Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Nastec SUND

- Page 1 SUND Installation, use and maintenance manual V 2.1 16/06/2022...

- Page 2 Copyright © Nastec srl The information contained in this document may be changed without notice Nastec srl, Via della Tecnica, 8, 36048, Barbarano Mossano, Vicenza, Italy, Tel. +39 0444 886289, Fax +39 0444 776099, info@nastec.eu, nastec.eu...

-

Page 3: Table Of Contents

Table of Contents 1. Introduction ............................5 1.1. Purpose of the manual ......................5 1.2. Product overview ........................5 1.3. Nastec NSC solar calculator ..................... 6 2. Safety ..............................6 2.1. Symbols ..........................6 2.2. Qualified personnel ........................7 2.3. Safety warnings ........................7 2.4. - Page 4 SUND 9.10.3. Stop for minimum flow ....................27 9.11. Control by flow switch ......................27 10. Constant pressure operation ......................28 10.1. Introduction .......................... 28 10.2. The pressure vessel ......................28 10.3. Electrical connections ......................28 11. Splitting the solar pumping system ....................29 11.1.

-

Page 5: Introduction

SUND it is powered by photovoltaic panels or, if necessary, by the mains. In this way, the operation of the pump is guaranteed at any time of day. It is also possible to satisfy the demand peaks through mains power supply thus avoid the oversizing of the photovoltaic system. -

Page 6: Nastec Nsc Solar Calculator

• achievement of the required daily flow rate • remote control via digital input. 1.3. Nastec NSC solar calculator To correctly size the solar pumping system, the Nastec NSC solar calculator is available free of charge on the site solar.nastec.eu. 2. Safety 2.1. -

Page 7: Qualified Personnel

SUND 2.2. Qualified personnel WARNING The installation, use and maintenance of the product are strictly for qualified personnel who have undergone appropriate training. Any use by unqualified personnel must be carried out under the approval, responsibility, and close monitoring of the latter. - Page 8 SUND DANGER During the entire period in which the device is powered, regardless of whether it is operated or remains in stand-by (digital shutdown), high voltage is present inside the device and at the input and output terminals. DANGER The device, previously in stand-by condition, may suddenly start up following the reset of an alarm or changed system conditions.

-

Page 9: Acoustic Emission

3.2. Warranty Nastec guarantees that the products accompanied by this warranty are free from material or workmanship defects. The Company has the right to inspect any product returned under warranty, and confirm that the product contains a material or workmanship defect. -

Page 10: Product Registration

If the warranty is applicable, Nastec will repair the device. Nastec is willing to refurbish the product upon offer. In the absence of a warranty, Nastec will make an offer to repair and/or refurbish the device. After 60 days from the offer, if no response is received from the buyer, Nastec will scrap the product upon notice. -

Page 11: Disposal

WARNING Failure to comply with the instructions may lead to loss of warranty. For more information contact the dealer or technical support at service@nastec.eu or by opening a support ticket on the portal service.nastec.eu 3.6. Disposal Devices marked with this symbol cannot be disposed of in household waste but must be disposed of at appropriate waste drop-off centres. -

Page 12: Storage

In particular, store the pump in a place with a minimum temperature that is not below 4 °C (40 °F). For more information contact the dealer or technical support at service@nastec.eu or by opening a support ticket on the portal service.nastec.eu 5. -

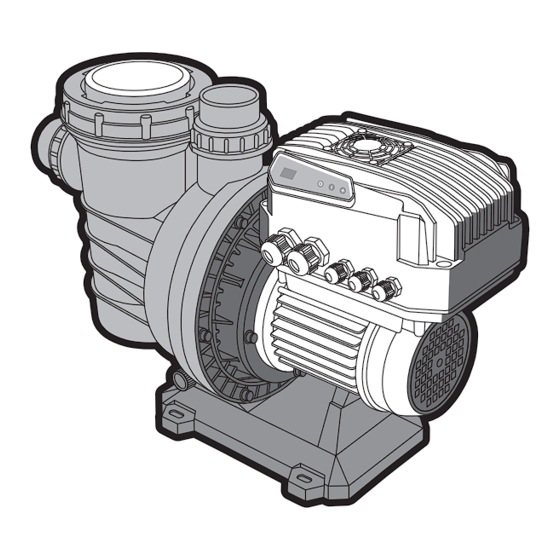

Page 13: Performance

20% compared to the absorbed electrical power. For a correct sizing of the system, use the solar calculator available free of charge by connecting to the site solar.nastec.eu Figure 1. SUND 50 4 m / 13 ft 6 m / 20 ft... -

Page 14: Dimensions And Weight

SUND 5.3. Dimensions and weight 225 mm 2 1/4” G 238 mm 520 mm Model Weight [kg] SUND 50 10,7 5.4. Cables entry Cable gland Tightening torque Cable diameter [Nm] [mm] 3,5-7 6. Mechanical installation WARNING Read the safety chapter carefully before continuing. -

Page 15: Cooling

The delivery and suction pipes must be correctly supported so as not to weigh down on the pump connections. 6.4. SUND priming In case of installation under the water level, fill the pump by slowly opening the gate valve in the suction line by keeping the delivery gate open to let the air out. -

Page 16: Connecting Cables

Recommended fuse Recommended circuit breaker ABB MCB S200 1 x 230 VAC SUND 50 S201-C10 Install on the DC side: • DC disconnector of suitable voltage and current • DC fuses of suitable voltage and current on both the positive and negative poles. Generally, DC fuses are chosen for a current that is approximately double the short-circuit current of a string of panels and are installed only if the photovoltaic system consists of three or more strings. -

Page 17: Power Connections

SUND 7.5.1. Power connections SUND 50 MOTOR LINE N/L2 L/L1 A [mm] Pre-insulated cable lug Stripping diagram L1/L 6.3 x 0.8 mm female Faston DC Power Sup- L2/N 6.3 x 0.8 mm female Faston LINE 6.3 x 0.8 mm female Faston P.E. -

Page 18: Control Connections

SUND 7.5.2. Control connections Type Description Functionality Comments Analog inputs 4-20 mA Sensor 1 4-20 mA Sensor 2 0-10 V External set value 0-10 V External frequency External set value 2 Power Supply +15V 15 VDC, max 100 mA Power supply for 4-20 mA ana-... -

Page 19: Powering

SUND • Check the implementation of electromagnetic compatibility (EMC) regulations and the correct connection of cable shields. • Check that the protective devices are present and correctly installed. • Check that the mechanical installation is correct, sturdy and complies with environmental and cooling require- ments. -

Page 20: Keyboard And Display

SUND FLASHING red led: undervoltage. 2. Green LED ON: motor running. Green led OFF: motor stopped. When the unit is in "constant value" control mode, the green LED flashes with a greater frequency the closer the measured value is to the set value. If the measured value is the same as the set value, the green LED is constantly on. -

Page 21: Control Via App

The device can be controlled using a smartphone or tablet equipped with Bluetooth BTLE connectivity and with the App Nastec NOW installed. The App is available for Android and iOS and may be downloaded, free of charge, from the respective online stores. -

Page 22: Control Parameters

SUND • Installer level: Allows editing the parameters related to pump operation in the hydraulic system on which it is installed. Password 1, default 001. • Advanced level: Allows editing the parameters that so critical that they may compromise the life of the device, the pump, and the system if they are set incorrectly. - Page 23 SUND Parameter Default Description Pipe fill ramp Ramp time to follow after a start if the measured value is lower than the minimum alarm value. The piping filling ramp expires XXX [s] Ramp up after the set time or if the measured value reaches the set time value.

- Page 24 SUND Parameter Default Description Delta control This parameter communicates by how much the measured value must fall in relation to the set value so that the pump, p = XXX.X [bar] during shutdown in control ramp, is restarted. 1: Min motor frequency; 2: Frequency min control; 3: Delta control;...

-

Page 25: Motor Parameters

SUND 9.7. Motor parameters Parameter Default Description Max motor frequency Maximum frequency intended to power the motor. Reducing the maximum motor frequency reduces the maximum current consumption. f = XXX [Hz] Min motor frequency Minimum motor frequency. f = XXX [Hz]... -

Page 26: Connectivity Parameters

SUND Parameter Default Description Digital input2 N.O. If N.O.(Normally Open) is selected, the device will continue to operate the motor if digital input 2 is open. Conversely, it will stop the motor if digital input 2 is closed. N.O./N.C. If N.C. (Normally Closed) is selected, the device will continue to operate the motor if digital input 2 is closed. -

Page 27: Pump Stop Under Low Irradiation Conditions

SUND Parameter Default Description MODBUS data format MODBUS data format: RTU N81, RTU N82, RTU E81, RTU O81 XXXXX MODBUS EEPROM Setting the writing mode of the parameters transmitted via MODBUS: write ON: the datum is saved in EEPROM ON/OFF... -

Page 28: Constant Pressure Operation

SUND 10. Constant pressure operation 10.1. Introduction TheSUND can manage the running speed of the pump in such a way as to keep the pressure constant as the water demand changes. A pressure sensor placed as close as possible to the pump is used for this purpose. -

Page 29: Splitting The Solar Pumping System

SUND 11. Splitting the solar pumping system 11.1. Introduction. To maximize the efficiency and reliability of a solar pumping system, instead of using a single high-power pump, it is possible to split it into two or more pumps in parallel, each controlled by a variable speed inverter and powered by the same photovoltaic system. -

Page 30: Electrical Connections

SUND 11.2.2. Electrical connections. MASTER: 0 SLAVE: 1 SLAVE: N COMBO COMBO COMBO S1+ S1- S1+ S1- G S1+ S1- G WARNING Respect the polarity of the connections. 11.2.3. Programming the master unit. Menu Parameter Value Control parameters COMBO ON to activate. -

Page 31: Automatic Master Replacement

SUND CAUTION When the master menu is accessed, the communication with the slave units is interrupted and the A13 No communication alarm is produced. Communication is automatically re-established by exiting the Master Menu. WARNING In case of pumps in COMBO mode, it is recommended to make the connections to the motor respecting the same phase sequence. - Page 32 SUND Alarm Description Possible solutions A03 Over temperature The temperature reached by the device • Check that the ambient temperature is within the allowed limits. inverter is higher than the maximum allowed • Make sure the device is protected from direct exposure to sunlight value.

-

Page 33: Alarms (Version Without Display)

SUND Alarm Description Possible solutions A10 IGBT trip alarm The current absorbed by the load in- • Check the possible solutions for alarms A01 Overcurrent motor and stantaneously exceeds the maximum A09 Overload inverter. current protection of the device's power •... - Page 34 SUND Alarm Notification LED Description Possible solutions 2 flashes of the The current absorbed by the motor • Check that motor parameters are correctly set. Overcur- yellow alarm led exceeds the maximum allowed value. • Check that the pump is turning in the correct direction.

- Page 35 SUND Alarm Notification LED Description Possible solutions 2 flashes of the The automatic frequency limitation • Check the possible solutions for the alarm A01 Overcurrent Locked yellow alarm led created by the inverter following an motor rotor excessive absorption by the motor...

-

Page 36: Warnings

SUND Alarm Notification LED Description Possible solutions A16 CPU 10 flashes of the Communication error between the • Check the value of the power supply voltage both under no alarm yellow alarm led control part and the power part or er- load and load conditions. -

Page 37: Warnings (Version Without Display)

SUND Warning Description Possible solutions W27 START/STOP The START/STOP buttons have been • Press the START or STOP button for at least 5 seconds to release block locked. the lock. 15. Warnings (version without display) Warning Notification LED Description Possible solutions... -

Page 38: Ec Declaration Of Conformity

SUND 16. EC Declaration of Conformity The manufacturer hereby: Nastec srl Via della Tecnica, 8, 36048, Barbarano Mossano, Vicenza, Italy declares under its own responsibility that the product: SUND complies with the following directives: • 2014/53 / EU Radio Equipment Directive (RED) •... -

Page 39: Declaration Of Conformity

SUND 17. UK Declaration of Conformity The manufacturer hereby: Nastec srl Via della Tecnica, 8, 36048, Barbarano Mossano, Vicenza, Italy declares, under its own responsibility, that the product: SUND complies with the following directives: • UK SI 2017 No. 1206 Radio Equipment Regulations 2017 •...

Need help?

Do you have a question about the SUND and is the answer not in the manual?

Questions and answers