Table of Contents

Advertisement

Quick Links

Operator´s manual p. 3

EN

Please read the operator's manual carefully and make sure you

understand the instructions before using the machine.

Manual de instrucciones p. 25

ES

Lea detenidamente el manual de instrucciones y asegúrese de entender

su contenido antes de utilizar la máquina.

Manuel d'utilisation p. 47

FR

Lire attentivement et bien assimiler le manuel d'utilisation avant

d'utiliser la machine.

Instruções para o uso p. 69

PT

Leia as instruções para o uso com toda a atenção e compreenda o seu

conteúdo antes de fazer uso da máquina.

RC 455

HUSQVARNA CONSTRUCTION PRODUCTS

EN ES FR PT

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Husqvarna RC 455

- Page 1 Please read the operator’s manual carefully and make sure you understand the instructions before using the machine. Manual de instrucciones p. 25 RC 455 Lea detenidamente el manual de instrucciones y asegúrese de entender su contenido antes de utilizar la máquina.

- Page 2 TO PURCHASE THIS PRODUCT PLEASE CONTACT US Equipment Financing and Extended Warranties Available Discount-Equipment.com is your online resource for commercial and industrial quality parts and equipment sales. 561-964-4949 visit us on line @ www.discount-equipment.com Select an option below to find your Equipment We sell worldwide for the brands: Genie, Terex, JLG, MultiQuip, Mikasa, Essick, Whiteman, Mayco, Toro Stone, Diamond Products, Generac Magnum, Airman, Haulotte, Barreto, Power Blanket, Nifty Lift, Atlas Copco, Chicago Pneumatic, Allmand, Miller Curber, Skyjack, Lull,...

-

Page 3: Table Of Contents

Operator's Man ual RC 455 Content English Content Key to symbols .............. Safety Instructions ............Introduction ..............What is what ..............Technical data ............. Assembling/Installing equipment ....Work process for wall sawing ......Start blade rotation ............After work is completed .......... -

Page 4: Key To Symbols

Operator's Manual RC 455 Key to symbols Key to symbols Remark A hand with a raised index finger with the text “Attention” The symbols below are used on the machine and in this signifies that a described element demands extra Operator's Manual. -

Page 5: Safety Instructions

Safety Instructions • Never disconnect any of the hydraulic hoses without first shutting off the unit and ensuring the motors have During the design and production of Husqvarna products, stopped completely. great importance is placed on safety, as well as •... - Page 6 Operator's Manual RC 455 Safety Instructions The pressure hoses in the system must always be • Store the machines in a locked area, where they are connected to the tool’s intake. The return hoses in the inaccessible to children and adults who have not been system must always go to the tool's outlet.

-

Page 7: Introduction

Husqvarna WS 355, WS 462, WS 463 and CS 2512. As RC 455 is equipped with a priority valve, the diesel- driven generating set, which can supply a flow, can be used to control machines that are driven by several different flows, for example, to drive the blade and motion. -

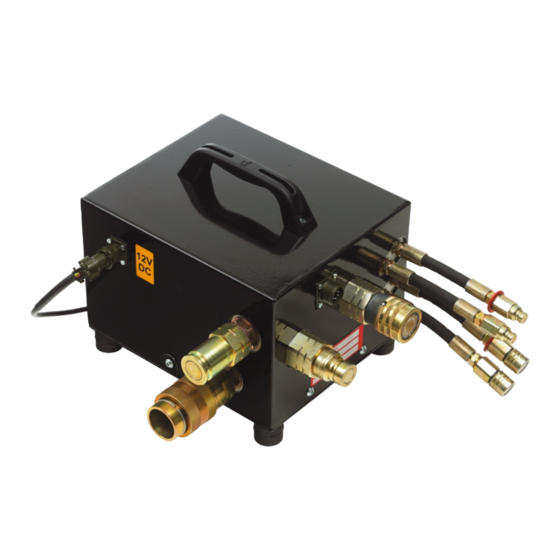

Page 8: What Is What

9. Remote control control the trolley motion while the male couplings control the blade motion. The remote control is used to control RC 455. In order for the remote control to work the hydraulic unit's 3. Canbus cable connection ignition must be switched on. - Page 9 What is what Operator's Manual RC 455 11.Blade rotation Control to start blade rotation/wire drive. In order for the blade to reach full power, the control must be turned to the right-hand end position. 12.Display Information is given on the display about essential settings, service requirements and any faults.

-

Page 10: Technical Data

Operator's Manual RC 455 Technical data Technical data Max. flow__________________________ 115 l/min (30 GPM) Max pressure ______________________ 230 bar (3340 psi) Rec. hydraulic oil flow from the hydraulic unit: WS 463___________________________ 80 l/min (21 GPM) WS 462___________________________ 70 l/min (18.5 GPM CS2512___________________________ 80 l/min (21 GPM) Weight ___________________________ 19.6 kg (43.3 lbs) -

Page 11: Assembling/Installing Equipment

5. Connect the incoming hydraulic hoses from the diesel- driven generating set to RC 455. When the RC 455 is delivered there is only one 12 V DC connector on the power cable. In order for the machine to work, the end of the cable not fitted with a connector is connected to the hydraulic unit's outgoing power cable. -

Page 12: Work Process For Wall Sawing

Operator's Manual RC 455 Work process for wall sawing Work process for wall sawing 3. Start the horizontal motion by turning the horizontal motion knob in the desired direction. Start blade rotation 1. Start the motor on the hydraulic unit by pressing the remote control's green button once. -

Page 13: Work Procedure For Wire Cutting

Work process for wall sawing Operator's Manual RC 455 Work procedure for wire cutting 6. Tension the wire by carefully turning the knob on the pressure reduction block clockwise until the wire is When all the equipment has been assembled cutting can tensioned sufficiently. -

Page 14: Menu Functions

“OK”. All information about operations and all setting options are accessed from this menu. The operations menu consists of seven menus: 1. 1a. Husqvarna PP-455, 1b Status 2. Settings 3. Time 4. Total machine time 5. - Page 15 Menu functions Operator's Manual RC 455 7. Battery status (only machines equipped with a radio) This function checks the remote control’s battery. CAUTION Different messages are shown on the display, Long electrical cables with a small core cross depending what is currently happening with the section can result in a voltage drop.

-

Page 16: Charge The Battery

Operator's Manual RC 455 Menu functions Charge the battery 8. Radio channel When the remote control is only used in battery mode, a radio antenna must first be connected to the smartbox: NOTE! Remove any cable connection. This chapter only concerns machines equipped with a radio. -

Page 17: Settings

Menu functions Operator's Manual RC 455 Settings 2.2 Change the end point for the blade The end point value should be adjusted so that the All Setting options for the hydraulic unit and the remote blade rotation is as high as possible when the blade control are accessed via this sub-menu. - Page 18 Operator's Manual RC 455 Menu functions 3.1 Change the start point for the trolley motion 3.3 Change the start point for blade motion The start point value should be adjusted so that the The start point value should be adjusted so that the...

- Page 19 Menu functions Operator's Manual RC 455 State the ramp time value: 4.4 Pressure sensor for the hydraulic pressure • Press OK when the part menu is shown. The pressure sensor measures the hydraulic pressure to the blade • The display shows: CHANGE RAMP TIME and the time in seconds.

- Page 20 2. Scroll using the arrow keys and press OK when “Calibrate pressure sensor for hydraulics” is shown. 1. Husqvarna Smartbox version. The display shows the 3. Press OK again when the display shows CALIBRATE version number, for example 2.0, for the software.

-

Page 21: Error Messages

NOTE! LOW VOLTAGE (1A) CHECK THE VOLTAGE is stated 4 times in succession the hydraulic unit is locked. SUPPLY AND THE CABLE TO THE HYDRAULIC A PUK code (provided by husqvarna) must then be stated UNIT to unlock the unit. - Page 22 Operator's Manual RC 455 Menu functions Error message (1B) Cause (3) “Low voltage Phase x low output. 32 A”, where x The motor temperature sensor is too high. represents phase 1, 2 or 3. Action (3) Action (1B) Press OK to acknowledge the error message.

- Page 23 Menu functions Operator's Manual RC 455 Error message (7) “No contact Check the CAN cable” Cause (7) The CAN cable, or its connector is damaged, which results in the hydraulic unit not being possible to control via the remote control.

- Page 24 115 04 31-95 2007-11-13...

- Page 25 TO PURCHASE THIS PRODUCT PLEASE CONTACT US Equipment Financing and Extended Warranties Available Discount-Equipment.com is your online resource for commercial and industrial quality parts and equipment sales. 561-964-4949 visit us on line @ www.discount-equipment.com Select an option below to find your Equipment We sell worldwide for the brands: Genie, Terex, JLG, MultiQuip, Mikasa, Essick, Whiteman, Mayco, Toro Stone, Diamond Products, Generac Magnum, Airman, Haulotte, Barreto, Power Blanket, Nifty Lift, Atlas Copco, Chicago Pneumatic, Allmand, Miller Curber, Skyjack, Lull,...

Need help?

Do you have a question about the RC 455 and is the answer not in the manual?

Questions and answers