Table of Contents

Advertisement

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Miller Bobcat 260

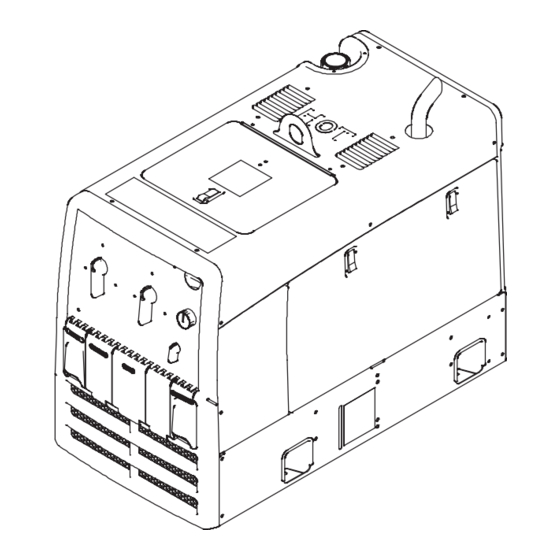

- Page 1 OM-286504M 2023-05 Processes Stick (SMAW) Welding MIG (GMAW) Welding Flux Cored (FCAW) Welding TIG (GTAW) Welding Description Engine Driven Welder/Generator Bobcat ™ OWNER’S MANUAL For product information, Owner’s Manual translations, and more, visit www.MillerWelds.com...

- Page 2 We know you don’t have time to do it any other way. That’s why when Niels Miller first started building arc welders in 1929, he made sure his products offered long-lasting value and superior quality.

-

Page 3: Table Of Contents

TABLE OF CONTENTS SECTION 1 – SAFETY PRECAUTIONS – READ BEFORE USING..............1 Symbol Usage . - Page 4 TABLE OF CONTENTS Overload Protection ....................42 Changing Engine Oil, Oil Filter, And Fuel Filter .

-

Page 5: Section 1 - Safety Precautions - Read Before Using

SECTION 1 – SAFETY PRECAUTIONS – READ BEFORE USING Protect yourself and others from injury—read, follow, and save these important safety precautions and operating instructions. 1-1. Symbol Usage DANGER! – Indicates a hazardous situation which, if not avoided, will result in death or serious injury. The possible hazards are shown in the adjoining symbols or explained in the text. - Page 6 Accidental contact of electrode to metal objects can cause sparks, ex- FLYING METAL OR DIRT can injure plosion, overheating, or fire. Check and be sure the area is safe be- eyes. fore doing any welding. � Welding, chipping, wire brushing, and grinding �...

-

Page 7: Engine Hazards

� Install cylinders in an upright position by securing to a stationary � Turn face away from valve outlet when opening cylinder valve. Do support or cylinder rack to prevent falling or tipping. not stand in front of or behind the regulator when opening the valve. -

Page 8: Compressed Air Hazards

1-4. Compressed Air Hazards � Reinstall doors, panels, covers, or guards when servicing is fin- COMPRESSED AIR EQUIPMENT can ished and before starting unit. injure or kill. � If ANY air is injected into the skin or body seek medical help immediately. - Page 9 � Follow the guidelines in the Applications Manual for the Revised HIGH PRESSURE FLUIDS can injure NIOSH Lifting Equation (Publication No. 94-110) when manually or kill. lifting heavy parts or equipment. � Engine fuel system components can be under high OVERHEATING can damage motors.

-

Page 10: California Proposition 65 Warnings

� If notified by the FCC about interference, stop using the equipment � Be sure all equipment in the welding area is electromagnetically at once. compatible. � Have the installation regularly checked and maintained. � To reduce possible interference, keep weld cables as short as �... -

Page 11: Section 2 - Consignes De Sécurité - Lire Avant Utilisation

SECTION 2 – CONSIGNES DE SÉCURITÉ - LIRE AVANT UTILISATION Pour écarter les risques de blessure pour vous-même et pour autrui — lire, appliquer et ranger en lieu sûr ces consignes relatives aux précautions de sécurité et au mode opératoire. 2-1. - Page 12 � Ne pas toucher aux portes-électrodes qui sont raccordés à deux bien ventilé, et en portant un respirateur à alimentation d’air. Les machines à souder en même temps, car cela entraîne la présence revêtements et tous les métaux renfermant ces éléments peuvent d’une tension de circuit-ouvert double.

-

Page 13: Dangers Existant En Relation Avec Le Moteur

� Ne pas souder là où l’air ambiant pourrait contenir des poussières, � Les porteurs d’implants médicaux doivent consulter leur médecin gaz ou émanations inflammables (vapeur d’essence, par et le fabricant du dispositif avant de s’approcher de la zone où se exemple). -

Page 14: Dangers Liés À L'air Comprimé

� Ne pas placer l’appareil sur, au-dessus ou à proximité de surfaces � Ne pas toucher aux pièces chaudes, utiliser les outils recomman- inflammables. dés et porter des gants de soudage et des vêtements épais pour éviter les brûlures. � Tenir à distance les produits inflammables de l’échappement. LA VAPEUR ET LE LIQUIDE DE Les PIÈCES MOBILES peuvent REFROIDISSEMENT CHAUD peuvent... -

Page 15: Symboles De Dangers Supplémentaires En Relation Avec L'installation, Le Fonctionnement Et La Maintenance

L’AIR COMPRIMÉ risque de Les PIÈCES MOBILES peuvent provoquer des blessures ou même la causer des blessures. mort. � S’abstenir de toucher des parties mobiles telles � Avant d’intervenir sur le circuit d’air comprimé, que des ventilateurs, courroies et rotors. couper l’alimentation électrique, verrouiller etéti- �... - Page 16 � Utiliser uniquement des équipements adéquats pour un fonction- � Régler les commandes de charge de batterie sur la position d’arrêt nement avec une alimentation de 50/60 ou de 60 Hz. avant de brancher la batterie. Veiller à ce que les pinces de charge ne se touchent pas.

-

Page 17: Proposition Californienne 65 Avertissements

� Effectuer l’installation, l’entretien et toute intervention selon les LE SOUDAGE À L’ARC risque de manuels d’utilisateurs, les normes nationales, provinciales et de provoquer des interférences. l’industrie, ainsi que les codes municipaux. � L’énergie électromagnétique risque de provoquer LE RAYONNEMENT HAUTE des interférences pour l’équipement électronique FRÉQUENCE (H.F.) risque de sensible tel que les ordinateurs et l’équipement... - Page 18 les porteurs d’implants médicaux doivent être prises: par exemple, 5. Connecter la pince sur la pièce aussi près que possible de la des restrictions d’accès pour les passants ou une évaluation indivi- soudure. duelle des risques pour les soudeurs. Tous les soudeurs doivent ap- 6.

-

Page 19: Section 3 - Definitions

� Complete Parts List is available at www.MillerWelds.com SECTION 3 – DEFINITIONS Become trained and read the instructions before working on the Become trained and read the instructions before working on the machine or heating. machine or heating. 3-1. Additional Safety Symbol Definitions Safe85 2012 06 Safe85 2012 06 �... - Page 20 � Complete Parts List is available at www.MillerWelds.com Gas Tungsten Arc Shielded Metal Arc Welding (GTAW) / Hertz Welding (SMAW) Tungsten Inert Gas (TIG) Welding Gas Metal Arc Single Phase Single Phase Welding (GMAW) Alternator Welding OM-286504 Page 16...

-

Page 21: Section 4 - Specifications

Information About Default Weld Parameters And Settings NOTICE – Each welding application is unique. Although certain Miller Electric products are designed to determine and default to certain typical welding parameters and settings based upon specific and relatively limited application variables input by the end user, such default settings are for reference purposes only;... -

Page 22: Wireless Remote Regulatory Approval

� Complete Parts List is available at www.MillerWelds.com 4-7. Wireless Remote Regulatory Approval This device complies with Part 15 of the FCC rules. Operation is subject to the following conditions: 1. This device may not cause harmful interference, and 2. This device may accept any interference received, including interference that may cause undesired operation. WARNING! Changes or modifications not expressly approved by the party responsible for compliance could void the user’s authority to operate this device. -

Page 23: Dimensions, Weights, And Operating Angles

Complete Parts List available at www.MillerWelds.com � Complete Parts List is available at www.MillerWelds.com 13-17. Dimensions, Weights, And Operating Angles 4-9. Dimensions, Weights, And Operating Angles Do not exceed tilt angles or engine Do not exceed tilt angles or could be damaged or unit could tip. engine could be damaged or unit could tip. -

Page 24: 4-10. Fuel Consumption

� Complete Parts List is available at www.MillerWelds.com 4-10. Fuel Consumption On a typical job using 1/8 in. 7018 electrodes (125 amps, 20% duty cycle), expect about 20 hours of operation (22 hours with EFI engine). Welding at 150 amps at 40% duty cycle uses approximately 3/4 gallon per hour. -

Page 25: 4-12. Volt-Ampere Curves

� Complete Parts List is available at www.MillerWelds.com 4-12. Volt-Ampere Curves The volt-ampere curve shows the minimum CC/AC Mode and maximum voltage and amperage output capabilities of the welding generator. Curves of all other settings fall between the curves shown. CC/DC Mode CV/DC Mode OM-286504 Page 21... -

Page 26: Section 5 - Installation

� Complete Parts List is available at www.MillerWelds.com 1-1. Installing Welder/Generator SECTION 5 – INSTALLATION 1-1. Installing Welder/Generator 5-1. Installing Welder/Generator Complete Parts List available at www.MillerWelds.com Do not move or operate unit where Movement it could tip. Do not lift unit from end. Do not weld on base. -

Page 27: 1-1. Grounding Generator To Truck Or Trailer Frame

� Complete Parts List is available at www.MillerWelds.com 5-2. Grounding Generator to Truck or Trailer Frame 1-1. Grounding Generator To Truck Or Trailer Frame GND/PE Bed liners, shipping skids, and 3 Metal Vehicle Frame Always ground generator frame to some running gear insulate the vehicle frame to prevent electric welding generator from the vehicle shock and static electricity hazards. -

Page 28: Engine Prestart Checks

� Complete Parts List is available at www.MillerWelds.com 5-4. Engine Prestart Checks Complete Parts List available at www.MillerWelds.com Check all fluids daily. Engine must be cold Complete Parts List available at www.MillerWelds.com and on a level surface. Unit is shipped with 10W-30 synthetic blend engine oil. -

Page 29: Connecting Or Replacing The Battery

� Complete Parts List is available at www.MillerWelds.com 5-5. Connecting Or Replacing The Battery Complete Parts List available at www.MillerWelds.com Connect negative (-) battery cable last. Battery is most easily accessed through the side door. Connect battery, negative cable last. Close access door. �... -

Page 30: Weld Output Terminals

� Complete Parts List is available at www.MillerWelds.com 5-7. Weld Output Terminals Complete Parts List available at www.MillerWelds.com Stop engine. Turn off power before connecting to weld output terminals. Do not use worn, damaged, under- sized, or repaired cables. 1 Work Weld Output Terminal 2 Electrode Weld Output Terminal Connect work cable to Work terminal. -

Page 31: Selecting Cable Sizes

� Complete Parts List is available at www.MillerWelds.com 5-9. Selecting Cable Sizes* NOTICE – The Total Cable Length in Weld Circuit (see table below) is the combined length of both weld cables. For example, if the power source is 100 ft (30 m) from the workpiece, the total cable length in the weld circuit is 200 ft (2 cables x 100 ft). Use the 200 ft (60 m) column to determine cable size. -

Page 32: Section 6 - Operation

� Complete Parts List is available at www.MillerWelds.com SECTION 6 – OPERATION 6-1. Front Panel Controls 1 Engine Control Switch A maintenance interval is reached when the Negative. Use AC position for alternating wrench icon appears in the display. current. Use switch to start engine, select speed, and stop engine. -

Page 33: Using Wireless Remote (If Equipped)

� Complete Parts List is available at www.MillerWelds.com 6-2. Using Wireless Remote (If Equipped) Place Engine Control switch in Off position when welder/generator is not in use to prevent unexpected starting. Check that all doors, panels, cov- ers, and guards are closed and se- curely in place before starting. -

Page 34: Cold Weather Engine Operation

Complete Parts List available at www.MillerWelds.com � Complete Parts List is available at www.MillerWelds.com 6-3. Cold Weather Engine Operation Ref. 236615-A � Run engine only when expecting to fre- Kohler (1-800-544-2444) offers a kit for cold 1 Engine Control Switch — Infrequently quently load it. -

Page 35: Typical Stick Welding Connections And Control Settings

� Set Weld Process Selector switch to + Stick position. � Set Coarse Range switch to 60-160 (1/ 8”) position. � Set Fine control at 7 or higher for best results. � Miller recommends Hobart filler metals. 3/4 in. philips head wrench crescent wrench OM-286504 Page 31... -

Page 36: Typical Mig Welding Connections And Settings

� Complete Parts List is available at www.MillerWelds.com 6-5. Typical MIG Welding Connections and Settings A. Solid Wire Applications Stop engine. � This section provides general guide- lines and may not suit all applications. � The control panel shows the typical set- tings for welding with 0.035 (ER70S-3) solid wire, short circuit transfer. - Page 37 � Do a test weld. To increase arc length, increase Fine Control setting. To short- en arc length, reduce fine control setting or increase wire feed speed. � Miller recommends Hobart filler metals. 3/4 in. philips head wrench crescent wrench...

-

Page 38: Typical Mig Connections And Settings Using Weld Control And Spoolgun

Fine Control setting to increase/ 10 Argon Cylinder decrease arc length. Connect gas hose from spoolgun to regula- 11 Trigger Control Cord tor on Argon bottle. � Miller recommends Hobart filler 12 Input Power Cord metals. Reinstall weld control wrapper. -

Page 39: Fuel/Hour Gauge Descriptions

� Complete Parts List is available at www.MillerWelds.com 6-7. Fuel/Hour Gauge Descriptions OM-286504 Page 35... -

Page 40: Section 7 - Operating Auxiliary Equipment

� Complete Parts List is available at www.MillerWelds.com SECTION 7 – OPERATING AUXILIARY EQUIPMENT 7-1. Generator Power Receptacles Complete Parts List available at www.MillerWelds.com 250916-A / 250290-A RC1 supplies 60 Hz single-phase power at CB2 protects RC2 and CB3 protects RC3 Use GFCI protection when operating weld/power speed. -

Page 41: Gfci Receptacle Information, Resetting, And Testing

� Complete Parts List is available at www.MillerWelds.com 7-2. GFCI Receptacle Information, Resetting, And Testing Use GFCI protection when operating If a ground fault is detected, the GFCI Reset Resetting GFCI Receptacles auxiliary equipment. If unit does not button pops out, and the circuit opens to dis- If a GFCI fault occurs, stop engine and dis- have GFCI receptacles, use GFCI- connect power to the faulty equipment. -

Page 42: Simultaneous Weld And Power

� Complete Parts List is available at www.MillerWelds.com 7-3. Simultaneous Weld And Power Weld Current in Amperes Total Power in Watts 120 V Full kVA Receptacle 240 V Full kVA Receptacle Amperes Amperes 2200 3500 Complete Parts List available at www.MillerWelds.com 5200 8000 11,000... -

Page 43: Section 8 - Maintenance And Troubleshooting

� Complete Parts List is available at www.MillerWelds.com SECTION 8 – MAINTENANCE AND TROUBLESHOOTING 8-1. Routine Maintenance Stop engine before maintaining. � See Engine Manual and Maintenance Label for important start-up, service, and storage information. Service engine more often if used in severe conditions. -

Page 44: Maintenance Label

� Complete Parts List is available at www.MillerWelds.com 8-2. Maintenance Label OM-286504 Page 40... -

Page 45: Servicing Air Cleaner

� Complete Parts List is available at www.MillerWelds.com 8-3. Servicing Air Cleaner Stop engine. NOTICE – Do not run engine without air cleaner or with dirty element. Engine dam- age caused by using a damaged element is not covered by the warranty. 1 Precleaner Wash precleaner with soap and water solu- tion. -

Page 46: Overload Protection

� Complete Parts List is available at www.MillerWelds.com 8-5. Overload Protection Stop engine. Disconnect negative (-) battery cable. � Fuses F1 and F2 located on bracket behind right side panel. 1 Fuse F2 F2 protects the weld excitation winding from overload. -

Page 47: Changing Engine Oil, Oil Filter, And Fuel Filter

� Complete Parts List is available at www.MillerWelds.com 8-6. Changing Engine Oil, Oil Filter, And Fuel Filter Stop engine and let cool. 1 Oil Drain Valve Change engine oil and filter according to en- gine owner’s manual. NOTICE – Close valve and valve cap before adding oil and running engine. -

Page 48: Adjusting Engine Speed (Kohler Ch730 Carbureted Units)

Complete Parts List available at www.MillerWelds.com � Complete Parts List is available at www.MillerWelds.com 8-7. Adjusting Engine Speed (Kohler CH730 Carbureted Units) After tuning engine, check engine speeds with a tachometer (see table). If necessary, adjust speeds as follows: Start engine and run until warm. Turn Fine Control to 10. -

Page 49: Adjusting Engine Speed (Kohler Ech730 Efi Units)

Complete Parts List available at www.MillerWelds.com � Complete Parts List is available at www.MillerWelds.com 8-8. Adjusting Engine Speed (Kohler ECH730 EFI Units) After tuning engine, check engine speeds with a tachometer (see table). If necessary, adjust speeds as follows: Start engine and run until warm. Turn A/V control to 10. -

Page 50: Troubleshooting

� Complete Parts List is available at www.MillerWelds.com 8-9. Troubleshooting A. Welding Troubleshooting Trouble Remedy Low or no weld output; generator Check control settings. power output okay at AC receptacles. Check weld connections. Check fuse F2, and replace if open (see Section 8-5). Have Factory Authorized Service Agent check brushes, slip rings, and integrated rectifiers SR2 and SR3. - Page 51 � Complete Parts List is available at www.MillerWelds.com Trouble Remedy Erratic power output at AC Check fuel level. receptacles. Check engine speed, and adjust if necessary (see Section 8-7 or 8-8). Check receptacle wiring and connections. Have Factory Authorized Service Agent check brushes and slip rings. C.

- Page 52 � Complete Parts List is available at www.MillerWelds.com D. Wireless Remote Troubleshooting Trouble Remedy Fob Communication LED (1st LED) Check that the Engine Control switch is set to Run or Run/Idle blinks rapidly after start or stop se- Remove obstructions between fob and unit. quence button presses.

-

Page 53: Section 9 - Parts List

� Complete Parts List is available at www.MillerWelds.com SECTION 9 – PARTS LIST 9-1. Recommended Spare Parts Recommended Spare Parts Dia. Mkgs. Part No. Description Quantity F1, F2 169296 Fuse, Mintr Gl 25. Amp 125 Volt 215621 Fuse, 30 Amp Ato Type (Kohler ECH730) F4, F5 215619 Fuse, 10 Amp Ato Type (Kohler ECH730) -

Page 54: Section 10 - Electrical Diagrams

SECTION 10 – ELECTRICAL DIAGRAMS Figure 10-1. Circuit Diagram For Gasoline Welder/Generator OM-286504 Page 50... - Page 55 291666-B OM-286504 Page 51...

- Page 56 PLG6/RC6 120V PLG6/RC6 PLG9/RC9 POWER EXCITATION 120V REVOLVING FIELD REVOLVING FIELD WELD PLG12 AC-Z START FUEL/HM/ RUN/IDLE IDLE CONTROL CASE 40-130 60-160 AMPS AMPS 80-225 WIRE AMPS HIGH WIRE 120V/240V 100-260 AMPS PLG4 PLG4 PLG4 PLG4 PLG4 PLG4 DC-Z LOW OIL PRESSURE N.O.

-

Page 57: Section 11 - Generator Power Guidelines

SECTION 11 – GENERATOR POWER GUIDELINES � The views in this section are intended to be representative of all engine-driven welder/generators. Your unit may differ from those shown. 11-1. Selecting Equipment 1 Generator Power Receptacles – Neutral Bonded To Frame 2 3-Prong Plug From Case Grounded Equipment 3 2-Prong Plug From Double Insulated... - Page 58 11-3. Grounding When Supplying Building Systems 1 Equipment Grounding Terminal 2 Grounding Cable GND/PE Use #8 AWG or larger insulated copper wire. 3 Ground Device � Use ground device as stated in electri- cal codes. Ground generator to system earth ground if supplying power to a premises (shop,...

- Page 59 11-5. Approximate Power Requirements For Industrial Motors Industrial Motors Rating Starting Watts Running Watts Split Phase 1/8 HP 1/6 HP 1225 1/4 HP 1600 1/3 HP 2100 1/2 HP 3175 Capacitor Start-Induction Run 1/3 HP 2020 1/2 HP 3075 3/4 HP 4500 1400 1 HP...

- Page 60 11-7. Approximate Power Requirements For Contractor Equipment Contractor Equipment Rating Starting Watts Running Watts Hand Drill 1/4 in. 3/8 in. 1/2 in. Circular Saw 6-1/2 in. 7-1/4 in. 8-1/4 in. 1400 1400 Table Saw 9 in. 4500 1500 10 in. 6300 1800 Band Saw...

- Page 61 11-8. Power Required To Start Motor 1 Motor Start Code 2 Running Amperage 3 Motor HP 4 Motor Voltage AC MOTOR VOLTS AMPS Step 1: Find code and use table to find kVA/ CODE HP. If code is not listed, multiply running am- PHASE perage by six to find starting amperage.

- Page 62 11-10. Typical Connections To Standby Power 1. Utility Electrical 2. Transfer Switch 3. Fused Disconnect 4. Welder/Generator Service Switch (If Required) Output 5. Essential Loads Have only qualified persons perform 1 Utility Electrical Service 4 Welder/Generator Output these connections according to all 2 Transfer Switch (Double-Throw) Generator output voltage and wiring must applicable...

- Page 63 11-11. Selecting Extension Cord (Use Shortest Cord Possible) A. Cord Lengths For 120 Volt Loads Use GFCI protection when operating auxiliary equipment. If unit does not have GFCI receptacles, use GFCI-protected extension cord. Do not use GFCI receptacles to power life support equipment. Maximum Allowable Cord Length In ft (m) for Conductor Size In AWG (mm Current (Amperes)

-

Page 64: Section 12 - Stick Welding (Smaw) Guidelines

SECTION 12 – STICK WELDING (SMAW) GUIDELINES tools/ 12-1. Stick Welding Procedure wrench crescent wrench allen_set flathead philips head wrench crescent wrench Weld current starts when electrode Tools Needed: touches workpiece. Weld current can damage elec- tronic parts in vehicles. Discon- nect both battery cables before welding on a vehicle. - Page 65 12-2. Electrode And Amperage Selection Chart 6010 DEEP 3/32 MIN. PREP, ROUGH HIGH SPATTER 6011 DEEP 6010 5/32 & 6013 EP,EN GENERAL 3/16 6011 7/32 SMOOTH, EASY, 7014 EP,EN FAST 1/16 LOW HYDROGEN, 7018 5/64 STRONG 3/32 FLAT SMOOTH, EASY, 7024 EP,EN 6013...

- Page 66 12-4. Positioning Electrode Holder 1 End View Of Work Angle Groove Welds 2 Side View Of Electrode Angle After learning to start and hold an arc, prac- tice running beads of weld metal on flat 10 -30 10 -30 plates using a full electrode. Hold the electrode nearly perpendicular to the work, although tilting it ahead (in the di- rection of travel) will be helpful.

- Page 67 12-7. Conditions That Affect Weld Bead Shape Electrode Angle � Weld bead shape is affected by elec- trode angle, arc length, travel speed, and thickness of base metal. 1 Angle Too Small 2 Correct Angle 3 Drag 4 Angle Too Large 5 Too Short 6 Normal Arc Length...

- Page 68 12-9. Welding Lap Joints 1-1. Welding Lap Joints 1 Electrode 2 Single-Layer Fillet Weld 1-1. Welding Lap Joints Move electrode in circular motion. 3 Multi-Layer Fillet Weld Weld a second layer when a heavier fillet is needed. Remove slag before making anoth- er weld pass.

- Page 69 12-11. Welding T-Joints 1-3. Welding T-Joints 1/16 in. (1.6 mm) 1 Electrode 2 Fillet Weld Keep arc short and move at definite rate of speed. Hold electrode as shown to provide fusion into the corner. Square edge of the weld surface. For maximum strength weld both sides of up- 1-3.

- Page 70 Excessive Spatter - scattering of molten metal particles that cool to solid form near weld bead. Possible Causes Corrective Actions Amperage too high for electrode. Decrease amperage or select larger electrode. Arc length too long or voltage too high. Reduce arc length or voltage. Incomplete Fusion - failure of weld metal to fuse completely with base metal or a preceding weld bead.

- Page 71 Distortion - contraction of weld metal during welding that forces base metal to move. Illustration: Base metal moves in the direction of the weld bead. Possible Causes Corrective Actions Excessive heat input. Use restraint (clamp) to hold base metal in position. Make tack welds along joint before starting welding operation.

-

Page 72: Section 13 - Gmaw Welding (Mig) Guidelines When Using A Voltage-Sensing Feeder

SECTION 1 GMAW WELDING (MIG) GUIDELINES WHEN SECTION 13 – GMAW WELDING (MIG) GUIDELINES WHEN USING A VOLTAGE-SENSING FEEDER USING A VOLTAGE-SENSING FEEDER 13-1. Typical GMAW (MIG) Process Connections Using A Voltage-Sensing Wire Feeder Weld current can damage elec- tronic parts in vehicles. Discon- nect both battery cables before welding on a vehicle. - Page 73 13-2. Holding And Positioning Welding Gun � Welding wire is energized when gun trigger is pressed. Before lowering hel- met and pressing trigger, be sure wire is no more than 1/2 in. (13 mm) past end of nozzle, and tip of wire is posi- tioned correctly on seam.

- Page 74 13-3. Conditions That Affect Weld Bead Shape Gun Angles and Weld Bead Profiles � Weld bead shape depends on gun an- 5-15° gle, direction of travel, contact to work distance (stickout), travel speed, thick- ness of base metal, wire feed speed (weld current), and voltage.

- Page 75 13-4. Gun Movement During Welding � Normally, a single stringer bead is sat- isfactory for most narrow groove weld joints; however, for wide groove weld joints or bridging across gaps, a weave bead or multiple stringer beads works better. 1 Stringer Bead - Steady Forward Move- ment Along Weld Joint 2 Weave Bead - Side To Side Movement Along Weld Joint...

- Page 76 13-8. Troubleshooting – Porosity Porosity - small cavities or holes resulting from gas pockets in weld metal. Possible Causes Corrective Actions Insufficient shielding gas at welding arc. Increase flow of shielding gas at regulator/flowmeter and/or prevent drafts near welding arc. Remove spatter from gun nozzle.

- Page 77 Maintain proper work and travel angles. 13-12. Troubleshooting – Burn-Through Burn-Through - a hole caused by excessive penetration. Possible Causes Corrective Actions Excessive heat input. Select lower voltage and reduce wire feed speed. Increase and/or maintain steady travel speed. 13-13. Troubleshooting – Waviness Of Bead Waviness Of Bead - weld metal that is not parallel and does not cover joint formed by base metal.

- Page 78 13-15. Common MIG Shielding Gases This is a general chart for common gases and where they are used. Many different combinations (mixtures) of shielding gases have been devel- oped over the years. The most commonly used shielding gases are listed in the following table. Application Short Cir- Short Cir-...

- Page 79 13-16. Troubleshooting Guide For Semiautomatic Welding Equipment Problem Probable Cause Remedy Wire feed motor operates, but wire does not Too little pressure on drive rolls. Increase pressure setting on drive rolls. feed. Incorrect drive rolls. Check size stamped on drive rolls, replace to match wire size and type if necessary.

- Page 80 Notes...

- Page 81 Notes...

- Page 82 Notes...

- Page 83 Effective January 1, 2023 (Equipment with a serial number preface of ND or newer) This limited warranty supersedes all previous Miller warranties and is exclusive with no other guarantees or war- ranties expressed or implied. � CoolBelt, PAPR Blower, and PAPR Face...

- Page 84 Transportation Department. International Headquarters–USA USA Phone: 920-735-4505 USA & Canada FAX: 920-735-4134 International FAX: 920-735-4125 For International Locations Visit www.MillerWelds.com ORIGINAL INSTRUCTIONS – PRINTED IN USA © 2023 Miller Electric Mfg. LLC 2023-05...

Need help?

Do you have a question about the Bobcat 260 and is the answer not in the manual?

Questions and answers