COSMOGAS AGUADENS 60T Instructions For Installation, Use And Maintenance Manual

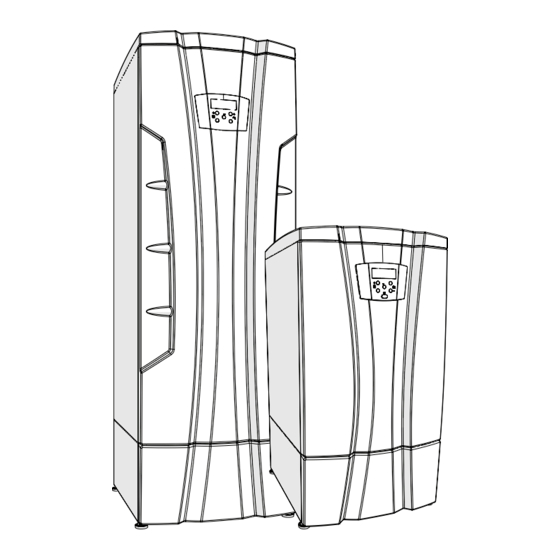

Gas condensing free-standing boiler

Hide thumbs

Also See for AGUADENS 60T:

Need help?

Do you have a question about the AGUADENS 60T and is the answer not in the manual?

Questions and answers