Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for eta SR Series

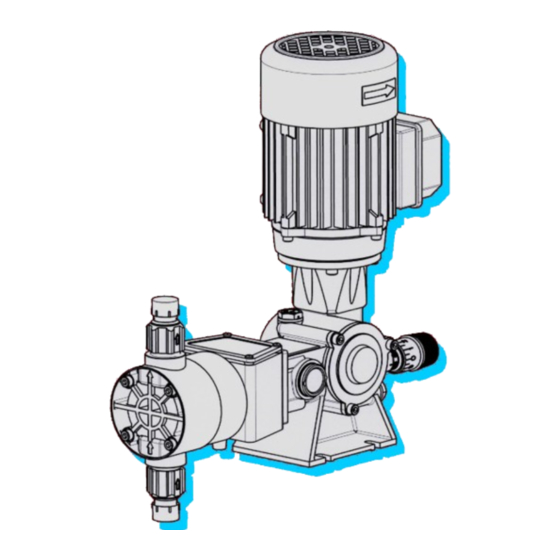

- Page 1 ATTENTION: Industrial machinery for professional use. These instructions are for qualified personnel Translation of the SPRING RETURN WITH original instructions METERING PUMPS SR Series mod. A PLUNGER A 125A A 175A A 125N A 175N A 250N A 350N Reciprocating metering pump...

-

Page 2: Table Of Contents

DOSEURO ® TABLE OF CONTENTS Ref. Title Page PREFACE General prescriptions TECHNICAL DATA Technical data of pump Sound vibration emitted by the pump Material pertinence execution OPERATIONS TO BE PERFORMED ON THE HEAD Periodic check of head Troubleshooting Residual risks HEAD DISASSEMBLY PLUNGER AND SEAL GASKET REPLACEMENT Plunger disassembly and re-assembly "PTFE”... -

Page 3: Preface

A 125A/ A 175° / A 125N/ A 175N/ A 250N/ A 350N. This manual is supplied together with the SR series pumps, model A/ B/ BR / SD / D use and maintenance manual, to be consulted for any further information and which contains the CE declaration of conformity. -

Page 4: Technical Data

DOSEURO ® TECHNICAL DATA Below are the tables with the technical data characteristic of each individual pump model. Technical data of pump ATTENTION! The pressures indicated in the tables must never be exceeded in order to avoid any kind of inconvenience. - Page 5 DOSEURO ® A 175N Characteristic data Model FREQUENCY Hz HEAD VALVE REDUCTION Max press. AISI Att. Ø (1/20) (1/14,5) RATIO bar (kg/cm (1/11) AISI STROKES Type Type G.m. 0.25 0.37 0.25 0.37 min/1' A 175N - 6 1.56 1.7 2.11 2.2 AB 3 AC 3 1/2"...

-

Page 6: Sound Vibration Emitted By The Pump

DOSEURO ® AP-A 175N Characteristic data Model FREQUENCY Hz HEAD VALVE REDUCTION RATIO Max. pressure bar (kg/cm AISI Att. Ø (1/20) (1/14,5) (1/11) AISI STROKES min/1' Type G.m. 0.25 kW 0.37 kW AP-A 175N - 8 AB 3 1/2" AP-A 175N - 12 10.1 12.1 12.6 AB 3 1/2"... -

Page 7: Operations To Be Performed On The Head

DOSEURO ® OPERATIONS TO BE PERFORMED ON THE HEAD Periodic check of the head Failures or malfunctions may occur due to negligence leading to extraordinary maintenance: proceeding with a periodic visual check, as described in the SR REDUCER manual, preventive maintenance chapter. -

Page 8: Troubleshooting

DOSEURO ® TROUBLESHOOTING Inconveniences Causes Solutions Check the motor plate again for 4 – incorrectly connected correct wiring sequence. motor: Check the phases. Inspect valve units. Clean or replace components 5 - dirty pump valves: necessary. 6 - Damaged plunger seal gasket. -

Page 9: Residual Risks

DOSEURO ® Residual risks Any leaks of the pumped liquid from the plunger gaskets, due to wear, must be channelled and collected for disposal. HEAD DISASSEMBLY PLUNGER AND SEAL GASKET REPLACEMENT Before intervening on the metering pump or on the piping, the necessary precautions must be taken so that the pumped product, especially if harmful, does not endanger personnel or the surrounding elements. -

Page 10: Ptfe" Gasket Replacement And Adjustment

DOSEURO ® "PTFE" GASKET REPLACEMENT AND ADJUSTMENT 4.2.1 Replacement of gasket pack (execution head 21) After maintenance, proceed as follows: Disconnect the pumping head 1 from the system and from the lantern on the metering pump. Wash the pumping head so that the operator can safely handle the component. -

Page 11: Routine Maintenance

DOSEURO ® Pumping head washing Connect the piping as per the diagram to wash the gaskets and head. C" The needle valve " must remain open throughout pump operation. After dosing, before stopping the pump, close valve "A", at the same time, open valve "B" and valve "C"... - Page 12 Via G. Carducci, 141 - 20093 Cologno Monzese (Mi) - Italy Tel. +39 0227301324 - Fax. +39 0226700883 http://www.doseuro.com e-mail: info@doseuro.it Cert. No. 5942 ETA Ekipman Teknoloji Ar. Sis. San. Tic. Ltd. Şti. www.etaekipman.com blog.etaekipman.com Tel:0 216 540 99 64 Fax:0 216 540 99 68 XMPE0TMA125SST014...

Need help?

Do you have a question about the SR Series and is the answer not in the manual?

Questions and answers