Table of Contents

Advertisement

Quick Links

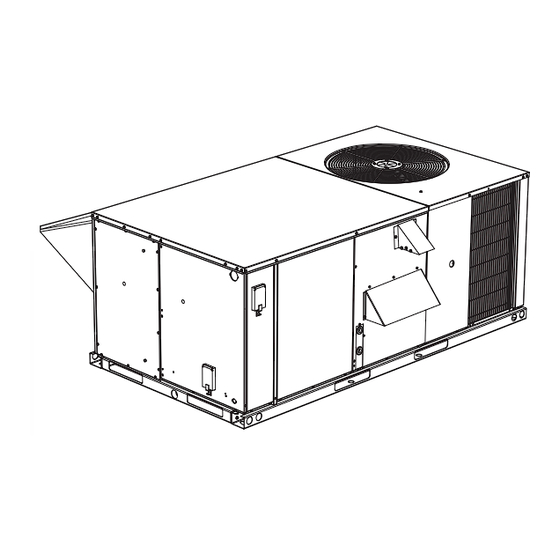

R-410A

ZD SERIES

3 - 6 Ton

60 Hertz

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Rigging And Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Ductwork . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Condensate Drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Compressors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Power And Control Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Typical Field Power and Control Wiring . . . . . . . . . . . . . . . . . . . . 15

Typical Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Typical Cool/Heat Control Wiring (Simplicity Lite ZD-03 through -

05) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

through -A6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Field Installed Electric Heat . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Options/Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

RRS Economizer Interface Overview . . . . . . . . . . . . . . . . . . . 35

Smart Equipment™ Economizer Sequences. . . . . . . . . . . . . . 36

Dry Bulb Changeover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Single Enthalpy Changeover . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Dual Enthalpy Changeover . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Auto . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

1 ZD-03 through -A6 Unit Limitations . . . . . . . . . . . . . . . . . . . . . 6

2 ZD-03 through -A6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 ZD-03 through -A6 Unit Accessory Weights . . . . . . . . . . . . . . 8

4 ZD-03 through -A6 Unit Clearances . . . . . . . . . . . . . . . . . . . 10

5 ZD-03 through -A6 Utilities Entry . . . . . . . . . . . . . . . . . . . . . . 11

6 Control Wire Sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7 Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

8 Electrical data: single-phase gas heat, belt drive . . . . . . . . . 29

9 ZD-03 through -A6 Physical Data . . . . . . . . . . . . . . . . . . . . . 30

10 Electric Heat Minimum Supply Air . . . . . . . . . . . . . . . . . . . . . 32

11 Gas Heat Application Data . . . . . . . . . . . . . . . . . . . . . . . . . . 32

12 Gas Pipe Sizing - Capacity of Pipe . . . . . . . . . . . . . . . . . . . . 33

13 Smart Equipment™ Economizer Board Details . . . . . . . . . . 38

14 Altitude/Temperature Correction Factors . . . . . . . . . . . . . . . 42

15 ZD Blower Performance Side Duct . . . . . . . . . . . . . . . . . . . . 45

16 ZD Blower Performance Bottom Duct . . . . . . . . . . . . . . . . . . 46

17 Belt Drive RPM Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

1 ZD-03 through -A6 Component Location . . . . . . . . . . . . . . . . 6

2 Unit 4 Point Load Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Unit 6 Point Load Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4 Center of Gravity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Hood Physical Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . 10

8 ZD-03 through -A6 Disconnect Location . . . . . . . . . . . . . . . 10

9 ZD-03 through -A6 Unit Side Duct Openings . . . . . . . . . . . . 11

10 ZD-03 through -A6 Roof Curb . . . . . . . . . . . . . . . . . . . . . . . 11

11 Condensate Drain. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

12 Compressor Restraining Bracket . . . . . . . . . . . . . . . . . . . . . 13

TABLE OF CONTENTS

Free Cooling Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Power Exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Checking Supply Air CFM . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Cooling Sequence Of Operation . . . . . . . . . . . . . . . . . . . . . . . 50

No Outdoor Air Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Cooling Operation Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Electric Heat Operation Errors . . . . . . . . . . . . . . . . . . . . . . . 52

Gas Heating Sequence Of Operations . . . . . . . . . . . . . . . . . . 53

Gas Heat Operation Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Flash Codes or Error Messages . . . . . . . . . . . . . . . . . . . . . . . 54

Resets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Heat Anticipator Setpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Start-up (Cooling) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Start-up (Gas Heat) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Checking Gas Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Start Up For Units Equipped for FER. . . . . . . . . . . . . . . . . . . . . . 57

Direct Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Belt Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Troubleshooting (Simplicity Lite Only) . . . . . . . . . . . . . . . . . . . . . 57

Fan On And Off Delays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Start-Up Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

LIST OF TABLES

18 Indoor Blower Specifications (Belt Drive) . . . . . . . . . . . . . . . 48

19 Power Exhaust Specifications . . . . . . . . . . . . . . . . . . . . . . . . 48

20 Additional Static Resistance . . . . . . . . . . . . . . . . . . . . . . . . . 49

21 Electric Heat Limit Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

22 Electric Heat Anticipator Setpoints . . . . . . . . . . . . . . . . . . . . 53

23 Single Stage Gas Heat Limit Control Setting . . . . . . . . . . . . 54

24 Gas Heat Anticipator Setpoints . . . . . . . . . . . . . . . . . . . . . . . 54

25 Gas Rate-Cubit Feet per Hour . . . . . . . . . . . . . . . . . . . . . . . 56

26 Fan setup commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

27 ZD-03 (3.0 Ton) Operating Pressures . . . . . . . . . . . . . . . . . 60

28 ZD-04 (4.0 Ton) Operating Pressures . . . . . . . . . . . . . . . . . 60

29 ZD-05 (5.0 Ton) Operating Pressures . . . . . . . . . . . . . . . . . 61

30 ZD-A6 (6.0 Ton) Operating Pressures . . . . . . . . . . . . . . . . . 61

31 Unit Control Board Flash Codes . . . . . . . . . . . . . . . . . . . . . . 66

32 Ignition Control Board Flash Codes . . . . . . . . . . . . . . . . . . . 66

33 Smart Equipment™ UCB Details . . . . . . . . . . . . . . . . . . . . . 67

34 Cable for FC Buses and SA Buses in Order of Preference . 72

LIST OF FIGURES

14 Typical Smart Equipment™ Control Wiring . . . . . . . . . . . . . 16

15 Side Entry Gas Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

16 Bottom Entry Gas Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

17 Vent And Combustion Air Hood . . . . . . . . . . . . . . . . . . . . . . 35

18 RRS Economizer LCD and Keypad Layout. . . . . . . . . . . . . 35

19 SE-ECO1001-0 Economizer Controller . . . . . . . . . . . . . . . . 38

20 Belt Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

21 Altitude/Temperature Correction Factors . . . . . . . . . . . . . . . 43

22 Pressure Drop Across Coil . . . . . . . . . . . . . . . . . . . . . . . . . . 49

23 Gas Valve Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

24 Typical Single Stage Gas Valves . . . . . . . . . . . . . . . . . . . . . 55

25 Proper Flame Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . 56

26 Typical Flame Appearance . . . . . . . . . . . . . . . . . . . . . . . . . 56

27 Unit Control Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

28 Smart Equipment™ Unit Control Board . . . . . . . . . . . . . . . . 67

Advertisement

Chapters

Table of Contents

Summary of Contents for Johnson Controls York ZD Series

-

Page 1: Table Of Contents

R-410A ZD SERIES 3 - 6 Ton 60 Hertz TABLE OF CONTENTS General ..........2 Free Cooling Operation . -

Page 2: General

Refer to this manual for assistance or department. for additional information, consult a qualified contractor, Installation and service must be performed by a qualified installer or service agency. installer, service agency or the gas supplier. Johnson Controls Ducted Systems... - Page 3 1/2 PSIG. This system uses R-410A Refrigerant which operates at higher pressures than R-22. No other refrigerant may be used in this system. Johnson Controls Ducted Systems...

- Page 4 4 = PCO (Powered Conv. Outlet) 5 = DSC,NCO 3. 3 - 5 ton only 6 = DSC,PCO Outdoor Air Option A = No Economizer C = Economizer w/o Barometric RLF F = Econ BAS Rdy w/o Barometric RLF Johnson Controls Ducted Systems...

-

Page 5: Installation

30° F. 208/230-3-60 and 380/415-3-50 units with factory installed Powered Convenience Outlet Option are wired for 230v and 415v power supply respectively. Change tap on transformer for 208-3-60 or 380-3-50 operation. See unit wiring diagram. Johnson Controls Ducted Systems... -

Page 6: Through -A6 Unit Limitations

Size Unit Voltage SCCR (kVA) Applied Voltage Outdoor DB Temp (Tons) Max (°F) 208/230-1-60 208/230-3-60 ZD-03 (3.0) 460-3-60 575-3-60 208/230-1-60 208/230-3-60 ZD-04 (4.0) 460-3-60 575-3-60 208/230-1-60 208/230-3-60 ZD-05 (5.0) 460-3-60 575-3-60 208/230-3-60 ZD-A6 460-3-60 (6.0) 575-3-60 Johnson Controls Ducted Systems... -

Page 7: Location

7.3, or 7.4 of Gas Installation Codes, CSA-B149.1 (in Canada) - The condenser coils should be protected from rigging Latest Edition, and/or applicable provisions of the local building cable damage with plywood or other suitable material. Johnson Controls Ducted Systems... -

Page 8: Through -A6

Unit Accessory Shipping Operating Economizer Power Exhaust Electric Heat Gas Heat 1. Weight given is for the maximum heater size available (30KW). 2. Weight given is for the maximum number of tube heat exchangers available (5 tube). Johnson Controls Ducted Systems... -

Page 9: Through -A6 Cooling Only Front View Physical Dimensions

5742638-BIM-D-0620 Figure 5: ZD-03 through -A6 Cooling Only Front View Physical Dimensions Figure 6: ZD-03 through -A6 Cooling Only/Gas Heat Front View Physical Dimensions Johnson Controls Ducted Systems... -

Page 10: Through -A6 Unit Clearances

Disconne t Switch Location 2. Units must be installed outdoors. Overhanging structures and Motor Access Panel for or shrubs should not obstruct condenser air discharge Unit with “Belt-Drive” Option outlet. Figure 8: ZD-03 through -A6 Disconnect Location Johnson Controls Ducted Systems... -

Page 11: Through -A6 Utilities Entry

1-1/2” KO Gas Piping (Bottom) 1. Opening in the bottom to the unit can be located by the slice in the insulation. 2. Do not remove the 2” knockout ring. Figure 10: ZD-03 through -A6 Roof Curb Johnson Controls Ducted Systems... -

Page 12: Ductwork

Units are shipped with compressor mountings which are factory-adjusted and ready for operation. Units with scroll compressors have a shipping bracket which must be removed after the unit is set in place. See Figure 12. Figure 11: Condensate Drain Johnson Controls Ducted Systems... -

Page 13: Filters

NEC and CEC as normal operation. The above water-proofing conditions specified above and/or local codes. will also apply when installing a field supplied disconnect switch. Johnson Controls Ducted Systems... -

Page 14: Control Wire Sizes

Table 6: Control Wire Sizes the unit using the (4) screws provided. Wire Size Maximum Length 18 AWG 150 Feet 1. From the unit to the thermostat and back to the unit. Johnson Controls Ducted Systems... -

Page 15: Typical Field Power And Control Wiring

R, RC, or RH. OCC is an output from the thermostat to indicate the Occupied X is an input to the thermostat to display Error Status condi ons. Figure 13: Typical Field Power and Simplicity Lite Control Wiring Johnson Controls Ducted Systems... -

Page 16: Typical Cool/Heat Control Wiring (Smart Equipment™ Zd-03 Through -A6)

R, RC, or RH. OCC is an output from the thermostat to indicate the Occupied X is an input to the thermostat to display Error Status condi ons. Figure 14: Typical Smart Equipment™ Control Wiring Johnson Controls Ducted Systems... -

Page 17: Electrical Data

230-3-60 13.7 83.1 21.4 10.6 25.5 37.2 15.9 38.2 53.2 21.2 69.1 NONE 11.1 12.8 460-3-60 10.1 12.1 17.8 13.6 16.4 23.1 19.5 23.5 31.9 NONE 10.6 10.2 15.1 575-3-60 15.9 15.3 21.5 21.2 20.4 27.9 Johnson Controls Ducted Systems... - Page 18 1. Minimum Circuit Ampacity. 2. Dual Element, Time Delay Type. 3. HACR type per NEC. 4. Electrical data for single phase gas heating units with belt drive is at the end of the electrical data section. Johnson Controls Ducted Systems...

- Page 19 230-3-60 13.7 83.1 21.4 10.6 25.5 37.2 15.9 38.2 53.2 21.2 69.1 NONE 11.1 12.8 460-3-60 10.1 12.1 17.8 13.6 16.4 23.1 19.5 23.5 31.9 NONE 10.6 10.2 15.1 575-3-60 15.9 15.3 21.5 21.2 20.4 27.9 Johnson Controls Ducted Systems...

- Page 20 23.1 21.2 20.4 29.5 30.4 29.3 40.6 1. Minimum Circuit Ampacity. 2. Dual Element, Time Delay Type. 3. HACR type per NEC. 4. Single phase, high static belt drive motors not available on gas heating units. Johnson Controls Ducted Systems...

-

Page 21: Rla Lra Mcc

66.2 92.3 21.2 88.3 119.9 (4.0) NONE 11.1 15.5 28.9 208-3-60 13.7 83.1 21.4 22.2 37.3 11.9 50.8 15.9 44.1 64.7 NONE 12.7 32.1 230-3-60 13.7 83.1 21.4 10.6 25.5 41.4 15.9 38.2 57.3 21.2 73.2 Johnson Controls Ducted Systems... - Page 22 44.1 64.7 22.2 61.6 86.5 NONE 12.7 32.1 230-3-60 24.9 10.6 25.5 41.4 15.9 38.2 57.3 21.2 73.2 29.6 71.2 98.5 1. Minimum Circuit Ampacity. 2. Dual Element, Time Delay Type. 3. HACR type per NEC. Johnson Controls Ducted Systems...

-

Page 23: E07

13.7 83.1 21.4 10.6 25.5 49.7 15.9 38.2 65.7 21.2 81.6 NONE 16.1 19.1 460-3-60 10.1 12.1 24.1 13.6 16.4 29.3 19.5 23.5 38.2 NONE 12.9 10.6 10.2 20.1 575-3-60 15.9 15.3 26.5 21.2 20.4 32.9 Johnson Controls Ducted Systems... -

Page 24: E30

1. Minimum Circuit Ampacity. 2. Dual Element, Time Delay Type. 3. HACR type per NEC. 4. Electrical data for single phase gas heating units with belt drive is at the end of the electrical data section. Johnson Controls Ducted Systems... -

Page 25: None E07

13.7 83.1 21.4 10.6 25.5 49.7 15.9 38.2 65.7 21.2 81.6 NONE 16.1 19.1 460-3-60 10.1 12.1 24.1 13.6 16.4 29.3 19.5 23.5 38.2 NONE 12.9 10.6 10.2 20.1 575-3-60 15.9 15.3 26.5 21.2 20.4 32.9 Johnson Controls Ducted Systems... -

Page 26: E30

28.1 21.2 20.4 34.5 30.4 29.3 45.6 1. Minimum Circuit Ampacity. 2. Dual Element, Time Delay Type. 3. HACR type per NEC. 4. Single phase, high static belt drive motors not available on gas heating units. Johnson Controls Ducted Systems... -

Page 27: E20

104.8 21.2 88.3 132.4 (4.0) NONE 11.1 15.5 41.4 208-3-60 13.7 83.1 21.4 22.2 49.8 11.9 63.3 15.9 44.1 77.2 NONE 12.7 37.9 44.6 230-3-60 13.7 83.1 21.4 10.6 25.5 53.9 15.9 38.2 69.8 21.2 85.7 Johnson Controls Ducted Systems... - Page 28 63.3 15.9 44.1 77.2 22.2 61.6 NONE 12.7 44.6 230-3-60 24.9 10.6 25.5 53.9 15.9 38.2 69.8 21.2 85.7 29.6 71.2 1. Minimum Circuit Ampacity. 2. Dual Element, Time Delay Type. 3. HACR type per NEC. Johnson Controls Ducted Systems...

-

Page 29: Electrical Data: Single-Phase Gas Heat, Belt Drive

208-1-60 19.6 17.4 None 54.2 230-1-60 19.6 17.4 None 54.2 208-1-60 24.4 144.2 17.4 None 62.3 230-1-60 24.4 144.2 17.4 None 62.3 1. Minimum Circuit Ampacity. 2. Dual Element, Time Delay Type. 3. HACR type per NEC. Johnson Controls Ducted Systems... -

Page 30: Through -A6 Physical Data

Quantity Unit Capacity Steps (%) 67/100 CONDENSER COIL DATA Face area (Sq. Ft.) 16.3 16.3 16.3 16.3 Rows Fins per inch Tube diameter (in.) 0.71 / 18 0.71 / 18 1.00 / 25.4 1.00 / 25.4 Johnson Controls Ducted Systems... - Page 31 3. FER or Fan Energy Rating is a Department of Energy (DOE) requirement for single phase gas/electric product rated 65K or less of cooling capacity. DOE ruling effective 7/2019. 4. ECM O.D. Fan Motor 5. Only Available On 208/230 Volt Models Johnson Controls Ducted Systems...

-

Page 32: Field Installed Electric Heat

NOTE: Gas Heaters are shipped available for natural gas, but can be converted to L.P. with Kit Model No. 1NP0440. All furnaces meet the latest California seasonal efficiency requirements. 1. Based on 1075 Btu/Ft. 2. The air flow must be adjusted to obtain a temperature rise within the range shown. Johnson Controls Ducted Systems... -

Page 33: Gas Pipe Sizing - Capacity Of Pipe

After the gas connections have been completed, open the main shut-off valve admitting normal gas pressure to the mains. Check all joints for leaks with soap solution or other material suitable for the purpose. NEVER USE A FLAME. Johnson Controls Ducted Systems... - Page 34 The proper pressure regulation. (Two-stage regulation is The products of combustion are discharged horizontally through recommended). this screened, hooded vent opening on the gas heat access panel. Johnson Controls Ducted Systems...

-

Page 35: Options/Accessories

Units with Simplicity Lite Controls will have a field installed down) or (enter) button. (RRS) Economizer Kit Offered. The LEDs at the center-left of the RRS Economizer Controller This section describes how to use the Economizer’s user indicate: interface for: • POWER (green) Johnson Controls Ducted Systems... -

Page 36: Smart Equipment™ Economizer Sequences

The control determines the type of free cooling changeover Units with the Smart Equipment™ Control will have a factory based on which sensors are present and reliable. Conditions option or field kit with Johnson Controls Economizer. include: Several functions can drive the economizer, including: minimum •... -

Page 37: Power Exhaust

Economizer Damper Position For Exhaust Fan On. is less than Economizer Setpoint -1°F, the control starts a 12- c. De-energizes exhaust fan when economizer output is minute timer to de-energize a compressor output. below the Economizer Damper Position for Exhaust Fan Johnson Controls Ducted Systems... -

Page 38: Smart Equipment™ Economizer Board Details

Negative of the SA BUS communication Common for SA BUS power and circuit to the UCB. Through the unit wiring harness, may continue communication circuits on to the 4-stage board and/or fault detection & diagnostics board Johnson Controls Ducted Systems... - Page 39 24V~ IN Pin connections at right on upper edge of economizer board 24 VAC common connection to power the economizer board. 24 VAC transformer Common referenced to Connects through circuit traces to C/COM terminals and pins cabinet ground distributed on the economizer board. Johnson Controls Ducted Systems...

- Page 40 Connects through circuit trace to 24V~ IN pin HOT sensor BldgPres parameter reports input status (-.250-.250”/w/-.062- BLDG 0-5 VDC positive input from the Building .062kPa). Used for modulating power exhaust functions when PRES Pressure sensor ExFType selection is Modulating Damper or Variable Frequency Fan. Johnson Controls Ducted Systems...

- Page 41 Check for proper supply air blower rotation. If the blower is level, the scroll is misphased.) rotating backwards, the line voltage at the unit point of power connection is misphased (See ‘PHASING’). Johnson Controls Ducted Systems...

-

Page 42: Altitude/Temperature Correction Factors

0.743 0.715 0.688 0.982 0.947 0.913 0.880 0.848 0.817 0.787 0.758 0.730 0.702 0.676 0.964 0.929 0.897 0.864 0.833 0.802 0.772 0.744 0.716 0.689 0.663 0.946 0.912 0.880 0.848 0.817 0.787 0.758 0.730 0.703 0.676 0.651 Johnson Controls Ducted Systems... -

Page 43: Altitude/Temperature Correction Factors

This value must be corrected for elevation. Example 2: A system, located at 5,000 feet of elevation, is to deliver 1,400 CFM at a static pressure of 1.5". Use the unit BHP at 5,000 ft. = 0.7 x .832 = 0.58 Johnson Controls Ducted Systems... - Page 44 Sheave Open Open Open Open Open Closed 1.73 1VL44 AK56 1060 1130 1195 1260 1VP56 AK56 1325 1395 1460 1525 1590 1660 If return static reaches -0.2" static, unit could experience a degradation in airflow performance. Johnson Controls Ducted Systems...

-

Page 45: Zd Blower Performance Side Duct

1. Blower performance includes gas heat exchangers and 1” filters. See STATIC RESISTANCE table for additional applications. 2. See RPM SELECTION table to determine desired motor sheave setting and to determine the maximum continuous BHP. 3. kW = BHP x 0.932. 4. Field Supplied Drive. Johnson Controls Ducted Systems... -

Page 46: Zd Blower Performance Bottom Duct

1. Blower performance includes gas heat exchangers and 1” filters. See STATIC RESISTANCE table for additional applications. 2. See RPM SELECTION table to determine desired motor sheave setting and to determine the maximum continuous BHP. 3. kW = BHP x 0.932. Johnson Controls Ducted Systems... - Page 47 1. Blower performance includes gas heat exchangers and 1” filters. See STATIC RESISTANCE table for additional applications. 2. See RPM SELECTION table to determine desired motor sheave setting and to determine the maximum continuous BHP. 3. 1kW = BHP x 0.862. Johnson Controls Ducted Systems...

-

Page 48: Belt Drive Rpm Selection

Table 19: Power Exhaust Specifications Motor Motor Fuse CFM @ Model Voltage Size 0.1 ESP 2PE04703725 208/230-1-60 1725 23.7 1350 2PE04703746 460-1-60 1725 1350 2PE04703758 575-3-60 1725 1350 1. Motors are multi-tapped and factory wired for high speed. Johnson Controls Ducted Systems... -

Page 49: Checking Supply Air Cfm

3. The pressure drop through the economizer is greater for 100% outdoor air than for 100% return air. If the resistance of the return air duct is less than 0.25 IWG, the unit will deliver less CFM during full economizer operation. Johnson Controls Ducted Systems... -

Page 50: Operation

When the “R” to “G” the compressor has been completed. After the compressor de- circuit is opened, the damper spring returns fully closed. Johnson Controls Ducted Systems... -

Page 51: Cooling Operation Errors

38 ± 5°F) or an evaporator low limit sensor (EC1) conclusion of the ASCD, the UCB will re-energize the halted (Located on the Suction Line at the Evaporator Coil.) compressor. (Smart Equipment™ Control) to protect against low Johnson Controls Ducted Systems... -

Page 52: Field Installed Electric Heating Sequence Of Operations

20 and 30 kW heater 460V and 575V heaters.): 2,4,6 a. Upon a call for first-stage heat by the thermostat, the 460-3-60 2,4,6 heater sequencer (1S) (15, 20, 30 kW 230 volt) and contactor (2M) (20, 30 kW 460 and 575 volt) will be Johnson Controls Ducted Systems... -

Page 53: Gas Heating Sequence Of Operations

If the centrifugal switch located on the end of the draft motor closes. auxiliary switch has opened, then special attention should be After the centrifugal switch closes, a 15 second heat exchanger Johnson Controls Ducted Systems... -

Page 54: Flash Codes Or Error Messages

• If blower rotation is in the wrong direction. Refer to flame sense circuit to be open. If open, then the ICB initiates the Phasing Section in general information section. purging and ignition sequence. Once the pilot flame is present, Johnson Controls Ducted Systems... -

Page 55: Start-Up (Gas Heat)

To decrease the gas pressure, turn the adjusting screw Set room thermostat to desired temperature. (If thermostat counterclockwise. “set” temperature is above room temperature, pilot burner To increase the gas pressure, turn the adjusting screw clockwise. Johnson Controls Ducted Systems... -

Page 56: Checking Gas Input

NOTE: To find the Btu input, multiply the number of cubic feet of gas consumed per hour by the Btu content of the gas in your particular locality (contact your gas company for this information - it varies widely from city to city.) Johnson Controls Ducted Systems... -

Page 57: Start Up For Units Equipped For Fer

(about six feet from the furnace) where The following table shows available fan speed commands. they will not be affected by radiant heat. Increase the blower cfm to decrease the temperature rise; decrease the blower cfm Johnson Controls Ducted Systems... -

Page 58: Troubleshooting (Simplicity Lite Only)

If 24 volts is not present at the C1 terminal, check for 24 volts are present at M2 but M2 is not pulled in, replace the volts from the room thermostat at the UCB Y1 terminal. If contactor. Johnson Controls Ducted Systems... - Page 59 15. If none of the above correct the error, replace the UCB. “OUT” terminal of the UCB. If 24 volts is present, trace the wiring from Y1 “OUT” for incorrect wiring. If 24 volts is not Johnson Controls Ducted Systems...

-

Page 60: 3.0 Ton) Operating Pressures

Indoor Db/Wb DB/WB Pressure Temp. Pressure Temp. Evap Db Evap Db Amps 300 Cfm/Ton 80/62 300 Cfm/Ton 80/67 300 Cfm/Ton 80/72 300 Cfm/Ton 75/63 400 Cfm/Ton 80/62 400 Cfm/Ton 80/67 400 Cfm/Ton 80/72 400 Cfm/Ton 75/63 Johnson Controls Ducted Systems... -

Page 61: 5.0 Ton) Operating Pressures

12.0 300 Cfm/Ton 80/72 13.6 15.3 11.9 300 Cfm/Ton 75/62 13.3 14.8 11.8 400 Cfm/Ton 80/62 13.3 14.8 11.9 400 Cfm/Ton 80/67 13.4 14.9 11.9 400 Cfm/Ton 80/72 13.5 15.1 11.8 400 Cfm/Ton 75/62 13.3 14.8 Johnson Controls Ducted Systems... - Page 62 Restore power to unit and induce a call for heat. indicated. All troubleshooting procedures assume the unit is Measure the voltage across the two draft motor leads Johnson Controls Ducted Systems...

- Page 63 If the flame is weak or unstable in the flame sensor area, within the published ranges. then verify the gas inlet pressure. If gas inlet pressure is above the minimum inlet pressure stated on unit data label, Johnson Controls Ducted Systems...

- Page 64 UCB, i.e. that the thermostat “W1” terminal is connected to the “W1” terminal of the UCB, and Place the thermostat fan switch in the “ON” position. If the for loose wiring. supply air blower motor energizes, go to Step 10. Johnson Controls Ducted Systems...

-

Page 65: Fan On And Off Delays

UCB. wire for good electrical connection. If all are intact, replace • Gas Heat Option #1 - Press the LAST ERROR and the ignition control. TEST RESET buttons simultaneously and then release. Johnson Controls Ducted Systems... -

Page 66: Smart Equipment™ Control Board Navigation Components

LPS1 - Compressor Lock out 7 Flashes FS1 - Compressor Lock out MAP Gateway Instruction P/N 24-10737-8 For more information on the Smart Equipment™ unit control board navigation, refer to the Smart Equipment™ Quick Start Guide. Johnson Controls Ducted Systems... -

Page 67: Smart Equipment™ Ucb Details

Connects through circuit trace to the thermostat connection 24 VAC hot for switched inputs to the UCB strip R terminal, right FAN OVR pin, right HPS1 pin, right HPS2 pin, lower DFS pin and lower APS pin Johnson Controls Ducted Systems... - Page 68 Supply Air Temperature sensor input from 10KΩ with open circuit. Used in heat/cool staging cutouts, free cooling SAT+ @ 77°F, Type III negative temperature coefficient operation, demand ventilation operation, comfort ventilation thermistor operation, economizer loading operation, VAV cooling operation, hydronic heat operation. Johnson Controls Ducted Systems...

- Page 69 The VFD alarm contact switches from R within the unit wiring 24 VAC hot input from the normally open VFD VFDFLT harness. 24 VAC input results in unit shutdown and a “VFD alarm contact fault” alarm Johnson Controls Ducted Systems...

- Page 70 Lockout” and C1 output is then prevented until alarm reset. HPS2 24 VAC hot out for refrigerant circuit 2 High Not effective for one stage compressor UCBs. Connects (right pin) Pressure Switch through circuit trace to the R terminal Johnson Controls Ducted Systems...

- Page 71 4-way Joystick for display menu navigation Item USB connector at right of UCB Used for backup, restoration, & copying of board parameters as Type A female Universal Serial Bus connector well as board software updating through a flash drive Johnson Controls Ducted Systems...

- Page 72 2. We recommend 26 AWG solid, 6-wire (3 twisted pairs) cable as the best fit for fabricating modular cables with the modular jack housing assembly. Be sure the cable you use fits the modular jack housing. The preassembled cables that are available from Anixter (Part No. CBL-NETWORKxxx) use 24 gauge wire. Johnson Controls Ducted Systems...

-

Page 73: Start-Up Sheet

5742638-BIM-D-0620 Start-Up Sheet Johnson Controls Ducted Systems... - Page 74 5742638-BIM-D-0620 Johnson Controls Ducted Systems...

- Page 75 5742638-BIM-D-0620 Johnson Controls Ducted Systems...

- Page 76 5742638-BIM-D-0620 Johnson Controls Ducted Systems...

- Page 77 5742638-BIM-D-0620 Johnson Controls Ducted Systems...

-

Page 78: 5742638-Bim-D-0620

Subject to change without notice. Printed in U.S.A. 5742638-BIM-D-0620 Copyright © 2020 by Johnson Controls, Inc. All rights reserved. Supersedes: 5742638-BIM-C-0220 York International Corporation 5005 York Drive Norman, OK 73069...

Need help?

Do you have a question about the York ZD Series and is the answer not in the manual?

Questions and answers