Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Zmotion ZMC412

- Page 2 This manual is copyrighted by Shenzhen Technology Co., Ltd., without the written permission of the Zmotion Technology, no person shall reproduce, translate and copy any content in this manual. The above-mentioned actions will constitute an infringement of the copyright of the company's manual, and Zmotion will investigate legal responsibility according to law.

- Page 3 ⚫ Zmotion will not take any legal responsibility for personal safety accidents and property losses caused by failure to comply with the contents of this manual or illegal operation of products. Safety Level Definition According to the level, it can be divided into "...

- Page 4 ◆ Improper installation of the controller may result in misoperation, failure and fire. Wiring ◆ The specifications and installation methods of the external wiring of the equipment shall comply with the requirements of local power distribution regulations. ◆ When wiring, all external power supplies used by the system should be disconnected before operation.

-

Page 5: Table Of Contents

ZMC412 Motion Controller User Manual V1.5 Content Chapter I Production Information..................3 1.1. Product Information ..................3 1.2. Function Features ....................3 1.3. System Frame ....................4 1.4. Hardware Installment ..................5 Chapter II Product Specification ..................7 2.1. Basic Specification .................... 7 2.2. - Page 6 ZMC412 Motion Controller User Manual V1.5 3.6. Analog Output (DA) ..................25 3.6.1. Analog Output Specification & Wiring ..........26 3.6.2. Basic Usage ..................27 3.7. U Disk ......................27 3.8. ETHERNET ....................... 28 3.9. AXIS Differential Pulse Axis Interface ............. 30 3.9.1.

-

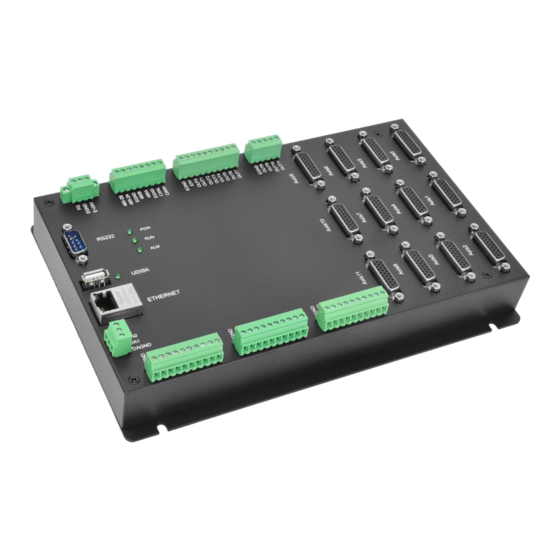

Page 7: Chapter I Production Information

ZMC412 Motion Controller User Manual V1.5 Chapter I Production Information 1.1. Product Information ZMC is the abbreviation of the network motion controller model launched by Zmotion Technology. ZMC4 series supports Zmotion XPLC function, and can be configured and displayed through the network. -

Page 8: System Frame

ZMC412 Motion Controller User Manual V1.5 ◆ Interfaces: RS232, RS485, U Disk, Ethernet. ◆ Support linear interpolation, any circular interpolation, helical interpolation and spline interpolation of 12 axes at most. ◆ Support electronic cam, electronic gear, position latch, synchronous follow, virtual axis, etc. -

Page 9: Hardware Installment

ZMC412 Motion Controller User Manual V1.5 1.4. Hardware Installment The ZMC412 motion controller adopts the horizontal installation method of screw fixing, and each controller should be installed with 4 screws for fastening. → Unit: mm → Installment Hole Diameter: 4.5mm ⚫... - Page 10 ZMC412 Motion Controller User Manual V1.5 ⚫ Considering the convenient operation and maintenance of the controller, please do not install the controller in the following places: places where the surrounding ambient temperature exceeds the range of -20° C-60° C places where the ambient humidity exceeds the range of 10%-...

-

Page 11: Chapter Ii Product Specification

ZMC412 Motion Controller User Manual V1.5 Chapter II Product Specification 2.1. Basic Specification Item Description Model ZMC412 ZMC412-14 Basic Axes Max Extended Axes Type of Basic Axes Local pulse axes General IO: 24 inputs, 12 outputs Digital IO IO inside the axis interface: there are 12 inputs and 12 outputs for these 12 pulse axes interfaces. -

Page 12: Order Information

12 axes, point to point, linear, circular, electronic cam, continuous ZMC412 trajectory motion, robotic car instructions. 14 axes, point to point, linear, circular, electronic cam, continuous ZMC412-14 trajectory motion, robotic car instructions. ZMC412R Functions of ZMC412 + Delta + 6-joint robotic arm instructions. 2.3. Interface Definition... - Page 13 ZMC412 Motion Controller User Manual V1.5 → Interface Description Mark Interface Number Description Power indicator: it lights when power is conducted. Status Indication Run indicator: it lights when runs Light normally Error indicator: it lights when runs abnormally RS232 serial port...

-

Page 14: Work Environment

ZMC412 Motion Controller User Manual V1.5 comparison output function Analog output Resolution: 12 bits, 0-10V It includes differential pulse output AXIS Pulse axis and differential encoder input 2.4. Work Environment Item Parameters Work Temperature -10℃-55℃ Work relative Humidity 10%-95% non-condensing -40℃~80℃... -

Page 15: Chapter Iii Wiring, Communication Configuration

ZMC412 Motion Controller User Manual V1.5 Chapter Wiring, Communication Configuration 3.1. Power Input The power supply input adopts a 3Pin (there are all 3 terminals, E+24V, EGND and FG) screw-type pluggable wiring terminal, and the interval (means the gap distance between two ports, namely, between E+24V and EGND) should be 3.81mm. -

Page 16: Rs485, Can Communication Interface

3.2. RS485, CAN Communication Interface The communication interface adopts an 8Pin screw-type pluggable wiring terminal and the gap spacing between 2 terminals should be 3.81mm. ZMC412 has 2 RS485 communication interfaces and 1 CAN communication interface, and for both RS485 communication and CAN communication, they can be used by connecting the corresponding interface. - Page 17 ZMC412 Motion Controller User Manual V1.5 Max Communication Rate (bps) 115200 Terminal Resistor 120Ω Topology Daisy chain connection structure Nodes can be extended Up to 127 Up to 16 Longer communication distance, lower Communication Distance communication rate, max 100m is recommended.

- Page 18 ZMC412 Motion Controller User Manual V1.5 → Wiring Notes: As above, the daisy chain topology is used for wiring (the star topology structure ⚫ cannot be used). When the use environment is ideal and there are no many nodes, the branch structure also can be used.

-

Page 19: Basic Usage Method

ZMC412 Motion Controller User Manual V1.5 3.2.2. Basic Usage Method (1) Please follow the above wiring instructions for correct wiring. (2) After power on, please use any of the three interfaces ETHERNET, RS232, and RS485 to connect to ZDevelop. (3) Please use the "ADDRESS" and "SETCOM" commands to set and view the protocol station number and configuration parameters, see "ZBasic Programming Manual"... -

Page 20: Rs232 Serial Port

ZMC412 Motion Controller User Manual V1.5 (5) Correctly set the relevant parameters of the third-party equipment according to their respective instructions to match the parameters of each node. (6) Correctly set the "address" and "speed" of the slave expansion module according to the manual of the slave. -

Page 21: Rs232 Communication Interface Specification & Wiring

ZMC412 Motion Controller User Manual V1.5 1、4、 Spare Reserved 6、7、8 Input RS232 signal receive Output RS232 signal send 5V power supply outputs negative EGND Output pole and this communication common terminal 5V power supply outputs positive Output pole, max is 300mA 3.3.1. -

Page 22: Basic Usage Method

ZMC412 Motion Controller User Manual V1.5 → Wiring Notes: ⚫ The wiring of RS232 is as above, the sending and receiving signals need to be cross- connected, and it is recommended to use a double-female cross line when connecting to a computer. -

Page 23: In Digital Input & High-Speed Latch Port

ZMC412 Motion Controller User Manual V1.5 (4) Correctly set the relevant parameters of the third-party equipment according to their respective instructions to match the parameters of each node. (5) When all is configured, it can start to do communicating. (6) Communication data of RS232 / RS485 can be directly viewed through “ZDevelop / Controller / State the Controller / CommunicationInfo”. -

Page 24: Digital Input Specification & Wiring

IN21 Input 22 IN22 Input 23 IN23 Note: ZMC412 has 8 latch inputs (for general firmware, there are 4 latch inputs, for special firmware, there are 8 latch inputs) 3.4.1. Digital Input Specification & Wiring → Specification Item High-Speed Input (IN0-7) -

Page 25: Basic Usage Method

ZMC412 Motion Controller User Manual V1.5 Isolation mode optoelectronic isolation optoelectronic isolation Note: the above parameters are standard values when the controller power supply voltage (E+24V port) is 24V. → Wiring Reference → Wiring Note: The wiring principle of high-speed digital input IN (0-7) and low-speed digital input ⚫... -

Page 26: Out: Digital Output, Pwm Terminal, Hardware Comparison Output, Single

ZMC412 Motion Controller User Manual V1.5 (4) Latch function can be set and opened through “REGIST” instruction, in software, use REG_INPUTS to configure. Please refer to “ZBasic” for details. 3.5. OUT: Digital Output, PWM Terminal, Hardware Comparison Output, Single-ended Pulse The digital output adopts 2 sets of screw-type pluggable terminals with a spacing of 3.81mm, and the digital output signals integrate with PWM and hardware comparison... -

Page 27: Digital Output Specification & Wiring

ZMC412 Motion Controller User Manual V1.5 OUT2 speed Output 2 PUL13 output OUT3 Output 3 DIR13 OUT4 Output 4 Leakage OUT5 Output 5 type, OUT6 Output 6 low- speed OUT7 Output 7 output External power EGND ground OUT8 Output 8... - Page 28 ZMC412 Motion Controller User Manual V1.5 Respond time to 3μs 80μs close Overcurrent Support Support protection Isolation method optoelectronic isolation Note: The times in the form are typical based on the resistive load, and may change when the load circuit changes.

-

Page 29: Basic Usage Method

ZMC412 Motion Controller User Manual V1.5 ⚫ The E5V port is a 5V power output port, which can be used when some loads need to provide an external 5V power input, the maximum current is 300mA. 3.5.2. Basic Usage Method (1) Please follow the above wiring instructions for correct wiring. -

Page 30: Analog Output Specification & Wiring

ZMC412 Motion Controller User Manual V1.5 → Wiring Definition Terminal Name Type Function Analog output terminal AOUT(0) Output Analog output terminal AOUT(1) DAGND Public end Analog public end 3.6.1. Analog Output Specification & Wiring → Specification DA(0-1) Item Resolution 12-bit... -

Page 31: Basic Usage

“ZDevelop/View/AD/DA”. Please refer to “ZBasic” for details. 3.7. U Disk The ZMC412 motion controller provides a USB communication interface to insert a U disk device, which is used for ZAR program upgrade, controller data import and export, and 3 file executions. Its schematic diagram is shown in the figure below:... -

Page 32: Ethernet

500mA Whether Isolates 3.8. ETHERNET ZMC412 motion controller has a 100M network port, supports MODBUS_TCP protocol and custom communication, and the default IP address is 192.168.0.11. The pin definition diagram is as follows: The Ethernet port of the controller can be connected point-to-point with a computer,... - Page 33 ZMC412 Motion Controller User Manual V1.5 The controller can also be connected to the interchanger through an Ethernet cable, and connected to other devices through the interchanger to realize multi-point connection. The schematic diagram is as follows: → Communication Cable Requirements ETHERNET communication interface adopts standard Ethernet RJ45 interface.

-

Page 34: Axis Differential Pulse Axis Interface

ZMC412 Motion Controller User Manual V1.5 Item Specification Cable type Flexible crossover cable, Cat 5e Cable type twisted pair Cable pair Isolation cross skeleton Connector Crystal head with iron shell Cable material Cable length Less than 100m Use RJ45 network cable connection method: When installing, hold the crystal head with the cable and insert it into the RJ45 ⚫... - Page 35 ZMC412 Motion Controller User Manual V1.5 → Interface Definition Interface Signal Description EGND Negative pole of IO 24V power IN24- Digital input, it is recommended to 35/ALM do drive alarm OUT12- Digital output, it is recommended 13ENABLE to do drive enable...

-

Page 36: Axis Interface Signal Specification & Wiring

ZMC412 Motion Controller User Manual V1.5 Note: ALM and ENABLE are recommended to be used as axis IO, because the drive capacity is small. OVCC, +5V are only used for communication between the controller and the servo driver, please do not use it as power supply for other places. - Page 37 ZMC412 Motion Controller User Manual V1.5 EGND Maximum output current for 24V 50mA → Wiring Reference: Reference example of wiring with Panasonic A5/A6 servo driver:...

-

Page 38: Basic Usage Method

ZMC412 Motion Controller User Manual V1.5 → Wiring Note: The wiring principle of the differential pulse axis interface is shown in the figure above, and the wiring methods of different types of drivers are different, please connect carefully. ... - Page 39 ZMC412 Motion Controller User Manual V1.5 (5) Control corresponding motion through “View – Manual”. Refer to BASIC Routine:...

- Page 40 ZMC412 Motion Controller User Manual V1.5 BASE(0,1) 'select axis 0 and axis 1 ATYPE = 1,1 'set axis 0 and axis as pulse axes UNITS = 1000,1000 'set pulse amount as 1000 pulses SPEED = 10,10 'set axis speed as 10/1000 pulse/s ACCEL = 1000,1000 ‘set axis acceleration as 1000*1000 pulse/s/s...

-

Page 41: Chapter Iv Expansion Module

ZMC412 Motion Controller User Manual V1.5 Chapter IV Expansion Module The controller can expand digital IO, analog IO, pulse axis and other resources through CAN bus (ZIO series expansion modules). For details, please refer to "ZIO Expansion Card Hardware Manual". Also, through EtherCAT bus (EIO series expansion cards) expansion of these resources also can be achieved, please refer to each EIO hardware manual for details. - Page 42 ZMC412 Motion Controller User Manual V1.5 → Wiring Note: ZMC412 controller uses the single power, and ZIO expansion module uses dual- power. When using, main power supply of expansion module and main power supply of controller can share one power. When they use different power supplies, controller power EGND needs to connect to expansion module power GND, otherwise CAN may be burnt out.

-

Page 43: Can Bus Expansion Resource Mapping

ZMC412 Motion Controller User Manual V1.5 4.3. CAN Bus Expansion Resource Mapping The ZCAN expansion module generally has an 8-bit DIP switch, dial ON to take effect, and the meaning of the DIP is as follows: 1-4: they are used for ZCAN expansion module IO address mapping, the corresponding value is 0-15. - Page 44 The initial digital IO mapping number starts from 16 and increases in multiples of 16. The distribution of digital IO numbers corresponding to different dial IDs is as follows (ZMC412 motion controller expansion board DIP ID starts from 2 at least, therefore, starting IO number should start from 48 at...

- Page 45 ZMC412 Motion Controller User Manual V1.5 The initial IO mapping number of the analog AD starts from 8 and increases in multiples of 8. The initial IO mapping number of the analog DA starts from 4 and increases in multiples of 4. The allocation of digital IO numbers corresponding to different dial code...

- Page 46 ZMC412 Motion Controller User Manual V1.5 When the CAN bus expansion mode is used to expand the pulse axis, ZIO16082M can be selected to expand two pulse axes. These two pulse axes need to be mapped and bound with the axis No., then access.

- Page 47 ZMC412 Motion Controller User Manual V1.5 ALMRM indicator light is on, please check whether the wiring, resistor and dial setting are correct, and whether the CANIO_ADDRESS command of the controller is set as the master end (32), and whether the CAN communication speed is consistent.

-

Page 48: Chapter V Program & Applications

5.1. ZDevelop Software Usage ZDevelop is a PC-side program development, debugging and diagnostic software for the ZMoiton series motion controllers of Zmotion Technology. Through it, users can easily edit and configure the controller program, quickly develop applications, diagnose system operating parameters in real time, and watch the motion controller. The running program is debugged in real time and supports Chinese and English bilingual environments. - Page 49 ZMC412 Motion Controller User Manual V1.5 Click “File” – “New File”, select file type to build, here select Basic, click “OK”. Double click “AutoRun”, enter task number 0.

- Page 50 ZMC412 Motion Controller User Manual V1.5 Edit program program editing window, click “save”, built basic file will be saved under “zpj.” project automatically. “Save all” means all files under this project will be saved. Click “controller – connect”, if no...

- Page 51 ZMC412 Motion Controller User Manual V1.5 parameters port address, then click “connect”. Click “Ram/Rom” – “download RAM download ROM”, if it is successful, there is print indication, the same time, program downloaded into controller runs automatically. RAM: it will not...

- Page 52 ZMC412 Motion Controller User Manual V1.5 Click “Debug” – “Start/Stop Debug” to call “Task” “Watch” window, because it was downloaded before, here select “Attach the current”. Click “View” – “Scope” to open oscilloscope. Note: ⚫ When opening an project, choose to open the zpj file of the project. If only the Bas file is opened, the program cannot be downloaded to the controller.

-

Page 53: Pc Upper-Computer Program Application

Mac, Android, and wince, and provides dll libraries in various environments such as vc, c#, vb.net, and labview, as shown in the figure below. PC software programming refers to "ZMotion PC Function Library Programming Manual". The program developed using the PC software cannot be downloaded to the controller, and it is connected to the controller through the dll dynamic library. - Page 54 ZMC412 Motion Controller User Manual V1.5 Select development language “Visual C++” and the select program type “MFC application type”. Select “Based on basic box”, click “next” or “finish” Find function library provided manufacturer. Routine below (64-bit library) Copy all DLL related library files under the above path to the newly created project.

- Page 55 ZMC412 Motion Controller User Manual V1.5 zmotion.lib Item". Related header 2) Add static files: libraries and zauxdll2.h, related zmotion.h header files in sequence in the pop-up window. Declare relevant header files and define controller connection handle, so far the project is...

-

Page 56: Chapter Vi Run And Maintain

ZMC412 Motion Controller User Manual V1.5 Chapter VI Run and Maintain The correct operation and maintenance of the device can not only guarantee and extend the life cycle of the equipment itself, but also take technical management measures according to the pre-specified plan or the corresponding technical conditions to prevent equipment performance degradation or reduce the probability of equipment failure. -

Page 57: Common Problems

ZMC412 Motion Controller User Manual V1.5 Should be within the range of Whether the device is subjected to vibration resistance vibration or shock impact resistance Keep good ventilation and Is the heat dissipation good heat dissipation The mounting screws should... - Page 58 ZMC412 Motion Controller User Manual V1.5 invalid. and whether the "input" view can watch the signal change of the limit sensor. Check whether the mapping of the limit switch is correct. Check whether the limit sensor is connected to the common terminal of the controller.

- Page 59 ZMC412 Motion Controller User Manual V1.5 Check master-slave configuration, communication speed configuration, etc. Check the DIP switch to see if there are multiple expansion modules with the same ID. Use twisted-pair cables, ground the shielding layer, and use dual power supplies for severe interference...

Need help?

Do you have a question about the ZMC412 and is the answer not in the manual?

Questions and answers