Subscribe to Our Youtube Channel

Summary of Contents for Mareli Systems LCG 22 KW

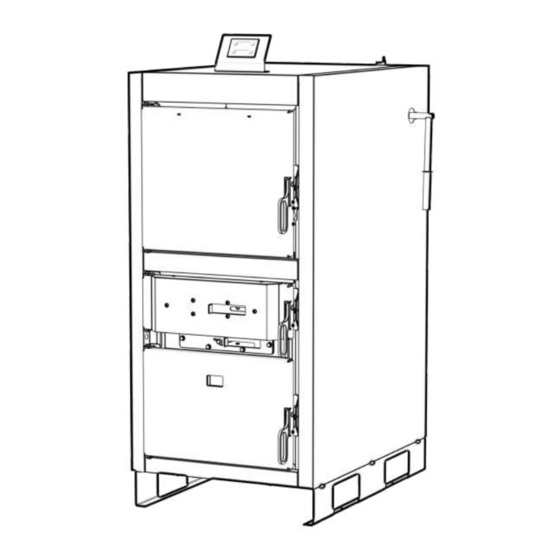

- Page 1 Mareli Systems LCG 22 / 32 / 40 / 50 KW WOOD GASIFICATION BOILER Assembly and exploitation manual...

- Page 2 Mareli Systems Observing the prescriptions of the present manual is in the user’s favour and is one of the warranty conditions. Compliance with this instruction is in the interest of the con- sumer and one of the warranty terms. These instructions are an integral part of this product. All rights reserved. Reproduction of content of this document and transfer to third parties is not allowed without written approval from manufacturer.

-

Page 3: Technical Data

Mareli Systems TECHNICAL DATA Nominal heat output (kW) Heat output range (kW) 11-22 16-32 20-40 25-50 Boiler class EN 303-5:2021 Required chimney underpressure (Pa) Water amount in boiler Exhaust gas temperature at nominal heat output Exhaust gas temperature at minimal heat output Minimum operating time at rated power (nominal Q ) (h) Min. - Page 4 Mareli Systems...

- Page 5 Mareli Systems G 3/4” G 1-1/2” G 1-1/2” G 3/4”...

- Page 6 Mareli Systems...

- Page 7 Mareli Systems (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) 1135 1016 1387 1280 Ø149 1180 1174 1185 1066 1387 1280 Ø149 1180 1174 1255 1136 1387 1280 Ø149 1180 1174 1255 1136 1537 1430 Ø149...

-

Page 8: General Information

Mareli Systems 1. GENERAL INFORMATION Steel boilers LCG, with an rated thermal output 22, 32, 40 and 50 kW are constructed for wood fir- ing and aimed for heating of small and middle sized premises. Due to the applied wood gasification principle, wood is totally burned. - Page 9 Mareli Systems 2. POSITIONING AND ASSEMBLY The installation of the boiler has to be carried out by the authorized person. We suggest the boiler to be installed on the solid concrete basis, which height is between 50-100 mm. The boiler room has to be absolutely protected from freezing and properly ventilated.

-

Page 10: Connection To The Chimney

Mareli Systems 2.1INSTALLATION OF THE COMBUSTION FAN Mount the combustion fan with the threaded screws to the designated connection points. Use the 4 (M8) nuts in the mounting kit with the boiler to fix the combustion fan in place. 3. CONNECTION TO THE CHIMNEY Properly calibrated and built chimney is the precondition for a safe operation of the boiler and eco- nomic heating. - Page 11 Mareli Systems Thermal insulation 10 mm Opening for the cleaning Thermal insulation 10 mm Opening for the cleaning min 500 mm min 500 mm The dimensioning of the chimney is a very important condition for the operation of the boiler at optimal parameters. The...

- Page 12 Mareli Systems FRESH AIR OPENING Each boiler room must be equipped with an opening for supply of make up air which is dimensioned in accordance with boiler output (minimum opening area according to the below shown equation). Such opening must be protected with a net or grate. All installation works have to be performed in accordance with valid national and European standards.

- Page 13 Mareli Systems Example scheme 1 for boiler instalation on closed central heating system with return flow protection with thermic valve (group) b b a a r r Example scheme 2 for boiler instalation on open central heating system with return flow...

- Page 14 Mareli Systems LCG BOILER Water storage tank Boiler pump Return flow protection 3-way thermic valve (min. temp 60°C) or 3-way mixing valve with motor drive (protection valve) Expansion vessel for closed heating systems (approx. 10% of the total volume of installation) Open expansion vessel for open heating systems (approx.

-

Page 15: Boiler Thermal Protection

Mareli Systems BOILER THERMAL PROTECTION According to European EN standards, boiler thermal protection must be installed in closed heating system. Boiler is factory prepared for installation of thermal protection. IMPORTANT: In case of any damage of boiler installed in the closed heating system due to its overheating, and boiler or system are not equipped with any thermal protection at all, or do not have properly installed thermal protection, guarantee will not be applied. -

Page 16: Ignition Procedure

Mareli Systems 5. IGNITION PROCEDURE... - Page 17 Mareli Systems...

- Page 18 Mareli Systems • Open the to and middle doors. • Check the ash level in the combustion chamber and empty if necessary. It is recommended that you do not remove the ash in the combustion chamber during each heating-up process, but rather when the middle row of holes of the combustion chamber guards is no longer visible.

- Page 19 Mareli Systems 6. CLEANING AND MAINTENANCE OF THE BOILER Protective gloves must be used. Ash remaining in boiler after solid fuel firing should be disposed into metal containers with a cover. As through the wood gasification principle the fuel burns out totally,...

- Page 20 Mareli Systems...

-

Page 21: Before Each Ignition

Mareli Systems BEFORE EACH IGNITION Before every ignition is necessary to clean the wood loading chamber from the ash. The canals for the primary air must always be clear of all residue. Use the special cleaning tool for this purpose. - Page 22 Control Panel: Use and Functions Mareli Systems CLICK LONG PRESSURE Ignition / Extinguishing / Visualisations / Exit Menu Using the P3/P4 buttons is possible to view all programs: Block reset Control Panel: Use and Functions STOP Combustion Power modify / •...

- Page 23 = External temperature [°C]; St = Remaining time before the system notices the message ‘Service’; [h]; Mareli Systems St2 =Remaining time before the system cleaning is performed [h]; P1 CLICK (3 sec) It is possible to activate the ignition process with long press on the button;...

- Page 24 Mareli Systems LINEA...

- Page 25 Mareli Systems...

- Page 26 Mareli Systems...

- Page 28 MARELI SYSTEMS disclaims any responsibility for possible inaccuracies contained in this manu- al if they are due to printing or transcription errors. We reserve the right to make any change that appears to be necessary or useful without harm the essential characteristics.

Need help?

Do you have a question about the LCG 22 KW and is the answer not in the manual?

Questions and answers