Daikin FDXM35F3V1B Installer's Reference Manual

Hide thumbs

Also See for FDXM35F3V1B:

- Operation manual (8 pages) ,

- Installer's reference manual (20 pages)

Summary of Contents for Daikin FDXM35F3V1B

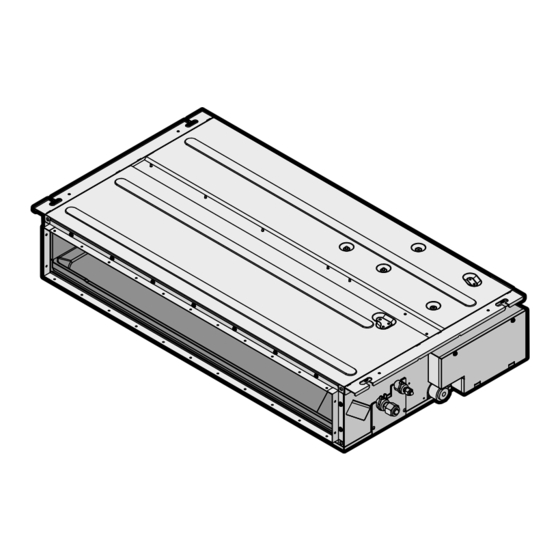

- Page 1 Installer reference guide Split system air conditioners FDXM25F3V1B FDXM35F3V1B FDXM50F3V1B FDXM60F3V1B FDXM25F3V1B9 FDXM35F3V1B9 Installer reference guide FDXM50F3V1B9 English Split system air conditioners FDXM60F3V1B9...

-

Page 2: Table Of Contents

Table of Contents 9 Hand-over to the user Table of Contents 10 Disposal 11 Technical data 1 General safety precautions 11.1 Wiring diagram ................18 About the documentation ............12 Glossary 1.1.1 Meaning of warnings and symbols......For the installer................1.2.1 General ............... -

Page 3: For The Installer

▪ Do NOT sit, climb or stand on the unit. Make sure installation, servicing, maintenance and repair comply with instructions from Daikin and with applicable NOTICE legislation (for example national gas regulation) and are executed only by authorised persons. - Page 4 1 General safety precautions WARNING If appliances contain R32 refrigerant, the floor area of the room in which the appliances are installed, operated and stored MUST be larger than the minimum floor area defined in table below A (m ). This applies to: ▪...

-

Page 5: Refrigerant

1 General safety precautions Floor-standing unit (= Floor-standing unit) ▪ Only use tools exclusively for the refrigerant type used in the system, this to ensure pressure resistance and prevent foreign 1.2.3 Refrigerant materials from entering into the system. ▪ Charge the liquid refrigerant as follows: If applicable. -

Page 6: Electrical

2 About the documentation 1.2.6 Electrical NOTICE Precautions when laying power wiring: DANGER: RISK OF ELECTROCUTION ▪ Turn OFF all power supply before removing the switch box cover, connecting electrical wiring or touching electrical parts. ▪ Disconnect the power supply for more than 1 minute, ▪... -

Page 7: Installer Reference Guide At A Glance

▪ A subset of the latest technical data is available on the regional 3.2.2 To remove the accessories from the Daikin website (publicly accessible). indoor unit ▪ The full set of latest technical data is available on the Daikin extranet (authentication required). 1× 1× 1×... -

Page 8: System Layout

5 Preparation WARNING System layout Do NOT install the air conditioner at any place where flammable gas may leak out. If the gas leaks out and stays around the air conditioner, a fire may break out. 5.2.1 Installation site requirements of the indoor unit INFORMATION Also read the following requirements:... -

Page 9: Preparing Refrigerant Piping

5 Preparation ▪ Protective guards. Make sure to install protective guards on the Outer diameter Temper grade Thickness (t) suction and discharge side to prevent somebody from touching (Ø) the fan blades or heat exchanger. Ø 6.4 mm (1/4") Annealed (O) ≥0.8 mm Do NOT install the unit in the following places: 9.5 mm (3/8") -

Page 10: Installation

6 Installation ▪ Ceiling strength. Check whether the ceiling is strong enough to WARNING support the weight of the unit. If there is a risk, reinforce the ceiling ▪ All wiring MUST be performed by an authorised before installing the unit. electrician and MUST comply with the applicable ▪... -

Page 11: Guidelines When Installing The Ducting

6 Installation 6.2.3 Guidelines when installing the ducting WARNING If the one or more rooms are connected with the unit via duct system make sure: ▪ there are no operating ignition sources (example: open flames, an operating gas appliance or an operating electric heater) in case the floor area is less than A specified in the General safety precautions;... -

Page 12: Connecting The Refrigerant Piping

6 Installation ▪ Set the plug and push it in using a Phillips screwdriver. 1~1.5 m Hanging bar Allowed Not allowed ▪ Condensation. Take measures against condensation. Insulate the complete drain piping in the building. Drain plug Phillips screwdriver To connect the drain piping to the indoor unit To check for water leaks NOTICE Gradually pour approximately 1 ... -

Page 13: Guidelines When Connecting The Refrigerant Piping

6 Installation NOTICE Piping size Tightening Flare Flare shape (mm) torque (N•m) dimensions (A) (mm) Take the following precautions on refrigerant piping into (mm) account: 90° ±2 Ø6.4 15~17 8.7~9.1 ▪ Avoid anything but the designated refrigerant to get Ø9.5 33~39 12.8~13.2 mixed into the refrigerant cycle (e.g. -

Page 14: To Check For Leaks

6 Installation WARNING: FLAMMABLE MATERIAL Connecting the electrical wiring The R32 refrigerant (if applicable) in this unit is mildly flammable. Refer to the outdoor unit specifications for the 6.4.1 About connecting the electrical wiring type of refrigerant to be used. Typical workflow ▪... -

Page 15: To Connect The Electrical Wiring On The Indoor Unit

7 Configuration Wire type Installation method Stranded conductor wire with round crimp-style terminal a Terminal Indoor PCB (ASSY) b Screw Power supply and earth wiring Transmission and user interface wiring c Flat washer Clamps O Allowed Not allowed Allowed X NOT allowed 5 Reattach the service cover. -

Page 16: Commissioning

8 Commissioning Action Open the liquid stop valve (A) and gas stop valve (B) by removing the stem cap and turning counterclockwise with a hex wrench until it stops. 45° Close the service cover to prevent electric shocks. Commissioning Turn ON power for at least 6 hours before starting operation to protect the compressor. -

Page 17: Error Codes When Performing A Test Run

Technical data ▪ A subset of the latest technical data is available on the regional Daikin website (publicly accessible). ▪ The full set of latest technical data is available on the Daikin extranet (authentication required). FDXM25~60F3V1B(9) Installer reference guide Split system air conditioners 4P550955-1 –... -

Page 18: Wiring Diagram

12 Glossary 11.1 Wiring diagram Unified Wiring Diagram Legend For applied parts and numbering, refer to the wiring diagram on the unit. Part numbering is by Arabic numbers in ascending order for each part and is represented in the overview below by symbol “*” in the part code. CIRCUIT BREAKER PROTECTIVE EARTH CONNECTION... - Page 19 Optional equipment Equipment made or approved by Daikin that can be combined with the product according to the instructions in the accompanying documentation. Field supply Equipment NOT made by Daikin that can be combined with product according instructions accompanying documentation.

- Page 20 4P550955-1 2018.07...

Need help?

Do you have a question about the FDXM35F3V1B and is the answer not in the manual?

Questions and answers