Summary of Contents for SPM Frosty1

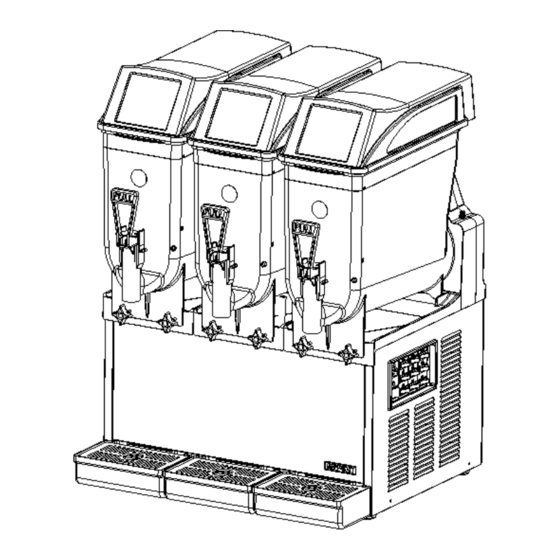

- Page 1 GRANITORE SLUSH MACHINE Frosty1 Frosty2 Frosty3 MANUALE D’USO E MANUTENZIONE ITALIANO PAG.2 OPERATOR’S MANUAL ENGLISH PAGE 19 Data di emissione: Dicembre, 2017 Revisione: 1 Pag. : 1/40...

- Page 2 All copying rights are reserved to SPM DRINK SYSTEMS; copying, even partial, is illegal. The descriptions and illustrations refer to the specific machine at issue. SPM Drink Systems reserves the right to modify at any time the equipment for mass production.

- Page 3 INDEX IMPORTANT WARNINGS AND ADVICES ..............21 EQUIPMENT KIT ........21 TRANPORT TIPS ........21 LIFTING TIPS ..........21 TECHNICAL SPECIFICATIONS ....22 POSITIONING ..........23 CONNECTION TO THE POWER SUPPLY MAINS ............24 ...

-

Page 4: Equipment Kit

1. IMPORTANT WARNINGS AND 2. EQUIPMENT KIT ADVICES In the packaging of this equipment you will find This installation and operation manual is also: an integral part of the equipment and must - operator’s manual, be kept for future consultation. - 1 tube of Vaseline grease lubricant to be used Unless otherwise stated, this manual is for machine maintenance;... -

Page 5: Technical Specifications

Dimensions and weight: any potential damage to the environment and to create health risks. Frosty1 In order to correctly dispose of the device, Height 83 cm. please contact the distributor from which you ... - Page 6 6. POSITIONING FOR SERVICEMAN ONLY The installation and subsequent servicing operations must be carried out by skilled members who have been trained to use the device and in compliance with the regulations in force. a) Remove the packing (fig.1), preserve it in order to reuse for winter storage and make sure the machine is in perfect condition.

- Page 7 7. CONNECTION POWER SUPPLY MAINS FOR SERVICEMAN ONLY Before fitting the plug in the power supply socket, your safety, already mentioned in the previous paragraph, please read the following precautions. machine’s electrical safety only guaranteed when it is connected to a suitable earth system, structured as provided by the national safety...

-

Page 8: Start-Up Procedures

8. START-UP PROCEDURES !IMPORTANT! BEFORE STARTING THE MACHINE, CARRY OUT THE CLEANING AND SANITISING PROCEDURES DESCRIBED IN CHAPTER 10. - Dilute and mix the product in a separate container according to the manufacturer’s instructions (see fig.4); never pour dry powder, Fig. - Page 9 9. MECHANICAL CONTROL BOARD a) Activate the general switch (D); b) Each tank is controlled by three switches which are activated as follows: In order to make ice slush or sorbets: ! Warning ! first select the switch (E) to start up the mixer If the machine is turned off at night, with the components (the green LED on the switch will bowls filled, or just partially filled, a layer of...

- Page 10 10. OPERATING INSTRUCTIONS a) To dispense the product, position the cup under the tap and pull the dispensing lever (see figure 8). Fig. 8 b) Adjusting the consistency: to alter the consistency of the product, turn the screws located on the back of the machine in the following way: clockwise to make the product less dense, counter clockwise to make the product denser (see figure 9).

- Page 11 11. DAILY CLEANING AND SANITIZING PROCEDURES In order to maintain the machine in like-new operating condition and to respect current regulations, it’s absolutely necessary to frequently and carefully perform the cleaning and sanitizing operations as described below. In case of prolonged shutdown (winter storage), the machine must be disassembled, washed and sanitized according to the instructions in this manual before start-up to ensure the best...

- Page 12 - Empty the bowl of any remaining product. - Remove both the main lid and then the transparent one. - Fill the bowl with lukewarm water to help melt off any sugar residuals and drain this water before proceeding with the next step. Caution To avoid electrical shock or contact with Fig.

- Page 13 - Unscrew the securing bolt (S) in the direction of the arrow (threading on the left), pull off of the mixing unit (U), and remove the sealing washers (X) and (T) (see figure 14). Caution Avoid the use of abrasive cleaners that can damage the finish.

- Page 14 Once performed all these cleaning and sanitizing procedures, it is possible to reassemble all the components. The correct assembly of the device is essential to prevent leakage of product and damage of the machine. To assemble the machine you will need an approved lubricant (such as Vaseline).

- Page 15 - Reassemble the upper mixing unit (O) so that its toothed crown is aligned with the lower crown. This will allow the front pin to fit perfectly into its fixed position on the bowl (see figure 20). - Remove the liquid-collector tray (AA) turning it slightly upwards and pulling it forward (see figure 21).

- Page 16 SANITIZING Whenever the machine has remained unused for some days after been cleaned and sanitized as described in the chapter 11, the sanitizing procedures described below must be performed just prior to start-up the machine. - Remove the main cover and the secondary transparent one.

-

Page 17: Special Maintentance

12. SPECIAL MAINTENTANCE Caution Before proceeding with any maintenance operation, it is compulsory to switch off the machine and unplug it from the mains. Condenser cleaning In order to guarantee good cooling system performance, condenser must well cleaned every month. How to reach it: - Switch off the power supply and disconnect the power cable. - Page 18 Control and replacement of seals 13. DISCLAIMER Rulon GASKET Replace every 9 to12 months according to the The manufacturer declines all responsibility for conditions of use and level of maintenance. This any damage that directly or indirectly might be part should be lubricated during every cleaning brought on to people, things, animals, as a operation.

-

Page 19: Troubleshooting Guide

14. TROUBLESHOOTING GUIDE NOTE: the following procedures must be performed by a qualified service technician. Problem Possible cause Solution The machine does not cool, space around machine Allow at least 20cm between the or cools only partially and inadequate for ventilation machine and anything next to it;... -

Page 20: Schema Elettrico -Wiring Diagram

15. SCHEMA ELETTRICO -WIRING DIAGRAM Data di emissione: Dicembre, 2017 Revisione: 1 Pag. : 37/40... - Page 21 Data di emissione: Dicembre, 2017 Revisione: 1 Pag. : 38/40...

Need help?

Do you have a question about the Frosty1 and is the answer not in the manual?

Questions and answers