Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Gamry Instruments ParaCell

- Page 1 ParaCell™ Electrochemical Cell Kit Operator’s Manual...

- Page 3 Limited Warranty Gamry Instruments, Inc. warrants to the original user of this product that it shall be free of defects resulting from faulty manufacture of the product or its components for a period of one year from the original shipment date of your purchase.

-

Page 4: If You Have Problems

(215) 682-9330 9:00 AM - 5:00 PM US Eastern Standard Time (877) 367-4267 Toll-free US & Canada Only Replacement parts for this kit are available from Gamry Instruments, Inc. Optional parts may be available from Gamry Instruments, or from third-party vendors. Contact your local Gamry sales representative to discuss any special requirements or accessories that you need. - Page 5 Copyrights and Trademarks ParaCell Operator’s Manual Copyright 2017 Gamry Instruments, Inc. Revision 1.41 November 30, 2017 988-00017...

- Page 6 Copyrights and Trademarks...

-

Page 7: Table Of Contents

If You Have Problems ........................ii Copyrights and Trademarks ......................ii Introduction ........................... 4 Chemical Compatibility of the ParaCell................... 5 Unpacking and Checking Your ParaCell ..................6 Checking for Shipping Damage ..................6 Parts List ........................... 7 Assembly ............................8 General Information ...................... -

Page 8: Introduction

Order your reference electrode separately. The ParaCell uses the two end plates and one of the four standard ports to implement its required functions. You can customize the cell by rearranging some of Gamry’s standard fittings or making or buying additional... -

Page 9: Chemical Compatibility Of The Paracell

Contact Gamry Instruments, if you need help selecting the proper replacement fittings. Gamry’s Paracell was not designed for use in electrolytes that dissolve glass (extremely basic solutions or HF containing solutions) or organic solvents which could damage the polycarbonate body. Be aware that some biological molecules will “stick”... -

Page 10: Unpacking And Checking Your Paracell

Unfortunately, no matter how carefully glass pieces are packaged, damage will sometimes occur. When you first receive your ParaCell kit, please check it for any signs of shipping damage. Be especially careful if the shipping container shows signs of rough handling. -

Page 11: Parts List

Unpacking and Checking Your ParaCellParts List Parts List Please check the contents of your kit versus the ParaCell packing list in Table 1. When shipped, all of the ParaCell components should be labeled with their Gamry Instruments, Inc. part number. -

Page 12: Assembly

If you are assembling your ParaCell for the first time, you may want to check for leaks after assembly. Because this cell is not designed to be pressurized, this is most easily accomplished by adding a small amount of dye to water, filling the cell, and setting it on some paper towels. -

Page 13: Main Cell Assembly

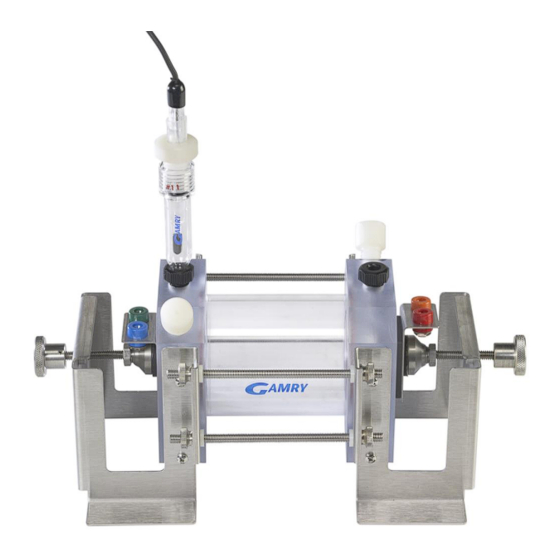

Figure 1 Assembled Cell (See Table 1 for Labels) The ParaCell includes a number of ACE-Thred™ connectors used for a wide variety of functions. #7 ACE- Thred™ connectors are particularly common. ACE-Thred™ fittings are designed to seal cylindrical objects into the cell. -

Page 14: Stirring With A Magnetic Stirrer

AssemblyBridge Tube and Reference Electrode 2. Slide the body (cylinder) into those grooves. 3. Draw the assembly tight with the four threaded rods. Make sure that the plastic “hats” are properly seated so that the metal rods nor nuts are in contact with the metal of the end bracket. Finger-tightening is generally sufficient to prevent leaks. -

Page 15: Counter Electrode

(normally the red/orange side). The graphite plate that is shipped with your ParaCell is spectroscopic grade. It is very pure and is therefore unlikely to be a significant source of contamination in your initial experiment. However, it is somewhat porous and can adsorb substances present in your test solution. -

Page 16: Pre-Saturation Of The Purge Gas

Gas Dispersion Apparatus In the ParaCell, gas-flow control apparatus is not included. Outlined is one way to handle gas flow. Use a thin flexible tubing (PTFE or other) for the gas feed line. With the cell assembled, run the feed line in through the angled, threaded access port on the counter side. -

Page 17: Attaching Gas Tubing To The Cell

Working Electrode (Sample) Because the working (and counter) electrodes form the end seals for the ParaCell, they must be in place prior to filling the cell with test solution. Take great care to insure that the surface of your test sample is not altered prior to the test. -

Page 18: Sample Masking

Electrode Connections: CorrosionSample Masking The ParaCell is designed for use with flat samples that are conductive through the sample—from the solution interface to the back wall, in contact with the leveling sample bracket. When this is the case, the banana jacks in the brackets can be used for electrical connection to the potentiostat. -

Page 19: Electrochemical Noise And Galvanic Corrosion

Electrochemical Noise and Galvanic Corrosion The ParaCell was designed to work for a wide variety of experiments, but it is ideal for galvanic corrosion and noise experiments. These are ZRA (Zero Resistance Ammeter)-mode corrosion experiments that measure the current passed between two electrodes of equal size. -

Page 20: Selected Specifications

Selected SpecificationsAddition of a pH Electrode Selected Specifications Cell Volume 300 mL standard operating volume Port Type End Plate Holes #7 thread Number of Ports 2 (O-ring sealed) 4 (two vented) Working Electrode(s) Exposed area 2.85 cm (0.44 in ) nominal... -

Page 21: Troubleshooting

TroubleshootingAddition of a pH Electrode Troubleshooting This section of the manual is organized as a list of problems that you may encounter. Following each problem is a list of some possible causes for that problem. Neither the list of problems nor the list of their causes is comprehensive. - Page 22 TroubleshootingAddition of a pH Electrode • Contaminants are entering the cell from the graphite counter electrode. • Your electrochemical system is inherently irreproducible; often true of localized corrosion phenomena.

-

Page 23: Index

IndexAddition of a pH Electrode Index working electrode, 13, 16 #7 ACE-thred, 9 basic, 5 bridge tube, 10, 17 cell connections, 14 chemical resistance, 5 counter electrode, 11 customization, 15 damage, 6 deaeration, 11 electrode connections, 14 electrode mounting, 13 exposed area, 16 Faraday cage, 14, 17 galvanic corrosion, 15... - Page 24 734 Louis Drive Warminster, PA 18974 Tel: (215) 682-9330 Redefining Electrochemical Measurement www.gamry.com Part #: 988-00017...

Need help?

Do you have a question about the ParaCell and is the answer not in the manual?

Questions and answers