Table of Contents

Advertisement

Date:

18/4-2017

Kent hojtryk\Clean-9000\Brugs-9000-EN-d.307.doc

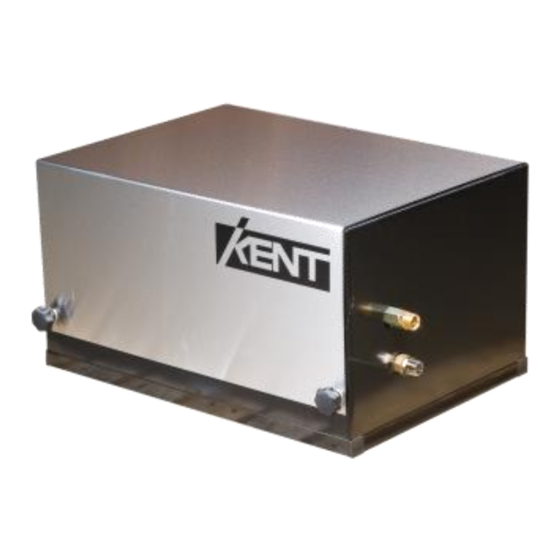

High-pressure cleaners.

Instruction manual

TLF. +45 75 19 80 33 E-mail:

High pressure cleaner Batch 9015 - 9020S

150 - 240 bar

Warning: Read this manual before operating the product

Table of contents:

FrontPage

Overensstemmelseserklæring på Højtryksrenser - Serie 9000 DK

Declaration of Conformity for High pressure cleaner - Model 9000 EN Page

1.

2.

4.2 Removal

Batch - 9000 -1500 + 3016

Page:

info@kent-as.dk

Batch 9015ST - 9020S-ST

Batch 2008 - 3016

Rev. E1- Feb. 2019

1 of 32

www.kent-as.dk

Page

1

Page

2

3

Page

4

Page

4

Page

5

Page

6

Page

6

Page

7

Page 12

Page 14

Page 14

Page 16

Page 17

Page 25

Page 25

Page 25

Page 26

Page 27

Page 29

Advertisement

Table of Contents

Need help?

Do you have a question about the 9015 and is the answer not in the manual?

Questions and answers