Subscribe to Our Youtube Channel

Summary of Contents for Westerbeke 9.5 MCGA 60 Hz

- Page 1 M U LT I - P O RT S I N G L E – P H A S E MARINE GASOLINE GENERATORS OPERATORS MANUAL 9.5 MCGA 60 Hz 7.6 MCGA 50 Hz PART NUMBER 056997 REVISION C May 2023...

- Page 2 In no event shall Westerbeke, publishers, authors, or editors of this guide be liable for any loss of profit or any other commercial damage caused or alleged to have been caused directly or indirectly by this document.

- Page 3 MTBE is no longer a primary concern since it is no longer available.) sludge, or gums entering or forming in the engine or fuel system is not covered by the Westerbeke Corporation limited warranty. Ethanol is a solvent and tends to clean any dirt or contaminants on contact.

-

Page 4: Table Of Contents

Operators Manual for Gasoline Generators 1 Important Safety Information C O N T E N T S 1 Important Safety Information 2 Introduction Quick Start Operators Guide ........................4 Documentation ............................4 Parts Diagram ............................5 Warranty Procedures ..........................6 Conventions Used in this Manual ...................... - Page 5 Operators Manual for Gasoline Generators 1 Important Safety Information Lay-Up Prep: Spare Parts......................... 41 How to Recommission After a Lay-Up ..................... 41 9 Generator Specifications Specifications: Engine ..........................42 Specifications: Fuel System ........................42 Specifications: Electrical System ......................42 Specifications: Air Requirements ......................42 Specifications: Cooling System ........................

- Page 6 Operators Manual for Gasoline Generators L I S T O F F I G U R E S Figure 1: Parts Diagram ............................5 Figure 2: Customer Identification Card ......................... 6 Figure 3: Product Serial Number, Model Number, and Other Specifications ............6 Figure 4: Spare Parts Kit............................

-

Page 7: Important Safety Information

Operator Manual for Gasoline Generators ▪ All fuel vapors are highly explosive. Use extreme care when handling and storing fuels. Store fuel in a well-ventilated area away from spark- Important Safety Information producing equipment and out of the reach of children. ▪... - Page 8 CO poisoning is one of the major safety risks associated with exhaust gas with an appropriate CO analyzer. boating. It is a threat that must not be underestimated. Westerbeke There are two locations where exhaust gas can be sampled: multiport EFI generators are designed to dramatically reduce normal levels of CO in the engine exhaust.

- Page 9 Control System consists of engine design and precision Scientific, GFG, TPI, Teledyne, and others. manufacturing. ▪ Westerbeke recommends analyzers with a probe connected to the Engine Valve analyzer by a length of transparent tubing. They are slightly more Adjustment expensive than those with the sensor built-in to one end of the analyzer,...

-

Page 10: Introduction

Operator Manual for Gasoline Generators 2 Introduction This Westerbeke generator is a product of our many years of experience and advanced technology. We take great pride in the superior durability and dependable performance of our engines and generators. Thank you for selecting Westerbeke. -

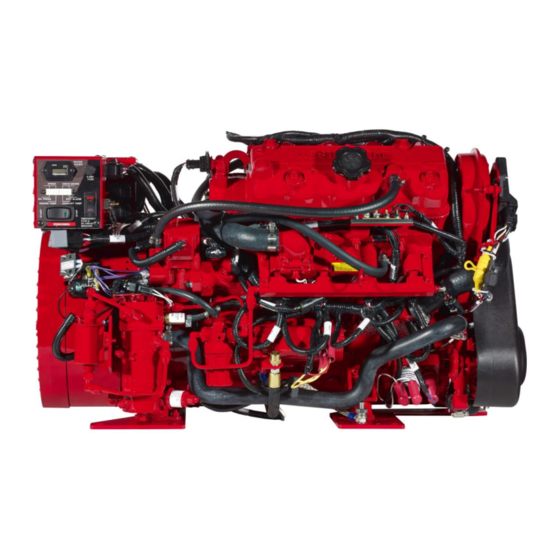

Page 11: Parts Diagram

Operator Manual for Gasoline Generators 2 Introduction Parts Diagram Figure 1: Parts Diagram page... -

Page 12: Warranty Procedures

Operator Manual for Gasoline Generators Warranty Procedures Your Westerbeke Warranty Statement is included in the product documentation package. Complete and return the included warranty registration card or register your product online at www.westerbeke.com. You should receive your customer warranty identification card in the mail within 30 days of registering. If you do not, contact the factory and have your product model number, serial number, and in-service date available. -

Page 13: Conventions Used In This Manual

Westerbeke distributor or dealer. Checklist: Protecting Your Investment Care at the factory during assembly and thorough testing have resulted in a Westerbeke generator capable of many hours of dependable service. However, the manufacturer cannot control where the generator is installed in the vessel or how well the unit is installed, operated, and serviced in the field. -

Page 14: Amperage Drain

2.11 Spare Parts, Kits, and Accessories Certain spare parts will be needed to support and maintain your Westerbeke generator. Your local Westerbeke dealer will assist you in preparing an inventory of suggested spare parts and accessories. TIP: We also recommend carrying enough spare engine oil for an oil change and one gallon of premixed coolant for the cooling system. -

Page 15: Figure 5: Suggested Spare Parts

Operator Manual for Gasoline Generators 2 Introduction For your convenience, we offer two spare part kits, each packaged in a water-tight storage case: Kit A includes the basic set of the most essential recommended spare parts. ■ Kit B includes everything in Kit A, plus additional spare parts for more extensive off-shore cruising. ■... -

Page 16: Installation

If you have any doubt about the position of the water-injected exhaust elbow relative to the vessel waterline under the various operating conditions for your vessel, install a siphon-break, available from Westerbeke or your local authorized Westerbeke dealer. -

Page 17: Exhaust System Requirements

Operator Manual for Gasoline Generators 3 Installation NOTE: A siphon-break requires periodic inspection and cleaning to ensure proper operation. Failure to properly maintain a siphon-break can result in catastrophic engine damage. Consult the siphon-break manufacturer for proper maintenance. Exhaust System Requirements To install exhaust system components, see the installation manual. -

Page 18: Startup And Basic Operation

5.1: Maintenance Schedule. Westerbeke does not approve or disapprove the use of synthetic oils. If synthetic oils are used, engine break-in must be performed using conventional oil. The required oil change intervals are listed in this manual and cannot be extended, even if synthetic oils are used. -

Page 19: Coolant Recovery Tank

Operator Manual for Gasoline Generators 4 Startup and Basic Operation Coolant Recovery Tank A coolant recovery tank kit is supplied with each generator to allow for engine coolant expansion and contraction during engine operation without the loss of coolant and without introducing air into the cooling system. -

Page 20: How To Start And Stop The Generator

4 Startup and Basic Operation Operator Manual for Gasoline Generators Figure 8: Fuel System How to Start and Stop the Generator 4.7.1 How to Start and Stop the Generator (Control Panel) The start/stop rocker switch is the only functional component on the generator control panel (and optional remote control panel) used to start and stop the generator. -

Page 21: Figure 9: Control Panel Dc Circuit Breaker And Start/Stop Switch

Operator Manual for Gasoline Generators 4 Startup and Basic Operation How to Bleed the Fuel NOTE: The STOP position is also used to prime the fuel system when necessary. See 4.6 System green LED goes out indicating the engine has shut down. Figure 9: Control Panel DC Circuit Breaker and Start/Stop Switch 4.7.2 How to Start and Stop the Generator (Remote Control Panel) -

Page 22: Safety Shutdown Switches And Leds

4 Startup and Basic Operation Operator Manual for Gasoline Generators Figure 10: Remote Start/Stop Panels 4.7.4 Failure to Start The start cycle will automatically terminate if the engine fails to start. Three crank cycles can be attempted before the ECU initiates a fault and prevents further crank cycle attempts. Investigate the cause of this no-start, correct it, and reset the power to the ECU. -

Page 23: Figure 11: Exhaust Temperature Switch

Operator Manual for Gasoline Generators 4 Startup and Basic Operation 4.8.1 Speed Sensor (Hall Effect) A speed sensor is mounted on a bracket adjacent to the front crankshaft pulley. This sensor monitors pulley rotation and sends a voltage signal to the ECU that interprets it as crankshaft speed. If both speed LEDs to the left are illuminated it indicates an engine speed fault. -

Page 24: Break-In Procedure

4 Startup and Basic Operation Operator Manual for Gasoline Generators 4.8.5 DC Circuit Breaker The engines electrical system is protected by a 20-amp manual reset circuit breaker. An electrical overload in the wiring harness or instrument panel will trip the breaker and shut down the engine/generator. Should this occur, inspect and repair the problem. -

Page 25: Figure 14: Engine Oil And Coolant System Components

Operator Manual for Gasoline Generators 4 Startup and Basic Operation ❑ Check the grounding and neutrals: Confirm that systems with a neutral line are properly grounded as the system requires, and that generator neutral is properly connected to the load neutral. In single phase systems, an incomplete or open neutral can supply the wrong line-to-neutral voltage on unbalanced loads. -

Page 26: Checklist: Daily Startup

4 Startup and Basic Operation Operator Manual for Gasoline Generators 4.11 Checklist: Daily Startup Follow this check list each day before starting your generator. ❑ Visually inspect the generator for fuel, oil, water leaks or loose parts. ❑ Check the oil level on the dipstick. ❑... -

Page 27: Maintenance

Operator Manual for Gasoline Generators 5 Maintenance 5 Maintenance Maintenance Schedule The maintenance intervals specify operating hours or a time interval, whichever comes first. For example, if maintenance is due every 250 hours or six months, and you have logged 300 hours in only two months, do not delay maintenance another four months. - Page 28 5 Maintenance Operator Manual for Gasoline Generators 5.1.4 Every 100 Operating Hours or Yearly ❑ Engine Oil and Filter: Change engine oil and filter. Spark plugs: check and clean/gap/replace as needed. ❑ Air Screen/Flame Arrestor: Remove, clean and re-install screen pack. Inspect rubber sealing ring ❑...

-

Page 29: Maintenance: Fuel System

Operator Manual for Gasoline Generators 5 Maintenance Maintenance: Fuel System Incoming fuel from the installer/OEM installed gasoline water separator and filter is pumped through the inlet fuel filter into the fuel module by the electric fuel pump. The fuel is cooled as it circulates through the fuel module and then is pumped by the electric fuel pump to the high-pressure pump module and to the secondary fuel filter. -

Page 30: Figure 16: Harness Lift Pump Dc Auxiliary Power Adapter

5 Maintenance Operator Manual for Gasoline Generators 5.2.3 Engine Fuel Filter Periodically check the fuel connections and the bowl for leakage. Replace the filter element after the first 50 hours then follow the maintenance schedule. 5.2.4 How to Change the Engine-Mounted Fuel Filter Element Shut off the fuel supply to the generator. -

Page 31: Maintenance: Cooling System

5.3.1 Fresh Water Cooling Circuit Westerbeke marine engines are designed and equipped for fresh water cooling. Heat produced in the engine by combustion and friction is transferred to fresh water, which circulates throughout the engine. This circulating fresh water cools the engine block and its internal moving parts. The heat is transferred externally from the fresh water to sea water by means of a heat exchanger, similar in function to an automotive radiator. - Page 32 5 Maintenance Operator Manual for Gasoline Generators Premix fresh coolant and distilled water or use premixed 50/50 coolant. Remove pressure cap. Slowly add coolant into the pressure cap opening until coolant reaches the bottom of the pressure cap opening. Slowly open the coolant hose bleeder and let any air out. Bleeding is complete when coolant comes out of bleeder with no air.

-

Page 33: Figure 18: Cooling System Heat Exchanger (Left) And Thermostat (Right)

Operator Manual for Gasoline Generators 5 Maintenance Figure 18: Cooling System Heat Exchanger (Left) and Thermostat (Right) 5.3.4 Cooling System Zinc Anode A zinc anode (or pencil) in the raw-water cooling circuit in the heat exchanger sacrifices itself to electrolysis action taking place in the raw-water cooling circuit, reducing the effects of electrolysis on other components of the system. -

Page 34: Maintenance: Engine

Chapter 5.1: Maintenance Schedule. Westerbeke does not approve or disapprove the use of synthetic oils. If synthetic oils are used, engine break-in must be performed using conventional oil. Oil change intervals must be as listed in 5.1: Maintenance Schedule and cannot be extended if synthetic oils are used. -

Page 35: Figure 19: Engine Oil Drain Hose (Left) And Oil Filter Assembly (Right)

Operator Manual for Gasoline Generators 5 Maintenance NOTE: The information under 5.4 (previous page) supersedes all previous statements regarding synthetic oil. 5.4.1 How to Change the Engine Oil Warm the oil/engine before draining. Remove the oil drain hose from its attachment bracket and lower it into a container, and allow the oil to drain. -

Page 36: Figure 20: Engine Oil System Componets

5 Maintenance Operator Manual for Gasoline Generators TIP: Use genuine Westerbeke oil filters. Generic filters are not recommended. 5.4.3 How to Refill the Engine Oil Add fresh oil through the valve cover. After refilling the oil, run the engine for a few moments. -

Page 37: Figure 22: Air Screen/Flame Arrestor

Operator Manual for Gasoline Generators 5 Maintenance 5.4.5 How to Clean the Air Screen/Flame Arrestor The air screen/flame arrestor should be cleaned after the first 50 hours of operation. Refer to the maintenance schedule in this manual. Clean using a good dish washing solution, rinse, and air dry. Inspect the seal edges. -

Page 38: Figure 24: Battery Charger And 30A Fuse

5 Maintenance Operator Manual for Gasoline Generators A separate group of stator windings, protected by a 30-amp, in line fuse, supplies AC voltage to a bridge rectifier, which converts the AC current to supply the charging unit. The unit senses the needs of the starting battery and supplies a DC charge when one is needed. -

Page 39: Maintenance: Connections, Motors, And Circuit Breakers

CO while the engine is running. This must be performed with a CO analyzer. WARNING : Never reuse an exhaust sealing gasket. Always replace with a new gasket. NOTE: For information on installing exhaust systems, see the Installation Manual available at www.westerbeke.com. Figure 25: Catalyst Installation... - Page 40 5.5.4 AC Circuit Breaker A circuit breaker is installed on all single-phase Westerbeke generators. This circuit breaker will automatically disconnect generator power in case of an electrical overload. The circuit breaker can be manually shut off when servicing the generator to ensure that no power is being supplied into the boat.

-

Page 41: Figure 26: Bc Generator Ac Terminal Connections

Operator Manual for Gasoline Generators 5 Maintenance Figure 26: BC Generator AC Terminal Connections Figure 27: Generator Windings Schematic Diagram INTEGRAL CONTROLLER 30A FUSE 30A FUSE ROTOR WINDING 60 Hz CHARGER 50 Hz BATTERY CHARGING CIRCUIT STATOR WINDING STATOR WINDING ROTOR WINDING EXCITER WINDING EXCITER WINDING... -

Page 42: Figure 28: Shore Power Transfer Switch

If the installer connects shore power to the AC circuit on your vessel, this must be done by means of a shore power transfer switch. Ship-to-shore switches are available from Westerbeke or an authorized dealer. Figure 28: Shore Power Transfer Switch Set the transfer switch shown in the diagram to the OFF position. -

Page 43: Diagnostics And Troubleshooting

The diagnostic software runs on most Microsoft Operating Systems. It requires a minimum of 128 MB of RAM. The communications cable plugs into a USB port. NOTE: The Westerbeke communications cable is unique to this diagnostic software and must be used. An incompatible cable may damage the ECU. -

Page 44: Engine Troubleshooting

6 Diagnostics and Troubleshooting Operator Manual for Gasoline Generators Engine Troubleshooting The following troubleshooting chart describes common engine problems and possible causes. CAUTION: When servicing the engine/generator, turn off the main AC circuit breaker to disconnect all AC power. Problem: Possible Cause: Engine does not crank: 1. -

Page 45: Wiring Diagrams

Operator Manual for Gasoline Generators 7 Wiring Diagrams 7 Wiring Diagrams The Wiring Diagram is available online and a printed copy is included in the standard equipment kit with your generator. Remote Start/Stop Panels Figure 31: Wiring Diagram for Start/Stop Panel with Fault Display NOTE: A 15-foot or 30-foot extension harness is also available. -

Page 46: Lay-Up And Recommissioning

8 Lay-Up and Recommissioning Operator Manual for Gasoline Generators 8 Lay-Up and Recommissioning Many owners rely on their boatyards to prepare their craft, including engines and generators, for lay-up during the off-season or for long periods of inactivity. Others prefer to accomplish lay-up preparation themselves. The following procedures allow you to perform your own lay-up and recommissioning, or you may use them as a checklist if others do the procedures. -

Page 47: Lay-Up Prep: Raw Water Cooling Circuit

Lay-Up Prep: Spare Parts Lay-up time provides an opportunity to inspect your Westerbeke engine to see if external items such as drive belts or coolant hoses need replacement. Check your basic spares kit and order items not on hand, or replace those items used during the lay-up, such as filters and zinc anodes. -

Page 48: Generator Specifications

9 Generator Specifications Operator Manual for Gasoline Generators 9 Generator Specifications Specifications: Engine Item Description Engine Type 4-cylinder, 4-cycle, overhead camshaft water cooled gasoline engine Bore & Stroke 2.57 x 3.07 inches (65.5 x 78.0 mm.) Total Displacement 64.1 cubic inches (1.051 liters) Bearings Four (4) main bearings Combustion Chamber... -

Page 49: Specifications: Cooling System

Battery ignition 12-volt negative ground, ignition coil and spark plugs. Ignition System TCI Ignition Spark Module Spark Plug Gap 0.032-0.035 inch (0.8-0.9mm) Spark Plug Thread 14.0 mm x 1.25 pitch Ignition Timing Electronic Control Spark Plugs Westerbeke 056754 Ignition Coil 12 volts – coil on plug type page... -

Page 50: 9.9 Specifications: Engine Component Tightening Torque

9 Generator Specifications Operator Manual for Gasoline Generators 9.9 Specifications: Engine Component Tightening Torque Engine Component Ft. Lbs. Timing Belt Flywheel Bolt 86-88 63-65 Timing Belt Cover Bolts 10-12 Camshaft sprocket bolts 80-100 58-72 Oil pump sprocket nuts 50-57 36-41 Timing tensioner nuts 22-30 16-22... - Page 51 Operator Manual for Gasoline Generators 9 Generator Specifications This page intentionally left blank. page...

- Page 52 9 Generator Specifications Operator Manual for Gasoline Generators ©2022 Westerbeke, Inc. All Rights Reserved. Westerbeke Corporation Myles Standish Industrial Park 150 John Hancock Rd. Taunton, MA 02780-7319 USA Phone: (508) 823-7677 FAX: (508) 884-9688 www.westerbeke.com page...

Need help?

Do you have a question about the 9.5 MCGA 60 Hz and is the answer not in the manual?

Questions and answers