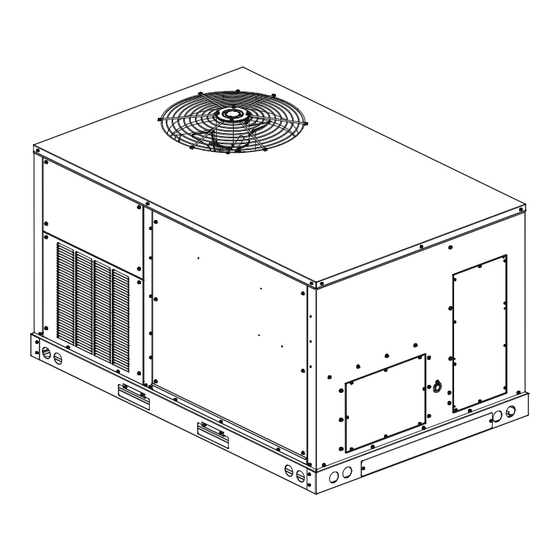

Daikin M Series Installation Instructions Manual

Self-contained package heat pump units

Hide thumbs

Also See for M Series:

- Service and troubleshooting (51 pages) ,

- Installation instructions manual (36 pages) ,

- Service manual (132 pages)

Table of Contents

Advertisement

Quick Links

Installation Instructions

For Self-Contained Package Heat Pump Units

GPHM5 15.2 SEER2 5-Ton "M" Series

Our continuing commitment to quality products may mean a change in specifications without notice.

IOG-3031A

09/2022

Daikin Comfort Technologies Manufacturing, L.P.

© 2022

19001 Kermier Rd. Waller, TX 77484

www.daikincomfort.com

ONLY PERSONNEL THAT HAVE BEEN TRAINED TO INSTALL,

ADJUST, SERVICE, MAINTENANCE OR REPAIR

(HEREINAFTER, "SERVICE") THE EQUIPMENT SPECIFIED

IN THIS MANUAL SHOULD SERVICE THE EQUIPMENT. THE

MANUFACTURER WILL NOT BE RESPONSIBLE FOR ANY

INJURY OR PROPERTY DAMAGE ARISING FROM IMPROPER

SERVICE OR SERVICE PROCEDURES. IF YOU SERVICE

THIS UNIT, YOU ASSUME RESPONSIBILITY FOR ANY INJURY

OR PROPERTY DAMAGE WHICH MAY RESULT. IN ADDITION,

IN JURISDICTIONS THAT REQUIRE ONE OR MORE

LICENSES TO SERVICE THE EQUIPMENT SPECIFIED IN THIS

MANUAL, ONLY LICENSED PERSONNEL SHOULD SERVICE

THE EQUIPMENT. IMPROPER INSTALLATION, ADJUSTMENT,

SERVICING, MAINTENANCE OR REPAIR OF THE EQUIPMENT

SPECIFIED IN THIS MANUAL, OR ATTEMPTING TO INSTALL,

ADJUST, SERVICE OR REPAIR THE EQUIPMENT SPECIFIED

IN THIS MANUAL WITHOUT PROPER TRAINING MAY RESULT

IN PRODUCT DAMAGE, PROPERTY DAMAGE, PERSONAL

INJURY OR DEATH.

DO NOT BYPASS SAFETY DEVICES

RECOGNIZE THIS SYMBOL

AS A SAFETY PRECAUTION.

WARNING

WARNING

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Daikin M Series

- Page 1 DO NOT BYPASS SAFETY DEVICES RECOGNIZE THIS SYMBOL AS A SAFETY PRECAUTION. Our continuing commitment to quality products may mean a change in specifications without notice. Daikin Comfort Technologies Manufacturing, L.P. © 2022 19001 Kermier Rd. Waller, TX 77484 IOG-3031A www.daikincomfort.com...

-

Page 2: Table Of Contents

M a i n t e n a n c e ..........1 5 HOMEOWNER’S SUPPORT Wiring Examples............17 DAIKIN COMFORT TECHNOLOGIES Appendix A Blower Performance Table....18 MANUFACTURING, L.P. Appendix B Electrial Data..........19 19001 KERMIER ROAD Appendix C Unit Dimensions.........20... -

Page 3: Important Safety Instructions

5, 10, 15 and 20kW. Do not connect to or use any device that is not design certified by daikin for use with this The GPHM5 SEER2 M-Series are self-contained packaged unit. Serious property damage, personal injury,... -

Page 4: National Codes

contact the local office of the EPA. reductions. d. Copy of the inspection report issued by carrier National Codes representative at the time damage is reported This product is designed and manufactured to permit to the carrier. The carrier is responsible for installation in accordance with National Codes. -

Page 5: Ground Level Installation

Proper installation of the unit ensures trouble-free Heat Pump Elevation Chart operation. Improper installation can result in problems Design Temperature Suggested Minimum Elevation ranging from noisy operation to property or equipment +15° and above 2 ½” damages, dangerous conditions that could result in injury or personal property damage and that are not covered by -5°... -

Page 6: Clearances

Full perimeter roof curbs are available from the factory Adequate clearance around the unit should be kept for and are shipped unassembled. Field assembly, squaring, safety, service, maintenance, and proper unit operation. A leveling and mounting on the roof structure are the clearance of 48”... -

Page 7: Horizontal Discharge

3. To ensure proper condensate drainage, unit must be installed in a level position. WARNING 4. Consideration should also be given to shade, appearance, and noise. To prevent possible equipment damage, property Install all duct connections on the unit before placing the damage, personal injury or death, the following unit on rooftop. -

Page 8: Rigging Removal

ELECTRICAL WIRING CONDENSER COIL WARNING RETURN HIGH VOLTAGE! EVAPORATOR COIL Disconnect all power before servicing or installing this unit. Multiple power sources may be SUPPLY present. Failure to do so may cause property damage, personal injury or death. COMPRESSOR WARNING Corner and center of gravity locations Note: Unit should be lifted at a point above center HIGH VOLTAGE! - Page 9 NOTE: If supply voltage is 208V, lead on primary of transformer(s) must be moved from the 240V to the 208V tap. Refer to wiring diagram on unit for details. Main power wiring should be sized for the minimum circuit ampacity shown on the unit’s database. Size wires in accordance with the ampacity tables in Article 310 of the National Electrical Code.

-

Page 10: Low Voltage Control Wiring

nuts) to prevent water leakage into building. All required Use #18 AWG solid conductor wire whenever conduit and fittings are to be field supplied. connecting thermostat wires to terminals on sub-base. DO NOT use larger than #18 AWG wire. A transition to #18 AWG wire may be required Supply voltage to roof top unit must not vary by more than 10% of the value indicated on the unit data plate. -

Page 11: Cleaning

Cleaning when the outside ambient rises above 55°F. Due to the fact that drain pans in any air conditioning unit will have some moisture in them, algae and fungus Temporary Heating Or Cooling will grow due to airborne bacteria and spores. Periodic If the unit is to be used for temporary heating or cooling, a cleaning is necessary to prevent this build-up from plugging “Startup, Adjustments, and Checks”... -

Page 12: Air Flow Adjustments

Nameplate Voltage - That voltage assigned to a piece of If an economizer is installed, check the unit operating equipment for the purpose of designating its voltage class balance with the economizer at full outside air and at and for the purpose of defining the minimum and maximum minimum outside air. -

Page 13: Checking Superheat

To obtain the amount of subcooling, subtract 109°F listed on the Design Superheat and Subcooling from 120°F. The difference is 11° subcooling. See the table. specification sheet or technical information manual for the a. If subcooling and superheat are low, adjust TXV design subcooling range for your unit. -

Page 14: Heat Pump Start-Up Procedure

8. Turn the thermostat system switch to “OFF” and If the outdoor ambient is low and the unit operates properly disconnect all power when servicing the unit. in the heating cycle, you may check the pressure cutout operation by blocking off the indoor return air until the unit trips. -

Page 15: Heating Cycle

the heating capacity of the heat pump. This phenomenon is a characteristic of a heat pump. It is a good practice to provide supplementary heat for all heat pump installations in areas where the temperature drops below 45° F. It is also a good practice to provide sufficient supplementary heat to handle the entire heating requirement should there be a component failure of the heat pump, such as a... - Page 16 defrost control board. Troubleshooting the Reversing Valve for 2. Remove jumper from timer pins and jump across test Electrical Failure pins on defrost control board. 1. Place unit into the cooling mode. Test for 24 volts at NOTE: Do not use screwdriver or field the solenoid.

-

Page 17: M A I N T E N A N C

made at least every two months; more often if necessary because of local conditions and usage. Dirty throwaway filters should be discarded and replaced with a new, clean filter. Disposable return air filters are supplied with this unit. See the unit Specification Sheet or Technical Manual for the correct size and part number. -

Page 18: Wiring Examples

Wiring Example Electric Heat Wiring Example... -

Page 19: Appendix A Blower Performance Table

APPENDIX A BLOWER PERFORMANCE TABLES - HEAT PUMP APPENDIX A BLOWER PERFORMANCE TABLES – HEAT PUMP 5 TON HEAT PUMP Standard Static Drive Model: GPHM56041 Horizontal Flow Down Flow External External Speed Static Speed Static SCFM SCFM Pressure Pressure (ESP), in w.c. (ESP), in w.c. - Page 20 APPENDIX B ELECTRICAL DATA Outdoor Fan Optional Powered Optional Model Electrical Compressor Indoor Fan Motor Optional Electric Heat Power Supply Motor Convienience Power Number Rating QTY RLA LRA QTY HP FLA Type HP FLA Part # Outlet FLA Exhaust FLA 44.1/44.1 70.0/70.0 7.2/6.5 51.3/50.6 70.0/70.0...

-

Page 21: Appendix C Unit Dimensions

APPENDIX C UNIT DIMENSIONS 73-3/8" 47-5/8" "A" 74" 48-5/16" Model Dim. "A" 5 Ton Heat Pump 43-1/2" 19-1/2 RETURN 5-5/16 11” X 25” EMBOSS DRAIN 5-7/8 THRU THRU CURB BASE LOCATION SUPPLY UTILITIES 12” X 17” 27-3/4 7-3/8 RETURN 4-1/2 11"... -

Page 22: Appendix D Air Flow For Electric Heat

APPENDIX D AIR FLOW FOR ELECTRIC HEAT HEATER KIT MODEL NUMBER NOMENCLATURE HEATER KIT MINIMUM MAXIMUM UNIT MODEL NUMBER SCFM SCFM 6, 7 EH*-*S05 1500 EH*-*S10 1500 GPHM56041 2500 Electric EH*-*S15 1500 EH*-*S20 1550 Heater Heater Type Staged SCR (modulating) Voltage 208-230/1/60 Single phase 60 Hz... -

Page 23: Wiring Diagram

WIRING DIAGRAMS Wiring is subject to change. Always refer to the wiring diagram on the unit for the most up-to-date wiring. -

Page 24: Start-Up Checklist

START-UP CHECKLIST Residential Package - (Indoor Section) Model Number Serial Number ELECTRICAL Line Voltage (Measure L1 and L2 Voltage) L1 - L2 Secondary Voltage (Measure Transformer Output Voltage) R - C Blower Amps Heat Strip 1 - Amps Heat Strip 2 - Amps BLOWER EXTERNAL STATIC PRESSURE Return Air Static Pressure IN. - Page 25 THIS PAGE INTENTIONALLY LEFT BLANK...

- Page 26 THIS PAGE INTENTIONALLY LEFT BLANK...

- Page 27 THIS PAGE INTENTIONALLY LEFT BLANK...

- Page 28 You can also scan the QR code on the right for the product brand you purchased to be directed to the Product Registration page. Our continuing commitment to quality products may mean a change in specifications without notice. Daikin Comfort Technologies Manufacturing, L.P. © 2022 19001 Kermier Rd. Waller, TX 77484...

Need help?

Do you have a question about the M Series and is the answer not in the manual?

Questions and answers