Table of Contents

Troubleshooting

Summary of Contents for Magnetek GP1000

- Page 1 Magnetek AC Drive GP1000 Technical Manual To properly use the product, read this manual thoroughly and retain for easy reference, inspection, and maintenance. Ensure the end user receives this manual. MANUAL NO. TMGP1000...

- Page 3 Magnetek must be supplied to the end user with appropriate warnings and instructions as to that part’s safe use and operation. Any warnings provided by Magnetek must be promptly provided to the end user. Magnetek offers an express warranty only as to the quality of its products in conforming to standards and specifications published in the Magnetek manual.

- Page 4 To avoid unnecessary fault displays caused by contactors or output switches placed between Drive and motor, auxil- • iary contacts must be properly integrated into the control logic circuit. Magnetek is not responsible for any modification of the product made by the user; doing so will void the warranty. • This product must not be modified.

- Page 5 Safety Precautions Installation CAUTION • Always lift drive by all four eyebolts. • Attach the Drive to a metal or other noncombustible material. Fire can result if the Drive is attached to a combustible material. • Install a cooling fan or other cooling device when installing more than one Drive in the same enclo- sure so that the temperature of the air entering the Drives is below 45C.

- Page 6 WARNING Risk of electric shock. Read manual before installing. Wait 5 minutes for capacitor discharge after disconnecting power supply. AVERTISSEMENT Risque de decharge electrique. Lire le manuel avant l' installation. Attendre 5 minutes apres la coupure de l' allmentation. Pour permettre la decharge des condensateurs.

- Page 7 Registered Trademarks The following registered trademarks are used in this manual. DeviceNet is a registered trademark of the ODVA (Open DeviceNet Vendors Association, Inc.). • MODBUS is a registered trademark of the MODBUS.org. •...

-

Page 8: Table Of Contents

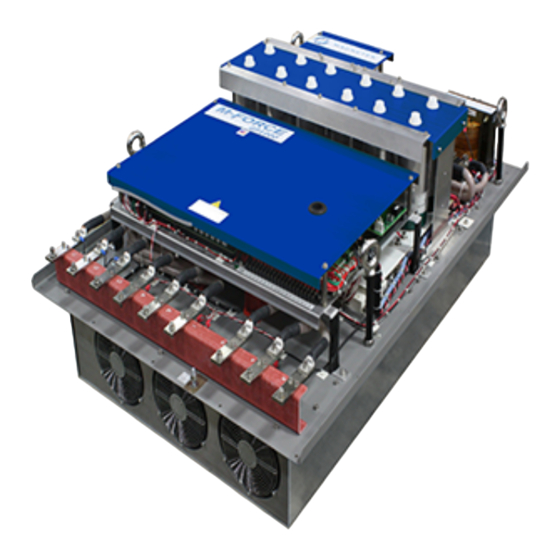

Contents Handling Drives ..............1-1 M-Force GP1000 Introduction ................1-2 M-Force GP1000 Models ..................... 1-2 Confirmations upon Delivery ................1-3 Checks..........................1-3 Nameplate Information ....................1-3 Component Names......................1-5 Exterior and Mounting Dimensions...............1-7 Open Chassis Drives (IP00) ................... 1-7 ... - Page 9 Control Circuit Wiring Precautions ................2-30 Control Circuit Wire Sizes .................... 2-30 Wire Checks ......................... 2-30 Installing and Wiring Option Cards............. 2-31 Option Card Models and Specifications ............... 2-31 Installation ........................2-32 PG Speed Control Card Terminals and Specifications ..........2-33 ...

- Page 10 User Parameters ..............5-1 User Parameter Descriptions ...............5-2 Description of User Parameter Tables ................5-2 Digital Operation Display Functions and Levels ...........5-3 User Parameters Settable in Quick Programming Mode..........5-4 User Parameter Tables................5-10 A: Setup Settings ......................5-10 ...

- Page 11 Speed Limit (Frequency Reference Limit Function) ........6-30 Limiting Maximum Output Frequency................6-30 Limiting Minimum Frequency ..................6-31 Improved Operating Efficiency ..............6-32 Reducing Motor Speed Fluctuation (Slip Compensation Function)......6-32 Compensating for Insufficient Torque at Startup and Low-speed Operation (Torque Compensation)....................

- Page 12 Monitor Parameterss ..................6-79 Using the Analog Monitor Parameters................6-79 Using Pulse Train Monitor Contents ................6-82 Individual Functions..................6-84 Using MODBUS Communications ................6-84 Using the Timer Function....................6-97 Using PID Control ......................6-98 Energy-saving......................6-107 ...

- Page 13 Specifications by Model....................9-2 Common Specifications....................9-4 Specifications of Options and Peripheral Devices........9-5 Appendix ................10-1 M-Force GP1000 Control Modes ..............10-2 Control Modes and Features..................10-2 Control Modes and Applications................... 10-6 Drive Application Precautions ..............10-7 ...

-

Page 14: Handling Drives

Handling Drives This chapter describes the checks required upon receiving or installing an Drive. M-Force GP1000 Introduction ...........1-2 Confirmations upon Delivery........1-3 Exterior and Mounting Dimensions......1-7 Checking and Controlling the Installation Site ...1-10 Installation Orientation and Space ......1-11 Removing and Attaching the Terminal Cover ....1-12 Removing/Attaching the Digital Operator and Front Cover ............1-14... -

Page 16: Confirmations Upon Delivery

Are any screws or other components Use a screwdriver or other tools to check for tightness. loose? If you find any irregularities in the above items, contact the agency from which you purchased the Drive or your Magnetek representative immediately. - Page 17 GP1000 Dimensions Dimensions Model 150/300 HP 45.6 in (1158 mm) 31 in (786 mm) 11.88 in (451 mm) 9.88 in (251 mm) Liquid 150/300 HP 45.6 in (1158 mm) 31 in (786 mm) 17.75 in (451 mm) 9.88 in (251 mm)

-

Page 18: Checking And Controlling The Installation Site

Checking and Controlling the Installation Site Install the Drive in the installation site described below and maintain optimum conditions. Installation Site Install the Drive to a non-combustible surface under the following conditions in UL Pollution Degree 2 envi- ronments. This excludes wet locations where pollution may become conductive due to moisture, and locations containing conductive foreign matter Protective covers are attached to the top and bottom of the Drive. -

Page 19: Wiring

Wiring This chapter describes wiring terminals, main circuit terminal connections, main circuit termi- nal wiring specifications, control circuit terminals, and control circuit wiring specifications. Connection Diagram ............2-2 Terminal Block Configuration ........2-4 Wiring Main Circuit Terminals ........2-5 Wiring Control Circuit Terminals ........2-22 Installing and Wiring Option Cards ......2-31... -

Page 20: Connection Diagram

External Choke Branch circuit protection supplied by customer. MCCB Motor R/L1 U/T1 3-Phase Power Supply S/L2 V/T2 GP1000 50/60Hz W/T3 T/L3 Digital Output 1 Foward Run/Stop Fault Contact Digital Inputs Reverse Run/Stop 250VAC, 30VDC, 1A 24VDC, 8mA External Fault S3 (H1-01) - Page 21 Connection Diagram 1. Control circuit terminals are arranged as shown below. R S IMPORTANT V E(G) E(G) 2. The output current capacity of the +V terminal is 20 mA. 3. Main circuit terminals are indicated with double circles and control circuit terminals are indicated with single circles.

-

Page 22: Wiring Main Circuit Terminals

Wiring Main Circuit Terminals Wiring Main Circuit Terminals Applicable Wire Sizes and Closed-loop Connectors Select the appropriate wires and crimp terminals from Table 2.1. - Page 23 Wiring Main Circuit Terminals Table 2.1 Closed-loop Connector Sizes (JIS C2805) (200-240 V Class and 380-480 V Class) Ring Tongue (R-Type) Closed-Loop Connectors (Lugs) Wire Size * Terminal Screw JST Corporation Part Numbers ** M3.5 1.25 - 3.7 1.25 - 4 M3.5 1.25 - 3.7 0.75...

- Page 24 Ring Tongue (R-Type) Closed-Loop Connectors (Lugs) Wire Size * Terminal Screw JST Corporation Part Numbers ** 100 - 10 100 - 12 100 - 16 150 - 10 250 / 300MCM 125 / 150 150 - 12 150 - 16 400MCM 200 - 12 M12 x 2...

-

Page 25: Wiring The Main Circuits

Wiring the Main Circuits This section describes wiring connections for the main circuit inputs and outputs. Wiring Main Circuit Inputs Observe the following precautions for the main circuit power supply input. Installing a Molded-case Circuit Breaker Always connect the power input terminals (R/L1, S/L2, and T/L3) and power supply via a molded-case circuit breaker (MCCB) suitable for the Drive. - Page 26 Wiring Main Circuit Terminals Installing a Magnetic Contactor If the power supply for the main circuit is to be shut off during a sequence, a magnetic contactor can be used. When a magnetic contactor is installed on the primary side of the main circuit to forcibly stop the Drive, however, the regenerative braking does not work and the Drive will coast to a stop.

- Page 27 Incorrect Noise Filter Installation • Power supply MCCB Drive MCCB General- Other purpose controllers noise filter Power MCCB supply General- Drive purpose noise filter MCCB Other controllers Do not use general-purpose noise filters. General- purpose noise filter can not effectively suppress noise generated from the Drive.

- Page 28 Wiring Main Circuit Terminals Do Not Use an Electromagnetic Switch Never connect an electromagnetic switch (MC) between the Drive and motor and turn it ON or OFF during operation. If the MC is turned ON while the Drive is operating, a large inrush current will be created and the overcurrent protection in the Drive will operate.

- Page 29 Countermeasures Against Radio Interference Radio noise is generated from the Drive as well as from the input and output lines. To reduce radio noise, install noise filters on both input and output sides, and also install the Drive in a totally enclosed steel box. The cable between the Drive and the motor should be as short as possible.

-

Page 30: Wiring Control Circuit Terminals

(1.25) * 1. Use shielded twisted-pair cables to input an external frequency reference. * 2. Magnetek recommends using straight solderless terminals on digital inputs to simplify wiring and improve reliability. * 3. Magnetek recommends using a thin-slot screwdriver with a 3.5 mm blade width. -

Page 31: Control Circuit Terminal Functions

Wiring Control Circuit Terminals Control Circuit Terminal Functions The functions of the control circuit terminals are shown in Table 2.10. Use the appropriate terminals for the correct purposes. Table 2.10 Control Circuit Terminals Signal Name Function Signal Level Type Forward run/stop command Forward run when CLOSED;... - Page 32 Table 2.10 Control Circuit Terminals (Continued) Signal Name Function Signal Level Type +15 V +15 V power supply for analog input +15 V power output (Max. current: 20 or transmitters -15 V -15 V power supply for analog input -15 V power output (Max.

- Page 33 Wiring Control Circuit Terminals Table 2.10 Control Circuit Terminals (Continued) Signal Name Function Signal Level Type Fault output signal (NO contact) Form C MA / MC: Closed during fault condition Dry contacts MB / MC: Open during fault condition Fault output signal capacity: (NC contact) 1 A max.

- Page 34 Table 2.10 Control Circuit Terminals (Continued) Signal Name Function Signal Level Type MODBUS Differential input, communications input PHC isolation For 2-wire RS-485, short R+ and S+ as well as R- and S-. 485/ MODBUS Differential output, communications output PHC isolation Communications shield wire * 1.

- Page 35 Wiring Control Circuit Terminals The functions of DIP switch S1 are shown in the following table. Table 2.11 DIP Switch S1 Name Function Setting RS-485 and RS-422 terminating resis- OFF: No terminating resistance S1-1 ON: Terminating resistance of 110 tance OFF: 0 to 10 V (internal resistance: 20 k) S1-2...

- Page 36 Sinking/Sourcing Mode The multi-function input terminal logic can be switched between sinking mode (0 Vdc common) and sourcing mode (+24 Vdc common) by using the terminals SN, SC, and SP. An external 24 Vdc power supply is also sup- ported, providing more freedom in signal input methods.

-

Page 37: Control Circuit Terminal Connections

Branch circuit protection supplied by others. MCCB Motor R/L1 U/T1 3-Phase Power Supply S/L2 V/T2 50/60Hz GP1000 T/L3 W/T3 Digital Output 1 Foward Run/Stop Fault Contact Digital Inputs Reverse Run/Stop 250VAC, 30VDC, 1A 24VDC, 8mA External Fault S3 (H1-01) Fault Reset... -

Page 38: Control Circuit Wiring Precautions

Control Circuit Wiring Precautions Observe the following precautions when wiring control circuits. Separate control circuit wiring from main circuit wiring (terminals R/L1, S/L2, T/L3, B1, B2, U/T1, V/T2, • W/T3, 2, and 3) and other high-power lines. Separate wiring for control circuit terminals MA, MB, MC, M1, M2, M3, M4, M5, and M6 (contact •... -

Page 39: Installing And Wiring Option Cards

Installing and Wiring Option Cards Installing and Wiring Option Cards Option Card Models and Specifications Up to three Option Cards can be mounted in the Drive. You can mount up one card into each of the three places on the controller card (A, C, and D) shown in Fig 2.18. Table 2.14 lists the type of Option Cards and their specifications. -

Page 40: Installation

Installation Before mounting an Option Board, remove power from the Drive and wait for the CHARGE LED to go out. Remove the Digital Operator, front cover, and option clip. Option Clip can be easily removed by squeezing the protruding portions of the clip and then pulling it out. Then, mount the Option Board(s). The A Option Board uses a mounting spacer to secure the board to the control board. -

Page 41: Pg Speed Control Card Terminals And Specifications

Installing and Wiring Option Cards PG Speed Control Card Terminals and Specifications The terminal specifications for the PG Speed Control Cards are given in the following tables. PG-A2 The terminal specifications for the PG-A2 are given in the following table. Table 2.15 PG-A2 Terminal Specifications Terminal Contents... - Page 42 PG-B2 The terminal specifications for the PG-B2 are given in the following table. Table 2.16 PG-B2 Terminal Specifications Terminal Contents Specifications 12 Vdc (±5%), 200 mA max. Power supply for pulse generator 0 Vdc (GND for power supply) H: +8 to 12 Vdc L: +1 Vdc max.

- Page 43 Installing and Wiring Option Cards PG-X2 The terminal specifications for the PG-X2 are given in the following table. Table 2.18 PG-X2 Terminal Specifications Terminal Contents Specifications 12 Vdc (±5%), 200 mA max.* Power supply for pulse generator 0 Vdc (GND for power supply) 5 Vdc (±5%), 200 mA max.* A-phase + input terminal A-phase - input terminal...

-

Page 44: Wiring

Wiring Wiring examples are provided in the following illustrations for the Control Cards. Wiring the PG-A2 Wiring examples are provided in the following illustrations for the PG-A2. Drive Three-phase, 200-240 Vac (380-480 Vac) R/L1 U/T1 V/T2 V/T2 W/T3 W/T3 PG-A2 +12 Vdc power supply... - Page 45 Installing and Wiring Option Cards PG power supply +12 Vdc Pulse input Short for open- collector input Pulse monitor output Pulse input Fig 2.21 I/O Circuit Configuration of the PG-A2...

- Page 46 Wiring the PG-B2 Wiring examples are provided in the following illustrations for the PG-B2. Three-phase Drive 200-240 Vac (380-480 Vac) Power supply +12 Vdc Power supply 0 Vdc A-phase pulse output (+) A-phase pulse output (-) B-phase pulse output (+) B-phase pulse output (-) A-phase pulse monitor output B-phase pulse monitor output...

- Page 47 Installing and Wiring Option Cards Wiring the PG-D2 Wiring examples are provided in the following illustrations for the PG-D2. Three-phase Drive 200-240 Vac (380-480 Vac) Power supply +12 Vdc Power supply 0 Vdc Power supply +5 Vdc Pulse input + (A/B phase) Pulse input - (A/B phase) Pulse monitor output •...

-

Page 48: Wiring Terminal Blocks

Wiring Terminal Blocks Use no more than 100 meters (328 ft) of wiring for PG (encoder) signal lines, and keep them separate from power lines. Use shielded, twisted-pair wires for pulse inputs and pulse output monitor wires, and connect the shield to the shield connection terminal. -

Page 49: Selecting The Number Of Pg (Encoder) Pulses

Installing and Wiring Option Cards Selecting the Number of PG (Encoder) Pulses The setting for the number of PG pulses depends on the model of PG Speed Control Card being used. Set the correct number for your model. PG-A2/PG-B2 The maximum response frequency is 32,767 Hz. - Page 50 PG-D2/PG-X2 There are 5 Vdc and 12 Vdc PG power supplies. Check the PG power supply specifications before connecting. The maximum response frequency is 300 kHz. Use the following equation to compute the output frequency of the PG (f Motor speed at maximum frequency output (RPM) ...

-

Page 51: Digital Operator And Modes

Digital Operator and Modes This chapter describes Digital Operator displays and functions, and provides an overview of operating modes and switching between modes. Digital Operator............3-2 Modes ................3-5... -

Page 52: Digital Operator

The Digital Operator is used for programming, operating, monitoring, and copying the Drive’s parame- ters. To copy parameters, GP1000 Drives must have the same software version, model, and control method. The various items included on the Digital Operator are described below. -

Page 53: Digital Operator Keys

Digital Operator Digital Operator Keys The names and functions of the Digital Operator Keys are described in Table 3.1. Table 3.1 Key Functions Name Function Switches between operation via the Digital Operator (LOCAL) and LOCAL/REMOTE Key control circuit terminal operation (REMOTE). This Key can be enabled or disabled by setting user parameter o2-01. - Page 54 Drive Mode Indicators The definition of the Drive mode indicators are shown in Table 3.2. Table 3.2 Drive Mode Indicators Indicator Definition Lit when a forward run command is input. Lit when a reverse run command is input. REMOTE SEQ See Table 3.3.

-

Page 55: Modes

Drive Mode Indicators Run Indicator The status of the “RUN” indicator is shown in Table 3.5 when the Drive is in either the “LOCAL” or “REMOTE” mode. Table 3.5 RUN Indicator Indicator Status Condition Drive is running. Blinking Drive is decelerating to a stop. Drive is stopped. -

Page 56: Switching Modes

Switching Modes The mode selection display will appear when the ENTER Key is pressed from a monitor or setting display. Press the Enter Key from the mode selection display to switch between the modes. Press the DATA Key from the mode selection key to monitor data and from a monitor display to access the setting display. -

Page 57: Drive Mode

Drive Mode Indicators Drive Mode Drive mode is the mode in which the Drive can be operated. The following monitor displays are possible in drive mode: The frequency reference, output frequency, output current, and output voltage, as well as fault information and the fault history. - Page 58 Example Operations Key operations in drive mode are shown in the following figure. Display at Startup -DRIVE- Frequency Ref U1- 01=60.00Hz U1-02=60.00Hz U1-03=10.05A MENU Mode Selection Monitor Display Frequency Setting Display DATA ENTER Display DATA ENTER DATA ENTER -DRIVE- -DRIVE- -DRIVE- -DRIVE- Monitor...

-

Page 59: Quick Programming Mode

Drive Mode Indicators Quick Programming Mode In quick programming mode, the parameters required for Drive trial operation can be monitored and set. Parameters can be changed from the setting displays. Use the Increment, Decrement, and Shift/RESET Keys to change the frequency. The user parameter will be written and the monitor display will be returned to when the DATA/ENTER Key is pressed after changing the setting. -

Page 60: Advanced Programming Mode

Advanced Programming Mode In advanced programming mode, all Drive parameters can be monitored and set. Parameters can be changed from the setting displays. Use the Increment, Decrement, and Shift/RESET Keys to change the frequency. The user parameter will be written and the monitor display will be returned to when the DATA Key is pressed after changing the setting. - Page 61 Drive Mode Indicators Setting User Parameters Here, the procedure is shown to change C1-01 (Acceleration Time 1) from 10 s to 20 s. Table 3.8 Setting User Parameters in Advanced Programming Mode Step Digital Operator Display Description -DRIVE- Frequency Ref U1- 01=60.00Hz Power supply turned ON.

- Page 62 External Fault Setting Procedure Examples of the Digital Operator displays that appear when setting an eternal fault for a multi-function contact input in Advanced Programming Mode are shown in the following diagram. Mode Selection Display Monitor Display Setting Display DATA DATA ENTER ENTER...

-

Page 63: Verify Mode

Drive Mode Indicators Verify Mode Verify mode is used to display any parameters that have been changed from their default settings in a programming mode or by autotuning. “None” will be displayed if no settings have been changed. Of the environment mode settings, only A1-02 will be displayed if it has been changed. Other environment modes settings will not be displayed even if they have been changed from their default settings. -

Page 64: Autotuning Mode

When V/f control has been selected, stationary autotuning for only line-to-line resistance can be selected. When the motor cannot be disconnected from the load, perform stationary autotuning. Contact your Magnetek representatives to set motor parameters by calculation. The Drive's autotuning function automatically determines the motor parameters, while a servo system's auto- tuning function determines the size of a load, the drives autotuning functions are fundamentally different. - Page 65 Drive Mode Indicators Mode Selection Display Monitor Display Setting Display DATA ENTER -VERIFY- ** Main Menu ** Modified Consts MENU DATA DATA ENTER -A.TUNE- -A.TUNE- -A.TUNE- ENTER Tuning Mode Sel Tuning Mode Sel ** Main Menu ** 01 = =0 *0* Auto-Tuning Standard Tuning Standard Tuning...

-

Page 66: Trial Operation

Trial Operation This chapter describes the procedures for trial operation of the Drive and provides an example of trial operation. Trial Operation Procedure..........4-2 Trial Operation Procedures..........4-3 Adjustment Suggestions ..........4-17... -

Page 67: Trial Operation Procedure

Trial Operation Procedure Perform trial operation according to the following flowchart. START Installation Wiring Turn ON power. Confirm status. Basic settings (Quick programming mode) Select operating method. Vector (A1-02 = 2, 3, or 4)*5 V/f control? V/f with PG (Default: A1-02 = 0) (A1-02 = 1) Set E1-03. -

Page 68: Trial Operation Procedures

Trial Operation Procedures Trial Operation Procedures The procedure for the trial operate is described in order in this section. Power ON Confirm all of the following items and then turn ON the power supply. Make sure that the motor output terminals (U/T1, V/T2, W/T3) and the motor are connected correctly. •... -

Page 69: Checking The Display Status

Checking the Display Status If the Digital Operator's display at the time the power is connected is normal, it will read as follows: -DRIVE- -DRIVE- Frequency Ref Frequency Ref The frequency reference monitor is dis- Display for normal operation U1- 01= 60.0 0Hz U1-01= 0 0 0.0 0Hz played in the data display section. - Page 70 GP1000 Quick Start Guide ONFIGURE ARDWARE 1. DC Bus Enable a. To configure the drive so the DC Bus charges up when power is applied place a jumper between TB9-1 and TB9-2. b. To configure the drive so the DC Bus charges up on demand place a switch between TB9-1 and TB9-2.

- Page 71 C6-02 Carrier Frequency Sets the carrier frequency to 2 KHz C6-11 Carrier Frequency for Open Loop Not applicable if V/F Vector Control control is selected. D1-01 thru Frequency Reference when using Frequency reference D1-04 multi-function inputs comes from operator. D1-17 Frequency Reference when Jog Frequency reference set Frequency Reference is selected...

- Page 72 E1-11 thru V/F Mid. Output Freq., Mid. Not normally adjusted. Used to set constant E1-13 Output Voltage, and base voltage Leave at default. horsepower area of V/F curve. E2-01 Motor Rated Full Load Amps Set to motor rated Enter motor rated current current.

-

Page 73: Basic Settings

Trial Operation Procedures Basic Settings Switch to the quick programming mode (“QUICK” will be displayed on the LCD screen) and then set the fol- lowing user parameters. Refer to Chapter 3 Digital Operator and Modes for Digital Operator operating proce- dures and to Chapter 5 User Parameters and Chapter 6 Parameter Settings by Function for details on the user parameters. - Page 74 Table 4.2 Parameters that Are Set as Required Setting Factory Parameter Name Description Range Setting Number Select stopping method when stop command is sent. Stopping method 0: Deceleration to stop b1-03 0 to 3 selection 1: Coast to stop 2: DC braking stop 3: Coast to stop with timer Depends on capac-...

- Page 75 Setting the Control Method Any of the following five control methods can be set. Parameter Control Mode Basic Control Main Applications Setting Variable speed control, particularly V/f control A1-02 = 0 Voltage/frequency ratio fixed control control of multiple motors with one Drive and replacing existing drives Applications requiring high-precision Voltage/frequency ratio fixed control...

-

Page 76: Autotuning

Trial Operation Procedures Set the number of rotations per pulse in F1-01 (PG Constant). If there is a reduction gear between the • motor and PG, set the reduction ratio in F1-12 and F1-13 in advanced programming mode. Perform stationary autotuning for the line-to-line resistance only if the motor cable is 50 m or longer for •... - Page 77 Stationary Autotuning for Line-to-Line Resistance Only (T1-01 = 2) Stationary autotuning for line-to-line resistance only can be used in any control method. This is the only auto- tuning possible for V/f control and V/f control with PG modes. Autotuning can be used to prevent control errors when the motor cable is long (50 m or longer) or the cable length has changed since installation or when the motor and Drive have different capacities.

- Page 78 Trial Operation Procedures Precautions for Rotational and Stationary Autotuning Lower the base voltage based on Fig 4.4 to prevent saturation of the Drive’s output voltage when the rated voltage of the motor is higher than the voltage of the power supply to the Drive. Use the following procedure to perform autotuning.

- Page 79 Parameter Settings for Autotuning The following parameters must be set before autotuning. Table 4.3 Parameter Settings before Autotuning Name Data Displays during Autotuning Open- Open- Parameter Setting Factory Display V/f with loop Flux loop Number Range Setting Display Vector Vector Vector Motor 1/2...

- Page 80 Trial Operation Procedures Table 4.3 Parameter Settings before Autotuning(Continued) Name Data Displays during Autotuning Open- Open- Parameter Setting Factory Display V/f with loop Flux loop Number Range Setting Display Vector Vector Vector Number of motor poles 2 to 48 T1-06 Set the number of motor poles.

-

Page 81: Application Settings

Application Settings User parameters are set as required in advanced programming mode (“ADV” will be displayed on the LCD screen). All the parameters that can be set in quick programming mode can also be displayed and set in advanced programming mode. Setting Examples The following are examples of settings for applications. -

Page 82: Loaded Operation

Trial Operation Procedures Loaded Operation Connect the machine to the motor and then start operation as described for no-load operation (i.e., from the Digital Operator or by using control circuit terminal signals). Connecting the Load After confirming that the motor has stopped completely, connect the mechanical system. •... -

Page 83: Check And Recording User Parameters

Check and Recording User Parameters Use verify mode (“VERIFY” will be displayed on the LCD screen) to check user parameters that have been changed for trial operation and record them in a user parameter table. Any user parameters that have been change by autotuning will also be displayed in verify mode. If required, the copy function in parameters o3-01 and o3-02 displayed in advanced programming mode can be used to copy the changed settings from the Drive to a recording area in the Digital Operator. -

Page 84: Adjustment Suggestions

Adjustment Suggestions Adjustment Suggestions If hunting, vibration, or other problems originating in the control system occur during trial operation, adjust the parameters listed in the following table according to the control method. This table lists only the most commonly used user parameters. Table 4.4 Adjusted User Parameters Control Name... - Page 85 Table 4.4 Adjusted User Parameters (Continued) Control Name Factory Recommended Performance Adjustment Method Method (Parameter Number) Setting Setting • Increasing torque • Reduce the setting if Speed feedback and speed response torque or speed response is detection control • Controlling hunting slow.

- Page 86 Adjustment Suggestions Table 4.4 Adjusted User Parameters (Continued) Control Name Factory Recommended Performance Adjustment Method Method (Parameter Number) Setting Setting • Increase the setting if ASR proportional • Torque and speed torque or speed response is gain 1 (C5-01) and response slow.

- Page 87 Table 4.4 Adjusted User Parameters (Continued) Control Name Factory Recommended Performance Adjustment Method Method (Parameter Number) Setting Setting • Increase the setting if ASR proportional • Torque and speed torque or speed response is gain 1 (C5-01) and response slow. 10.00 10.00 to 50.00 ASR proportional...

- Page 88 Adjustment Suggestions Table 4.5 Parameters Indirectly Affecting Control and Applications Name (Parameter Number) Application Dwell function (b6-01 to b6-04) Used for heavy loads or large machine backlashes. Used to soften the torque or to balance the load between two motors. Can Droop function (b7-01 to b7-02) be used when the control mode (A1-02) is set to 3 or 4.

-

Page 89: User Parameters

User Parameters This chapter describes all user parameters that can be set in the Drive. User Parameter Descriptions........5-2 Digital Operator Display Functions and Levels....5-3 User Parameter Tables ..........5-10... -

Page 90: User Parameter Descriptions

User Parameter Descriptions This section describes the contents of the user parameter tables. Description of User Parameter Tables User parameter tables are structured as shown below. Here, b1-01 (Frequency Reference Selection) is used as an example. Name Control Methods Change Open Open... -

Page 91: User Parameters Settable In Quick Programming Mode

User Parameters Settable in Quick Programming Mode The minimum user parameters required for Drive operation can be monitored and set in quick programming mode. The user parameters displayed in quick programming mode are listed in the following table. These, and all other user parameters, are also displayed in advanced programming mode. - Page 92 Digital Operator Display Functions and Levels Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during -loop Flux Loop Number Range Setting Register Display with Operation Vector Vector Vector Carrier Selects the number of pulses per Frequency second of the output voltage Selection waveform.

- Page 93 Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during -loop Flux Loop Number Range Setting Register Display with Operation Vector Vector Vector Input Set to the nominal voltage of the Voltage incoming line. Sets the maximum and Setting base voltage used by preset V/F patterns (E1-03 = 0 to E), adjusts the...

- Page 94 Digital Operator Display Functions and Levels Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during -loop Flux Loop Number Range Setting Register Display with Operation Vector Vector Vector Max. Output 40.0 Frequency 60.0Hz E1-04 303H (FMAX) 400.0 Frequency Max.

- Page 95 Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during -loop Flux Loop Number Range Setting Register Display with Operation Vector Vector Vector Terminal Sets terminal FM output level when FM Gain selected monitor is at 100%.In order to Setting adjust the meter, 100% of the appropriate output is multiplied for the...

- Page 96 Digital Operator Display Functions and Levels Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during -loop Flux Loop Number Range Setting Register Display with Operation Vector Vector Vector Stall When using a braking resistor, use Prevention setting "0". Setting "3" is used in Selection specific applications.

-

Page 97: User Parameter Tables

User Parameter Tables A: Setup Settings The following settings are made with the environment parameters (A parameters): Language displayed on the Digital Operator, access level, control method, initialization of parameters. Initialize Mode: A1 User parameters for the environment modes are shown in the following table. Name Control Methods Change... - Page 98 User Parameter Tables Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display with Operation Vector Vector Vector Initialize Used to return all parameters Parameters to their factory or user default settings.

-

Page 99: Application Parameters: B

Application Parameters: b The following settings are made with the application parameters (B parameters): Operation method selection, DC injection braking, speed searching, timer functions, dwell functions, and energy saving functions. Operation Mode Selections: b1 User parameters for operation mode selection are shown in the following table. Name Control Methods Change... - Page 100 User Parameter Tables Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display with Operation Vector Vector Vector Minimum Used to set the method of Output operation when the Frequency frequency reference input is (E1-09) or less than the minimum output...

- Page 101 DC Injection Braking: b2 User parameters for injection braking are shown in the following table. Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Display Range Setting Register with Operation Vector Vector Vector DC Injection Sets the frequency at which Braking Start...

- Page 102 User Parameter Tables Speed Search: b3 User parameters for the speed search are shown in the following table. Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display with Operation Vector Vector Vector...

- Page 103 Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display with Operation Vector Vector Vector Speed Sarch Delays the speed search Delay Time operation after a momentary b3-05 power loss to allow time for an 0.2 s 195H Search...

- Page 104 User Parameter Tables Timer Function: b4 User parameters for timer functions are shown in the following table. Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display with Operation Vector Vector Vector Timer...

- Page 105 Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display with Operation Vector Vector Vector PID Output Sets the maximum output Limit possible from the entire PID b5-06 100.0% 1AAH controller.

- Page 106 User Parameter Tables Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display with Operation Vector Vector Vector Feedback Loss Sets the PID feedback loss Detection detection level as a b5-13 1B1H Level...

- Page 107 Dwell Functions: b6 User parameters for dwell functions are shown in the following table. Name Control Methods Fac- Change Open Open Parameter Setting MODBUS Description tory during Loop Flux Loop Number Range Register Display with Setting Operation Vector V ector Vector Dwell Reference...

- Page 108 User Parameter Tables Energy Saving: b8 User parameters for energy-saving control functions are shown in the following table. Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display with Operation Vector Vector Vector...

- Page 109 Acceleration Parameters: C The following settings are made with the acceleration parameters (C parameters): Acceleration/ deceleration times, s-curve characteristics, slip compensation, torque compensation, speed control, and carrier frequency functions. Acceleration/Deceleration: C1 User parameters for acceleration and deceleration times are shown in the following table. Name Control Methods Change...

- Page 110 User Parameter Tables Name Control Methods Change Parameter Setting Factory Open Open MODBUS Description during V/f with Loop Flux Loop Number Range Setting Register Display Operation Vector Vec-tor Vector Accel/decel Sets the frequency for Switch automatic switching of Frequency accel / decel times. Fout <...

- Page 111 Motor Slip Compensation: C3 User parameters for slip compensation are shown in the following table. Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display with Operation Vector Vector Vector Slip This parameter is used to Compensation...

- Page 112 User Parameter Tables Torque Compensation: C4 User parameters for are torque compensation shown in the following table. Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display with Operation Vector Vector Vector Torque...

- Page 113 Speed Control (ASR): C5 User parameters for speed control are shown in the following table. Name Control Methods Change Parameter Open Open Setting Factory MODBUS Description during Loop Flux Loop Number Display Range Setting Register with Operation Vector Vector Vector 0.00 Proportional 20.00...

- Page 114 User Parameter Tables Carrier Frequency: C6 User parameters for the carrier frequency are shown in the following table. Name Control Methods Fac- Change Parameter Open Open Setting MODBUS Description Flux tory during Loop Loop Number Display Range Register with Vec- Setting Operation Vector...

-

Page 115: Reference Parameters: D

Reference Parameters: d The following settings are made with the reference parameters (d parameters): Frequency references. Preset Reference: d1 User parameters for frequency references are shown in the following table. Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during... - Page 116 User Parameter Tables Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display with Operation Vector Vector Vector Frequency Frequency reference when Reference 10 multi-function input d1-10 "Multi-step speed reference 1, 4" 0.00Hz 28BH is ON.

- Page 117 Reference Limits: d2 User parameters for frequency reference limits are shown in the following table. Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display with Operation Vector Vector Vector Frequency Determines maximum Reference...

- Page 118 User Parameter Tables Reference Frequency Hold: d4 User parameters for the reference frequency hold function are shown in the following table. Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display with Operation...

- Page 119 Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display with Operation Vector Vector Vector Speed Limit Sets the speed limit Selection command method for the torque control method. 1: Analog Input - Limited by the output of the soft starter (b1-01 selection d5-03...

- Page 120 User Parameter Tables Field Control: d6 User parameters for the field weakening command are shown in the following table. Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display with Operation Vector Vector...

-

Page 121: Motor Setup Parameters: E

Motor Setup Parameters: E The following settings are made with the motor setup parameters (E parameters): V/f characteristics and motor setup parameters. V/f Pattern: E1 User parameters for V/f characteristics are shown in the following table. Name Control Methods Change Open Open... - Page 122 User Parameter Tables Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Display Range Setting Register with Operation Vector Vector Vector Maximum Output 40.0 Frequency 60.0Hz E1-04 303H 400.0 Frequency Maximum Output 255.0 Voltage (240V) 230.0V...

- Page 123 Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Display Range Setting Register with Operation Vector Vector Vector Base Set only when the V/F pattern is Voltage finely adjusted in the constant 255.0 power (HP) area above base speed.

- Page 124 User Parameter Tables Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display with Operation Vector Vector Vector Motor Sets the motor mechanical Mechanical loss as a percentage of motor Loss rated power (kW) capacity.

- Page 125 Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Display Range Setting Register with Operation Vector Vector Vector Motor 2 Maximum 40.0 Output Frequency E3-02 60.0Hz 31AH 400.0 (FMAX) Frequency Motor 2 Maximum 255.0 Output Volt- 230.0V...

- Page 126 User Parameter Tables Motor 2 Setup: E4 User parameters for motor 2 are shown in the following table. Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display with Operation Vector Vector Vector...

- Page 127 Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display with Operation Vector Vector Vector 0.00 Proportional 20.00 Gain - Motor 2 Sets the proportional gain for E4-09 33FH the speed control loop (ASR.) 300.00 ASR P Gain Mtr2...

-

Page 128: Option Parameters: F

User Parameter Tables Option Parameters: F The following settings are made with the option parameters (F parameters): Settings for Option Cards. PG Option Setup: F1 User parameters for the PG Speed Control Card are shown in the following table. Name Control Methods Change... - Page 129 Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display with Operation Vector Vector Vector PG Rotation 0: Fwd=C.C.W. - Phase A Selection leads with forward run command. (Phase B leads with reverse run command.) F1-05 0 or 1...

- Page 130 User Parameter Tables Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display with Operation Vector Vector Vector Excessive Configures the speed Speed deviation fault (DEV) Deviation detection. Detection F1-10 0 to 50 389H DEV fault will occur if the...

- Page 131 Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display with Operation Vector Vector Vector PG Gear Teeth Sets the number of gear teeth Count 1 F1-23 3B2H (deceleration ratio) between PG Gear 1000 Motor-2 and the pulse generator.

- Page 132 User Parameter Tables Digital Reference Card: F3 User parameters for the Digital Reference Card are shown in the following table. Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display with Operation Vector...

- Page 133 Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display with Operation Vector Vector Vector AO-08/ Sets the channel 2 gain. AO-12 In order to adjust the Channel 2 meter, 100% of the Gain appropriate output is multiplied for the gain...

- Page 134 User Parameter Tables Digital Output Card (DO-02 and DO-08): F5 User parameters for the Digital Output Card are shown in the following table. Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display...

- Page 135 Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display with Operation Vector Vector Vector DO-08 Sets the digital output Channel 8 function number for channel 8. Output See the H2 parameter group F5-08 0 to 37 3A0H...

- Page 136 User Parameter Tables Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display with Operation Vector Vector Vector Trace Sampling from Sets the sample trace for the Communication F6-04 3A5H CP-916 option board.

-

Page 137: Terminal Function Parameters: H

Terminal Function Parameters: H The following settings are made with the terminal function parameters (H parameters): Settings for external terminal functions. Multi-function Contact Inputs: H1 User parameters for multi-function contact inputs are shown in the following tables. Name Control Methods Change Open Open... - Page 138 User Parameter Tables Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display with Operation Vector Vector Vector Multi- Function Digital Input Terminal S9 H1-07 Multi-Function Relay Input 7 0 to 79 406H Function Selection...

- Page 139 Control Methods Setting Open Open Function Loop Flux Loop Value with Vector Vector Vector Multi-function analog input selection (ON: Enable) No V/f control with PG (ON: Speed feedback control disabled,) (normal V/f control) Speed control integral reset (ON: Integral control disabled) Not used (Set when a terminal is not used) Up command (Always set with the down command) Down command (Always set with the up command)

- Page 140 User Parameter Tables Control Methods Setting Open Open Function Loop Flux Loop Value with Vector Vector Vector Speed/torque control change (ON: Torque control) Zero-servo command (ON: Zero-servo) Speed control (ASR) proportional gain switch (ON: C5-03) Polarity reversing command for external torque reference Closed Brake Signal* Closed = Reverse polarity.

- Page 141 Multi-function Contact Output Functions Control Methods Setting Open Open Function Loop Flux Loop Value with Vector Vector Vector During run (ON: run command is ON or voltage is being output) Zero-speed Frequency agree 1 (L4-02 used.) Desired frequency agree 1 (ON: Output frequency = ±L4-01, L4-02 used and during frequency agree) Frequency (FOUT) detection 1 (ON: +L4-01 ...

- Page 142 User Parameter Tables Control Methods Setting Open Open Function Loop Flux Loop Value with Vector Vector Vector Motor overload (OL1, including OH3) pre-alarm (ON: 90% or more of the detection level) Drive overheat (OH) pre-alarm (ON: Temperature exceeds L8-02 setting) During torque limit (current limit) (ON: During torque limit) During speed limit (ON: During speed limit) Speed control circuit operating for torque control (except when stopped).

- Page 143 Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display with Operation Vector Vector Vector Terminal A3 Gain Setting Sets the output level when H3-06 100.0% 415H 10V is input. Terminal A3 1000.0 Gain...

- Page 144 User Parameter Tables H3-05,H3-09 Settings Control Methods Setting Open Open Function Contents (100%) Loop Flux Loop Value with Vector Vector Vector Frequency Bias 100% = Maximum output frequency (E1-04) Frequency Reference Gain 100% = Frequency reference command value A1 (FGAIN) Total gain = Internal gain (H3-02) x FGAIN Used in conjunction with multi-function inputs Aux Frequency Reference 1...

- Page 145 Multi-function Analog Outputs: H4 User parameters for multi-function analog outputs are shown in the following table. Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display with Operation Vector Vector Vector Terminal Selects the monitor output...

- Page 146 User Parameter Tables MODBUS Communications: H5 User parameters for MODBUS communications are shown in the following table. Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display with Operation Vector Vector Vector Drive Node...

- Page 147 Pulse Train I/O: H6 User parameters for pulse I/O are shown in the following table. Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display with Operation Vector Vector Vector Terminal RP Pulse Selects the function of pulse...

-

Page 148: Protection Function Parameters: L

User Parameter Tables Protection Function Parameters: L The following settings are made with the protection function parameters (L parameters): Motor selection function, power loss ridethrough function, stall prevention function, frequency detection, torque limits, and hardware protection. Motor Overload: L1 User parameters for motor overloads are shown in the following table. - Page 149 Power Loss Ridethrough: L2 User parameters for power loss ridethroughs are shown in the following table. Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display with Operation Vector Vector Vector Momentary Enables and disables the...

- Page 150 User Parameter Tables Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display with Operation Vector Vector Vector Sets the time required to Deceleration decelerate to zero speed when a Rate L2-06 0.0sec...

- Page 151 Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display with Operation Vector Vector Vector Stall This function is enabled when Prevention L3-01 is "1" or "2". Level Drive rated current is 100%. During L3-02 150%...

- Page 152 User Parameter Tables Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display with Operation Vector Vector Vector Stall Selects the stall prevention Prevention method to use to prevent Drive Selection faults during run.

- Page 153 Reference Detection: L4 User parameters for the reference detection function are shown in the following table. Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display with Operation Vector Vector Vector Speed These parameters configure the...

- Page 154 User Parameter Tables Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display with Operation Vector Vector Vector Frequency If the frequency reference loss Reference function is enabled (L4-05=1) and frequency reference is lost, Reference the Drive will run at a reduced L4-06...

- Page 155 Torque Detection: L6 User parameters for the torque detection function are shown in the following table. Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display with Operation Vector Vector Vector Torque Determines the Drive's...

- Page 156 User Parameter Tables Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display with Operation Vector Vector Vector Torque Sets the Overtorque/ Detection Undertorque detection level as Level 1 a percentage of Drive rated L6-02 current or torque for Torque 150%...

- Page 157 Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display with Operation Vector Vector Vector Torque Determines the Drive's Detection response to an Overtorque/ Selection 2 Undertorque condition. Overtorque and Undertorque are determined by the settings in parameters L6-05 and L6-06.

- Page 158 User Parameter Tables Torque Limits: L7 User parameters for torque limits are shown in the following table. Control Methods Change Open Open Parameter Setting Factory MODBUS Name Description during Loop Flux Loop Number Range Setting Register with Operation Vector Vector Vector Forward Torque...

- Page 159 Vector Vector Vector Internal Selects the DB protection Dynamic only when using 3% duty Braking cycle heatsink mount Magnetek braking Resistor L8-01 Protection resistor. This parameter 0 to 1 4ADH Selection does not enable or disable the DB function of the DB Resistor Drive.

- Page 160 User Parameter Tables Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display with Operation Vector Vector Vector Heatsink Controls the heatsink Cooling Fan cooling fan operation. Operation 0: Fan On-Run Mode - Fan Selection will operate only when the Drive is running and for...

-

Page 161: N: Special Adjustments

n: Special Adjustments The following settings are made with the special adjustments parameters (n parameters): Hunting prevention and speed feedback detection control. Hunting Prevention Function: n1 User parameters for hunting prevention are shown in the following table. Name Control Methods Change Open Open... - Page 162 User Parameter Tables Speed Feedback Protection Control Functions: n2 User parameters for speed feedback protection control functions are shown in the following table. Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display...

- Page 163 Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display with Operation Vector Vector Vector High Slip Sets the amount of time the Braking Drive will dwell at E1-09 Dwell Time (Minimum Frequency) at the at Stop end of deceleration.

- Page 164 User Parameter Tables Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display with Operation Vector Vector Vector Torque Adjustment Sets the torque adjustment Gain n4-17 5A4H gain for low-speed power. TRQ adjust gain Gain for...

- Page 165 Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display with Operation Vector Vector Vector U1-48 Gain Setting this parameter to a Reduction low value can improve Coefficient operation when acceleration 0.50 during low speeds or n4-35...

- Page 166 User Parameter Tables Feed Forward: n5 User parameters for the feed forward control are shown in the following table. Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display with Operation Vector Vector...

-

Page 167: Digital Operator Parameters: O

Digital Operator Parameters: o The following settings are made with the Digital Operator parameters (o parameters): Multi-function selections and the copy function.Monitor Select: o1 User parameters for Digital Operator Displays are shown in the following table. Name Control Methods Change Open Open... - Page 168 User Parameter Tables Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display with Operation Vector Vector Vector Setting unit Sets the setting units related for frequency to V/F pattern frequency parameters related parameters related to V/F...

- Page 169 Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display with Operation Vector Vector Vector Drive/kVA Sets the kVA of the Drive. Selection Enter the number based on Drive model number. Use the last four digits of the model number.

- Page 170 User Parameter Tables Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display with Operation Vector Vector Vector Fault Trace/ Clears the fault memory Fault History contained in the U2 and U3 Clear monitors.

-

Page 171: T: Motor Autotuning

T: Motor Autotuning The following settings are made with the motor autotuning parameters (T parameters): Settings for autotuning. Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display with Operation Vector Vector... - Page 172 User Parameter Tables Name Control Methods Change Open Open Parameter Setting Factory MODBUS Description during Loop Flux Loop Number Range Setting Register Display with Operation Vector Vector Vector Motor Base Sets the base speed of the 1750 Speed T1-07 motor in revolutions per 707H 1 minute (RPM).

-

Page 173: U: Monitor Parameters

U: Monitor Parameters The following settings are made with the monitor parameters (U parameters): Setting parameters for monitoring in drive mode. Status Monitor Parameters: U1 The parameters used for monitoring status are listed in the following table. Name Control Methods Output Signal Level Min. - Page 174 User Parameter Tables Name Control Methods Output Signal Level Min. Open Open Parameter MODBUS Description During Multi-Function Loop Flux Loop Number Unit Register Display with Analog Output Vector Vector Vector Torque Reference 10V: Motor Rated Torque U1-09 Torque reference 0.1% (possible for -10V thru +10V) Torque Reference...

- Page 175 Name Control Methods Output Signal Level Open Open Parameter Min. MODBUS Description During Multi-Function Loop Flux Loop Number Unit Register Display with Analog Output Vector Vector Vector Cumulative Operation Total operating or power-on Time U1-13 No output possible. time of the Drive. Elapsed Time Software...

- Page 176 User Parameter Tables Name Control Methods Output Signal Level Open Open Parameter Min. MODBUS Description During Multi-Function Loop Flux Loop Number Unit Register Display with Analog Output Vector Vector Vector Feedback Feedback signal level when 10V: Maximum Frequency Value U1-24 PID control is used.

- Page 177 Name Control Methods Output Signal Level Open Open Parameter Min. MODBUS Description During Multi-Function Loop Flux Loop Number Unit Register Display with Analog Output Vector Vector Vector First Parameter Causing an Parameter number causing an U1-34 "OPE" fault. No output possible. Detected Zero Servo Pulse Count Number of PG pulses times 4...

- Page 178 User Parameter Tables Name Control Methods Output Signal Level Open Open Parameter Min. MODBUS Description During Multi-Function Loop Flux Loop Number Unit Register Display with Analog Output Vector Vector Vector Output Output from the speed control without loop (ASR) before the ASR 10V: Motor Rated Secondary Filter U1-44...

- Page 179 Fault Trace: U2 User parameters for error tracing are shown in the following table Name Control Methods Output Signal Level During Open Open Parameter Min. MODBUS Description Loop Flux Loop Multi-Function Number Display Unit Register with Vector Vector Vector Analog Output Current Fault U2-01...

- Page 180 User Parameter Tables Name Control Methods Output Signal Level During Open Open Parameter Min. MODBUS Description Loop Flux Loop Number Multi-Function Unit Register Display with Vector Vector Vector Analog Output Torque Reference at Previous Gives the torque reference at the U2-10 0.1% Fault...

- Page 181 Fault History: U3 User parameters for the error log are shown in the following table. Name Control Methods Output Signal Level Open Open Parameter Min. MODBUS Description During Multi-Function Loop Flux Loop Number Unit Register Display with Analog Output Vector Vector Vector Most Recent...

- Page 182 User Parameter Tables Name Control Methods Output Signal Level Open Open Parameter Min. MODBUS Description During Multi-Function Loop Flux Loop Number Unit Register Display with Analog Output Vector Vector Vector 7th Most Shows the seventh most Recent Fault U3-11 806H recent fault.

-

Page 183: Factory Settings That Change With The Control Method (A1-02)

Factory Settings that Change with the Control Method (A1-02) The factory settings of the following user parameters will change if the control method (A1-02) is changed. Name Factory Setting Open Open Parameter Setting Range Unit V/f with Loop Flux Loop Number Display... - Page 184 User Parameter Tables Name Factory Setting Open Open Parameter Setting Range Unit V/f with Loop Flux Loop Number Display Control Vector Vector Vector Mid Output Frequency A E1-07 0.0 to 400.0 0.1Hz E3-05 Mid Frequency A Mid Output Voltage A E1-08 0.0 to 255.0 15.0...

- Page 185 208-240Vac and 380-480Vac Drives of 0.4 to 1.5 kW Table 5.1 V/F Pattern for Drive Capacities G7U20P4 - 21P5 for 208-240V Class Parameter Name Unit Factory Setting E1-03 V/F Pattern Selection — Max. Output E1-04 50.0 60.0 60.0 72.0 50.0 50.0 60.0 60.0...

- Page 186 User Parameter Tables 208-240Vac and 380-480Vac Drives of 2.2 to 45 kW Table 5.4 V/F Pattern for Drive Capacity G7U22P2 - 2045 for 208-240V Class Parameter Name Unit Factory Setting E1-03 V/F Pattern Selection — E1-04 Max. Output Frequency 50.0 60.0 60.0 72.0...

- Page 187 208-240Vac Drives of 55 to 110 kW and 380-480Vac Drives of 55 to 300 kW Table 5.5 V/F Pattern for Drive Capacity G7U2055 and higher for 208-240V Class Parameter Name Unit Factory Setting V/F Pattern E1-03 – Selection Max. Output E1-04 50.0 60.0...

- Page 188 User Parameter Tables Table 5.6 lists the factory settings of V/F patterns when open loop vector or flux vector control method is selected (A1-02 = 2 or 3). Table 5.6 V/F Pattern for 208-240V Class Drives Factory Setting Parameter No. Name Unit Open Loop Vector...

-

Page 189: Factory Settings That Change With The Drive Capacity (O2-04)

Factory Settings that Change with the Drive Capacity (o2-04) The factory settings of the following user parameters will change if the Drive capacity (o2-04) is changed. 208-240Vac Drives Parameter Name Unit Factory Setting Number Drive Capacity 0.75 o2-04 kVA selection Energy Saving Control b8-03 0.50 (Open-loop vector control) - Page 190 User Parameter Tables Parameter Name Unit Factory Setting Number Drive Capacity 18.5 o2-04 kVA selection Energy Saving Control b8-03 0.50 (Open-loop vector control) 2.00 (Open-loop vector control) Filter Time Constant Energy Saving Coefficient b8-04 57.87 51.79 46.27 38.16 35.78 31.35 23.10 20.65 18.12...

- Page 191 380-480Vac Drives Parameter Name Unit Factory Setting Number Drive Capacity 0.75 o2-04 kVA selection Energy Saving Control b8-03 0.50 (Open-loop vector control) Filter Time Constant Energy Saving b8-04 576.40 447.40 338.80 313.60 245.80 236.44 189.50 145.38 140.88 126.26 Coefficient Value Carrier Frequency C6-02 Selection...

- Page 192 User Parameter Tables Parameter Name Unit Factory Setting Number Drive Capacity 18.5 o2-04 kVA selection Energy Saving Control b8-03 0.50 (Open-loop vector control) Filter Time Constant Energy Saving Coefficient b8-04 115.74 103.58 92.54 76.32 71.56 Value Carrier Frequency Selection C6-02 Carrier Frequency Selection C6-11 for Open Loop Vector 2...

- Page 193 Parameter Name Unit Factory Setting Number Drive Capacity o2-04 kVA selection Energy Saving Control b8-03 2.00 (Open-loop vector control) Filter Time Constant Energy Saving Coefficient b8-04 67.20 46.20 38.91 36.23 32.79 30.13 Value Carrier Frequency Selection C6-02 Carrier Frequency Selection C6-11 for Open Loop Vector 2 Carrier frequency selection...

-

Page 194: Parameter Settings By Function

Parameter Settings by Function Frequency Reference ..........6-2 Run Command.............6-7 Stopping Methods ............6-9 Acceleration and Deceleration Characteristics ..6-15 Adjusting Frequency References.......6-24 Speed Limit (Frequency Reference Limit Function)..6-30 Improved Operating Efficiency........6-32 Machine Protection ............6-39 Continuing Operation..........6-57 Drive Protection ............6-67 Input Terminal Functions..........6-69 Monitor Parameters ...........6-79 Individual Functions ...........6-84 Digital Operator Functions ........6-139... -

Page 195: Frequency Reference

Frequency Reference This section explains how to input the frequency reference. Selecting the Frequency Reference Source Set parameter b1-01 to select the frequency reference source. Related Parameters Name Control Methods Change Open Open Parameter Setting Factory Description during loop Flux Loop Number... - Page 196 Frequency Reference Inputting the Frequency Reference Using Voltage (Analog Setting) When b1-01 is set to 1, you can input the frequency reference from control circuit terminal A1 (voltage input), or control circuit terminal A2 (voltage or current input). Inputting Master Speed Frequency Reference Only When inputting a voltage for the master speed frequency reference, input the voltage to control circuit termi- nal A1.

- Page 197 Switch between 2 Step Speeds: Master/Auxiliary Speeds When switching between the master and auxiliary speeds, connect the master speed frequency reference to control circuit terminal A1 or A2 and connect the auxiliary speed frequency reference to terminal A3. The ref- erence on terminal A1 or A2 will be used for the Drive frequency reference when the multi-function input allocated to multi-speed command 1 is OFF and the reference on terminal A3 will be used when it is ON.

-

Page 198: Using Multi-Step Speed Operation

Using Multi-Step Speed Operation With M-Force GP1000 series Drives, you can change the speed to a maximum of 17 steps, using 16 frequency ref-erences, and one jog frequency reference. The following example of a multi-function input terminal function shows a 9-step operation using multi-step references 1 to 3 and jog frequency selection functions. - Page 199 Setting Precautions When setting analog inputs to step 1 to step 3, observe the following precautions. When setting terminal A1's analog input to step 1, set b1-01 to 1, and when setting d1-01 (Frequency Ref- • erence 1) to step 1, set b1-01 to 0. When setting terminal A2's analog input to step 2, set H3-09 to 2 (auxiliary frequency reference).

-

Page 200: Run Command

Run Command Run Command This section explains input methods for the run command. Selecting the Run Command Source Set parameter b1-02 to select the source for the run command. Related Parameters Name Control Methods Change Open- Open Parameter Setting Factory Description during... - Page 201 Performing Operations Using a 3-wire Sequence When any parameter from H1-01 to H1-10 (multi-function contact input terminals S3 to S12) is set to 0, ter- minals S1 and S2 are used for a 3-wire sequence, and the multi-function input terminal that has been set func- tions as a forward/reverse run command terminal.

-

Page 202: Stopping Methods

Stopping Methods Stopping Methods This section explains methods of stopping the Drive. Selecting the Stopping Method when a Stop Command is Sent There are four methods of stopping the Drive when a stop command is sent: Deceleration to stop •... - Page 203 Name Control Methods Change Open- Open Parameter Setting Factory Description during Loop Flux Loop Number Range Setting Display with Operation Vector Vector Vector Sets the DC injection braking current as a Injection percentage of the Drive rated current. Braking Note: The DC excitation current is b2-02 Current determined by the setting in E2-03 when...

- Page 204 Stopping Methods The operation after stopping depends on the setting of b1-05 when flux vector control is selected (A1-02 = 3). Run command OFF Frequency reference E1-09 via analog input Run command turns OFF and zero speed control start when motor speed drops to b2-01. b1-05=0 (frequency reference) Zero speed...

- Page 205 DC Braking Stop If the stop command is input (i.e., the run command is turned OFF) when b1-03 is set to 2, a wait is made for the time set in L2-03 (Minimum Baseblock (BB) Time) and then the DC injection brake current set in b2-02 is sent to the motor to apply a DC injection brake to stop the motor.

-

Page 206: Using The Dc Injection Brake

Stopping Methods Using the DC Injection Brake Set parameter b2-03 to apply the DC injection brake voltage to the motor while it is coasting to a stop, to stop the motor and then restart it. Set b2-03 to 0 to disable the DC injection brake at start. Set the DC injection brake current using b2-02. -

Page 207: Using An Emergency Stop

Changing the DC Injection Brake Current Using an Analog Input If you set H3-09 (Multi-function Analog Input Terminal A2 Function Selection) or H3-05 (Multi-function Analog Input Terminal A3 Function Selection) to 6 (DC injection brake current), you can change the DC injection brake current level using the analog input. -

Page 208: Acceleration And Deceleration Characteristics

Acceleration and Deceleration Characteristics Acceleration and Deceleration Characteristics This section explains the acceleration and deceleration characteristics of the Drive. Setting Acceleration and Deceleration Times Acceleration time indicates the time taken for the output frequency to climb from 0% to 100%. Deceleration time indicates the time taken for the output frequency to reduce to 0%. - Page 209 Name Control Methods Change Open Open Parameter Setting Factory Description during Loop Flux Loop Number Range Setting Display with Operation Vector Vector Vector Accel/Decel Sets the frequency for automatic Switch switching of accel / decel times. Frequency Fout < C1-11: Accel/Decel Time 4 Fout ...

- Page 210 Acceleration and Deceleration Characteristics Switching Acceleration and Deceleration Time Using Multi-Function Input Terminal Commands Using the Drive, you can set four acceleration times and four deceleration times. When the multi-function input terminals (H1-) are set to 7 (acceleration/deceleration time selection 1) and 1A (acceleration/decel- eration time selection 2), you can switch the acceleration/deceleration time even during operation by combin- ing the ON/OFF status of the terminals.

- Page 211 Acceleration/deceleration time gain (set value: 5) (Acceleration/deceleration gain from 1 to 10 V) = 10 V/Input voltage (V) x 10 (%) Fig 6.19 Acceleration/Deceleration Time Gain Using an Analog Input Entering S-curve Characteristics in the Acceleration and Deceleration Time By performing acceleration and deceleration using an S-curve pattern, you can reduce shock when starting and stopping the machine.

-

Page 212: Accelerating And Decelerating Heavy Loads (Dwell Function)

Acceleration and Deceleration Characteristics Accelerating and Decelerating Heavy Loads (Dwell Function) The dwell function stores the output frequency when starting or stopping heavy loads. By temporarily storing the output frequency, you can prevent the motor from stalling. When using the dwell function, you must select a deceleration stop. -

Page 213: Preventing The Motor From Stalling During Acceleration (Stall Prevention During Acceleration Function)

Preventing the Motor from Stalling During Acceleration (Stall Prevention During Acceleration Function) The Stall Prevention During Acceleration function prevents the motor from stalling if a heavy load is placed on the motor, or sudden rapid acceleration is performed. If you set L3-01 to 1 (enabled) and the Drive output current exceeds the -15% level of the set value in L3-02, the acceleration rate will begin to slow down. - Page 214 Acceleration and Deceleration Characteristics Time Chart The following figure shows the frequency characteristics when L3-01 is set to 1. Output current Stall level during acceleration Time Output frequency Output frequency is controlled to prevent the motor stalling. Time Fig 6.21 Time Chart for Stall Prevention During Acceleration Setting Precautions If the motor capacity is small compared to the Drive capacity, or if the motor is operated using the factory •...

-

Page 215: Preventing Overvoltage During Deceleration (Stall Prevention During Deceleration Function)

Preventing Overvoltage During Deceleration (Stall Prevention During Deceleration Function) The Stall Prevention During Deceleration function makes the rate of deceleration more gentle to suppress increases in DC bus voltage when the DC bus voltage exceeds the set value during motor deceleration. This function automatically lengthens the deceleration time with respect to the bus voltage, even if the decel- eration time has been set to a considerably small value. - Page 216 Acceleration and Deceleration Characteristics Setting Example An example of stall prevention during deceleration when L3-04 is set to 1 as shown below. Output frequency Deceleration time controlled to prevent overvoltage Time Deceleration time (set value) Fig 6.23 Stall Prevention During Deceleration Operation...

-

Page 217: Adjusting Frequency References

Adjusting Frequency References This section explains methods of adjusting frequency references. Adjusting Analog Frequency References Gain and bias are among the parameters used to adjust analog inputs. Related Parameters Name Control Methods Change Open Open Parameter Setting Factory Description during Loop Flux... - Page 218 Adjusting Frequency References Name Control Methods Change Open Open Parameter Setting Factory Description during Loop Flux Loop Number Range Setting Display with Operation Vector Vector Vector Terminal A2 Selects the signal level of Signal Level terminal A2. Selection 0: 0 to 10Vdc (switch S1-2 must be in the OFF position).

- Page 219 Adjusting Frequency Gain Using an Analog Input When H3-09 or H3-05 is set to 1 (frequency gain), you can adjust the frequency gain using the analog input terminal A2 or A3. Frequency gain Multi-function analog input terminal A2 input level Fig 6.25 Frequency Gain Adjustment (Terminal A2 Input) The frequency gain for terminal A1 is the sum of H3-02 and terminal A2 gain.

-

Page 220: Operation Avoiding Resonance (Jump Frequency Function)

Adjusting Frequency References For example, if H3-02 is 100%, H3-03 is 0%, and terminal A2 is set to 1 V, the frequency reference from terminal A1 when 0Vis input to A1 will be 10%. Frequency reference H3-02 Bias Terminal A1 input voltage 10 V ... - Page 221 Output frequency Frequency reference descending Jump frequency width d3-04 Frequency reference ascending Jump frequency Jump width d3-04 frequency width d3-04 Jump frequency reference Jump Jump Jump frequency frequency frequency 3 (d3-03) 2 (d3-02) 1 (d3-01) Fig 6.27 Jump Frequency Setting Jump Frequency Reference Using an Analog Input When parameter H3-09 (Multi-function Analog Input Terminal A2 Function Selection) or H3-05 (Multi-func- tion Analog Input Terminal A3 Function Selection) is set to A (jump frequency), you can change the jump fre- quency using the terminal A2 input level.

-

Page 222: Adjusting Frequency Reference Using Pulse Train Inputs

Adjusting Frequency References Adjusting Frequency Reference Using Pulse Train Inputs The frequency reference can be adjusted when b1-01 (Reference Selection) is set to 4 (Pulse Train Input). Set the pulse frequency in parameter H6-02 to 100% reference, and then adjust the gain and bias accordingly using H6-03 and H6-04. -

Page 223: Speed Limit (Frequency Reference Limit Function)

Speed Limit (Frequency Reference Limit Function) This section explains how to limit the motor speed. Limiting Maximum Output Frequency If you do not want the motor to rotate above a given frequency, use parameter d2-01. Set the upper limit value of the Drive output frequency as a percent, taking E1-04 (Maximum Output Fre- quency) to be 100%. -

Page 224: Limiting Minimum Frequency

Speed Limit (Frequency Reference Limit Function) Limiting Minimum Frequency If you do not want the motor to rotate at below a given frequency, use parameters d2-02 or d2-03. There are two methods of limiting the minimum frequency, as follows: Adjust the minimum level for all frequencies. -

Page 225: Improved Operating Efficiency

Improved Operating Efficiency This section explains functions for improving motor operating efficiency. Reducing Motor Speed Fluctuation (Slip Compensation Function) When the load is large, the amount of motor slip also grows large and the motor speed decreases. The slip compensation function controls the motor at a constant speed, regardless of changes in load. - Page 226 Improved Operating Efficiency Adjusting Slip Compensation Gain You can switch the C3-01 parameter settings as shown below by changing the control method. V/f control without PG: 0.0 • Open-loop vector control: 1.0 • Flux vector control: 1.0 • Set C3-01 to 1.0 to compensate the rated slip set using the rated torque output status. Adjust the slip compensation gain using the following procedure.