Table of Contents

Summary of Contents for Toro 75969TE

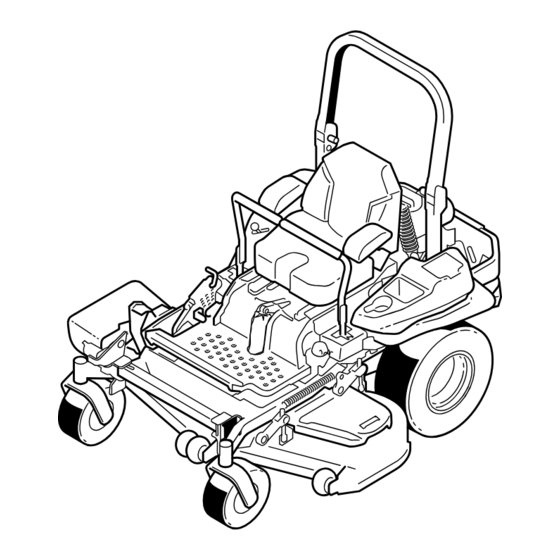

- Page 1 Form No. 3414-644 Rev C Z Master ® Professional 6000 Series Riding Mower with 132cm TURBO FORCE ® Side Discharge Mower Model No. 75969TE—Serial No. 400000000 and Up *3414-644* C Register at www.Toro.com. Original Instructions (EN)

- Page 2 Whenever you need service, genuine Toro parts, or additional information, contact an Authorized Service Dealer or Toro Customer Service and have the model and serial numbers of your product ready. Figure 1 identifies the location of the model and serial numbers on the product.

-

Page 3: Table Of Contents

Contents Greasing the Caster-Wheel Bearings ....41 Lubricating the Caster-Wheel Hubs ....42 Engine Maintenance ........... 43 Safety ............... 4 Engine Safety ........... 43 General Safety ........... 4 Servicing the Air Cleaner ........43 Slope Indicator ........... 5 Servicing the Engine Oil........44 Safety and Instructional Decals ...... -

Page 4: Safety

Safety Cleaning and Storing the Machine ....73 Troubleshooting ............74 Schematics ............. 76 This machine has been designed in accordance with EN ISO 5395:2013. General Safety This product is capable of amputating hands and feet and of throwing objects. Always follow all safety instructions to avoid serious personal injury. -

Page 5: Slope Indicator

Slope Indicator g011841 Figure 3 This page may be copied for personal use. 1. The maximum slope you can safely operate the machine on is 15 degrees. Use the slope chart to determine the degree of slope of hills before operating. Do not operate this machine on a slope greater than 15 degrees. Fold along the appropriate line to match the recommended slope. -

Page 6: Safety And Instructional Decals

Safety and Instructional Decals Safety decals and instructions are easily visible to the operator and are located near any area of potential danger. Replace any decal that is damaged or missing. decal58-6520 58-6520 1. Grease decal99-8939 99-8939 3. Remove the ignition key 1. - Page 7 decalbatterysymbols Battery Symbols Some or all of these symbols are on your battery 1. Explosion hazard 6. Keep bystanders a safe distance from the battery. 2. No fire, open flame, or 7. Wear eye protection; smoking. explosive gases can cause blindness and other injuries 8.

- Page 8 decal110-2068 110-2068 1. Read the Operator's Manual. decal114-4470 114-4470 decal112-9028 112-9028 1. Read the Operator's 3. Locked 1. Warning—stay away from moving parts; keep all guards in Manual. place. 2. Height of cut 4. Unlocked decal114-4466 114-4466 1. Main (25 A) 3.

- Page 9 decal117-3848 117-3848 1. Thrown object hazard—keep bystanders a safe distance away from the machine. 2. Thrown object hazard, mower-do not operate the machine without the deflector, discharge cover, or grass collection system in place. 3. Cutting/dismemberment of hand or foot—stay away from moving parts;...

- Page 10 decal126-2055 126-2055 1. Wheel-lug nut torque 129 N∙m (95 ft-lb) (4x) 2. Wheel-hub nut torque 319 N∙m (235 ft-lb) 3. Read and understand the Operator’s manual before performing any maintenance, check the torque after the first 100 hours then every 500 hours thereafter. decal136-5508 136-5508 1.

- Page 11 decal125-9383 125-9383 1. Check the hydraulic fluid every 50 operating hours. 3. Check the tire pressure every 50 operating hours. 2. Read the Operator’s Manual for information on lubricating 4. Read the Operator’s Manual before servicing or performing the machine. maintenance.

- Page 12 decal132-0871 132-0871 Note: This machine complies with the industry standard stability test in the static lateral and longitudinal tests with the maximum recommended slope indicated on the decal. Review the instructions for operating the machine on slopes in the Operator’s Manual as well as the conditions in which you would operate the machine to determine whether you can operate the machine in those conditions on that day and at that site.

-

Page 13: Product Overview

Hour Meter Product Overview The hour meter records the number of hours the engine has operated. It operates when the engine is running. Use these times for scheduling regular maintenance (Figure Fuel Gauge The fuel gauge is located with the hour meter, and the bars light up when the ignition switch is in the O position (Figure... -

Page 14: Specifications

A selection of Toro approved attachments and accessories is available for use with the machine to enhance and expand its capabilities. Contact your Authorized Service Dealer or Distributor or go to www.Toro.com for a list of all approved attachments and accessories. -

Page 15: Before Operation

Operation containers on the ground, away from your vehicle before filling. • Remove the equipment from the truck or trailer Note: Determine the left and right sides of the and refuel it while it is on the ground. If this is not machine from the normal operating position. -

Page 16: Using Stabilizer/Conditioner

Using Stabilizer/Conditioner Use a fuel stabilizer/conditioner in the machine to provide the following benefits: • Keeps fuel fresh during storage of 90 days or less (drain the fuel tank when storing the machine for more than 90 days) • Cleans the engine while it runs •... -

Page 17: Checking The Engine-Oil Level

Checking the Engine-Oil Lower the roll bar to the down position (Figure Level Before you start the engine and use the machine, check the oil level in the engine crankcase; refer to Checking the Engine-Oil Level (page 17). Breaking in a New Machine New engines take time to develop full power. -

Page 18: Think Safety First

Think Safety First CAUTION This machine produces sound levels in Please read all safety instructions and symbols in the safety section. Knowing this information could help excess of 85 dBA at the operator’s ear and you or bystanders avoid injury. can cause hearing loss through extended periods of exposure. -

Page 19: Unlatching The Seat

to the N position. Try starting the EUTRAL LOCK engine; the engine should not start. Unlatching the Seat To unlatch the seat, push the seat latch forward (Figure 12). g009181 Figure 11 1. Triangles light up when the interlock components are in the correct position Testing the Safety-Interlock System... -

Page 20: Adjusting The Myride™ Suspension System

Adjusting the MyRide™ Adjust the rear-shock assemblies (Figure 14). Suspension System The MyRide™ suspension system adjusts to provide a smooth and comfortable ride. You can adjust the rear 2-shock assemblies to quickly and easily change the suspension system. Position the suspension system where you are most comfortable. -

Page 21: During Operation

Do not operate the machine while ill, tired, or under the influence of alcohol or drugs. • Use accessories and attachments approved by Toro only. • Never carry passengers on the machine and keep bystanders and pets away from the machine during operation. -

Page 22: Operating The Parking Brake

Disengaging the Parking Brake • Avoid operating the machine on wet grass. Tires may lose traction; regardless if the brakes are available and functioning. • Avoid starting, stopping, or turning the machine on a slope. • Keep all movement on slopes slow and gradual. Do not suddenly change the speed or direction of the machine. -

Page 23: Operating The Mower Blade-Control Switch (Pto)

Operating the Mower Blade-Control Switch (PTO) The blade-control switch (PTO) starts and stops the mower blades and any powered attachments. Engaging the Blade-Control g008946 Figure 19 Switch (PTO) Note: Engaging the blade-control switch (PTO) with the throttle position at half or less causes excessive wear to the drive belts. -

Page 24: Operating The Ignition Switch

Operating the Ignition Starting and Shutting Off Switch the Engine Turn the ignition key to the S position TART Starting the Engine (Figure 21). Raise the roll bar up and lock it into place, sit on Note: When the engines starts, release the key. the seat, and fasten the seat belt. - Page 25 time after the fuel system has been without fuel completely. g008947 Figure 23 Shutting Off the Engine CAUTION Children or bystanders may be injured if they move or attempt to operate the machine while it is unattended. Always remove the ignition key and engage the parking brake when leaving the machine unattended, even if just for a few minutes.

-

Page 26: Using The Motion-Control Levers

Using the Motion-Control CAUTION Levers Machine can spin very rapidly. Operator may lose control of machine and cause personal injury or damage to machine. • Use caution when making turns. • Slow the machine down before making sharp turns. Driving Forward Note: The engine stops when you move the traction-control with the parking brake engaged. -

Page 27: Stopping The Machine

Driving Backward Stopping the Machine Move the levers to the center, unlocked position. To stop the machine, move the traction-control levers to neutral, and then move them to the locked position, To go backward, slowly pull the motion-control disengage the blade-control switch (PTO), and turn levers rearward (Figure 27). -

Page 28: Adjusting The Height Of Cut

Adjusting the Height of Cut Adjusting the Height-of-Cut Pin The height-of-cut is adjusted from 25 to 140 mm (1 Using the Transport Lock to 5-1/2 inches) in 6 mm (1/4 inch) increments by relocating the clevis pin into different hole locations. The transport lock has 2 positions, and is used with Move the transport lock to the lock position. -

Page 29: Adjusting The Anti-Scalp Rollers

Adjusting the Anti-Scalp Rollers Whenever you change the height-of-cut, it is recommended to adjust the height of the anti-scalp rollers. Disengage the blade-control switch (PTO), move the motion-control levers to the N EUTRAL LOCK position, and engage the parking brake. Shut off the engine, remove the key, and wait for all moving parts to stop before leaving the operating position. -

Page 30: Adjusting The Flow Baffle Cam Locks

Adjusting the Flow Baffle Positioning the Flow Baffle Cam Locks The following figures are only recommendations for use. Adjustments vary by grass type, moisture This procedure is applicable only to machines with the content, and the height of the grass. flow-baffle locks. - Page 31 Position C This is the full open position. The suggested use for this position is as follows: • Tall, dense grass mowing conditions • Wet conditions • Lowers the engine-power consumption • Allows increased ground speed in heavy conditions g005834 Figure 36...

-

Page 32: Operating Tips

It is best to cut only about a third of the grass blade. genuine Toro replacement blade. Cutting more than that is not recommended unless grass is sparse, or it is late fall when grass grows more slowly. -

Page 33: After Operation

Using the After Operation Drive-Wheel-Release After Operation Safety Valves General Safety WARNING • Clean grass and debris from the cutting units, Hands may become entangled in the rotating mufflers, and engine compartment to help prevent drive components below the engine deck, fires. -

Page 34: Transporting The Machine

Transporting the Machine Use a heavy-duty trailer or truck to transport the machine. Ensure that the trailer or truck has all the necessary brakes, lighting, and marking as required by law. Please carefully read all the safety instructions. Knowing this information could help you, your family, pets, or bystanders avoid injury. -

Page 35: Loading The Machine

Loading the Machine Use extreme caution when loading or unloading machines onto a trailer or a truck. Use a full-width ramp that is wider than the machine for this procedure. Back up the ramp and drive forward down the ramp (Figure 40). -

Page 36: Using The Z Stand Tm

Using the Z Stand Swing the stand foot out front and slide it toward machine, into the bottom of slot (Figure Figure 43). The Z Stand raises the front end of the machine to allow you to clean the mower and remove the blades. WARNING The machine could fall onto someone and cause serious injury or death. - Page 37 Driving off the Z Stand Remove the chocks or blocks. Raise the latch to the unlocked position (Figure 44). g001813 Figure 44 1. Z Stand 3. Locked position 2. Latch 4. Unlocked position Start the engine and place it at half throttle. Disengage the parking brake.

-

Page 38: Maintenance

Every 500 hours • Adjust the caster-pivot bearing. • Check the parking brake adjustment. • Change the hydraulic filters and hydraulic fluid when using Toro® HYPR-OIL™ 500 hydraulic fluid (more often in dirty or dusty conditions). • Check the battery charge. -

Page 39: Pre-Maintenance Procedures

• To ensure optimum performance and continued safety certification of the machine, use only Procedures genuine Toro replacement parts and accessories. Replacement parts and accessories made by other manufacturers could be dangerous, and Maintenance and Storage such use could void the product warranty. -

Page 40: Removing The Sheet-Metal Guard

Removing the Sheet-Metal Lubrication Guard Grease more frequently when operating conditions are extremely dusty or sandy. Loosen the 2 front bolts and remove the sheet-metal Grease Type: No. 2 general-purpose lithium-based guard to access the mower belts and spindles or molybdenum-based grease (Figure 46). -

Page 41: Greasing The Mower Deck

Greasing the Mower Deck Service Interval: Every 50 hours—Grease the mower deck spindles and idler arm (if applicable). Important: Make sure that the cutting unit spindles are full of grease weekly. Disengage the blade-control switch (PTO), move the motion-control levers to the NEUTRAL LOCK position, and engage the parking brake. -

Page 42: Lubricating The Caster-Wheel Hubs

Lubricating the With the open end of the wheel facing up, fill the area inside the wheel around the axle full of Caster-Wheel Hubs general-purpose grease. Insert the second bearing and new seal into the Service Interval: Yearly wheel. Shut off the engine, wait for all moving parts to Apply a thread-locking adhesive to the second stop, remove the key, and engage the parking spacer nut, and thread it onto the axle with the... -

Page 43: Engine Maintenance

Engine Maintenance Note: Holes in the filter appear as bright spots. Note: If the filter is damaged discard it. WARNING Contact with hot surfaces may cause personal injury. Keep your hands, feet, face, clothing, and other body parts away the muffler and other hot surfaces. -

Page 44: Servicing The Engine Oil

Installing the Filters Servicing the Engine Oil Important: To prevent engine damage, always Oil Type: Detergent oil (API service SG, SH, SJ, or operate the engine with both air filters and the higher) cover installed. Oil Capacity: with a filter change, 1.9 L (64 oz); with If installing new filters, check each filter for no filter change, 1.7 L (57 oz) shipping damage. - Page 45 Changing the Engine Oil Service Interval: After the first 8 hours Every 100 hours (more often in dirty or dusty conditions). Note: Dispose of the used oil at a recycling center. Start the engine and let it run for 5 minutes. g035392 Note: This warms the oil so it drains better.

- Page 46 Changing the Engine-Oil Filter Slowly pour approximately 80% of the specified oil into the filler tube and slowly add the Service Interval: Every 200 hours additional oil to bring it to the Full mark (Figure 56). Note: Change the engine-oil filter more frequently when operating conditions are extremely dusty or sandy.

-

Page 47: Servicing The Spark Plug

Servicing the Spark Plug Service Interval: Every 100 hours Make sure that the air gap between the center and side electrodes is correct before installing the spark plug. Use a spark plug wrench for removing and installing the spark plug(s) and a gapping tool/feeler g035393 gauge to check and adjust the air gap. -

Page 48: Checking The Spark Arrester

Installing the Spark Plug Fuel System Tighten the spark plug(s) to 24.4 to 29.8 N∙m (18 to Maintenance 22 ft-lb). Replacing the Fuel Filter Service Interval: Every 500 hours/Yearly (whichever comes first) (more often in dirty or dusty conditions). The fuel filter is located near the engine on the front or rear side of the engine. -

Page 49: Servicing The Fuel Tank

Servicing the Fuel Tank Electrical System Maintenance Do not attempt to drain the fuel tank. Ensure that an Authorized Service Dealer drains the fuel tank and services any components of the fuel system. Electrical System Safety • Disconnect the battery before repairing the machine. - Page 50 Removing the Battery Installing the Battery Note: Position the battery in the tray with the terminal WARNING posts opposite from the hydraulic tank (Figure 63). Battery terminals or metal tools could short against metal machine components causing sparks. Sparks can cause the battery gasses to explode, resulting in personal injury.

-

Page 51: Servicing The Fuses

Drive System Maintenance Checking the Seat Belt Service Interval: Before each use or daily Visually inspect seat belt for wear, cuts, and proper operation of retractor and buckle. Replace before operating if damaged. Checking the Rollover g000960 Figure 65 Protection System (ROPS) 1. -

Page 52: Adjusting The Tracking

If it tracks to the left, loosen the bolts and adjust the right stop plate rearward on the right T-slot until the machine tracks straight (Figure 68). Tighten the stop plate (Figure 68). g035394 Figure 68 Left control lever shown 1. -

Page 53: Checking The Wheel-Lug Nuts

Checking the Wheel-Lug Important: Make sure that the spring washers are installed correctly as shown in Nuts Figure Install the dust cap (Figure 71). Check and torque the wheel lug nuts to 122 to 129 N∙m (90 to 95 ft-lb). Checking the Wheel-Hub Slotted Nut Service Interval: After the first 100 hours... - Page 54 Removing the Clutch Shim Using needle-nose pliers, or by hand, hold the tab and remove the shim (Figure 75). Shut off the engine, wait for all moving parts to stop, remove the key, engage the parking brake, Note: Do not discard the shim until proper and allow the machine to cool completely before clutch function has been confirmed.

-

Page 55: Cooling System Maintenance

Cooling System Maintenance Cleaning the Engine Screen and Engine-Oil Cooler Service Interval: Before each use or daily g010873 Figure 77 Remove any buildup of grass, dirt, or other debris from the oil cooler (Figure 78). 1. Feeler gauge • If the gap is less than 0.25 mm (0.01 inch), then install the shim;... -

Page 56: Cleaning The Engine-Cooling Fins And Shrouds

Cleaning the Checking and Cleaning the Engine-Cooling Fins and Hydraulic Unit Shrouds Shrouds Service Interval: Before each use or daily Important: The fasteners on the covers of this Service Interval: Every 100 hours/Yearly (whichever machine are designed to remain on the cover comes first) after removal. -

Page 57: Brake Maintenance

Brake Maintenance Adjusting the Parking Brake Service Interval: After the first 100 hours Every 500 hours thereafter Note: Follow this procedure also after removing or replacing a brake component. Drive the machine onto a level surface. Disengage the blade-control switch (PTO), move the motion control levers to the N EUTRAL LOCK... -

Page 58: Belt Maintenance

Belt Maintenance Inspecting the Belts Service Interval: Every 50 hours Replace the belt if it is worn. The signs of a worn belt include squealing while the belt is rotating; the blades slipping while cutting grass; and frayed edges, burn marks, and cracks on the belt. - Page 59 g027730 Figure 85 1. Position the belt cover 3. Ensure that the tab is under the metal catch 2. Slide the belt cover under the side catches Install the sheet-metal guard. Refer to Removing g009038 the Sheet-Metal Guard (page 40). Figure 84 Tighten the bolt for the mower-deck curtain.

-

Page 60: Replacing The Hydraulic Pump-Drive Belt

Replacing the Hydraulic Controls System Pump-Drive Belt Maintenance Disengage the blade-control switch (PTO) and engage the parking brake. Adjusting the Shut off the engine, remove the key, and wait Control-Handle Position for all moving parts to stop before leaving the operating position. -

Page 61: Adjusting The Motion-Control Linkage

Remove the electrical connection from the seat safety switch, located under the bottom cushion of the seat. Note: The switch is a part of the seat assembly. Temporarily install a jumper wire across the terminals in the connector of the main wire harness. -

Page 62: Adjusting The Motion-Control Damper

Adjusting the Motion the lever, allow the reverse-indicator springs to bring the levers back to neutral. Control Neutral-Lock Pivot Note: The wheels must stop turning or slightly creep in reverse. The flanged nut can be adjusted to obtain a more desired motion-control lever resistance when moving Shut off the unit, remove the jumper wire from it to the N... -

Page 63: Hydraulic System Maintenance

Seek immediate medical attention if fluid is injected into skin. Injected fluid must be surgically removed within a few hours by a doctor. Servicing the Hydraulic System Hydraulic-Fluid Type: Toro ® HYPR-OIL ™ hydraulic fluid or Mobil ® 1 15W-50. - Page 64 Mobil ® 1 fluid (more often in dirty or dusty conditions). Every 500 hours—Change the hydraulic filters and hydraulic fluid when using Toro ® HYPR-OIL ™ 500 hydraulic fluid (more often in dirty or dusty conditions).

-

Page 65: Mower Deck Maintenance

Mower Deck Install the replacement hydraulic filter. Install the pump-drive belt and the mower belt. Maintenance Remove the jack stands and lower the machine (Figure 93). Leveling the Mower Deck Add fluid to the hydraulic reservoir and check for any leaks. Clean up any spilled fluid. - Page 66 g009196 Figure 96 1. 7.6 cm (3 inches) at 3. Measure here from the position A is correct blade tip to the hard surface 4. Measure at position A and 2. 8.3 cm (3-1/4 inches) at g027343 position B is correct B on both sides Figure 95 1.

- Page 67 Note: To adjust the single-point system, loosen the In most conditions, the back blade tip 2 bolts at the bottom of the height-of-cut plate should be adjusted 6.4 mm (1/4 inch) higher (Figure 98). than the front. Torque the 2 bolts to 37 to 45 N∙m (27 to 33 ft-lb). On both sides of the deck, measure from the level surface to the back tip of the blade (postion B) as shown in...

-

Page 68: Servicing The Cutting Blades

Servicing the Cutting Blades To ensure a superior quality of cut, keep the blades sharp. For convenient sharpening and replacement, you may want to keep extra blades on hand. Blade Safety g006530 Figure 100 A worn or damaged blade can break, and a piece of the blade could be thrown toward you or bystanders, 1. - Page 69 LOCK position, and engage the parking brake. ensure optimum performance and continued safety conformance of the machine, use genuine Toro Shut off the engine, remove the key, and wait replacement blades. Replacement blades made by for all moving parts to stop before leaving the other manufacturers may result in nonconformance operating position.

-

Page 70: Removing The Mower Deck

Removing the Mower Deck Note: If the blade stays in a horizontal position, the blade is balanced and can be used. Before servicing or removing the mower deck, lock Note: If the blade is not balanced, file some out the spring-loaded deck arms. metal off the end of the sail area only (Figure 103). - Page 71 g009197 Figure 107 g009038 1. Right stabilizer Figure 106 2. Deck strut (right side shown) 1. Clutch pulley 5. Square hole in the idler 3. Remove the shoulder bolt and nut. arm for the ratchet 4. Remove the shoulder bolt and nut. 2.

-

Page 72: Replacing The Grass Deflector

Replacing the Grass Cleaning Deflector Cleaning under the Mower WARNING Service Interval: Before each use or daily An uncovered discharge opening could allow Disengage the blade-control switch (PTO), move the lawn mower to throw objects at you or the motion-control levers to the N EUTRAL LOCK bystanders, resulting in serious injury. -

Page 73: Storage

Storage Note: A fuel stabilizer/conditioner is most effective when mixed with fresh fuel and used at all times. Cleaning and Storing the Run the engine to distribute conditioned fuel through the fuel system (5 minutes). Machine Shut off the engine, allow it to cool, and Disengage the blade-control switch (PTO), drain the fuel tank;... - Page 74 Troubleshooting Problem Possible Cause Corrective Action The starter does not crank. 1. The blade-control switch (PTO) is 1. Move the blade-control switch (PTO) engaged. to the disengaged position. 2. The parking brake is disengaged. 2. Engage the parking brake. 3. The motion-control levers are not in 3.

- Page 75 Problem Possible Cause Corrective Action The machine does not drive. 1. The bypass valves are not closed tight. 1. Tighten the bypass valves. 2. The pump belt is worn, loose, or 2. Change the belt. broken. 3. The pump belt is off a pulley. 3.

- Page 76 Schematics g009180 Wire Diagram (Rev. A)

- Page 77 Notes:...

- Page 78 Notes:...

- Page 79 The Way Toro Uses Information Toro may use your personal information to process warranty claims, to contact you in the event of a product recall and for any other purpose which we tell you about. Toro may share your information with Toro's affiliates, dealers or other business partners in connection with any of these activities. We will not sell your personal information to any other company.

- Page 80 Contact your seller to arrange service of the product. If for any reason it is impossible for you to contact your seller, you may contact any Toro Authorized Distributor to arrange service. Visit http://www.toro.com/ to locate a Toro distributor in your area.

Need help?

Do you have a question about the 75969TE and is the answer not in the manual?

Questions and answers