCY LIMIT limit switch.

-

Page 31: Assembling The Wire Rope

® Rope winch GEDA AB 450 / AB 650 Assembling the wire rope CAUTION Damage to the winch. Check rope for damage before introducing it. There must be no discernible protruding strands, kinks or deformations in the rope. (Criteria according to DIN ISO 4309) In the event of any noticeable noises or uneven retraction: Immediately pull out the rope and check the end of the rope or traction hoist. - Page 32 ® Rope winch GEDA AB450 / AB 650 SAFETY ROPE Push the lever (3) up to open the rope stop. The traction hoist must be in vertical position at this. Guide the rope (2) through the rope stop from above and pull it all the way through the rope stop by hand.

-

Page 33: Inspection After Assembly And Before Each Operation

® Rope winch GEDA AB 450 / AB 650 Inspection after assembly and before each operation Check to ensure that o the specified maintenance work and inspection procedures have been carried out. o the wire rope indicates no damage. o notices are present and legible (refer to Chapter 11) -

Page 34: Operation

® Rope winch GEDA AB450 / AB 650 Operation Functional description Handwheel Plug-in device for control Rope stop The rope winch must be mounted to the retainers provided on the respective machine. Operation uses external controls plugged into a plug-in device on the traction hoist. -

Page 35: Safety During Operation

® Rope winch GEDA AB 450 / AB 650 Safety during operation Also observe the safety instructions in Chapter 2. WARNING Danger to life Raised load! Do not stand under suspended loads. Only lift loads at the mooring points. Only use suitable slinging / load carrying equipment. -

Page 36: Operation Of The Rope Winch

® Rope winch GEDA AB450 / AB 650 Operation of the rope winch Different controls are available depending on the machine in which the rope winch is installed. Operation of these controls is outlined in the instruction manuals of the machines into which the traction hoist has been incorporated and where it is used. -

Page 37: Maintenance - Checking - Cleaning

® Rope winch GEDA AB 450 / AB 650 Maintenance - Checking - Cleaning WARNING The entire manual and instruction manual must be read for all maintenance/servicing tasks. It is not permitted to carry out tasks if the type and scope of the tasks are unclear, or the resulting hazards and actions to be initiated to avert hazards are unclear. -

Page 38: Documenting The Results

Recurring checks must be carried out in accordance with national regulations. GEDA recommends that you carry out a recurring check on an annual basis. In the event of increased demand (e.g. multiple shift operation), carry out checks at shorter intervals. -

Page 39: Checks After Extreme Weather Conditions

® Rope winch GEDA AB 450 / AB 650 8.1.5 Checks after extreme weather conditions Special check after temperatures of - 30 °C [-22° F] NOTE: If it is unclear whether the temperature fell below -30 °C [-22 °F], follow procedures as if this temperature had been reached when restarting the machine. -

Page 40: Maintenance Schedule

® Rope winch GEDA AB450 / AB 650 Maintenance schedule The inspections to be carried out on a daily basis before the start of operation are not included in the maintenance schedule. They are described in the instruction manual of the complete machine as these checks are carried out by the operating personnel. -

Page 41: Replenishment And Inspection Tasks

® Rope winch GEDA AB 450 / AB 650 WARNING Supplement the maintenance plan with details regarding maintenance/servicing/operating equipment/replacement/repair of component parts contained in the instructions provided by the suppliers. Replenishment and inspection tasks 8.3.1 Lubricate drive sprocket of winch Attach the grease gun to the nipple (1) and pump approx. -

Page 42: Wear And Function Checks

® Rope winch GEDA AB450 / AB 650 Wear and Function Checks 8.4.1 Motor / Motor brake Carry out the maintenance and servicing tasks as follows. Motor: Cleaning Check the ball bearing, replace as necessary (if conspicuous noises when operating) - Page 43 ® Rope winch GEDA AB 450 / AB 650 Readjustment: Switch off drive power supply. Unscrew the manual brake release bolts, loosen the fan cover fastening screws and remove fan cover. Pull dust protection ring out of the groove in the magnetic body and put over the motor end shield.

-

Page 44: Inspecting / Lubricating Wire Ropes

® Rope winch GEDA AB450 / AB 650 8.4.2 Inspecting / lubricating wire ropes WARNING Risk of injury when handling ropes/cables Always wear protective gloves when handling ropes. Lubricate the working rope CAUTION Only the drive rope must be lubricated! - Page 45 ® Rope winch GEDA AB 450 / AB 650 wire ropes Inspecting If a rope/cable is damaged, it must be replaced immediately. When evaluating the damage (state of wear), the criteria listed in standard DIN ISO 4309 can be used as an aid.

- Page 46 ® Rope winch GEDA AB450 / AB 650 Cable deformation Deformation of the wire cable means visible changes to the cable structure. If deformation is identified on the wire rope, it must be replaced immediately. Examples of cable deformation: Heald smashes...

-

Page 47: Guide Bushes At The Rope Inlet

® Rope winch GEDA AB 450 / AB 650 8.4.3 Guide bushes at the rope inlet Inspect guide bushing at entry point of drive and safety rope. Replace if damaged. 8.4.4 Check rope end control To test the rope end control... -

Page 48: Check Emergency Limit Limit Switch

® Rope winch GEDA AB450 / AB 650 8.4.7 Check EMERGENCY LIMIT limit switch The winch must stop immediately if the EMERGENCY LIMIT limit switch is operated. No drive is possible any more (both directions blocked). Limit switch on winch retainer... -

Page 49: Inspect Rope Stop

Inspect rope stop WARNING GEDA recommends that the rope stop be replaced with a GEDA rope stops (rope stop exchange unit) after 5 years at the latest. The rope stop test must only be carried out by a competent person... -

Page 50: Malfunctions - Diagnosis - Repair

® Rope winch GEDA AB450 / AB 650 Malfunctions - Diagnosis – Repair WARNING Troubleshooting and rectification of malfunctions only to be carried out by persons specially trained and authorized for this. If possible, before troubleshooting lower the load to the ground! -

Page 51: Malfunction Table

® Rope winch GEDA AB 450 / AB 650 Malfunction table In the following table you will find potential faults and the appropriate remedial action. Malfunction Cause Remedial action Winch does not Power cord unplugged Insert power cord operate Phase failure... -

Page 52: Malfunction Rectification

® Rope winch GEDA AB450 / AB 650 Malfunction rectification 9.2.1 Motor is not producing full output Voltage drop of more than 10% of the rated voltage. Select conductor line with larger cross-section. If overloaded, the integrated thermal switch turns off the control current. -

Page 53: Rope Stop Has Triggered

® Rope winch GEDA AB 450 / AB 650 9.2.3 Rope stop has triggered The rope stop automatically triggers when the drive rope breaks or if the working platform is slanted by more than 10°. The rope stop can be manually triggered by engaging the lever. -

Page 54: Checks And Release Of Rope Stop After Rope Break

® Rope winch GEDA AB450 / AB 650 9.2.4 Checks and release of rope stop after rope break NOTE The tests carried out following breakage of a rope are performed a short distance above the ground. The rope stop is pulled up when the rope stop is triggered after a rope break. - Page 55 ® Rope winch GEDA AB 450 / AB 650 Remove the protective cover of the rope stop. If damages are detected on the protective cover or rope stop, the protective cover or rope stop must be replaced immediately. Operation of the machine is prohibited until then.

- Page 56 ® Rope winch GEDA AB450 / AB 650 Mount the protective cover of the rope stop. The arrows on the winch (5) and protective cover (6) must point toward each other with their tips! Check after mounting the drive rope...

-

Page 57: Emergency Lowering

® Rope winch GEDA AB 450 / AB 650 9.2.5 Emergency lowering Emergency lowering allows controlled lowering of the machine in the event of a defect or power failure. Pull slightly on the brake lever (1) on the motor of the rope winch(es). - Page 58 ® Rope winch GEDA AB450 / AB 650 Rope stop has triggered in the event of a power failure As a result of this, no emergency lowering is possible. To carry out emergency lowering of the working platform/load, proceed as follows: Open the cover (2) over the motor.

-

Page 59: Repair

The identification plate is located on the trolley of the base unit. Spare parts must conform to the technical specifications of the manufacturer! Only use original spare parts from GEDA. For service or repair work, please contact our customer service department: For the sales and customer service address, refer to Chapter 1.4... -

Page 60: Disposal Of The Machine

® Rope winch GEDA AB450 / AB 650 Disposal of the machine Dismantle the equipment properly at the end of its service life and dispose of according to national provisions. Observe the following when disposing of equipment components: Drain and dispose of oil/grease in an eco-friendly way. -

Page 61: Documenting The Checks

® Rope winch GEDA AB 450 / AB 650 Documenting the checks Documentation for regular checks in accordance with the maintenance schedule recurring check in accordance with national rules unplanned check after specific events Name: Serial number: Year of construction: Serial number: The machine was checked on______________. - Page 62 ® Rope winch GEDA AB450 / AB 650 Documentation for regular checks in accordance with the maintenance schedule recurring check in accordance with national rules unplanned check after specific events Name: Serial number: Year of construction: Serial number: The machine was checked on______________. As a result...

- Page 63 ® Rope winch GEDA AB 450 / AB 650 Documentation for regular checks in accordance with the maintenance schedule recurring check in accordance with national rules unplanned check after specific events Name: Serial number: Year of construction: Serial number: The machine was checked on______________. As a result...

- Page 64 ® Rope winch GEDA AB450 / AB 650 Documentation for regular checks in accordance with the maintenance schedule recurring check in accordance with national rules unplanned check after specific events Name: Serial number: Year of construction: Serial number: The machine was checked on______________. As a result...

- Page 65 ® Rope winch GEDA AB 450 / AB 650 Documentation for regular checks in accordance with the maintenance schedule recurring check in accordance with national rules unplanned check after specific events Name: Serial number: Year of construction: Serial number: The machine was checked on______________. As a result...

- Page 66 ® Rope winch GEDA AB450 / AB 650 Documentation for regular checks in accordance with the maintenance schedule recurring check in accordance with national rules unplanned check after specific events Name: Serial number: Year of construction: Serial number: The machine was checked on______________. As a result...

- Page 67 ® Rope winch GEDA AB 450 / AB 650 Documentation for regular checks in accordance with the maintenance schedule recurring check in accordance with national rules unplanned check after specific events Name: Serial number: Year of construction: Serial number: The machine was checked on______________. As a result...

- Page 68 ® Rope winch GEDA AB450 / AB 650 Documentation for regular checks in accordance with the maintenance schedule recurring check in accordance with national rules unplanned check after specific events Name: Serial number: Year of construction: Serial number: The machine was checked on______________. As a result...

- Page 69 ® Rope winch GEDA AB 450 / AB 650 Space for notes Notice entered Name: / Date Position BL094 GB Edition 03/2016 69 / 72 Assembly and Instruction Manual...

- Page 70 ® Rope winch GEDA AB450 / AB 650 Space for notes Notice entered Name: / Date Position Assembly and Instruction Manual 70 / 72 BL094 GB Edition 03/2016...

- Page 72 GEDA-Dechentreiter GmbH & Co. KG Mertinger Strasse 60 86663 Asbach-Bäumenheim Tel.: +49 (0)9 06 / 98 09-0 Fax: +49 (0)9 06 / 98 09-50 E-Mail: info@geda.de Web: www.geda.de BL094 GB Edition 03/2016...

Need help?

Do you have a question about the AB 450 and is the answer not in the manual?

Questions and answers