Summary of Contents for Beko DRYPOINT RA CT Series

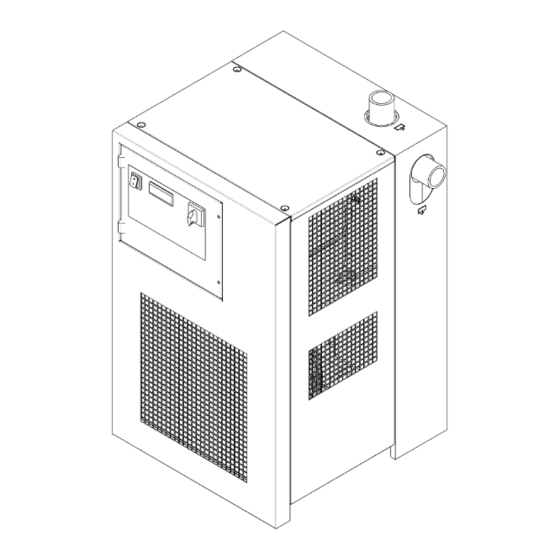

- Page 1 EN - english Instructions for installation and operation Compressed air refrigeration dryer ® DRYPOINT RA CT 200-500 NA 3PH...

-

Page 2: Electric Diagram Drypoint Ra Ct 200-500 Na 3Phase Sheet

Dear customer, ® Thank you for deciding in favour of the DRYPOINT RA CT 200-500 NA compressed-air refrigeration dryer. Please ® read these installation and operating instructions carefully before mounting and starting up the DRYPOINT RA CT ® 200-500 NA and follow our directions. Perfect functioning of the DRYPOINT RA CT 200-500 NA and thus reliable compressed-air drying can only be guaranteed when the provisions and notes stipulated here are strictly adhered to. -

Page 3: Table Of Contents

Contents Name plate Safety instructions Safety pictograms in accordance with DIN 4844 Signal words in accordance with ANSI Overview of the safety instructions Proper use Exclusion from a field of application ... - Page 4 Electric diagram DRYPOINT RA CT 200-500 NA 3phase Sheet 2/3 13.3.4 Electric diagram DRYPOINT RA CT 200-500 NA 3phase Sheet 3/3 Pos: 1 /Beko Technische Dokumentation/Überschriften/1/Sicherheitshinweise @ 0\mod_1183637609261_6.doc @ 5365 DRYPOINT® RA CT 200-500 NA 3PH...

-

Page 5: Name Plate

This manual must be available at all times for future reference and is a constituent part of the dryer. If you have any queries regarding these installation and operating instructions, please contact BEKO TECHNOLOGIES... -

Page 6: Safety Pictograms In Accordance With Din 4844

Do not operate with open cover (housing) Maintenance works or controlling measures must only be carried out by qualified personnel Do not smoke Note Pos: 4 /Beko Technische Dokumentation/Sicherheit/Gefahr Druckluft @ 0\mod_1184148143854_6.doc @ 577 ARIA Connection point compressed-air inlet LUFT... - Page 7 Safety instructions Works can be carried out by the operator of the plant, provided that they are skilled accordingly NOTE: Text that contains important specifications to be considered – does not refer to safety precautions. The device was carefully designed with particular attention paid to environmental protection: ...

-

Page 8: Signal Words In Accordance With Ansi

Make sure that the power supply is switched off and that the device is off and marked for maintenance measures. Please also ensure that the power supply cannot be re-established during the works. Pos: 7 /Beko Technische Dokumentation/Sicherheit/Maßnahmen Netzspannung BM 31/32/33 @ 0\mod_1216898430699_6.doc @ 11319 Caution! Refrigerant! The compressed-air refrigeration dryer uses HFC-containing refrigerants as a coolant. - Page 9 Safety instructions Warning! Refrigerant leak! A refrigerant leak involves the danger of serious injury and damage to the environment. ® The DRYPOINT RA CT 200-500 NA compressed-air refrigeration dryer contains fluorinated greenhouse gas/refrigerant. Installation, repair and maintenance works at the refrigeration system must only be carried out by certified skilled personnel (specialists).

- Page 10 Operators of the devices must observe the local and national pressure equipment regulations in the country of installation. Pos: 8 /Beko Technische Dokumentation/Sicherheit/Sicherheitshinweise, weitere BM (nicht Ex) @ 0\mod_1183616103770_6.doc @ 4009os: 9 /Beko Technische Dokumentation/Sicherheit/Zusatz Sicherheitshinweise BM33 @ 0\mod_1231926887620_6.doc @ 12829s: 10 /Beko Technische Dokumentation/Sicherheit/Vorsicht Fehlfunktion @ 0\mod_1214378096290_6.doc @ 9359 Note!

-

Page 11: Proper Use

This dryer is not suitable for the treatment of contaminated air or of air containing solids. Pos: 16 /Beko Technische Dokumentation/Bestimmungsgemäße Verwendung/BEKOMAT/Ausschluß Anwendung BM 31/32/33 @ 0\mod_1236003837511_6.doc @ 13736 Operating instructions in accordance with the 2014/68/EU Pressure Equipment Directive The DRYPOINT®... -

Page 12: Transport

Transport Transport Check the packaging for visible loss or damage. If no visible damage can be ascertained, place the unit in close proximity to the place of installation and unpack the device. During this procedure, the dryer must always remain in an upright position. The components may be damaged when the unit is tilted or turned upside down. -

Page 13: Installation Plan

Installation Installation plan - A - Air compressor Aftercooler Condensate separator Prefilter Bypass group Dryer Compressed-air tank - B - Final filter Bekomat condensate drain Installation type A is recommended when the total consumption corresponds to the throughput rate of the compressor. Installation type B is recommended when the air consumption constantly varies, with peak values which considerably exceed the throughput rate of the compressor. -

Page 14: Correction Factors

Installation Correction factors Correction factor for operating pressure modifications: Inlet air pressure psig barg Factor (F1) 0.79 0.91 1.00 1.07 1.13 1.18 1.23 1.27 Correction factor for ambient temperature modifications : Ambient temperature ºF ºC Factor (F2) 1.11 1.09 1.06 1.00 0.94 0.87... -

Page 15: Connection To The Compressed-Air System

Installation Connection to the compressed-air system Danger! Compressed air! All works must only be carried out by qualified skilled personnel. Never work on compressed-air systems which are under pressure. The operator or the user must ensure that the dryer is never operated with a pressure exceeding the maximum pressure value indicated on the name plate. -

Page 16: Condensate Drain

Installation Condensate drain Danger! Compressed air and condensate under pressure! The condensate is discharged at system pressure. The drain pipe needs to be secured. Never direct the condensate drain pipe at persons. The dryer is delivered with an already integrated electronically level-controlled BEKOMAT condensate drain. Connect the condensate drain with a collection system or container by properly screwing it on. -

Page 17: Start-Up

Start-up Start-up Preliminary stages Note! Exceeding of the operating parameters! Ensure that the operating parameters comply with the nominal values indicated on the name plate of the dryer (voltage, frequency, air pressure, air temperature, ambient temperature etc.). Prior to delivery, this dryer was thoroughly tested, packed and checked. Please verify the soundness of the dryer during the initial start-up and check the perfect functioning during the first operating hours. -

Page 18: Shut Down And Restart

Start-up In the cycling operating mode (Energy Saving, ESS=YES – see section 11.12.7), the refigerating compressor is switched ON and OFF by the electronic control unit, according to thermal load applied to the dryer. The dryer needs to be switched on during the entire compressed-air usage time, even if the compressed-air compressor works periodically. -

Page 19: Technical Data

Technical data 10 Technical data 10.1 Technical data DRYPOINT RA CT 200-500 NA 3phase 3/460/60 DRYPOINT® RA CT 200-500 NA 3PH... -

Page 20: Technical Description

Technical description 11 Technical description 11.1 Control panel The control panel explained below is the only dryer user interface. reset Main switch Electronic control unit DMC51 ON-OFF switch Air and refrigerant-gas flow chart 11.2 Functional description Operating principle – All dryer models described in this manual function according to the same principle. The hot and moisture-loaded air is led into an air/air heat exchanger. -

Page 21: Flow Chart

Technical description 11.3 Flow chart 12.2 P< P> 12.1 Aluminium heat exchanger module Filter dryer a – Air/air heat exchanger Capillary tube b – Air/refrigerant heat exchanger 12.1 T1 temperature sensor (dew point) c – Condensate separator 12.2 T2 temperature sensor (compressor discharge) Refrigerant pressure switch LPS (P<) Condensate drain service valve Refrigerant pressure switch HPS (P>) -

Page 22: Refrigerating Compressor

Technical description 11.4 Refrigerating compressor The employed refrigerating compressors are constructed by leading manufacturers. The hermetically sealed construction is absolutely gastight. The integrated safeguard protects the compressor against overheating and excess current. The protection is automatically reset as soon as the nominal conditions are reached again. 11.5 Condenser The condenser is the component in which the gas coming from the compressor is cooled down, condensed and liquefied. -

Page 23: Refrigerant Pressure Switches Lps - Hps - Pv

Technical description 11.10 Refrigerant pressure switches LPS – HPS – PV To ensure the operational reliability and the protection of the dryer, a series of pressure switches are installed in the gas cycle. LPS : Low-pressure guard on the suction side of the compressor, which is triggered when the pressure drops below the predetermined value. -

Page 24: Dmc51 Electronic Control Unit

Technical description 11.12 DMC51 electronic control unit Led - temperature in °C Led - temperature in °F Led - compressor ON Led – Alarm reset Led - service warning Button – access configuration menu / Discharge temp. DISPLAY Button – decrease / service Button –... -

Page 25: Indication Of A Service Warning

Technical description 11.12.4 Indication of a service warning A service warning is an exceptional event and requires the attention of the operator/service technician. The dryer will not be stopped. When a service warning is active, the Led flashes. When a service warning is no longer active but not reset yet (so it has been stored) Led is continuously on. -

Page 26: Operation Of The Potential-Free Failure/Alarm Contact

Technical description 11.12.6 Operation of the potential-free failure/alarm contact The DMC51 is equipped with a 12Vdc signal (max 15 mA) to indicate service warning or alarm conditions. Dryer is switched on, no service warning and no alarm (active and not yet reset) are indicated. -

Page 27: Maintenance, Troubleshooting, Spare Parts And Dismantling

Maintenance, troubleshooting, spare parts and dismantling 12 Maintenance, troubleshooting, spare parts and dismantling 12.1 Checks and maintenance Certified skilled personnel Installation works must exclusively be carried out by authorised and qualified skilled personnel. Prior to ® undertaking any measures on the DRYPOINT RA CT 200-500 NA compressed-air refrigeration dryer, the certified skilled personnel shall read up on the device by carefully studying the operating... -

Page 28: Troubleshooting

Maintenance, troubleshooting, spare parts and dismantling DAILY: • Check whether the dew point indicated on the electronics is correct. • Ensure that the condensate drain system functions properly. • Make sure that the condenser is clean. EVERY 200 HOURS OR MONTHLY •... - Page 29 Maintenance, troubleshooting, spare parts and dismantling Prior to carrying out maintenance works at the dryer, switch it off and wait for at least 30 minutes. Caution! Hot surfaces! During operation, several components can reach surface temperatures of more than 140°F (60°C). There is the risk of burns.

- Page 30 Maintenance, troubleshooting, spare parts and dismantling The compressor does not work – see specific point. Dew point too high. The DewPoint probe T1 doesn’t correctly detect the temperature - ensure the sensor is pushed into the bottom of probe well. ...

- Page 31 Maintenance, troubleshooting, spare parts and dismantling Check which of the following reasons has caused the activation: The internal heat protection of the 1. Excessive thermal load – restore the standard operating conditions. compressor has been 2. The inlet air is too hot – restore the nominal conditions. activated 3.

- Page 32 Maintenance, troubleshooting, spare parts and dismantling If ESS=YES (see section 11.12.7) - The refrigerating compressor must remain ON for The alarm a minimum time (approx. 6 minutes) within which, if necessary, DMC51 will activate (toC), - ON/OFF the solenoid EVH that enables the operation of the hot gas by-pass valve. To avoid cycles of the freezing, if the DewPoint drops too low in despite the hot gas by-pass valve is in compressor too...

-

Page 33: Recommended Spare Parts

Maintenance, troubleshooting, spare parts and dismantling 12.3 Recommended spare parts Spare parts list is printed on a dedicated sticker applied inside the dryer. On this sticker each spare part is identified with its ID Number and related Spare Part Number. Here below the cross-reference table between ID Numbers and exploded drawings Ref. -

Page 34: Maintenance Works At The Refrigeration Cycle

When delivered, the dryer is ready to operate and filled with a refrigerant of the R134a or R407C type. Should you detect a refrigerant leak, please contact a BEKO service technician. Prior to any intervention, the room needs to be ventilated. -

Page 35: Appendices

Appendices 13 Appendices 13.1 Dryer dimensions 13.1.1 Dryer dimensions DRYPOINT RA CT 200-250 NA 3phase DRYPOINT® RA CT 200-500 NA 3PH... -

Page 36: Dryer Dimensions Drypoint Ra Ct 300-350 Na 3Phase

Appendices 13.1.2 Dryer dimensions DRYPOINT RA CT 300-350 NA 3phase DRYPOINT® RA CT 200-500 NA 3PH... -

Page 37: Dryer Dimensions Drypoint Ra Ct 400-500 Na 3Phase

Appendices 13.1.3 Dryer dimensions DRYPOINT RA CT 400-500 NA 3phase DRYPOINT® RA CT 200-500 NA 3PH... -

Page 38: Exploded Diagrams

Appendices 13.2 Exploded diagrams 13.2.1 Components of the exploded diagrams Al drying module Front panel Insulation material Back plate Refrigerant pressure switch LPS Right sidewall Refrigerant pressure switch HPS Left sidewall Refrigerant fan pressure switch PV Cover Compressor Base plate Hot-gas bypass valve Upper plate Condenser... -

Page 39: Exploded Diagram Drypoint Ra Ct 200-250 Na 3Phase / Ac

Appendices 13.2.2 Exploded diagram DRYPOINT RA CT 200-250 NA 3phase / AC DRYPOINT® RA CT 200-500 NA 3PH... -

Page 40: Exploded Diagram Drypoint Ra Ct 300-350 Na 3Phase / Ac

Appendices 13.2.3 Exploded diagram DRYPOINT RA CT 300-350 NA 3phase / AC DRYPOINT® RA CT 200-500 NA 3PH... -

Page 41: Exploded Diagram Drypoint Ra Ct 400-500 Na 3Phase / Ac

Appendices 13.2.4 Exploded diagram DRYPOINT RA CT 400-500 NA 3phase / AC DRYPOINT® RA CT 200-500 NA 3PH... -

Page 42: Electric Diagrams

Appendices 13.3 Electric diagrams 13.3.1 Electric diagrams – list of components Compressor Compressor thermal protection Compressor starting relay Compressor starting capacitor Compressor operating capacitor Condenser fan Fan starting capacitor (if installed) DMC51 DMC51 electronic control unit – main module DMC51 electronic control unit – display module T1 Temperature probe –... -

Page 43: Electric Diagram Drypoint Ra Ct 200-500 Na 3Phase Sheet

Appendices 13.3.2 Electric diagram DRYPOINT RA CT 200-500 NA 3phase Sheet 1/3 DRYPOINT® RA CT 200-500 NA 3PH... - Page 44 Appendices 13.3.3 Electric diagram DRYPOINT RA CT 200-500 NA 3phase Sheet 2/3 DRYPOINT® RA CT 200-500 NA 3PH...

-

Page 45: Electric Diagram Drypoint Ra Ct 200-500 Na 3Phase Sheet

Appendices 13.3.4 Electric diagram DRYPOINT RA CT 200-500 NA 3phase Sheet 3/3 DRYPOINT® RA CT 200-500 NA 3PH... - Page 46 Appendices BLANK PAGE DRYPOINT® RA CT 200-500 NA 3PH...

- Page 47 Appendices BLANK PAGE DRYPOINT® RA CT 200-500 NA 3PH...

- Page 48 Phone: +81 44 328 76 01 info@beko-technologies.co.jp Benelux Polska / Poland Scandinavia BEKO TECHNOLOGIES B.V. BEKO TECHNOLOGIES Sp. z o.o. BEKO TECHNOLOGIES AB Veenen 12 ul. Chłapowskiego 47 Industrivägen 39 NL - 4703 RB Roosendaal PL-02-787 Warszawa S-43361 Sävedalen...

Need help?

Do you have a question about the DRYPOINT RA CT Series and is the answer not in the manual?

Questions and answers