Summary of Contents for Hobart Welding Products Stickmate 160i

- Page 1 OM-278400E 2020−10 Processes Stick (SMAW) Welding Description Arc Welding Power Source Stickmate 160i www.HobartWelders.com File: Stick (SMAW)

-

Page 2: Table Of Contents

TABLE OF CONTENTS SECTION 1 − SAFETY PRECAUTIONS - READ BEFORE USING ....... . . 1-1. - Page 3 TABLE OF CONTENTS SECTION 10 − GUIDELINES FOR STICK WELDING (SMAW) ........10-1.

-

Page 4: Section 1 − Safety Precautions - Read Before Using

SECTION 1 − SAFETY PRECAUTIONS - READ BEFORE USING som 2020−02 Protect yourself and others from injury — read, follow, and save these important safety precautions and operating instructions. 1-1. Symbol Usage DANGER! − Indicates a hazardous situation which, if Indicates special instructions. - Page 5 D Do not cut or weld on tire rims or wheels. Tires can explode if heat- FUMES AND GASES can be hazardous. ed. Repaired rims and wheels can fail. See OSHA 29 CFR 1910.177 listed in Safety Standards. D Do not weld on containers that have held combustibles, or on Welding produces fumes and gases.

-

Page 6: Additional Hazards For Installation, Operation, And Maintenance

D Never weld on a pressurized cylinder − explosion will result. CYLINDERS can explode if damaged. D Use only correct compressed gas cylinders, regulators, hoses, and fittings designed for the specific application; maintain them Compressed gas cylinders contain gas under high and associated parts in good condition. -

Page 7: California Proposition 65 Warnings

H.F. RADIATION can cause interference. ARC WELDING can cause interference. D High-frequency (H.F.) can interfere with radio D Electromagnetic energy can interfere with navigation, safety services, computers, and sensitive electronic equipment such as communications equipment. computers and computer-driven equipment such as robots. D Have only qualified persons familiar with electronic equipment D Be sure all equipment in the welding area is electromagnetically perform this installation. -

Page 8: Section 2 − Consignes De Sécurité − Lire Avant Utilisation

SECTION 2 − CONSIGNES DE SÉCURITÉ − LIRE AVANT UTILISATION som_2020−02_fre Pour écarter les risques de blessure pour vous−même et pour autrui — lire, appliquer et ranger en lieu sûr ces consignes relatives aux précautions de sécurité et au mode opératoire. 2-1. - Page 9 D Déplacer toutes les substances inflammables à une distance de LES PIÈCES CHAUDES peuvent 10,7 m de l’arc de soudage. En cas d’impossibilité les recouvrir provoquer des brûlures. soigneusement avec des protections homologués. D Ne pas toucher à mains nues les parties chaudes. D Ne pas souder dans un endroit là...

-

Page 10: Symboles De Dangers Supplémentaires En Relation Avec L'installation, Le Fonctionnement Et La Maintenance

D Protéger les bouteilles de gaz comprimé d’une chaleur excessive, Les CHAMPS ÉLECTROMAGNÉTIQUES (CEM) des chocs mécaniques, des dommages physiques, du laitier, des peuvent affecter les implants médicaux. flammes ouvertes, des étincelles et des arcs. D Placer les bouteilles debout en les fixant dans un support station- D Les porteurs de stimulateurs cardiaques et naire ou dans un porte-bouteilles pour les empêcher de tomber ou autres implants médicaux doivent rester à... -

Page 11: Proposition Californienne 65 Avertissements

D Effectuer régulièrement le contrôle et l’entretien de l’installation. LIRE LES INSTRUCTIONS. D Maintenir soigneusement fermés les portes et les panneaux des sources de haute fréquence, maintenir les éclateurs à une distan- D Lire et appliquer les instructions sur les ce correcte et utiliser une terre et un blindage pour réduire les étiquettes et le Mode d’emploi avant l’instal- interférences éventuelles. -

Page 12: Section 3 − Definitions

A complete Parts List is available at www.HobartWelders.com SECTION 3 − DEFINITIONS 3-1. Miscellaneous Symbols And Definitions Some symbols are found only on CE products. Direct Current Amperage Negative Shielded Metal Arc Input Power Or Welding (SMAW) Voltage Input Voltage Single Phase Rated No-Load Voltage (OCV) -

Page 13: Section 4 − Specifications

4-4. Unit Specifications Do not use information in unit specifications table to determine electrical service requirements. See Sections 5-8 thru 5-10 for information on con- necting input power. A. Stickmate 160i Maximum Amperage Maximum Input At... -

Page 14: Duty Cycle Chart

A complete Parts List is available at www.HobartWelders.com 4-6. Duty Cycle Chart A. Stickmate 160i Duty Cycle is percentage of 10 min- utes that unit can weld at rated load without overheating. If unit overheats, thermostat(s) opens, output stops, and cooling fan runs. -

Page 15: Volt-Ampere Curves

A complete Parts List is available at www.HobartWelders.com 4-7. Volt-Ampere Curves The volt-ampere curves show the minimum and maximum voltage A. Stickmate 160i (120 Volt Input) and amperage output capabilities. Curves of other settings fall be- tween the curves shown. -

Page 16: Section 5 − Installation

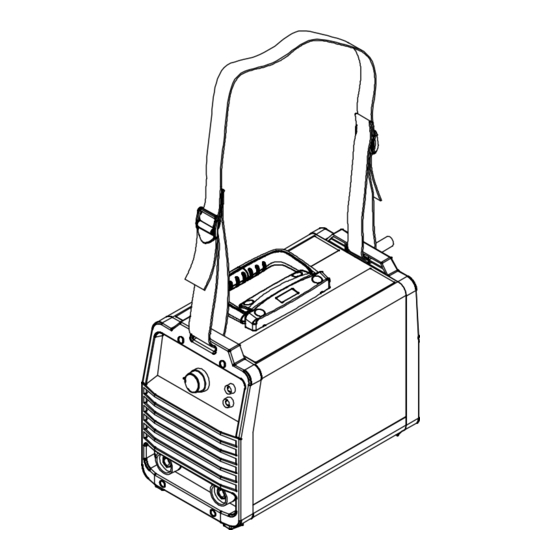

A complete Parts List is available at www.HobartWelders.com SECTION 5 − INSTALLATION 5-1. Selecting a Location Do not move or operate unit where it could tip. Movement Location And Airflow Special installation may be required where gasoline or volatile liquids are present − see NEC Article 511 or CEC Section 20. -

Page 17: Installing Electrode Holder And Work Clamp

A complete Parts List is available at www.HobartWelders.com 5-2. Installing Electrode Holder And Work Clamp Removing Barrel From Electrode Holder Barrel Barrel Set Screw Electrode Holder Loosen barrel set screw. Slide barrel away from electrode holder. Installing Electrode Cable and Barrel onto Electrode Holder Electrode Cable From Unit (Has Bare Conductors on End) -

Page 18: Connecting To Weld Output Terminals

A complete Parts List is available at www.HobartWelders.com 5-4. Connecting To Weld Output Terminals Turn off power before connecting to weld output terminals. Do not use worn, damaged, un- dersized, or repaired cables. Negative (−) Weld Output Terminal Positive (+) Weld Output Terminal Dinse Weld Connector Insert Dinse connector fully into termi- nal. -

Page 19: Multi−Voltage Plug Adapter (Mvp) Connection

A complete Parts List is available at www.HobartWelders.com 5-6. Multi−Voltage Plug Adapter (MVP) Connection Selecting Plug Adapter Do not cut off power cord connector and rewire. The power cord connector and plugs adapters will work with standard NEMA receptacles. Modifying power cord, connector, and plug adapter... -

Page 20: Weld Output Cables

5-8. Electrical Service Guide Elec Serv 2017-01 A. Stickmate 160i Failure to follow these electrical service guide recommendations could create an electric shock or fire hazard. These recommenda- tions are for a dedicated circuit sized for the rated output and duty cycle of the welding power source. -

Page 21: Connecting 120 Volt Input Power

A complete Parts List is available at www.HobartWelders.com 5-9. Connecting 120 Volt Input Power Installation must meet National and Local Codes − have only qualified persons make this installation. Special installation required where gasoline or volatile liquids are present − see NEC Ar- ticle 511 or CEC Section 20. -

Page 22: Connecting 240 Volt Input Power

A complete Parts List is available at www.HobartWelders.com 5-10. Connecting 240 Volt Input Power Installation must meet all National and Local Codes − have only qualified persons make this installation. Disconnect and lockout/tagout in- put power before installing recep- tacle. Follow established proced- ures regarding the installation and removal of lockout/tagout devices. -

Page 23: Section 6 − Operation

A complete Parts List is available at www.HobartWelders.com SECTION 6 − OPERATION 6-1. Controls A. Stickmate 160i Amperage Adjustment Control Use control to select desired weld amperage. Power Indicator Light Lamp goes on when unit is on. Over Temperature Light... -

Page 24: Section 7 − Maintenance & Troubleshooting

A complete Parts List is available at www.HobartWelders.com SECTION 7 − MAINTENANCE & TROUBLESHOOTING 7-1. Routine Maintenance Disconnect power Maintain more often before maintaining. during severe conditions. n = Check Z = Change ~ = Clean l = Replace Reference * To be done by Factory Authorized Service Agent Every Months... -

Page 25: Section 8 − Parts List

A complete Parts List is available at www.HobartWelders.com SECTION 8 − PARTS LIST 8-1. Recommended Spare Parts Dia. Part Mkgs. Description Quantity ... . . 254330 Adapter, Power Cable 5−15PXL630R (120V/15A) . -

Page 26: Section 9 − Electrical Diagrams

SECTION 9 − ELECTRICAL DIAGRAMS 279190-A Figure 9-1. Circuit Diagram For Stickmate 160 Model OM-278400 Page 23... -

Page 27: Section 10 − Guidelines For Stick Welding (Smaw)

SECTION 10 − GUIDELINES FOR STICK WELDING (SMAW) 10-1. Stick Welding Procedure Weld current starts when electrode touches work- piece. Weld current can damage electronic parts in vehicles. Disconnect both battery Equipment Needed: Tools Needed: cables before welding on a vehicle. -

Page 28: Electrode And Amperage Selection Chart

10-2. Electrode And Amperage Selection Chart 6010 DEEP 3/32 MIN. PREP, ROUGH HIGH SPATTER 6011 DEEP 6010 5/32 & 6013 EP,EN GENERAL 3/16 6011 7/32 SMOOTH, EASY, 7014 EP,EN FAST 1/16 LOW HYDROGEN, 7018 5/64 STRONG 3/32 SMOOTH, EASY, FLAT 7024 EP,EN 6013... -

Page 29: Positioning Electrode Holder

10-4. Positioning Electrode Holder End View Of Work Angle Side View Of Electrode Angle After learning to start and hold an arc, practice running beads of weld metal on flat plates using a full electrode. ° ° Hold the electrode nearly per- pendicular to the work, although tilting it ahead (in the direction of °... -

Page 30: Conditions That Affect Weld Bead Shape

10-7. Conditions That Affect Weld Bead Shape Weld bead shape is affected by electrode angle, arc length, travel speed, and thickness of base metal. Correct Angle Angle Too Large ° - ° Angle Too Small Electrode Angle Drag Spatter Arc Length Normal Too Long Too Short... -

Page 31: Welding Groove (Butt) Joints

10-10. Welding Groove (Butt) Joints Tack Welds Prevent butt joint distortion by tack welding the materials in position before final weld. Workpiece distortion occurs when heat is applied locally to a joint. One side of a metal plate will curl up toward the weld. -

Page 32: Weld Test

10-12. Weld Test Vise Weld Joint Hammer Strike the weld joint in the direction shown. A good weld bends over but does not break. If the weld breaks, examine it to determine the cause. If the weld is porous (many holes), the arc length was probably too long. - Page 33 Lack Of Penetration − shallow fusion between weld metal and base metal. Lack of Penetration Good Penetration Possible Causes Remedy Improper joint preparation. Material too thick. Joint preparation and design must provide access to bottom of groove. Improper weld technique. Keep arc on leading edge of weld puddle.

- Page 34 Notes...

- Page 35 Service LIMITED WARRANTY − Subject to the terms and conditions 6 Months — Parts You always get the fast, below, Miller Electric Mfg. LLC, dba Hobart Welding Products, Batteries reliable response you Appleton, Wisconsin, warrants to its original retail purchaser need.

- Page 36 Owner’s Record Please complete and retain with your personal records. Model Name Serial/Style Number Purchase Date (Date which equipment was delivered to original customer.) Distributor Address City State Thank you for purchasing Hobart. Our trained technical support team is dedicated to your satisfaction. For questions regarding performance, op- eration, or service, contact us! Resources Available Always provide Model Name and Serial/Style Number.

Need help?

Do you have a question about the Stickmate 160i and is the answer not in the manual?

Questions and answers