Advertisement

Table of Contents

- 1 Table of Contents

- 2 Introduction

- 3 Mounting the Pump

- 4 Cleaning and Disinfection

- 5 Annual Safety Check

- 6 Key to Symbols

- 7 Specifications

- 8 Operation

- 9 Using the Pump in Parallel or

- 10 Alarm System

- 11 Warranty

- 12 Design Changes

- 13 Performance Data

- 14 Technical Description

- 15 Trouble Shooting

- 16 Replacement of Parts

- Download this manual

Maintenance Manual

syramed ® µSP6000

syringe pump

0123

Swiss Made

ARCOMED AG

8105 Regensdorf / Zürich

an ISO 9001 company

CAUTION: This manual is exclusively intended for authorised personnel who

have been instructed by ARCOMED AG in the use, maintenance and repair of

the infusion pump indicated above.

ARCOMED AG shall assume no liability for tampering by unauthorised

persons.

Note: No amendment service is provided for this manual.

Edition 43/03 -VA-TM-6000-E

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Arcomed syramed mSP6000

- Page 1 ISO 9001 company CAUTION: This manual is exclusively intended for authorised personnel who have been instructed by ARCOMED AG in the use, maintenance and repair of the infusion pump indicated above. ARCOMED AG shall assume no liability for tampering by unauthorised persons.

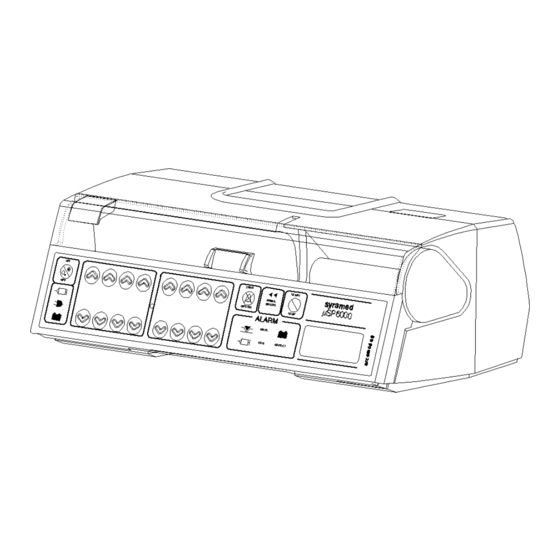

- Page 2 RATE ML/H VOLUME ML 2 MIN START syramed PRIME µSP6000 BOLUS OPTION STOP ALARM RATE DEFECT syramed 6000 Front view...

- Page 3 syramed µSP6000 Rear View...

- Page 4 Index numbers Door latch Syringe clamp Drive head Syringe ALARM SILENCE/OPTION key LCD window for messages and infusion parameters START/STOP key PRIME/BOLUS key RATE display VOLUME display ON/OFF key RATE keys VOLUME keys Alarm indicators Door Carrying handle Power and running indicators Mains power connector Mains fuse Nurse call connector...

-

Page 5: Table Of Contents

CONTENTS Page Introduction Mounting the pump 1.2.1 Cleaning and disinfection 1.2.2 Annual safety check Key to symbols Specifications Operation 4 - 9 3.18. Using the pump in parallel or multiple infusions Alarm system 10 - 12 Warranty Design changes Saftey checks Performance data Technical description Trouble shooting... -

Page 6: Introduction

EC Guideline 93/42 EEC and is marked CE 0123 (TUV PS Munich, Germany). The manufacturer according to MDD is Arcomed AG, Althardstrasse 146, CH 8105 Regensdorf, Zurich, Switzerland. Responsible for the EC is Arcomedical Infusion Ltd., West Horndon, Essex CM13 3XL, UK. -

Page 7: Cleaning And Disinfection

1.2.1 Cleaning and disinfection CAUTION: The pump must be switched off and disconnected from the mains power supply before cleaning and disinfecting. The pump must be kept clean and dry. Remove any spillage immediately. The pump must not be placed in an autoclave. The unit is disinfected by wiping over with a cloth which has been damped slightly with an alcohol-based disinfectant. -

Page 8: Specifications

Specifications CE Marking No. G5 01 08 13006 010 Classification Software revision 1.xx Flow rate range (ml/h) 0.1 - 500 (750 max) Flow rate increments (ml/h) Volume range (ml) 0.1 - 999.9 Volume increments (ml) Syringe size (ml) 5, 10, 20, 30, 50/60 (Automatic size recognition) Syringe brands B Braun, Fresenius, BD, Monoject,... -

Page 9: Operation

Operation The figures in brackets refer to the illustrations of front and rear views shown in the appendices. CAUTION: Use only approved disposable syringes! (cf. leaflet "Accessories and Consumables") The pump may be configured for one or several brands of disposable syringe: B. - Page 10 extension set. e) Press the ON/OFF key (11). The audible alarm beeps and all indicators illuminate. The software revision number (rx.xx) and then the pump configuration (C.xxx) illuminate briefly. f) Open the pump door (15) by releasing the latch (1). Open the syringe clamp (2).

- Page 11 to KVO operation when this volume has been infused and an audible and visual alarm (14) activates. The near end of syringe alarm activates three minutes before the syringe is empty (audible and visual warning). The time before end of syringe may be adjusted (by a technician) as required.

- Page 12 3.8. Setting volume and time If a specific volume is to be infused in a given time the RATE display must be left at zero. When the syringe has been primed, press the START/STOP key (7) to confirm. Then press and hold the OPTION key (5) until the RATE and VOLUME displays flash.

- Page 13 3.11. Different configurations If a different configuration is required, please contact our Customer Service Department or the official ARCOMED distributor in your country. 3.12. Accessories and consumables Accessories, expendable parts and single-use items may only be used if they comply with the appropriate international standard and national approvals.

-

Page 14: Using The Pump In Parallel Or

Use cable number 94070 to connect the Nurse call system. Please contact the Customer Service Department of ARCOMED AG for details of the RS232 interface (IR interface) and how to link it to external systems. -

Page 15: Alarm System

Alarm system 4.1. Alarm causes The electronic self-monitoring system continuously monitors the correct functioning of the pump and its displays whilst in operation. If a fault should occur, the infusion is stopped immediately and the alarm activates. The corresponding alarm symbol is illuminated continuously with a red colour and there is a continuous audible alarm. - Page 16 4.6. Battery alarm The pump may be operated independently of the mains power supply using the internal battery. If the mains power supply fails, the pump switches automatically to battery operation to continue the infusion without interruption. Battery operation is indicated by illumination of the battery symbol (17). Battery capacity permits from 3 up to 12 hours operation (1.85 Ah battery) depending on the infusion rate set.

-

Page 17: Warranty

The warranty is rendered null and void if changes or repairs are carried out by persons who have not been authorized in writing to do so by Arcomed AG or Arcomedical Infusion Ltd and if the inspection and maintenance intervals are not observed. - Page 18 µSP6000 syringe pump Schedule: every 24 months or after 10,000 hours operation: this unit must be checked by technical staff who have been trained and authorised in writing to do so by Arcomed AG or Arcomedical Infusion Ltd. Check list...

-

Page 19: Performance Data

Fluctuations in pump output depend to a great extent on the rate set and decrease as the rate is increased. Remark: Performance data on other syringes can be requested at Arcomed. The accuracy depends mainly on the tolerances of the syringes. - Page 20 Weight [mg]: Flow: ø Flow: ø Error[%]: Time: 50390.1 25.25 25.250 1.000 120.30 File Name: µSP6000-25ml/h(Plastipak 50 ml) Rec. date: Rec. time: Rate (ml/h): Evaporation: # Scans: Interval (s): 8.9.1998 8.9.1998 0:05:39 Uhr 0:05:39 Uhr 0.05 Flow [ml/h]: 50.0 37.5 25.0 12.5 0:00...

- Page 21 Weight [mg]: Flow: ø Flow: ø Error[%]: Time: 3894.4 2.04 1.997 -0.120 120.30 File Name: µSP6000-2 ml/h (Plastipak 50ml) Rec. date: Rec. time: Rate (ml/h): Evaporation: # Scans: Interval (s): 10.7.1999 10.7.1999 9:59:49 Uhr 9:59:49 Uhr 0.05 Flow [ml/h]: 0:00 0:10 0:20 0:30...

-

Page 22: Technical Description

TECHNICAL DESCRIPTION Introduction The Syramed µSP6000 is a microprocessor-controlled syringe pump having comprehensive software management functions and monitoring. Flow rate may be set over the range 0.1 ml/h to 1500 ml/h depending on the syringe size used. The pump accomodates several major brands of syringe of sizes 5, 10, 20, 30 and 50/60ml. - Page 23 The relay D10 is periodically switched off for a short period to test the watchdog and the correct functioning of the microcontroller is monitored. There is a second watchdog in the microcontroller. Operating voltages The supply voltage, the 5V logic supply rail and reference voltage are measured and monitored via disc resistors by the analog/digital converter in the microcontroller.

- Page 24 A/D converter The microcontroller controls the internal A/D converter and measures the results. Infra red interface The microcontroller sends and receives data via IC's D10 to D12. The encoder D10 converts the signals to Standard IrDA 1.0. The unit can receive and transmit data from above (D11), below and to the rear (D12).

- Page 25 Prime/Bolus Prime/Bolus key Alarm silence/Option 2 MIN, Option (In an emergency the audible alarm is silenced for 2 minutes) 8.2.4. Power supply Mains power is supplied via a toroidal transformer and the rectifier V10. In the event of a mains power supply failure, power is supplied without interruption by the internal battery.

-

Page 26: Trouble Shooting

Trouble shooting When a DEFECT signal is given a fault code is displayed automatically. In the Volume ML (12) window a 2-digit figure appears and the cause of the fault indicated is listed in the table that follows. When a fault occurs the code appears automatically as F-xx. -

Page 27: Replacement Of Parts

10. Replacement of parts The syramed symbol µSP6000 may only be repaired by ARCOMED AG or persons officially authorised in writing by Arcomed AG or Arcomedical Infusion Ltd to do so. In the event of a warranty claim please send the unit to the address shown in Chapter 1.1. - Page 28 11. syramed µSP6000: List of spare parts Please quote the serial number of the pump when ordering. Part no. Description Assy Rev. Material 70000 Case rear Back 1 BC00 70010 8mm safety ring Back 1, Front 1 BC00 steel 70020 Rubber foot - blue Back 1, Front1 BC00...

- Page 29 70570 Drive pulley 32MXL complete Drive 12 BC00 70580 Gear wheel 10/28-M0.5 No.1 Drive 6, Drive 13 BC00 70590 Membrane pressure sensor Drive 3 BC00 70600 Pressure sensor bolt Drive 7 BC00 steel 70610 Pressure sensor PCB Drive 3 BC00 electronics 70620 Cable Pressure print...

- Page 30 71200 Cable syringe print Front 10 BC00 cable 71210 Lithium battery time keeper Front 10 BC00 Litium 71220 Packaging 6000 complete final BC00 Paper/PE 71230 Labels ø8mm final BC00 71240 Screw M3/10 Back 5 BC05 steel 71250 Cylinder screw M3x4 Back 5 BC05 steel...

- Page 31 Drawings...

- Page 34 70630 70650 70580 70710 70680 70360 70740 70750 70700 70530 70780 70440 70480 70380 70600 70410 71110 70540 70640 70430 70670 70420 70590 70760 70570...

- Page 35 Schematics...

- Page 36 KeyIn External IOKeyIn IOKeyIn 16 1.0 PowerHold ST24C02 EEPROM 12 4.5 SDA/1.7 SCL/1.6 35 XTAL1 backlight illum. ADC5/5.5 XTAL2 EndPos EndPos Switch date 19.02.2001 drawn Main PCB µSP6000 P1-1.07 scale [mm] checked copyright arcomed - confidential Nr. 6001-0101 material: (PCB)

- Page 37 External PExt/Hall Clutch1 CheckPower1 CheckPower2 PowerSupply L4960 DC converter Transformer COMP Sense Start +9.6V Battery PowerHold 2,3,6,7 IOKey/5VCtr 2.5V BattCharge 2,3,6,7 IOKeyIn date 2.11.2000 drawn Main PCB µSP6000 P2 scale [mm] checked copyright arcomed - confidential material: (PCB) Nr. 6001-0102...

- Page 38 Hall Sensor Syringe/Drop Press1 Extern/ Contact External Pressure Clutch1 Connector 12V 4 Hall PCB Pressure PCB Hall Out P-Sensor INA122 Hall Contact Pressure date 2.11.2000 drawn Sensor PCB µSP6000 scale [mm] checked copyright arcomed - confidential material: (PCB) Nr. 6001-0104...

- Page 39 R1A- 74HC154 8 x 1K0 8 x 1K0 VLCD 3 D13a D15a D10a D17a D13b D15b D10b D17b D13c D15c D10c D17c D11a D14a D16a D12a D11b D14b D16b D12b D11c D14c D16c D12c 10K R1E 0Ω 0.25W Display µSP6000 Schematic mvo 17.5.1998 / 1.01 Page 1/1...

- Page 40 Component layout...

- Page 43 Hall Print Syringe Print Connector Print Pressure Print (12V option/PCA) date 25.3.2000 drawn Sensor-PCB µSP6000 1.02 scale [mm] checked material: copyright arcomed Nr. 6001-0043...

Need help?

Do you have a question about the syramed mSP6000 and is the answer not in the manual?

Questions and answers