Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Humboldt HM-5240.3F

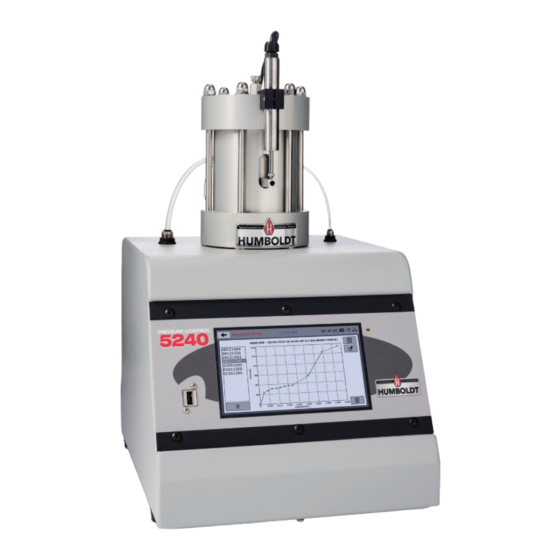

- Page 1 HM-5240.3F product manual 07.17 Pressure Controller...

-

Page 3: Table Of Contents

Test Setup Wizard – Select Stop Condition Save too USB Test Setup Wizard – Start Initial Set Up — Network Tests – Current Tests Tab Network Settings Screen HM-5240.3F Specifications DHCP General Warnings IP Information SafetyWarnings Local Status Electrical Warnings... -

Page 4: Quick Start Guide

Unpacking Initial inspection should include checking for physical dam- age during shipping and obvious external damage to the product. Package contents are defined by your packing list. Each Order is configured according to customer specifications. In your inspection, make certain that the contents of your shipment match the documentation provided by your pack- ing list. -

Page 5: Instrumentation Connections And Setup

Instrumentation Connections and Setup HM-5240 Rear Instrumentation Panel Above is a photo of the rear instrumentation panel of the HM-5240. Network (1) Ethernet input for connecting machine to a local area net- work (LAN) and/or the internet. USB Power (2) The USB Power port is used for powering a wireless access appliance for those who want to use a wireless LAN setup. -

Page 6: Instrument Inputs

Instrument Inputs (3) The back panel features four (4) inputs for connecting instrumen- tation to the machine. Each input represents a separate channel. Channel 1 has been assigned to Cell Pressure and is pre-calibrat- ed. Channel 2 has been assigned to Back Pressure and is pre-cal- ibrated. - Page 7 DO NOT RECALIBRATE! When your HM-5420 is first turned on, the screen below will appear. From this screen, to confirm your machine instrumentation has been calibrated, navigate to the Calibration section by clicking the Menu icon in the top left corner of the screen (1). When you click on this button, you will see a drop-down menu appear, see below.

-

Page 8: Initial Set-Up - Calibration

Initial Set Up — Calibration Click on the Calibration tab in the top left corner (2). You will see the following screen. Calibration Input Screen The Calibration Input Screen (above) is used to monitor and calibrate instrumentation and assign them to specific chan- nels of the HM-5240. -

Page 9: Units

Calibration Input Screen, cont. Each channel has a “Limits On” check box (1). Use the Limits On to keep the machine from exceeding the sensor limits of the instrumentation. By selecting this option, before the test can exceed the limits of the sensors, all tests will stop run- ning and the motor will stop to avoid damaging connected instrumentation. -

Page 10: Export Calibration Via Usb

For the HM-5240, the value for vertical displacement is used to indicate changes in volume. This is measured by a 1.0" (25mm) LSCT and a 100cc chamber. Export Calibration via USB (4) Press this button to select calibrations to export via USB. It is a good practice to export all your calibrations to a thumb drive. -

Page 11: Date

Date (1) Set the month, day, year, and date display format. Time (2) Set the hours, minutes, seconds, and am/pm. Clock Style (3) Select a clock view, either a 24-hour or 12-hour clock, as well as the option to show seconds or not. Clock (4) The current time is displayed and is located on every control- ler screen. -

Page 12: Brightness

Brightness (1) Slide the gray bar to the left or right to adjust brightness. Dim Display (2) The backlight of the display will automatically dim to save power. Click the yellow box to change the number of min- utes before the display goes dim. After the time has elapsed, touch the display to deactivate dimming. -

Page 13: Preferences - General Tab

Click on the Preferences tab (1). You will see the following screen. Preferences – General Tab The Preferences panel is comprised of four (4) tabs and defaults to the General tab, see above. Logger ID (1) Each machine that is connected to your network requires a unique Logger ID. -

Page 14: Ambient Temperature

Ambient Temperature (1) This field displays the current ambient temperature and allows you to select desired units (Fahrenheit or Celsius) for temperature recording. Manual Control This screen is accessed by clicking on the Manual Control Tab under System Preferences. Bypass (1) This option allows you to bypass the volume change appara- Flow Up (2) This option allows you to use the volume change apparatus... -

Page 15: Flow Down

Flow Down (3) This option allows you to use the volume change apparatus in the down direction. Preferences – Storage Tab This screen is accessed by clicking on the Storage Tab under System Preferences. Test Storage Limit (1) This field allows you to set the number of previously run tests to be available on the “Previous Tests”... -

Page 16: Initial Set Up - Network

Initial Set Up — Network To set up Network settings, return to the System Settings screen and click on the Network panel. (1) A password is required to access the Network Settings. That password is: 27604. -

Page 17: Network Settings Screen

Network Settings Screen The screen above is the Network Settings screen, it provides information on your IP information and network status. DHCP (1) Check this box to enable/disable the Dynamic Host Configu- ration Protocol (DHCP). If enabled, your machine will pick up IP information from your router. -

Page 18: System Information

System Information Below is a view of the System Information screen. It provides a current status of the machine. Firmware Version (1) The current version of the machine firmware is shown here. If you contact product support, you will need to supply this information. IP Information (2) This information will be filled in automatically if DHCP is checked, otherwise you will have to manually supply this in-... -

Page 19: Internet Status

This will provide us with the necessary in- formation to assist you and you will be added to the next position in the support cue. You can also email Humboldt Support at support@hum- boldtmfg.com or Humboldt Service at service@humboldtm- fg.com. Please include contact information and a detailed... -

Page 20: Initial Set Up - Update

Initial Set Up — Update Clicking on this panel provides information on checking for Updates, performing updates and an update history for the machine. (1) -

Page 21: Update From Usb

Once on this page, click on the Elite Series Firmware tab. You will see a list of Humboldt Elite Series machines. Click on the HM-5240 Current Version link and the firmware update will begin to download to your computer. Once the down- load is complete. -

Page 22: Check For Update

This manual covers the setup and operation of the HM- 5240.3F Pressure Controller in Stand-alone Mode only. For information on operating your load frame with Humboldt’s NEXT Software and a computer, please refer to the Hum- boldt NEXT software manual. -

Page 26: Installation And Equipment Setup

Installation and Equipment Setup Electrical Connections The HM-5240 is equipped with an internal digital switching power supply, which allows it to be used with most power configurations throughout the world. The unit is supplied with an IEC electrical cord with a standard 110V plug. The HM-5240 arrives ready for operation. -

Page 27: Instrumentation Connections And Setup

Instrumentation Connections and Setup HM-5240 Rear Instrumentation Panel Above is a photo of the rear instrumentation panel of the HM-5240. Network (1) Ethernet input for connecting machine to a local area network (LAN) and/or the internet. USB Power (2) The USB Power port is used for powering a wireless access appli- ance for those who want to use a wireless LAN setup. -

Page 28: Instrument Inputs

Instrument Inputs (3) The back panel features four (4) inputs for connecting instrumentation to the machine. Each input represents a separate channel. Channel 1 has been assigned to Cell Pressure and is pre-calibrated. Channel 2 has been as- signed to Back Pressure and is pre-calibrated. Channel 3 has been assigned to Pore Pressure and is pre-calibrated. -

Page 29: Hm-5240 Setup Overview

Instrumentation Connections and Setup HM-5240 Rear Instrumentation Panel HM-5240 Hookup Overview Below is a drawing that illustrates the installation of the HM-5240. Testing Equipment for Construction Materials FRONT BACK Pressure Control 5240 5240 Testing Equipment for Construction Materials MASTER LOADER 5030 5030 FRONT... -

Page 30: Bladder A

Bladder A (2) Measure a length of 0.25" tubing and insert one end into the Blad- der A Input (2) on the HM-5240. Insert the tubing until you feel it seat into place. Take the other end of the tubing, add a HM-4150.72 Quick Vqlve Coupling and insert it into the Left-side port of Bladder A. -

Page 31: Cell Hookups

Cell Hookups (3) (4) To connect the HM-5240 Controller to a Triaxial Cell, while looking at the controller from behind, Measure a length of 0.25" tubing and insert one end into the Cell Valve Input (3) on the Right-side of the HM-5240. -

Page 32: Priming Volume Chambers

Priming the Volume Chambers The volume chambers for the HM-5240 are shipped empty and you will have to prime them before operation. To do this, add tubing to the Top Valve of the Triaxial Cell. Place the tubing end into a drain or bucket. - Page 33 Select the Volume Up Tab (2). The HM-5240 will begin to fill the Upper Chamber. Water should be coming out of the Base Tube into the drain or bucket. Monitor Input 4 Volume (3) until the number no longer increases, turn the V.C. part of the HM-5240 upside down and vent until water flows from the vent and then place back.

-

Page 36: Test Setup

Prior to begining a new test setup using the HM-5240 be sure to do the following: • Setup your specimen in a Triaxial Cell • Fill the Triaxial Cell with water • Purge the drainage lines of air. To begin a new test, Click on the Menu icon in the top left corner of the screen (1). -

Page 37: Template

Template (4) If you are just beginning to use your new machine, there will be no templates, which have been saved, so at this point, clicking on the template button will provide no templates to choose from. To create templates, you essentially save a completed test as a template. Once you have completed some tests and save them as templates, they will then show up when you press the template button. - Page 38 In the previous screen, we chose Saturation for the Test Type, so the value in the above screen is Pressure Parameters for a Saturation test. Click on the Step psi field (1) and a pop-up menu will appear. See below Use this menu to type in the psi value you want to use for each Step of the test (1).

- Page 39 Now set the Stop Parameters for the Test. Select the B-Value (1) you wish to use for the test and the Max Pressure (2) you'd like to use for the Stop Value. If you set the Max Pressure to "0", the Max Pressure constraint will not be evaluated for Stop.

-

Page 40: Test Setup - Consolidation

Test Setup Wizard – Select Test Type — Consolidation On the first screen of the Test Setup Wizard, you can select the type of test you want to perform — Saturation or Consolidation (2). Here we have chosen Consolidation, to continue, click on the arrow button in the bottom right-hand corner (3). -

Page 41: Test Setup Wizard - Setup Target Load

Test Setup Wizard – Setup Target Load In the previous screen, we chose Consolidation for the Test Type, so the value in the above screen is the Effective Pressure the machine will apply during a Consolidation test. Click on the Effective psi field (1) and a pop-up menu will appear. - Page 42 A new pop-up window will appear entitled Logging Time Table, see below. Above is a blank . In order for the logging table LOGGING TIME TABLE to function, you will need to fill in the table with values from either an ASTM standard or your own values.

-

Page 43: Test Setup Wizard - Select Stop Condition

Test Setup Wizard – Stop Condition To set the Stop Condition for the test, click on the yellow field (1) next to Stop Value. See below, Click the Check Mark (2) in the lower right-hand corner to save the value. Click the Arrow (3) in the lower, right-hand corner of the window to continue the Test Setup process. -

Page 44: Test Setup Wizard - Start

Test Setup Wizard – Start You should now see the Start Screen (below). You will need to set the Trigger Input Value for the Volume reading. Click on the Trigger Value field (1) and an input screen will popup. Insert the desired value in the Value field (1), using the keyboard. Click the Check Mark (2) in the lower right-hand corner to save the value. - Page 45 You are now setup to run your test. Proceed with your test by press- ing the Green Arrow (5) in the bottom, right-hand corner of the screen. When you press the Green Arrow (5) in the bottom, right-hand corner of the screen. You will see the following screen. In the Value Field (1) give you test a name.

-

Page 46: Tests - Current Tests Tab

Tests — Current Tests Tab On the screen below, the Green Arrow (1) in the screen header indicates that a test is currently running. The name of the test (2) is shown in the current tab. To access different views, control or stop the current test, click on the Test Control tab (3) at the right of the screen. - Page 47 From this new panel you are given the Current Status of your test, in this case, Running (1). You can also see the number of points cur- rently read (2) and the current duration of the test (3). In addition, by clicking on the Test View button (4) you can toggle through three different views of the current test.

- Page 48 Stop button. Operation from a Computer and NEXT Software This manual covers the setup and operation of the HM-5240.3F Pres- sure Controller in Stand-alone Mode only. For information on operat- ing your load frame with Humboldt’s NEXT Software and a computer,...

-

Page 49: Hm-5240.3F Specifications

Then can be viewed simultaneously or downloaded later to a computer in the lab, in the next room or at a different location, while also providing report generation capabilities from within Humboldt’s NEXT software or our enhanced test- specific modules. Specifications... -

Page 50: General Warnings

The Humboldt Mfg. Co. liability under the warranty contained in this clause is limited to the repair or replacement of defective goods and making good, defective... - Page 51 99 years. Transfer of the license can be obtained by a request, in writing, from HUMBOLDT MFG. CO. With the exception of HUMBOLDT Authorized Service Facilities, you may not copy, alter, de-compile, or reverse assemble the software in any fashion except as instruct- ed in this manual.

- Page 52 99 years. Transfer of the license can be obtained by a request, in writing, from HUMBOLDT MFG. CO. With the exception of HUMBOLDT Authorized Service Facilities, you may not copy, alter, de-compile, or reverse assemble the software in any fashion except as instruct- ed in this manual.

Need help?

Do you have a question about the HM-5240.3F and is the answer not in the manual?

Questions and answers