Summary of Contents for ALPHA DYNAMIC PUMPS Ruby Black Line 020 Non Metallic

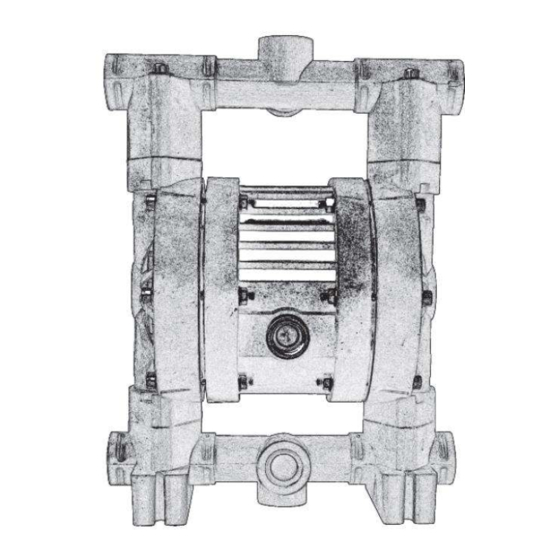

- Page 1 Air Operated Diaphragm Pumps Installation, Operation and Maintenance Installation, Operation Ruby 020 Non Metallic Maintenance...

-

Page 2: Table Of Contents

INDEX 1.0 Introduction .......................... 1 1.0.1 Pump Identification ......................2 1.0.2 Markings and general information ..................3 1.0.3 Composition Codes ......................3 1.1 Warranty ..........................4 1.2 Transport, unipacking, storage ..................... 5 1.3 Principle of function ......................5 1.4 Pump operation ........................6 1.5 Improper use ........................ -

Page 5: Introduction

ATEX Pumps - Conditions For Safe Use 1. Ambient temperature range is as specified in page 16. 2. ATEX compliant pumps are suitable for use in explosive atmospheres when the equipment is properly grounded in accordance with local electrical codes 3. -

Page 6: Pump Identification

personnel. Each pump is subjected to stringent inspections and function tests before leaving the factory. You should always bear in mind that a correct function, a long lifetime and optimal operational reliability of the pump mainly depend on : ▪ correct installation ▪... -

Page 7: Markings And General Information

1.0.2 Markings and general information In compliance with the 2014/34/EU standards, the Ruby pumps carry the following identification marks: ▪ EU Directive 2014/34/EU Equipment and protective systems intended for use in potentially explosive atmospheres (ATEX) ▪ EN ISO 80079-36 :2016 Non electrical equipment for use in potentially explosive atmospheres - Basic method and requirements ▪... -

Page 8: Warranty

1.1 Warranty The correct function of each Ruby pump is tested in the factory. However, should any defect appear, please contact the Manufacturer’s After-Sales Service, your dealer or the nearest Customer Service Centre where you will receive assistance as quickly as possible. -

Page 9: Transport, Unipacking, Storage

1.2 Transport, unipacking, storage In order to avoid any problems you should check the delivered goods against the delivery note for completeness and correctness. Be careful when unpacking the pump and proceed as follows: ▪ Check the packaging material for transport damage. ▪... -

Page 10: Pump Operation

1.4 Pump operation Ruby Air Operated Diaphragm Pumps are oscillating positive displacement pumps with two pump chambers arranged opposite each other. Both of these are separated by a diaphragm each into an air and a fluid section. Both diaphragms are linked by a piston rod, so that with every stroke product is displaced to the outside from the one pump chamber and product is drawn into the opposite pump chamber. -

Page 11: Safety Rules

2.0 Safety Rules Dangerous or hazardous practices or practice not complying with the safety rules and with the recommendations contained herein, may cause serious injuries, material damage and even explosions and /or death for which the manufacturer cannot be held responsible. WARNING: these instructions are essential for the pumps' compliance to the requirements of the 2006/42/EC directive and must therefore be available, known, understood and applied. - Page 12 ▪ also ascertain that the connection piping is strong enough and cannot be deformed by the pump weight or by the intake. Also check hat the pump is not burdened by the weight of the piping. ▪ If the pump is to stay in disuse for a long period of time, clean it carefully by running a non- flammable liquid detergent through it that is compatible with the pump's construction materials.

- Page 13 WARNING: The pumps must always be grounded irrespective of any organ to which they are connected. Lack of grounding or incorrect grounding will cancel the requirements for safety and protection against the risk of explosion. WARNING: the use of pumps made with non-conductive material, which become charged with static, and without suitable grounding for flammable liquids is forbidden: RISK OF EXPLOSIONS DUE TO STATIC CHARGE.

- Page 14 WARNING: Periodic controls must be made to ensure that there is no powder and/or deposits on the external and internal. surfaces of the pump and, if necessary, they must be cleaned with a damp cloth WARNING: removal of the silencer and the air supply fitting must be done when free from powder.

-

Page 15: Equipotential Bonding / Earthing

2.1 Equipotential bonding / earthing In principle, pumps and accessories must be earthed or provided with equipotential bonding if there is the possibility of product specific electro-static charging and when used in potentially explosive areas. Pumps and pulsation dampers with ATEX II 2/2 G Ex h IIC T4 Gb – II 2/2 D Ex h IIC T35 Db approval are therefore fitted with an earthing screw. -

Page 16: Installation

3.0 Installation To be observed before installation 1. The installation must only be carried out by persons who have the necessary skills for this work. 2. Before installation align the pump correctly and fasten it without any tension. Pipelines must be assembled in a way that the basic weight of the lines is not reasting on the pump. -

Page 17: Connection Of Air Supply Line

3.1 Connection of air supply line We recommend to supply the air through a hose to the pump. Using moisturized compressed air requires the installation of a service unit with water separator. This control equipment can additionally be used to regulate the flow capacity of the pump. The diaphragm must not be subjected to shock loads. -

Page 18: Connection Of Cuction And Pressure Lines

3.2 Connection of suction and pressure lines Suction and pressure lines must be installed in a way that no additionally loads are applied to the pump ports. The tightening torque of the mounting screws and the pressure strength of the sockets and flanges must be observed with the installation of the suction and pressure lines. -

Page 19: Noise Emissions (2003/10/Ec)

WARNING: the pump must be connected with FLEXIBLE HOSES REINFORCED WITH A RIGID SPIRAL of a diameter never smaller than the pump's connection. The filters or other equipment installed at the intake side must be suitably dimensioned in οrder to avoid pressure drops. For negative installations and/or viscous fluids, use hoses with an OVERSIZE DIAMETER, especially on the intake side. -

Page 20: Temperature Range Of The Diaphragm Material

3.7 Temperature range of the diaphragm material TFM Compound Diaphragm C - 130 NBR Conductive Diaphragm C - 100 TFM Full capacity Compound Diaphragm C - 130 EPDM Conductive Diaphragm C - 100 VITON Conductive diaphragm C - 170 3.8 Temperature range of the Housing material Stainless steel C - 130 Aluminium... -

Page 21: Troubleshooting

4.0 Troubleshooting The following instructions are intended exclusively for authorized skilled maintenance engineers. In event of abnormal behavior and in order to fix faults, please refer to the following troubleshooting instructions. WARNING: For more serious problems, we strongly recommend that you contact the ALPHADYNAMIC PUMPS SA: our engineers will provide you assistance as quickly as possible. -

Page 22: Technical Data

5.0 Technical Data 5.1 Dimensional Drawings... -

Page 23: Performance

5.2 Performance Ruby 020 Non Metallic pump PTFE A Full Capacity Diaphragm Fitted Flow. Rate 114 L/min Air inlet 1/2" Suction – Discharge port 1 /2 " BSP G Suction lift (dry) Max. Solid size ( diameter) * The curves and performance values refer to pumps with submerged suction and a free delivery outlet with water at 20°C, and vary according to the construction material. - Page 24 Ruby 020 Non Metallic pump NBR-EPDM-VITON Diaphragm Fitted Flow. Rate 115 L/min Air inlet 1/2" Suction – Discharge port 1 /2 " BSP G Suction lift (dry) Max. Solid size ( diameter) * The curves and performance values refer to pumps with submerged suction and a free delivery outlet with water at 20°C, and vary according to the construction material.

- Page 25 Ruby 020 Non Metallic pump PTFE Diaphragm Fitted Flow. Rate 95 L/min Air inlet 1/2" Suction – Discharge port 1 /2 " BSP G Suction lift (dry) Max. Solid size ( diameter) * The curves and performance values refer to pumps with submerged suction and a free delivery outlet with water at 20°C, and vary according to the construction material.

-

Page 26: Exploded View

5.3 Exploded View Description Req. Qty Description Req. Qty CENTRAL BLOCK VALVE SEAT ORING SUCTION MANIFOLD VALVE BALL DISCHARGE MANIFOLD BALL SEAT PUMP HOUSING BALL RUNNER CAGE DIAPHRAGMS VALVE SEAT ORING INSIDE PISTON INNER RETAINING RING AIR VALVE SHAFT AIR CONTROL UNIT RETAINING RING SHAFT HOUSING SCREW O-RING BEARING... - Page 27 ALPHADYNAMIC PUMPS www.alphadynamic.eu...

Need help?

Do you have a question about the Ruby Black Line 020 Non Metallic and is the answer not in the manual?

Questions and answers