Table of Contents

Advertisement

Quick Links

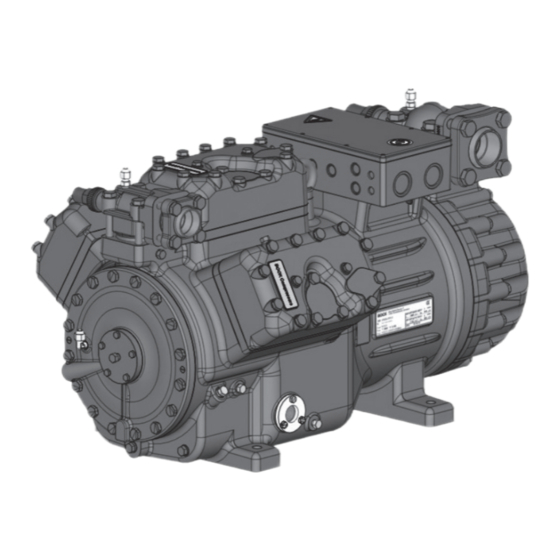

BOCK HG66e (HC/LG)

Assembly instructions

96446-11.2022-Gb

Translation of the original instructions

HG(X)66e/1340-4 (S)

HG(X)66e/1540-4 (S)

HG(X)66e/1750-4 (S)

HG(X)66e/2070-4 (S)

HGX66e/1340 ML 31 LG

HGX66e/1540 ML 36 LG

HGX66e/1750 ML 44 LG

HGX66e/2070 ML 50 LG

BOCK

®

HG66e/1340-4 (S) HC

HG66e/1540-4 (S) HC

HG66e/1750-4 (S) HC

HG66e/2070-4 (S) HC

HGX66e/1340 S 37 LG

HGX66e/1540 S 42 LG

HGX66e/1750 S 50 LG

HGX66e/2070 S 60 LG

colour the world

of tomorrow

Advertisement

Table of Contents

Need help?

Do you have a question about the HG66e/1340-4 and is the answer not in the manual?

Questions and answers