Table of Contents

Advertisement

Quick Links

DATASHEET AND OPERATING GUIDE

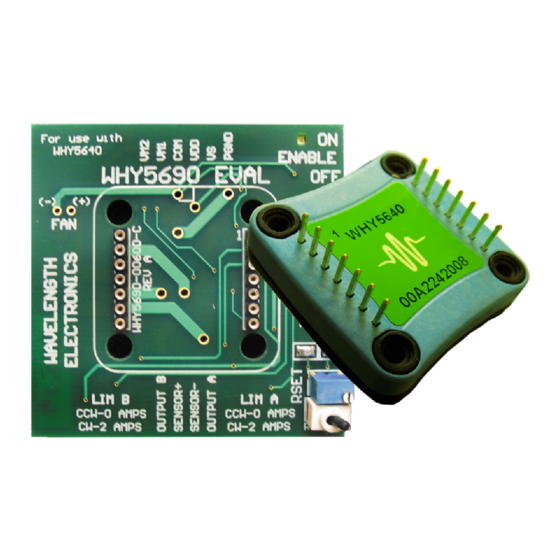

WHY5640 & WHY5690

Low Profile Temperature Controller & Evaluation Board

PRECISION, STABILITY & VERSATILITY

The advanced and reliable circuitry of the WHY5640

Temperature Controller achieves 0.005ºC temperature

stability with thermistors. Its small, low profile package

is ideal for designs with space constraints. The linear,

PI (Proportional, Integrator) control loop offers maximum

stability and efficiency.

The WHY5640 is a general purpose analog PI control

loop for use with thermoelectrics or resistive heaters. The

WHY5640 maintains precision temperature regulation

using an active resistor bridge circuit that operates directly

with thermistors or RTD temperature sensors. (AD590 and

LM335 sensors require external circuits.) Supply up to

±2.2 A of heat and cool current to your thermoelectric from

a single +5 V power supply.

CONTENTS

e

Pb

RoHS

406-587-4910

www.teamWavelength.com

DISCONTINUED - USE THE WHY56ND

FEATURES

• Small Package Size

• +5 to +26 V Control Electronics Supply

• +4.5 to +30 V Power Drive Supply

• Low Cost

• 0.005ºC Stability (typical)

• Linear PI Temperature Control

• High ±2.2 A Output Current

• Control Above and Below Ambient

• Master/Booster Operation

• Temperature Setpoint, Heat and Cool Current

Limits, Proportional Gain, and Integrator Time

Constant are set with external components.

BUILT-IN SAFETY

To protect the device, heat and cool limits can be set

independently. This safety feature guarantees that your

thermoelectric cooler will never be driven beyond your

specified limits.

Connect two or more WHY5640 units together and drive

higher output currents.

LEADING EDGE APPLICATIONS

Onboard switches, connectors, and trimpots make

configuration and operation simple with the WHY5690

evaluation board. The WHY5640 has proven reliable in

such diverse fields as electro-optical systems, airborne

instrumentation, spectroscopic monitors, and medical

diagnostic equipment.

ORDERING INFORMATION

PAGE

2

PART NO

4

WHY5640

6

WHY5690

7

WEV300

8

WEV301

15

WEV302

18

24

WTW002

25

WHS302

27

WXC303

28

WXC304

WXC305

© August 2023

DESCRIPTION

±2.2 A Temperature Controller

Evaluation PCB for WHY5640

Thermal Solution Kit

Thermal Solution Kit with +5 V Fan

Thermal Solution Kit with +12 V Fan

Thermal Washer for Wxx Controllers

Heatsink for Wxx Controllers

+5 V Fan

+12 V Fan

Screw Kit

Advertisement

Table of Contents

Summary of Contents for Wavelength Electronics WHY5640

-

Page 1: Table Of Contents

PI (Proportional, Integrator) control loop offers maximum stability and efficiency. Connect two or more WHY5640 units together and drive higher output currents. The WHY5640 is a general purpose analog PI control loop for use with thermoelectrics or resistive heaters. The... -

Page 2: Quick Connect Guide

3 WHY5640 Temperature Controller. page 14 WHY5690 Evaluation Board Top view Figure 2 is the Quick Connect schematic for the WHY5640. page 21 WHY5690 Eval Board Electrical Schematic NOTE: If you are upgrading from the WHY5640 to the To ensure safe operation of the WHY5640... - Page 3 Figure 3. LOAD NOTE: Use a max of +5 V power supply with the test load shown. Values shown can simulate any load up to the WHY5640 maximum of 2.2 A. Always check the SENS OUTA Calculator before operating the WHY5640 controller.

-

Page 4: Pin Descriptions

BUFB in a master/booster configuration. NOTE: If you are upgrading from the WHY5640 to the WTC3243: The position of Pin 1 on the WHY5640 is reversed (or mirrored) relative to the position of Pin 1 on the WTC3243. © 2023... - Page 5 See Table 8 for output configuration for maximum voltage connection. Provides power to the WHY5640 H-Bridge Power Stage. Supply range input for this Power Drive pin is +4.5 to +30 VDC. The maximum current drain on this terminal should not exceed Supply Input 2.5 A.

-

Page 6: Electrical Specifications

WHY5640 TEMPERATURE CONTROLLER ELECTRICAL SPECIFICATIONS ABSOLUTE MAXIMUM RATINGS SYMBOL WHY5640 UNIT Supply Voltage 1 (Voltage on Pin 8) +5 to +26 Supply Voltage 2 (Voltage on Pin 10) +4.5 to +30 Output Current (See SOA Chart) ±2.2 Power Dissipation, T = +25ºC... -

Page 7: Safety Information

WHY5640 TEMPERATURE CONTROLLER SAFETY INFORMATION THEORY OF OPERATION The WHY5640 is a analog Proportional, Integral (PI) control SAFE OPERATING AREA — DO NOT EXCEED loop for use in thermoelectric or resistive heater temperature INTERNAL POWER DISSIPATION LIMITS control applications. The WHY5640 maintains precision... -

Page 8: Operating Instructions - Standalone

STANDALONE 100 mA of current. The V power supply is used to power the WHY5640 output H-Bridge and must be capable of supplying a current greater than the LIMA and LIMB current NECESSARY EQUIPMENT limit settings. - Page 9 6.36 change per ºC for best stability. Table 4 compares temperature sensors versus their ability to maintain stable load temperatures with the WHY5640. Figure 6 shows the circuit for adjustable current limits. Table 4. Temperature Sensor Comparison of voltage change 5 kΩ...

- Page 10 (cooler than) the setpoint temperature. considerable temperature overshoot. RTDs Figure 9 illustrates how to connect the WHY5640 for STEP 4 Control Loop Proportional Gain & operation with PTC (Positive Temperature Coefficient) RTD Integrator Time Constant - Pins 1, 3, 5, &...

- Page 11 WHY5640 TEMPERATURE CONTROLLER Table 5. Recommended Gain and Integrator Values Sensor Type/ Gain Integrator Time Constant Thermal Load Speed , seconds ] Thermistor / Fast 800 kΩ 1.0 MΩ 15 µF Thermistor / Slow 400 kΩ 2.0 MΩ 47 µF RTD / Fast 0.53...

- Page 12 INCREASING OUTPUT CURRENT DRIVE AGND SENS LIMA The WHY5640 is specifically designed to operate in a master/booster output current boosting configuration. Two WHY5640 or more WHY5640 controllers can be coupled to boost the +0.5V output current. PROPORTIONAL/INTEGRAL SENSOR CONTROL LOOP BRIDGE...

- Page 13 WHY5640 TEMPERATURE CONTROLLER THERMISTOR THERMOELECTRIC WHY5640 WHY5640 TEC MASTER CONTROLLER TEC BOOSTER CONTROLLER SETPOINT TRIMPOT 1.5 kΩ 1.5 kΩ 5 kΩ 5 kΩ SINGLE TURN SINGLE TURN ENABLE DISABLE SWITCH 1 Figure 11. Boosting Output Current Drive Table 6. Maximum Output Current (Amps) - NOTE: Do not use more than five controllers together...

-

Page 14: Operation Instructions - Evaluation Board

WHY5690 WITH HEATSINK AND FAN The equipment is the same as on page 8 with the • Match up the notch (Figure 12) on the WHY5640 with addition of the WHY5690 Evaluation Board and a Digital the silkscreen on the PCB multimeter, 4-½... - Page 15 WHY5640 internal control limits from zero to a full 2.0 A. Clockwise turns will increase electronics and must be capable of supplying 100 mA of the limit, and counter-clockwise turns will decrease the current.

- Page 16 STEP 8 ENABLING AND DISABLING THE OUTPUT CURRENT Enable and disable the WHY5640 output current using the onboard toggle switch. The output is enabled when the green ON LED indicator is lit. NOTE: Before enabling the output, make sure the RUN/SET switch is set to the “RUN”...

-

Page 17: Additional Technical Information

(x.75” w/o FAN)(x1” w/FAN) WHY SERIES: FAN & HEATSINK MOUNTING Airflow Direction To mount the WHY5640 Series to the heatsink and fan (Figure 13) and optional evaluation PCB, refer to the 30 mm FAN WXC303 (+5VDC) or drawings and instructions below:... - Page 18 Figure 16. External Voltage Control Using Thermistor Temperature Coefficient) RTDs. This setup is useful Sensors when operating the WHY5640 in a DAC controlled system. Figure 18 illustrates an effective circuit. Equation 7 illustrates how to determine the setpoint voltage, , given a desired thermistor resistance (temperature).

- Page 19 Operation with AD590 & LM335 Sensors - AGND SENS Pins 1, 6, & 7 WHY5640 Use an AD590 and LM335 Sensor to operate the WHY5640 controller. Figure 20 illustrates how to connect the WHY5640 +0.5 V SENSOR BRIDGE AMPLIFIER for operation with PTC (Positive Temperature Coefficient) linear sensors AD590 or LM335.

- Page 20 If the SOA Calculator indicates the WHY5640 will be outside of the Safe Operating Area, the system must be changed SOA charts are included in this datasheet for quick reference, so that less power is dissipated within the controller.

- Page 21 WHY5640 TEMPERATURE CONTROLLER WHY5690 EVALUATION BOARD SCHEMATIC Note: WHY5690 Revision A uses 68µF capacitors for C1, C2, and C3 © 2023 www.teamWavelength.com...

-

Page 22: Troubleshooting

Switch off power to the system, reverse the connections to the The TEC may be connected -OR- WHY5640, and then try again to operate the system. backwards to the WHY5640 Temperature is increasing TEC wiring polarity is dependent on the temperature sensor type (NTC vs. -

Page 23: Mechanical Specifications

WHY5640 TEMPERATURE CONTROLLER MECHANICAL SPECIFICATIONS 0.07 with heatsink and fan with heatsink Airflow 0.40 Direction WEIGHTS WHY5640 0.6 oz 1.27 0.48 WHS302 Heatsink 0.5 oz 0.87 WXC303/4 Fan 0.3 oz 0.01 0.31 BOTTOM VIEW 4-40 UNC 2 PLS 0.945 PIN DIAMETER: 0.020”... - Page 24 WHY5640 TEMPERATURE CONTROLLER MECHANICAL SPECIFICATIONS — WHY5690 EVALUATION BOARD For use with WHY5640 ENABLE WHY5690 EVAL 0.945" [24.0 mm] 2.25" [57.2 mm] 0.65" [16.6 mm] LIM B LIM A CCW-0 AMPS CCW-0 AMPS CW-2 AMPS CW-2 AMPS 0.65" [16.6 mm] 0.945"...

-

Page 25: Cabling Specifications

WHY5640 TEMPERATURE CONTROLLER CABLING SPECIFICATIONS These cables are included with the WHY5690 Evaluation Board. WTC3293-00101 INPUT CABLE PIN # COLOR FUNCTION MOLEX #43645-0600 BLUE PGND MICRO-FIT 6 CIRCUIT ORANGE SINGLE ROW RECPT BLACK WHITE GREEN WTC3293-00102 OUTPUT CABLE MOLEX #43645-0400... -

Page 26: Certification And Warranty

CERTIFICATION AND WARRANTY There are no user-serviceable parts inside this product. Return the CERTIFICATION product to Wavelength Electronics for service and repair to ensure that safety features are maintained. Wavelength Electronics, Inc. (Wavelength) certifies that this product met its published specifications at the time of shipment.

Need help?

Do you have a question about the WHY5640 and is the answer not in the manual?

Questions and answers