Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Janome HD523

- Page 1 INSTRUCTION MANUAL...

- Page 3 IMPORTANT SAFETY INSTRUCTIONS When using an electrical appliance, basic safety precautions should always be followed, including the following: This sewing machine is designed and manufactured for household use only. Read all instructions before using this sewing machine. DANGER — To reduce the risk of electric shock: 1.

-

Page 4: Table Of Contents

TABLE OF CONTENTS ESSENTIAL PARTS DECORATIVE STITCHING Names of Parts ............ 3 Shell Tuck ............26 Standard Accessories ......... 4 Box Stitching ............. 26 Fagoting ............. 27 GETTING READY TO SEW Smocking ............27 Connecting the Machine to the Power Supply ..5 Applique ............ -

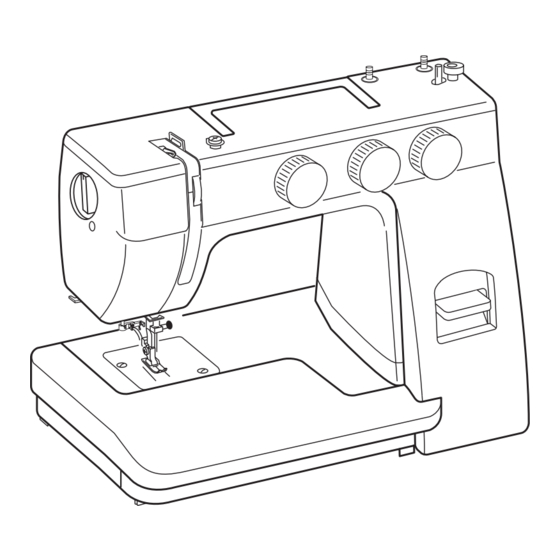

Page 5: Essential Parts Names Of Parts

ESSENTIAL PARTS Names of Parts Reverse stitch button Stitch selector dial Stitch length dial Stitch width dial Bobbin winder stopper Bobbin winder spindle Spool pins Bobbin winder thread guide Top cover thread guide Thread take-up lever Thread tension dial Pressure regulator Face plate Thread cutter Needle threader... -

Page 6: Standard Accessories

Standard Accessories Bobbin Needle set Seam ripper/ Buttonhole opener Buttonhole foot Hemmer foot Zipper foot Satin stitch foot Hemming guide Screwdriver (large) Screwdriver (small) Foot control* Dust cover * The power supply plug (Foot control) included may differ from the illustration. -

Page 7: Getting Ready To Sew Connecting The Machine To The Power Supply

GETTING READY TO SEW Connecting the Machine to the Power Supply z Turn off the power switch. x Insert the machine plug into the machine socket. c Insert the power supply plug into the outlet. v Turn on the power switch to activate the power and sewing light. -

Page 8: To Attach And Remove The Presser Foot

To Attach and Remove the Presser Foot To remove Turn the handwheel toward you to raise the needle to its highest position. Raise the presser foot. Press the lever on the back of the foot holder. The presser foot will drop off. q Lever CAUTION: Turn off the power switch when changing the... -

Page 9: Presser Foot Lifter

Presser Foot Lifter The presser foot lifter raises and lowers your presser foot. You can raise it about 0.6 cm (1/4˝) higher than the normal up position for easy removal of the presser foot or to help you to place heavy fabric under the foot. -

Page 10: Changing Needle

Changing Needle Raise the needle by turning the handwheel toward you, then lower the presser foot. Loosen the needle clamp screw by turning it counterclockwise. Remove the needle from the clamp. Insert the new needle into the needle clamp with the flat side away from you. -

Page 11: Setting Spool Pins

Setting Spool Pins The spool pins are used for holding the spool of thread in order to feed thread to the machine. To use, pull up the spool pin. Push down for storage. q Spool w Hole e Tangle * Set the spool pins at the highest or lowest position only. -

Page 12: Winding The Bobbin

Winding the Bobbin z Draw the thread from the spool. Guide the thread around the bobbin winder thread guide. x Insert the thread through the hole in the bobbin from the inside to the outside. Put the bobbin on the bobbin winder spindle. c Push it to the right. -

Page 13: Threading The Machine

Remove the loop from the threader and pull out the thread end from the needle eye. NOTE: The needle threader can be used with a #11/75 to #16/100 needle or Janome Blue Tipped needle. Thread size 50 to 100 would work well. -

Page 14: Drawing Up Bobbin Thread

Drawing Up Bobbin Thread z Raise the presser foot and hold the needle thread lightly with your left hand. x Turn the handwheel slowly toward you with your right hand until the needle goes down and continue turning the handwheel until the take- up lever is at its highest position. -

Page 15: Stitch Selector Dial

Stitch Selector Dial Turn the stitch selector dial to set the setting mark with the symbol corresponding to the desired pattern. q Setting mark CAUTION To avoid needle or fabric damage, make sure the needle is up and out of the fabric while selecting a stitch. -

Page 16: Stitch Width Dial

Stitch Width Dial Turn the stitch width dial to set the desired stitch width at the setting mark . The higher the number, the wider the stitch width q Setting mark NOTE: Raise the needle above the fabric, when you turn the stitch width dial. -

Page 17: Basic Sewing Straight Stitch Sewing

BASIC SEWING Straight Stitch Sewing q Pattern selector: w Presser foot: Zigzag foot e Thread tension: 2–6 r Stitch length: 1.5–4 t Stitch width: (0) or z Raise the presser foot and position the fabric with its edge lining up with a seam guide line on the needle plate. -

Page 18: Seam Guide Lines

Seam Guide Lines The numbers on the needle plate indicate the distance between the center needle position and the guideline. The numbers in front are centimeters. The numbers in back are fractions of an inch. Numbers 10 15 20 3/8 4/8 5/8 6/8 Distance (cm) 1 1.5 2 —... -

Page 19: Zigzag Stitching

Zigzag Stitching q Pattern selector: w Presser foot: Zigzag foot e Thread tension: 2–5 r Stitch length: 0.5–4 t Stitch width: Simple zigzag stitching is widely used for overcasting, sewing on buttons, etc. -

Page 20: Utility Stitching Tricot Stitching

UTILITY STITCHING Tricot Stitching q Pattern selector: w Presser foot: Zigzag foot e Thread tension: 1–4 r Stitch length: 0.5–4 t Stitch width: This stitch is used to finish the raw edge on synthetics and other fabrics that tend to pucker. Place your fabric to allow a 1.6 cm (5/8˝) seam. -

Page 21: Straight Stretch

Straight Stretch q Pattern selector: w Presser foot: Zigzag foot e Thread tension: 2–6 r Stitch length: S.S. t Stitch width: (0) or This strong, durable stitch is recommended where both elasticity and strength are necessary to ensure comfort and durability. Use it to reinforce areas such as crotch and armhole seams as well as to eliminate puckering on knits and stretch fabrics. -

Page 22: Buttonhole

Buttonhole q Pattern selector: (BH) w Presser foot: Buttonhole foot e Thread tension: 1–5 r Stitch length: t Stitch width: * Make a test buttonhole on a sample duplicating the fabric, interfacing and seams of the actual garment. * Place the button on the fabric sample and mark the top and bottom to determine the position of the buttonhole. -

Page 23: Adjusting Buttonhole Stitch Density

v Set the pattern selector dial at “ ”. Sew up the right side of the buttonhole. Stop the machine when you are directly opposite the fine stitch on the left-hand side and raise the needle. b Set the pattern selector dial at “ ”. -

Page 24: Sewing Buttons

Sewing Buttons q Pattern selector: w Presser foot: Zigzag foot e Thread tension: 3–7 r Stitch length: t Stitch width: Adjust as necessary y Feed dog: Dropped Drop the feed dogs (See page 14). Match the holes in the button with the horizontal slot on the presser foot. -

Page 25: Zipper Application

Zipper Application q Pattern selector: w Presser foot: Zipper foot e Thread tension: 2–6 r Stitch length: 1.5-4 t Stitch width: Pin or baste zipper tape to fabric and place it under the foot. Smooth the threads toward the back and lower the foot. -

Page 26: Blind Hem Stitch

Blind Hem Stitch q Pattern selector: w Presser foot: Zigzag foot e Thread tension: 1–3 r Stitch length: 1–3 t Stitch width: y Hemming guide z Fold up the hem and fold it back to from a 0.4 to 0.7 cm (1/4˝) allowance as illustrated. q Wrong side of the fabric w 0.4 to 0.7 cm (1/4˝) [A] Heavy weight fabrics... -

Page 27: Rolled Hem

Rolled Hem q Pattern selector: w Presser foot: Hemmer foot e Thread tension: r Stitch length: t Stitch width: z Trim off the corner of the fabric 0.5 cm (3/16˝) by 0.8 cm (5/16˝) to avoid a bulkiness of the hem at the corner. -

Page 28: Decorative Stitching Shell Tuck

DECORATIVE STITCHING Shell Tuck q Pattern selector: w Presser foot: Zigzag foot e Thread tension: 6–8 r Stitch length: 2–3 t Stitch width: Use a lightweight fabric (tricot, for example). Fold and stitch on the bias. When the needle swings to the right, allow the needle to just clear the folded edge of the fabric. -

Page 29: Fagoting

Fagoting q Pattern selector: w Presser foot: Zigzag foot e Thread tension: 3–8 r Stitch length: 0.5–2 t Stitch width: Fold under 1.5 cm (5/8˝) on each fabric edge and press. Pin the two edges to paper 0.3 cm (1/8˝) apart. Sew slowly, guiding the fabric so the needle catches the folded edge on each side. -

Page 30: Applique

Applique q Pattern selector: w Presser foot: Satin stitch foot e Thread tension: 1–4 r Stitch length: 0.5–1 t Stitch width: y Presser foot pressure: Baste (or fuse with iron-on fabric joiner) applique pieces on the fabric. Stitch around the applique making sure the needle falls along the outer edge of the applique. -

Page 31: Stretch Stitch Patterns

Stretch Stitch Patterns q Pattern selector: A–L w Presser foot: Zigzag foot e Thread tension: 1–4 r Stitch length: S.S. t Stitch width: If forward and reverse feeds become unbalanced due to the type of fabric, adjust the balance by turning the stitch length dial as follows: If patterns are compressed, turn the dial toward “+”. -

Page 32: Taking Care Of Your Machine Cleaning The Bobbin Case And The Hook

TAKING CARE OF YOUR MACHINE Cleaning the Bobbin Case and the Hook CAUTION: Turn off the power switch and/or unplug the machine before dismantling the sewing machine. To dismantle shuttle race unit: Raise the needle to its highest position and open the hook cover. -

Page 33: Troubleshooting

Troubleshooting Condition Cause Reference The needle thread 1. The needle thread is not threaded properly. Page 11 breaks. 2. The needle thread tension is too tight. Page 12 3. The needle is bent or blunt. Page 8 4. The needle is incorrectly inserted. Page 8 5. - Page 34 This page is left intentionally blank...

- Page 36 312-XXX-XXX (PL)

Need help?

Do you have a question about the HD523 and is the answer not in the manual?

Questions and answers