Table of Contents

Advertisement

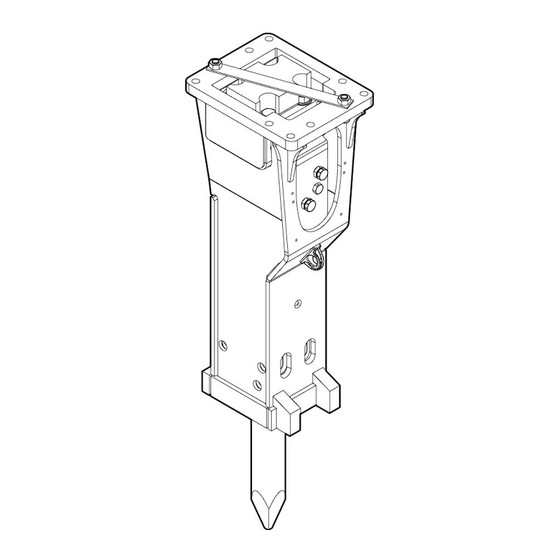

MB

750 E, 1000 E, 1200 E, 1500 E, 1650 E

Safety and operating instructions

Hydraulic breakers

Interactive and updated spare part catalogues go to:

www.epiroc.com/docmine

For log in details please contact your local Epiroc office or dealer in your area

Static PDF spare part catalogues go to:

www.podshop.se/epiroc

© Construction Tools GmbH | 3390 5201 01 | 2023-05-15

Original Instructions

Advertisement

Table of Contents

Summary of Contents for Epiroc MB Series

- Page 1 Hydraulic breakers Interactive and updated spare part catalogues go to: www.epiroc.com/docmine For log in details please contact your local Epiroc office or dealer in your area Static PDF spare part catalogues go to: www.podshop.se/epiroc © Construction Tools GmbH | 3390 5201 01 | 2023-05-15...

-

Page 3: Table Of Contents

Contents Table of Contents 1 Introduction .......................... 7 About these Safety and Operating Instructions .................... 7 2 Safety instructions ........................ 8 Signal words ............................... 8 Qualification ................................ 9 Intended use................................ 9 Use other than intended............................. 9 Protective equipment ............................ 10 Carrier, precautions............................ - Page 4 Contents 5.1.3 Grease................................ 21 5.1.4 Gas.................................. 21 Manufacturing the adapter plate ........................ 22 Installing the adapter plate .......................... 22 Attaching the hydraulic attachment to the carrier.................. 23 5.4.1 Mechanical mounting aspects ......................... 23 5.4.2 Making the hydraulic connections ........................ 23 Removing the hydraulic attachment from the carrier ...................

- Page 5 Contents 7.4.3 Chisel paste filling device .......................... 41 Checking the tensioning bolts ........................ 42 Checking the working tool.......................... 42 Checking the retainer bars .......................... 43 Checking the percussion piston impact surface................... 43 Checking the wear bushes and impact ring.................... 44 7.10 Piston accumulator ............................

- Page 6 Contents 12.3 Noise declaration statement.......................... 61 13 EC Declaration of Conformity (EC Directive 2006/42/EC) ............ 62 © Construction Tools GmbH | 3390 5201 01 | 2023-05-15 Original Instructions...

-

Page 7: Introduction

1.1 About these Safety and 1 Introduction Operating Instructions Epiroc is a leading productivity partner for the mining, in- frastructure and natural resources industries. With cut- The aim of these Instructions is to familiarise you with ting-edge technology, Epiroc develops and produces in-... -

Page 8: Safety Instructions

Safety and operating instructions 2.1 Signal words 2 Safety instructions The signal words Danger, Warning, Caution, and Notice This is the safety alert symbol. It is used to alert are used as follows in these Safety and operating in- you to potential personal injury hazards. Obey structions: all safety messages that follow this symbol to avoid possible injury or death. -

Page 9: Qualification

Safety and operating instructions 2.2 Qualification 2.3 Intended use Transporting the hydraulic attachment is only permitted Only attach the hydraulic breaker to a hydraulic carrier of if carried out by people who: a suitable load-bearing capacity. • are authorised to operate a crane or a forklift truck Only use the hydraulic breaker function of the device to according to the applicable national provisions, break or fragment concrete, stone and rocks. -

Page 10: Protective Equipment

Before working with a hydraulic attachment mounted to a long reach boom consult the Epiroc Customer Center / Dealer in your area. © Construction Tools GmbH | 3390 5201 01 | 2023-05-15... -

Page 11: Hydraulic Installation, Precautions

Safety and operating instructions 2.8 Hydraulic installation, 2.9 Special parts, precautions precautions 2.9.1 Piston accumulator WARNING Hydraulic pressure too high DANGER Danger of explosions If the hydraulic pressure is too high, the parts of the hy- draulic attachment will be exposed to excessively high The integrated piston accumulator is filled with nitrogen loads. -

Page 12: Media/Consumables, Precautions

Safety and operating instructions 2.10 Media/consumables, 2.11 Explosion and fire, precautions precautions WARNING Hot hydraulic oil under high pressure DANGER Explosion and fire Hydraulic oil will squirt out under high pressure if there is Explosions cause serious injury or death. If the working a leakage. -

Page 13: Electrical Shock, Precautions

Safety and operating instructions 2.12 Electrical shock, precautions 2.14 Emissions, precautions DANGER Electrical shock WARNING Noise hazard Any contact of the hydraulic attachment with electric cir- Operating the hydraulic attachment creates a loud noise. cuits or other sources of electricity will lead to an electric Long term high sound pressure level can affect your shock, resulting in serious injury or death. -

Page 14: Repair, Precautions

Never carry out any changes to the hydraulic attach- ment or the adapter plate. u Only use original parts or accessories approved by Epiroc. u Modifications that entail new hazards may require a new procedure for assessing conformity. © Construction Tools GmbH | 3390 5201 01 | 2023-05-15... -

Page 15: Overview

Safety and operating instructions H. The working tool can be replaced as required. The 3 Overview working tool is not included in the scope of supply of the hydraulic breaker. The working tool is retained in the lower breaker 3.1 Equipment description part. -

Page 16: Signs / Labels

Safety and operating instructions 3.3.2 Labels 3.3 Signs / labels Sound Power WARNING Missing warnings The label states the guaranteed The name plate and the labels on the hydraulic attach- sound power level in accordance ment contain important information about the hydraulic with EC directive 2000/14/EC. -

Page 17: Applications

Check the delivery for visual damage. Demolition Masonry and non-rein- forced concrete n If any defects are found, consult the Epiroc Customer Reinforced concrete Center / dealer in your area. Rock mining/breaking Secondary breaking, bench leveling, trench- (not for MB 750 E) -

Page 18: Transport

● you detect cracks in the lifting eye or the weld u Replace a missing elastic pad, if necessary e.g. with seam. u Contact the Epiroc Customer Center / Dealer in your a wooden block. This keeps the percussion unit fixed in the breaker box during transport. -

Page 19: Transport Using A Crane

Safety and operating instructions 4.1 Transport using a crane 4.2 Transport using a forklift truck n Secure the hydraulic attachment with ropes or chains as shown in the following illustration. WARNING Hydraulic attachment tipping over The hydraulic attachment tipping off the fork of the forklift truck or the pallet may cause serious injury. -

Page 20: Transport Using A Truck

Safety and operating instructions 4.3 Transport using a truck WARNING Hydraulic attachment tipping over / slipping The hydraulic attachment slipping or tipping over and falling from the loading area of a lorry may cause serious injury. u Place the hydraulic attachment on a pallet. u Strap the hydraulic attachment to the pallet using suitable strapping (see illustration in chapter Trans- port using a forklift truck). -

Page 21: Installation

Before working with a hydraulic attachment mounted such fluids are possible. to a long reach boom consult the Epiroc Customer Our hydraulic attachments are basically designed for use Center / Dealer in your area. -

Page 22: Manufacturing The Adapter Plate

Safety and operating instructions 5.2 Manufacturing the adapter WARNING Hands and fingers being cut off or hurt Bores and surfaces can act like a pair of scissors and plate cut off or hurt parts of your body. Construction Tools GmbH also supplies base plates to u Never use your fingers to check bores or fitting sur- manufacture adapter plates alternatively to the adapter faces. -

Page 23: Attaching The Hydraulic Attachment To The Carrier

The adapter plate must not be stopped by mechanical cut off or hurt parts of your body. stops in either position. Consult the Epiroc Customer u Never use your fingers to check bores or fitting sur- Center/Dealer in your area if the adapter plate is stopped faces. - Page 24 Safety and operating instructions n Check that the ports and connections on the hy- NOTICE Total damage to the hydraulic attachment draulic breaker and/or on the hydraulic hoses are not Polluted hydraulic lines and connections may enable damaged. sand, fragments of material and dirt to penetrate the hy- draulic attachment and damage it completely.

-

Page 25: Removing The Hydraulic Attachment From The Carrier

Safety and operating instructions 5.5 Removing the hydraulic WARNING Injury by impacts A sudden movement of the carrier may cause your as- attachment from the carrier sistant to be hit and injured by the boom or the hydraulic n Place the hydraulic attachment on timber support attachment. -

Page 26: Working Tool

Safety and operating instructions 5.7.1 Selecting the right working tool 5.7 Working tool The standard available working tools are shown. The dif- WARNING Unexpected movement ferent cutter geometries may influence the production re- Sudden movements of the carrier may cause serious in- sult, depending on the actual use. -

Page 27: Installation

Safety and operating instructions n Clean the insertion area of the working tool (A). 5.7.2 Installation n Grease the insertion area of the working tool (A) with n Place the hydraulic breaker on timber support blocks. chisel paste. NOTICE The working tool may break n Grease both retainer bars (D) with chisel paste. -

Page 28: Removal

Safety and operating instructions 5.7.3 Removal n Place the hydraulic breaker on timber support blocks. WARNING The working tool suddenly comes loose A clamped working tool is still under the pressure of the piston accumulator. When the working tool is loosened, it will partly jump out of the hydraulic breaker;... -

Page 29: Operation

Safety and operating instructions NOTICE Damage due to idling strokes 6 Operation If the percussion piston carries out a hammer action WARNING Hot hydraulic oil squirting out without hitting the working tool, it is carrying out an idling stroke. If this happens it will lead to hydraulic peak pres- The hydraulic system is under high pressure. -

Page 30: Preparations Before Starting

/ or the the hydraulic attachment may be flung away and can Epiroc Customer Center / Dealer in your area. cause serious injury if people are hit by them. Small ob- jects falling from a great height can also cause serious n Switch the hydraulic attachment on and off, as de- damage. -

Page 31: Correct Operation

Safety and operating instructions Larger swing angles would lead to bending loads and 6.5 Correct operation damage to the working tool and the hydraulic breaker. 6.5.1 Working angle n Always position the tool so that it hits the material to 6.5.2 Advance be broken at a right angle. -

Page 32: High Ambient Temperature

Safety and operating instructions 6.5.4 High ambient temperature 6.6 Prohibited operation n Only use hydraulic oils of sufficient viscosity. In summer and in tropical climates, the minimum re- 6.6.1 Lifting/Transporting quirement is a hydraulic oil of type HLP 68. WARNING Falling load The lifted object can fall and cause serious injuries or 6.5.5 Low ambient temperature death. -

Page 33: Moving Objects

Safety and operating instructions 6.6.3 Moving objects 6.6.5 Blank firing of the working tool The working tool "blank fires" if the percussion energy is n Never use the hydraulic attachment to move debris. transferred to the retainer bars instead of to the material This would damage the hydraulic attachment. -

Page 34: Cylinder End Positions

Before using the hydraulic breaker in or under water, consult the Epiroc Customer Center / Dealer in your area. 6.7.2 Usage in tunnels Using the hydraulic breaker for tunnelling with overhead... -

Page 35: Autocontrol System

The hydraulic system is under high pressure. If hydraulic connections come loose or are disconnected, hydraulic For further information, please contact the Epiroc Cus- oil will squirt out under high pressure. Hydraulic lines tomer Center / Dealer in your area. - Page 36 Safety and operating instructions “AutoStart” integration setting “AutoStop” integration setting n Remove the plug (C). n Screw a screw (M 10) into the valve piston (D). n Pull the valve piston (D) by its screw from the bore in cylinder (A). n Remove the screw from the valve piston (D) and in- stall it again the other way around.

-

Page 37: Maintenance

Safety and operating instructions 7 Maintenance WARNING Unexpected movement Sudden movements of the carrier may cause serious in- The maintenance activities are carried out by the carrier jury. driver. u Secure the carrier such that it cannot move unex- pectedly. WARNING Hot hydraulic oil squirting out u Observe the carrier manufacturer’s instructions. -

Page 38: Maintenance Schedule

Safety and operating instructions 7.1 Maintenance schedule during a shift Monitor the lubricant film on the shaft of the working tool. Manual lubrication of the working tool approx. every 2 hours. daily Check the bolted connections at the adapter plate and tighten as required. Check the hydraulic lines for leaks. -

Page 39: Depressurising The Hydraulic System

Safety and operating instructions Case 2: If no facility for measuring the pressure is 7.2 Depressurising the hydraulic present in the supply pipe to the hydraulic breaker and system the return pipe is connected to the tank without an inter- mediate valve connection, you must observe the follow- Even when you have switched off the carrier, a consider- ing steps in order to depressurise the hydraulic breaker:... -

Page 40: Cleaning

Safety and operating instructions the shut-off valves or disconnect the quick-release 7.4 Lubrication couplings, so that no hydraulic oil can flow back from the carrier. 7.4.1 Checking the lubricant film The lubricant film on the shaft of the working tool must 7.3 Cleaning be checked during the work shift. -

Page 41: Manual Lubrication

3363 0946 69 Filling device for use with 45-kg containers: part number 3363 0664 11 For further information, please contact the Epiroc Cus- tomer Center / Dealer in your area. • Lubrication interval: approx. every 2 hours • 5 to 15 strokes from the manual grease gun ©... -

Page 42: Checking The Tensioning Bolts

Have broken tensioning bolts immediately replaced. n If you have any questions about replacement of bro- ken tensioning bolts, consult the Epiroc Customer Center / Dealer in your area. You can only check the front tensioning bolts, if you dis- mount the adapter plate and the elastic pad (see chapter Removing the adapter plate). -

Page 43: Checking The Retainer Bars

Do not use the hydraulic breaker again if you have found the surface to be chipped or cracked. n Consult the Epiroc Customer Center / Dealer in your area. n Replace the working tool if the shaft has worn to the minimum diameter D stated below. -

Page 44: Checking The Wear Bushes And Impact Ring

Clean the area around the impact ring to enable a visual check. The lower wear bush can be replaced on site. Consult the Epiroc Customer Center / Dealer in your area. n Remove all remnants of lubricant from the inside of the lower breaker part before installing new parts. -

Page 45: Piston Accumulator

Safety and operating instructions 7.10.1 Checking the pressure in the piston 7.10 Piston accumulator accumulator The pressure in the piston accumulator is measured at Check the gas pressure in the piston accumulator the filling valve (G). The piston accumulator is also filled monthly, and in cases of decreasing power or failure of through this valve. -

Page 46: Release The Pressure From The Piston Accumulator

Safety and operating instructions n Close the pressure relief valve (D). 7.10.2 Release the pressure from the piston accumulator n Connect the filling hose end (H) to the minimess con- nection (C) of the pressure relief valve (D). n Release gas from the piston accumulator to depres- surise the piston accumulator or if the value mea- n Open the valve of the nitrogen bottle (F). -

Page 47: Checking The Hydraulic Lines

The wear rails (A) in the lower section of the breaker 7.12 Checking and cleaning the box can be replaced as required. Please consult the Epiroc Customer Center / dealer in your area. hydraulic oil filter An oil filter must be integrated in the tank line of the hy- draulic system. -

Page 48: Bolt Connections / Tightening Torques Mb 750 E, Mb 1000 E

Safety and operating instructions 7.15 Bolt connections / Tightening torques MB 750 E, MB 1000 E The bolt connections of hydraulic breakers are subjected to very high loads. Tighten any loose connections without exceeding the recommended tightening torques. MB 750 E MB 1000 E Connection point Interval Type of span-... - Page 49 Safety and operating instructions © Construction Tools GmbH | 3390 5201 01 | 2023-05-15 Original Instructions...

-

Page 50: Bolt Connections / Tightening Torques Mb 1200 E, Mb 1500 E, Mb 1650 E

Safety and operating instructions 7.16 Bolt connections / Tightening torques MB 1200 E, MB 1500 E, MB 1650 E The bolt connections of hydraulic breakers are subjected to very high loads. Tighten any loose connections without exceeding the recommended tightening torques. MB 1200 E MB 1500 E MB 1650 E Connection point... - Page 51 Safety and operating instructions © Construction Tools GmbH | 3390 5201 01 | 2023-05-15 Original Instructions...

-

Page 52: Troubleshooting

Operating pressure too low Check the carrier engine speed, the pump delivery and Carrier driver or the pressure relief valve; check the operating pressure Epiroc Customer Center / Dealer in Adjust settings and replace defective parts if required your area 8.2 Hydraulic breaker operates too slowly... -

Page 53: Impact Force Too Low

(see chapter Technical specifications) Return pressure too high Check and lower the return pressure Epiroc Customer Center / Dealer in your area Hydraulic oil return to the tank via Connect the hydraulic oil return circuit directly to the tank... -

Page 54: Oil Escapes Between The Cylinder Cover And The Cylinder

Center / Dealer in your area Operation in high outside temper- Check oil temperature and install an oil cooler if required Workshop or Epiroc ature without oil cooler Customer Center / Dealer in your area Pressure relief valve defective or... -

Page 55: Repair

Construction Tools GmbH. These professionals must follow all safety instructions and guidelines for repair. n For technical support contact the Epiroc Customer Center / Dealer in your area. 9.1 Sending in the hydraulic attachment for repairs... -

Page 56: Storage

Safety and operating instructions NOTICE Environmental damage due to hydraulic oil 10 Storage Hydraulic oil is environmentally harmful and must not WARNING Hydraulic breaker / working tool fall penetrate the ground or enter the water table or water supplies. The hydraulic breaker and the working tool are heavy. If u Collect any hydraulic oil which escapes. -

Page 57: Working Tool

Safety and operating instructions n Contact the Epiroc Customer Center / Dealer in your area. n Professionals trained by Construction Tools GmbH will disassemble the hydraulic breaker properly and: – check any parts liable to corrosion (percussion piston, cylinder, control) for corrosion damage. -

Page 58: Disposal

Safety and operating instructions 11.2 Hydraulic hoses 11 Disposal n Drain the hydraulic oil from the hydraulic hoses and NOTICE Environmental damage due to consumables collect it. Hydraulic oil and chisel paste are environmentally harm- ful and must not penetrate the ground or enter the water n Dispose of the hydraulic hoses in accordance with table or water supplies. -

Page 59: Technical Specifications

AutoStart AutoStart Weights apply to standard carriers only. Any variances must be agreed with Epiroc and/or the carrier manufacturer prior to attachment Hydraulic breaker incl. breaker box, working tool and adapter plate of medium size. Please note that the service weight can be considerably higher, depending on the adapter plate. -

Page 60: Mb 1200 E, Mb 1500 E, Mb 1650 E

StartSelect StartSelect Weights apply to standard carriers only. Any variances must be agreed with Epiroc and/or the carrier manufacturer prior to attachment Hydraulic breaker incl. breaker box, working tool and adapter plate of medium size. Please note that the service weight can be considerably higher, depending on the adapter plate. - Page 61 Safety and operating instructions 12.3 Noise declaration statement MB 750 E MB 1000 E MB 1200 E Sound pressure dB(A) Sound power dB(A) MB 1500 E MB 1650 E Sound pressure dB(A) Sound power dB(A) Sound pressure level according to EN ISO 3744 in accordance with directive 2000/14/EC at 10 metres distance. Guaranteed sound power according to EN ISO 3744 in accordance with directive 2000/14/EC inclusive spread in pro- duction.

- Page 62 Safety and operating instructions 13 EC Declaration of Conformity (EC Directive 2006/42/EC) We, Construction Tools GmbH, hereby declare that the machines listed below conform to the provisions of EC Directive 2006/42/EC (Machinery Directive) and 2000/14/EC, ANNEX V (Noise Directive), and the harmonised standards men- tioned below.

- Page 64 Any unauthorized use or copying of the contents or any part thereof is prohibited. This applies in particular to trademarks, model denominations, part numbers, and drawings. epiroc.com...

Need help?

Do you have a question about the MB Series and is the answer not in the manual?

Questions and answers