Summary of Contents for Miller Spectrum 700i

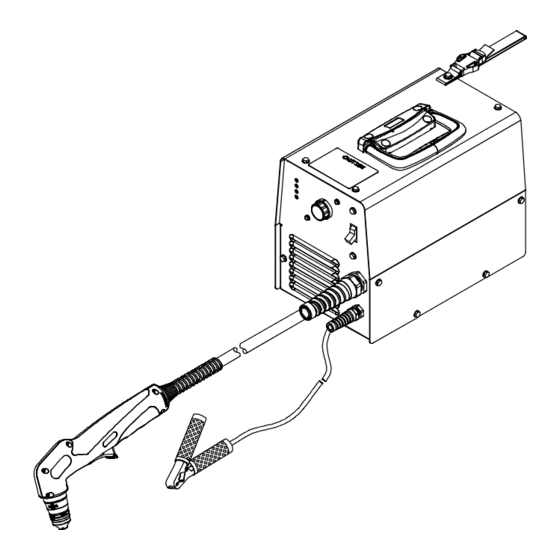

- Page 1 OM-256 119A 2013−01 Processes Air Plasma Cutting and Gouging Description Air Plasma Cutter Spectrum 700i And XT40i Torch File: Plasma Cutters Visit our website at www.MillerWelds.com...

- Page 2 We know you don’t have time to do it any other way. That’s why when Niels Miller first started building arc welders in 1929, he made sure his products offered long-lasting value and superior quality.

-

Page 3: Table Of Contents

TABLE OF CONTENTS SECTION 1 − SAFETY PRECAUTIONS - READ BEFORE USING ....... . . 1-1. -

Page 5: Section 1 − Safety Precautions - Read Before Using

SECTION 1 − SAFETY PRECAUTIONS - READ BEFORE USING pom_2011-10 Protect yourself and others from injury — read, follow, and save these important safety precautions and operating instructions. 1-1. Symbol Usage DANGER! − Indicates a hazardous situation which, if Indicates special instructions. not avoided, will result in death or serious injury. - Page 6 FUMES AND GASES can be hazardous ELECTRIC SHOCK can kill. SIGNIFICANT DC VOLTAGE exists in Cutting produces fumes and gases. Breathing inverter power sources AFTER the re- these fumes and gases can be hazardous to your health. moval of input power. Keep your head out of the fumes.

-

Page 7: Additional Symbols For Installation, Operation, And Maintenance

1-3. Additional Symbols For Installation, Operation, And Maintenance HOT PARTS can burn. FALLING EQUIPMENT can injure. D Do not touch hot parts bare handed. D Use lifting eye to lift unit only, NOT running gear, gas cylinders, or any other accessories. D Allow cooling period before working on equipment. -

Page 8: California Proposition 65 Warnings

1-4. California Proposition 65 Warnings Welding or cutting equipment produces fumes or gases This product contains chemicals, including lead, known to which contain chemicals known to the State of California to the state of California to cause cancer, birth defects, or other cause birth defects and, in some cases, cancer. -

Page 9: Section 2 − Consignes De Sécurité − Lire Avant Utilisation

SECTION 2 − CONSIGNES DE SÉCURITÉ − LIRE AVANT UTILISATION pom_2011−10fre Pour écarter les risques de blessure pour vous−même et pour autrui — lire, appliquer et ranger en lieu sûr ces consignes relatives aux précautions de sécurité et au mode opératoire. 2-1. - Page 10 D Coupez l’alimentation d’entrée avant d’installer l’appareil ou d’ef- ÉTINCELLES PROJETÉES fectuer l’entretien. Verrouillez ou étiquetez la sortie d’alimentation peuvent provoquer des blessures. selon la norme OSHA 29 CFR 1910.147 (reportez−vous aux Prin- cipales normes de sécurité). Le coupage plasma produit des étincelles et projec- tions de métal à...

-

Page 11: Dangers Supplémentaires En Relation Avec L'installation, Le Fonctionnement Et La Maintenance

D Si vous êtes à l’intérieur au moment du coupage, ventilez la pièce D Ne pointez pas le chalumeau en direction de votre corps ni de la ou ayez recours à une ventilation aspirante installée près de l’arc pièce à couper lorsque vous appuyez sur la gâchette − l’arc pilote pour évacuer les vapeurs et les gaz. - Page 12 Risque D’INCENDIE OU LIRE LES INSTRUCTIONS. D’EXPLOSION. D Lire et appliquer les instructions sur les étiquettes et le Mode d’emploi avant l’instal- D Ne pas placer l’appareil sur, au-dessus ou à lation, l’utilisation ou l’entretien de l’appareil. proximité de surfaces infllammables. Lire les informations de sécurité...

-

Page 13: Proposition Californienne 65 Avertissements

2-4. Proposition californienne 65 Avertissements Les équipements de soudage et de coupage produisent des Ce produit contient des éléments chimiques, dont le plomb, fumées et des gaz qui contiennent des produits chimiques reconnus par l’État de Californie pour leur caractère dont l’État de Californie reconnaît qu’ils provoquent des mal- cancérogène ainsi que provoquant des malformations formations congénitales et, dans certains cas, des cancers. -

Page 14: Section 3 − Definitions

A complete Parts List is available at www.MillerWelds.com SECTION 3 − DEFINITIONS 3-1. Additional Safety Symbols And Definitions Some symbols are found only on CE products. Warning! Watch Out! There are possible hazards as shown by the symbols. Safe1 2012−05 Do not remove or paint over (cover) the label. - Page 15 A complete Parts List is available at www.MillerWelds.com Do not cut on drums or any closed containers. Safe17 2012−05 Do not grip material near cutting path. Safe18 2012−05 Turn off power before disassembling torch. Safe19 2012−05 Wear hat and safety glasses. Use ear protection and button shirt collar.

-

Page 16: Miscellaneous Symbols And Definitions

A complete Parts List is available at www.MillerWelds.com 3-2. Miscellaneous Symbols And Definitions Plasma Arc Cutting Adjust Air/Gas Low Air Pressure Amperes (PAC) Pressure Light No − Do Not Do Volts Increase Temperature This Protective Earth Single Phase Constant Current Voltage Input (Ground) Percent... -

Page 17: Section 4 − Specifications

A complete Parts List is available at www.MillerWelds.com SECTION 4 − SPECIFICATIONS 4-1. Unit Specifications Power Supply Input −− Rated AC Phase and line frequency (Hz) 1 − Phase 50 / 60 Hz Rated Input Voltage (U ) and rated Input Current (I and I eff at rated output. - Page 18 Toppling or tilting Up to 15 incline Torch − The XT40i torch is intended for handheld use only. The torch conforms to IEC 60974-7 when used with the Spectrum 700i. Do not use this torch in combination with any other machines. −−...

-

Page 19: Duty Cycle And Overheating

A complete Parts List is available at www.MillerWelds.com 4-2. Duty Cycle And Overheating Duty Cycle is percentage of 10 min- utes that unit can cut at rated load without overheating. If unit overheats, thermostat(s) opens, output stops, Temperature 50%dutycycle trouble light goes On, and cooling fan runs. -

Page 20: Section 5 − Installation

A complete Parts List is available at www.MillerWelds.com SECTION 5 − INSTALLATION 5-1. Serial Number And Rating Label Location The serial number and rating information for this product is located on the back. Use rating label to determine input power requirements and/or rated output. -

Page 21: Connecting Gas/Air Supply

A complete Parts List is available at www.MillerWelds.com 5-3. Connecting Gas/Air Supply Tools Needed: 9/16 in. From Gas/Air Supply 257 249-B Teflon Tape (optional) or apply pipe sealant, and install Use only clean, dry air with 621 to 827 fitting in opening. Route hose to gas/air kPa (90 to 120 psi) pressure. -

Page 22: Electrical Service Guide For 230 Vac

A complete Parts List is available at www.MillerWelds.com 5-5. Electrical Service Guide For 230 VAC Failure to follow these electrical service guide recommendations could create an electric shock or fire hazard. These recommenda- tions are for a dedicated branch circuit sized for the rated output and duty cycle of the welding power source. 50/60 Hz Single Phase Input Voltage (V) Input Amperes (A) At Rated Output... -

Page 23: Cable Management Strap

A complete Parts List is available at www.MillerWelds.com 5-8. Cable Management Strap Cable Management Strap Coil cables together and secure to unit using the cable management strap. 257 263-B Notes OM-256 119 Page 19... -

Page 24: Section 6 − Operation

A complete Parts List is available at www.MillerWelds.com SECTION 6 − OPERATION 6-1. Controls Output Control Use control to set cutting output. Power Light Trouble Lights (See Section 7-4) 256 063-B OM-256 119 Page 20... -

Page 25: Mild Steel Recommended Cut Speed

A complete Parts List is available at www.MillerWelds.com 6-2. Mild Steel Recommended Cut Speed Recommended Cut Speeds At 40 Amperes Output Thickness Approximate Travel Speed* Inches mm/min 3962 Mild Steel 1626 12.7 15.9 *Recommended Cut Speed is approximately 80% of maximum. Aluminum and stainless steel cut speeds at these thicknesses may be reduced as much as 30%. -

Page 26: Plasma Cutting System Practices

A complete Parts List is available at www.MillerWelds.com 6-4. Plasma Cutting System Practices The pilot arc starts immediately when trigger is pressed. Always connect work clamp to a clean, DO NOT start pilot arc without cutting or paint-free location on workpiece, as close to gouging as this shortens the service life cutting area as possible. -

Page 27: Sequence Of Cutting Operation

A complete Parts List is available at www.MillerWelds.com 6-5. Sequence Of Cutting Operation Connect work clamp to a clean, paint-free For standard (shielded) cutting, place drag shield on edge location on workpiece, as close to cutting of metal. For extended (non-shielded) cutting, use 1/8 in. area as possible. -

Page 28: Sequence Of Piercing Operation

A complete Parts List is available at www.MillerWelds.com 6-6. Sequence Of Piercing Operation The pilot arc starts immediately when trigger is pressed. Connect work clamp to a clean, paint-free Hold torch at approximately 45 location on workpiece, as close to cutting to the workpiece. -

Page 29: Section 7 − Maintenance & Troubleshooting

A complete Parts List is available at www.MillerWelds.com SECTION 7 − MAINTENANCE & TROUBLESHOOTING 7-1. Routine Maintenance Maintain more often Disconnect power during severe conditions. before maintaining. n = Check Z = Change ~ = Clean l = Replace Reference * To be done by Factory Authorized Service Agent Each Section 4-1,... -

Page 30: Checking Or Replacing Filter Element

A complete Parts List is available at www.MillerWelds.com 7-2. Checking Or Replacing Filter Element Turn power Off, disconnect input power plug from receptacle. Check to see that all diagnostic LED’s have stopped flashing before removing wrapper from unit. Turn power Off, and disconnect input power plug from receptacle. -

Page 31: Status/Trouble Lights

A complete Parts List is available at www.MillerWelds.com 7-4. Status/Trouble Lights Difficulty establishing a pilot arc may indicate consumables need to be cleaned or replaced. Light Condition Status/Possible Cause Power Input power is okay. When Power light is on, system is normal if these lights Pressure/Cup/T emp are off. -

Page 32: Torch And Work Cable Connections

A complete Parts List is available at www.MillerWelds.com 7-5. Torch And Work Cable Connections Tools Needed: 3/8 in. Ref. 804 887-A / 257 595-B OM-256 119 Page 28... -

Page 33: Torch And Work Cable Connections

A complete Parts List is available at www.MillerWelds.com 7-6. Torch And Work Cable Connections Cut large cable tie. Connect ring terminal for pilot (red) lead to Turn power Off, and disconnect the TORCH RED terminal, and torque to input power plug from receptacle. Ferrite Core 20 in. -

Page 34: Checking/Replacing Retaining Cup, Tip, And Electrode

A complete Parts List is available at www.MillerWelds.com 7-7. Checking/Replacing Retaining Cup, Tip, And Electrode Overtightening will strip threads. Do not overtighten retaining cup during assembly. Do not cross-thread parts causing stripping. Use care during torch assembly and parts replacement. Inspect shield cup, tip, and electrode for wear before cutting or whenever cutting speed has been signifi- cantly reduced. -

Page 35: Troubleshooting Power Source

A complete Parts List is available at www.MillerWelds.com 7-8. Troubleshooting Power Source Trouble Remedy Clean or replace worn consumables as necessary (see torch Owner’s Manual). No pilot arc; difficulty in establishing an arc. Check for damaged torch or torch cable (see torch Owner’s Manual). No cutting output;... -

Page 36: Troubleshooting Torch

A complete Parts List is available at www.MillerWelds.com 7-9. Troubleshooting Torch Trouble Remedy Arc goes on and off while cutting. Torch travel speed too slow; increase travel speed (see Section 6-5). Clean or replace torch consumables as necessary (see Section 7-7). Be sure work clamp is securely attached to workpiece. Arc goes out while cutting. - Page 37 Notes OM-256 119 Page 33...

-

Page 38: Section 8 − Electrical Diagram

SECTION 8 − ELECTRICAL DIAGRAM Figure 8-1. Circuit Diagram OM-256 119 Page 34... - Page 39 256 479-A OM-256 119 Page 35...

-

Page 40: Section 9 − Parts List

SECTION 9 − PARTS LIST 9-1. Recommended Spare Parts Item Dia. Part Mkgs. Description Quantity Recommended Spare Parts ....238486 Element, Filter Air ........... . - Page 41 Item Part Description 249 970 Torch Handle Kit (1) 249 971 Torch Trigger (1) 249 959 Leads, 12 ft (1) 252 938 Torch Body Kit (1) 249 972 Torch Trigger Assembly w/Spring (1) 252 951 Grease, Silicone (1) 256 109 Torch, Replacement 12 ft (1) Figure 9-2.

- Page 42 Notes MATERIAL THICKNESS REFERENCE CHART 24 Gauge (.025 in.) (0.64 mm) 22 Gauge (.031 in.) (0.79 mm) 20 Gauge (.037 in.) (0.94 mm) 18 Gauge (.050 in.) (1.27 mm) 16 Gauge (.063 in.) (1.60 mm) 14 Gauge (.078 in.) (1.98 mm) 1/8 in.

- Page 43 Effective January 1, 2013 (Equipment with a serial number preface of MD or newer) This limited warranty supersedes all previous Miller warranties and is exclusive with no other guarantees or warranties expressed or implied. Warranty Questions? LIMITED WARRANTY − Subject to the terms and conditions below, 6 Months —...

- Page 44 Contact the Delivering Carrier to: File a claim for loss or damage during shipment. For assistance in filing or settling claims, contact your distributor and/or equipment manufacturer’s Transportation Department. ORIGINAL INSTRUCTIONS − PRINTED IN USA 2013 Miller Electric Mfg. Co. 2013−01...

Need help?

Do you have a question about the Spectrum 700i and is the answer not in the manual?

Questions and answers