Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for GAL MOVFE 2500

- Page 1 1 (888) 425-2262 2500 - 3069 2500 - 3069 ELECTRICAL...

- Page 2 Rev.1-10/20...

-

Page 3: Table Of Contents

TABLE OF CONTENTS Foreword Comments & Important Notes Table of Contents OVERVIEW ELECTRICAL COMPONENTS OF VFE25 1. Toggle switches 2. LED Indicators 3. Optical Sensors for Harmonic Model 4. Hall-effect Sensors for Linear Model 5. Inputs 6. Outputs 7. Additional I/O Board 8. - Page 4 Inputs and Outputs Monitoring Faults Counters User List User parameters Motor and Encoder Door parameters Open parameters Digital I/O parameters Direction Communication Maximum Close Speed Maximum Close Force ECI Defaults Harmonic Linear Straight Linear Geared Display Groups Code Distance (CD) Closing Time Display CD Closing Time DCL Time CD Opening Time...

- Page 5 SUPPORTIVE GRAPHS V/F curve for Normal door V/F curve for Heavy door V/F curve for Narrow door DC Injection Stall Reverse detection Frequency Failure detection Infrared Detector Edges detection Edges Timeout relay and Buzzer timing Edges Timeout relay and Buzzer mode Interaction between Re-open and Edges Timeout relay FAULTS LIST FAULTS RESET HANDLING FLOWCHART...

-

Page 6: Overview

OVERVIEW: The general block diagram of the VFE2500 is in the illustration below: INFRARED HALL-EFFECT SENSORS DETECTOR OPTICAL FOR LINEAR OPERATOR EDGES SENSORS (OPTIONAL) HARMONIC SIGNALS TRANSFER OPERATOR SECTION FOR LINEAR OPERATOR TERMINAL INPUTS VFE2500 INDUCTION CAN BUS DRIVE MOTOR KEYPAD RS 485 230VAC... - Page 7 SAFETY STANDARDS: CSA Certified. B44.1/ASME- A17.5 Complies with the following CE and IEEE safety standards of EN61000-4-2, EN61000-4-3 EN61000-4-4, EN61000-4-5, EN61000-4-6, EN61000-4-8, and IEEE STD C62.45-1992 EMC conformity report is available A POWERFUL SYSTEM: 230VAC and 115VAC power supply versions are available Variable voltage, variable frequency (VVVF) drive A ½...

- Page 8 TOGGLE SWITCHES FOR MANUAL TESTING: Toggle switches are provided for manual operation, diagnostics, and operational verification regardless of the control wiring to the elevator controller OVER-TORQUE AND OVER-SPEED DETECTIONS: Over-torque and over-speed detection and restriction are parameterized for easy adjustment to comply with codes PLUG-AND-PLAY INFRARED DETECTOR EDGES: Both NPN and PNP infrared detector edges can be connected directly to the VFE2500...

-

Page 9: Electrical Components Of Vfe25

ELECTRICAL COMPONENTS OF THE VFE2500: 1. Toggle switches: Six toggle switches are provided to run the door operator in manual mode. However, users can also use these switches to troubleshoot and verify the operation. Order Label Meaning Remarks RUN: The RUN position is for normal operation. SETUP: The SETUP position allows users to adjust the optical cams of the Harmonic model, or the hall-effect sensors... -

Page 10: Led Indicators

2. LED indicators: A red LED is provided on each of the input modules (Open, Close, or Nudge). Heavy and Narrow inputs are optional and require an additional I/O board, which will be provided on request to carry out the Heavier and Narrower door functions. Note that if the input signals voltage is 60V or less, the jumpers on each input module must be removed. -

Page 11: Optical Sensors For Harmonic Model

3. Optical Sensors for Harmonic Model: For the harmonic model, there are 4 optical cams to set the final limits, door protection monitor, and an AUX. cam for the narrower door. The Optical cam board, 2500-3056, carries the optical sensors, and the table below describes the functions of those sensors. -

Page 12: Inputs

5. Inputs: Three input modules are provided to receive OPEN, CLOSE, and NUDGE commands from the elevator controller. These universal input modules receive control signals either in form of contacts or signal voltages; from 24-230V AC or DC. Jumpers on the input modules must be removed if the input signal voltage is 60V or less. -

Page 13: Additional I/O Board

7. Additional I/O Board: Additional I/O board, 2500-3055, is optional. If used, this board will be connected to the connector J7 of the main board 2500-3050. The additional features of this board are: Inputs for the Heavier, and Narrower doors. Elevator controller must provide command signals to the Heavy and Narrow inputs to use the functions of the parameters sets of the Heavier and Narrower doors. -

Page 14: Learn Door Width Led

DEFAULT VALUE FOR THE ENCODER DIRECTION OF PAR. 42 LINEAR HARMONIC STRAIGHT GEARED CENTER LEFT RIGHT CENTER LEFT RIGHT LEFT RIGHT CENTER 10. LEARN DOOR WIDTH LED: The “LEARN DOOR WIDTH” LED is an indicator to show the status of the door width learning process. - Page 15 Test the detector edges: - Obstruct the infrared detector edges. The DETECTOR EDGES LED, near the Re-Open relay, should be ON. - The REOPEN relay should be activated to send the REOPEN flag to the elevator controller. - The elevator controller will send the Door Open command signal to the VFE2500 to REOPEN the door. The LED of the Open Input module should be ON.

-

Page 16: Parameter Unit

13. Parameter Unit: Parameter Unit not included, if required part # 2500-3051 The Parameter Unit is a tool that plugs into the VFE2500 drive and permits changing values of relevant parameters. Parameter unit is also needed for door width learning, monitoring, troubleshooting, storing, copying (reading), and downloading (writing) reference sets of parameters, to the VFE2500 drive. - Page 17 15. Motors: ½ HP 3-Phase 230V Induction Motor 91W 3-Phase 230V Induction Motor Two different types of motor are used in the VFE2500 systems. ½ HP 3-Phase 230V induction motor is used for the Harmonic and Heavy Duty Linear models. 91W 3-Phase 230V induction geared motor is used for Light Duty Linear model.

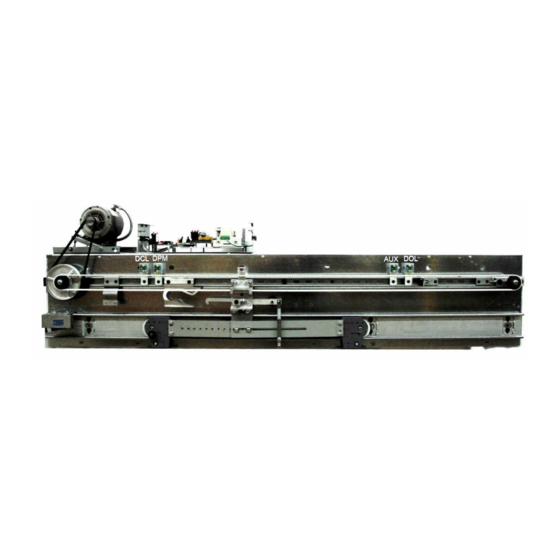

- Page 18 MOVFE2500 Heavy Duty Harmonic Model Parameter Unit not included, if required part # 2500-3051 MOVFE2500 Light Duty Linear Model Parameter Unit not included, if required part # 2500-3051...

-

Page 19: Turn Power On

NITIAL SET TUP: CI has don ne the initia al setup pr rior to shipp ping the VF FE2500 to users. How wever, the ollowing ini tial proced dure is help pful for use ers, if need This initial p procedure i is to assure e the follow... - Page 20 4. Download an GAL default parameter set: Follow steps of the illustration below to download (write) a correct default parameter set to the VFE2500 drive then go to 6.

-

Page 21: Learn The Door Width

. Learn th he door w width: lip the RUN |SETUP swit tch to SETU et Par. 63 = = 1. lip the RUN |SETUP swit tch to RUN. se Manual m mode to run n the door fr rom DOL to DCL, or vic ce versa. -

Page 22: Set The Operation Source

6. Set the operation source: Flip the 1 toggle switch to SETUP. Set par. 11 = 1 for Terminals operation. Set par. 11 = 5 for CAN bus operation. Flip the 1 toggle switch to RUN. Flip the 2 switch to MAN to run the door in manual mode. Flip the 2 switch to AUTO to run the door in automatic mode. -

Page 23: Parameter Unit

PARAMETER UNIT : Parameter Unit not included, if required part # 2500-3051 The Parameter Unit is a tool to assist users in the following tasks: Learning the door widths of the regular door and narrower door. Changing accelerations, decelerations, speeds, torques, and all pertinent parameters of peripheral devices. -

Page 24: Default Parameters

6. DEFAULT PARAMETERS... -

Page 25: Inputs And Outputs Monitoring

7. CONVENIENCE KEYS SPEED Press to display speeds in Hz. Press to display input and output signals. FAULT Press to display recent faults. Press to view all recent faults. Press to display currents. RESET Press to reset the drive. 8. THE VIEW KEY VIEW key will help users navigate through the Parameter Unit seamlessly. -

Page 26: Faults

FAULTS AN EXAMPLE OF FAULTS DISPLAY COUNTERS... - Page 27 USER LIST...

- Page 31 MAXIMUM CLOSE SPEED AND FORCE...

- Page 32 ECI DEFAULT PARAMETER SETS...

-

Page 33: Code Distance (Cd) Closing Time Display

DISPLAY GROUPS FOR MONITORING AND TROUBLESHOOTING CODE DISTANCE CLOSING TIME DISPLAY CAN ANALYZER (AN EXAMPLE) 9. LED INDICATORS There are 7 LEDs on the Parameter Unit. DO, DC, NUD, HLD, PRG, FLT, and OVT. They have the following meanings: DO= Door Open. DC= Door Close. NUDG.=Nudging HLD= Holding. -

Page 34: Speed Profiles Of The Vfe2500

SPEED PROFILES OF THE VFE2500 FOR NORMAL DOOR... -

Page 35: Heavy Door

SPEED PROFILES OF THE MOVFE2500 FOR HEAVY DOOR... - Page 36 SPEED PROFILES OF THE MOVFE2500 FOR NARROW DOOR...

-

Page 37: Narrow Door

HALL EFFECT SENSORS SETTING FOR LINEAR DOOR OPERATOR: Last Magnet Last ½ Inch Use as DOL of the ¼ Inch & ¼ Inch before Narrower door. Magnet Gate Also can be used Carrier Switch as a 2 DOL. When makes not used, set Par. -

Page 38: Parameters List For Users

PARAMETERS LIST FOR USERS GROUP 0 : USER PARAMETERS Par. Description Range Unit Default Setting Display Related Par. Carrier Frequency 0 15 12KHz Carrier Freq. 06: Clear all faults Parameter Reset 0 9999 Parameter Reset 08: Keypad locked Monitor Data 0 65535 0000 Testpoint Sel... -

Page 39: Group 1: Motor & Encoder Parameters

GROUP 1: MOTOR & ENCODER PARAMETERS (CONTINUED) Par. Description Range Unit Default Setting Display Related Par. Enter Single Speed 0: Single Speed Door Speed 1: Two Speed Two Speed Here Read Only Par. This Par. is changed by loading ECI’s defaults. 0: Harmonic, S/O Door Type 1: Harmonic, C/P... - Page 40 GROUP 3: OPEN DIRECTION PARAMETERS Par. Description Range Unit Default Setting Display Related Par. Clutch Engage 0: % CLUTCH Unit Par. 83 Unit 1: pulses Maximum Open 0.00 60Hz Max. Open Spd Speed 400.00 1.2A: Harmonic C/P 1.4A: Harmonic S/O Quick Stop On 2.0A: Linear Straight C/P 0 .0–4.5...

-

Page 41: Group 3: Open Direction Parameters

GROUP 3: OPEN DIRECTION PARAMETERS (CONTINUED) Par. Description Range Unit Default Setting Display Related Par. 95%: Harmonic C/P 95%: Harmonic S/O Final Speed Open 0.0 – 98%: Linear Straight C/P FSO Start Start 98%: Linear Straight S/O 90%: Linear Geared C/P 95%: Linear Geared S/O 6sec: Harmonic C/P 4sec: Harmonic S/O... - Page 42 GROUP 3: OPEN DIRECTION PARAMETERS (CONTINUED) Par. Description Range Unit Default Setting Display Related Par. Heavy 0.00 – Hvy Open HLD Spd Holding Speed 400.00 Heavy 0.0 – Hvy HLD Start Holding Start 5Hz: Harmonic C/P 5Hz: Harmonic S/O Heavy 0.00 –...

- Page 43 GROUP 3: OPEN DIRECTION PARAMETERS (CONTINUED) Par. Description Range Unit Default Setting Display Related Par. 100Hz: Harmonic C/P 100z: Harmonic S/O Heavy 0.00 – 60Hz: Linear Straight C/P Hvy Open Torq. . Open Torque 400.00 60Hz: Linear Straight S/O 60Hz: Linear Geared C/P 80Hz: Linear Geared S/O Heavy 0.0 –...

- Page 44 GROUP 3: OPEN DIRECTION PARAMETERS (CONTINUED) Par. Description Range Unit Default Setting Display Related Par. 7Hz: Harmonic C/P 7Hz: Harmonic S/O Narrow 0.00 – 3Hz: Linear Straight C/P Nar FSO Final Speed Open 400.00 5Hz: Linear Straight S/O 3Hz: Linear Geared C/P 5Hz: Linear Geared S/O 90%: Harmonic C/P 90%: Harmonic S/O...

- Page 45 GROUP 3: OPEN DIRECTION PARAMETERS (CONTINUED) Par. Description Range Unit Default Setting Display Related Par. Narrow DOL 0.0 – 3.0 0.6A Nar. HLD Torque Holding Torque DC Brake 0.00 – 60Hz DC Brake Freq Frequency 400.00 0.0 – DC Brake Time 1.0sec DC Brake Time 999.0...

- Page 46 GROUP 4: CLOSE DIRECTION PARAMETERS Par. Description Range Unit Default Setting Display Related Par. Maximum 0.00 – 30Hz Max. Close Spd Close Speed 400.00 0.6A: Harmonic C/P 0.6A: Harmonic S/O Close 0.6A: Linear Straight C/P 0.0 3.0 Close HLD Torque Holding Torque 0.6A: Linear Straight S/O 0.2A: Linear Geared C/P...

-

Page 47: Group 4: Close Direction Parameters

GROUP 4: CLOSE DIRECTION PARAMETERS (CONTINUED) Par. Description Range Unit Default Setting Display Related Par. 15Hz: Harmonic C/P 9Hz: Harmonic S/O 0.00 – 10Hz: Linear Straight C/P Nudging Speed Nudging Spd 400.00 15Hz: Linear Straight S/O 15Hz: Linear Geared C/P 15Hz: Linear Geared S/O 4sec: Harmonic C/P 6sec: Harmonic S/O... - Page 48 GROUP 4: CLOSE DIRECTION PARAMETERS (CONTINUED) Par. Description Range Unit Default Setting Display Related Par. 3.0%: Harmonic C/P 3.0%: Harmonic S/O Heavy 0.0 – 2.0%: Linear Straight C/P Close Hvy HLD Start 2.0%: Linear Straight S/O Holding Start 2.0%: Linear Geared C/P 2.0%: Linear Geared S/O 220Hz: Harmonic C/P 145Hz: Harmonic S/O...

- Page 49 GROUP 4: CLOSE DIRECTION PARAMETERS (CONTINUED) Par. Description Range Unit Default Setting Display Related Par. 6sec: Harmonic C/P 8sec: Harmonic S/O Heavy 0.1 – 12sec: Linear Straight C/P Close Hvy Clo. Dec. 3600.0 18sec: Linear Straight S/O Deceleration Time 8sec: Linear Geared C/P 2sec: Linear Geared S/O 1.8A: Harmonic C/P 2.2A: Harmonic S/O...

- Page 50 GROUP 4: CLOSE DIRECTION PARAMETERS CONTINUED Par. Description Range Unit Default Setting Display Related Par. 25Hz: Harmonic C/P 19Hz: Harmonic S/O Narrow 0.00 – 25Hz: Linear Straight C/P Nar HSC High Speed Close 400.00 20Hz: Linear Straight S/O 25Hz: Linear Geared C/P 20Hz: Linear Geared S/O 5Hz: Harmonic C/P 5Hz: Harmonic S/O...

-

Page 51: Group 5: Digital I/O Parameters

GROUP 4: CLOSE DIRECTION PARAMETERS (CONTINUED) Par. Description Range Unit Default Setting Display Related Par. Narrow 0.0 – Nar Close Mid. V Close Mid. Volt 100.0 Narrow 0.00 – Close 0.5Hz Nar Close Mid. F 400.00 Mid. Frequency Fast Deceleration 0.1 –... -

Page 52: Group 6: Protection Parameters

GROUP 5: DIGITAL I/O PARAMETERS Par. Description Range Unit Default Setting Display Related Par. 0: Disable Infrared 0 – 2 1: NPN (active LOW) (DF) Infrared Type Output Type 2: PNP (active HIGH) 0: Enable door position reset in DCL. (Default) DCL Reset 0 - 1 DCL Reset... -

Page 53: Group 7: Communication Parameters

Overload Time GROUP 7: COMMUNICATION PARAMETERS Par. Description Range Unit Default Setting Display Related Par. RS485 1 254 Comm Node Addr Node Number 0: Baud rate 4800bps RS485 1: Baud rate 9600bps Comm Data Rate Baudrate 2: Baud rate 19200bps (DF) 3: Baud rate 38400bps 0: 7,N,2 (Modbus, ASCII) 1: 7,E,1 (Modbus, ASCII) - Page 54 DISPLAY PARAMETERS (CONTINUED) Par. Function Display Unit Commanded Frequency Commanded Freq Output Current Output Current Output Voltage Output Voltage DC Bus Voltage DC Bus Voltage Door Close Time Door Close Time Switch Input Status Bit0 0: SETUP 1:RUN Bit1 0:MAN 1:AUTO Bit2 OPEN Bit3 CLOSE SW IN 87654321...

- Page 55 DISPLAY PARAMETERS (CONTINUED) Par. Function Display Unit LED Output Status Bit0 CLOSE Bit1 NUDG Bit2 CLOSE SLOWDOWN Bit3 OPEN Bit4 OPEN SLOWDOWN Bit5 HOLDING LED LDFS87654321 Bit6 ENCODER FAILED Bit7 SENSORS FAILED Bit8 STALL REVERSE Bit9 FREQUENCY FALURE Bit10 DETECTOR EDGES Bit11 LEARN DOOR WIDTH Max.

- Page 56 CONTROLLER NARROW HEAVY NARROW NARROW 6-CONDUCTOR CABLE FOR ENCODER CONNECTION DIAGRAM NARROW HEAVY GAL CANADA HEAVY MISSISSAUGA, ONTARIO NARROW 2 2 CANADA ELEVATOR CONTROLLER MUST TEL: (905) 624-6565 PROVIDE COMMAND SIGNALS TO HEAVY AND/OR NARROW INPUT(S) FAX: (905) 624-4262 TO USE HEAVIER DOOR AND/OR NARROWER DOOR FUNCTION(S).

- Page 57 HEAVY NARROW NARROW 6-CONDUCTOR CABLE FOR ENCODER VFE2500 CLOSED LOOP DOOR OPERATOR CONNECTION DIAGRAM NARROW HEAVY GAL CANADA HEAVY MISSISSAUGA, ONTARIO NARROW 2 2 CANADA ELEVATOR CONTROLLER MUST TEL: (905) 624-6565 PROVIDE COMMAND SIGNALS TO HEAVY AND/OR NARROW INPUT(S) FAX: (905) 624-4262 TO USE HEAVIER DOOR AND/OR NARROWER DOOR FUNCTION(S).

-

Page 58: V/F Curve For Heavy Door

SUPPORTIVE GRAPHS 1. V/F CURVE FOR NORMAL DOOR Vbase Par. 26 Vmid Par. 90 (OPEN) Par. 150 (CLOSE) Vmin Par. 28 OUTPUT FREQUENCY (Hz) Fbase Fmax Fmin Fmid Par. 89 (OPEN) Par. 27 Par. 29 Par. 91 (OPEN) Par. 140 (CLOSE) Par. -

Page 59: Dc Injection

3. V/F CURVE FOR NARROW DOOR Vmax Par. 26 Vmid Par. 118 (OPEN) Par. 180 (CLOSE) Vmin OUTPUT FREQUENCY (Hz) Par. 28 Fmin Fbase Fmax Fmid Par. 29 Par. 117 (OPEN) Par. 27 Par. 119 (OPEN) Par. 181 (CLOSE) Par. 170 (CLOSE) V/F GRAPH FOR NARROW DOOR 4. -

Page 60: Stall Reverse Detection

5. STALL REVERSE DETECTION STALL REVERSE DETECTION Par. 148 TIME RE-OPEN RELAY STALL REVERSE DETECTION 6. FREQUENCY FAILURE DETECTION FREQUENCY FAILURE DETECTION Par. 136 TIME RE-OPEN RELAY FREQUENCY FAILURE DETECTION 7. INFRARED DETECTOR EDGES DETECTION LCSE FROM INFRARED DEACTIVATE ACTIVATE DEACTIVATE DETECTOR EDGES... -

Page 61: Edges Timeout Relay And Buzzer Timing

8. EDGES TIMEOUT RELAY AND BUZZER TIMING LCSE FROM INFRARED DEACTIVATE DEACTIVATE ACTIVATE DETECTOR EDGES EDGES EDGES DELAY HOLD TIME Par. 197 Par. 206 EDGES TIMEOUT RELAY BUZZER DELAY BUZZER Par. 198 EDGES TIMEOUT RELAY AND BUZZER 9. EDGES TIMEOUT RELAY AND BUZZER MODES LCSE FROM INFRARED... - Page 62 10. INTERACTION BETWEEN REOPEN RELAY AND EDGES TIMEOUT RELAY LCSE FROM INFRARED DEACTIVATE DEACTIVATE ACTIVATE DETECTOR EDGES EDGES EDGES DELAY HOLD TIME Par. 197 Par. 206 EDGES TIMEOUT RELAY REOPEN RELAY WITH Par. 207 = 1 REOPEN RELAY & EDGES TIMEOUT RELAY...

-

Page 63: Faults List

FAULTS LIST Fault Auto Drive Meaning Reset Record Reset Condition Display Reset Response Continuous current must be less than 50% of Over current Over current Coast to Stop rated current for 5 seconds 1. Check the wiring connections to U, V, W for possible short circuits. 2. - Page 64 FAULTS LIST (CONTINUED) Fault Auto Drive Meaning Reset Record Reset Condition Display Reset Response Hardware Hardware protection Coast to Stop Failure failure Remedy Return to ECI Fault Auto Drive Meaning Reset Record Reset Condition Display Reset Response Over current Continuous current must be less than 50% of during Coast to Stop at Accel...

- Page 65 FAULTS LIST (CONTINUED) Fault Auto Drive Meaning Reset Record Reset Condition Display Reset Response EEPROM CPU Read Coast to Stop Immediately Read Fail Failure Remedy Return to factory Fault Auto Drive Meaning Reset Record Reset Condition Display Reset Response Parameter CPU WRITE Coast to Stop Immediately...

- Page 66 FAULTS LIST (CONTINUED) Fault Auto Drive Meaning Reset Record Reset Condition Display Reset Response Coast to Stop Encoder Encoder Ramp to Stop Movement direction is in agreement with the Direction Fbk Error Warning & encoder direction defined by the drive. Error Scan Speed 1.

-

Page 67: Faults Reset Handling Flowchart

FAULTS RESET HANDLING FLOWCHART FAULT(S) OCCURED NUMBER OF RETRIES STOP THE DRIVE RECORD A FAULT FINISHED? PAR. 221 = FAULT WAITING FOR FAULT CONDITION CONDITION TO BE REMOVED REMOVED RESET SWITCH WAITING TIME BEFORE RETRY PAR. 222 FAULT RESET PAR. 222 (NEW) = PAR. 222 (OLD) 1 START RESET TIMER RESET TIMER >... -

Page 68: Clutch Engaged Distance Setup

CLUTCH ENGAGED DISTANCE SETUP To set the Clutch Engaged Distance (CED), flip the 1 switch to SETUP. Press the VOLT PULSE key. Physically move the door to the fully closed position. Record the count as Count1. Move the door in the Open direction until the mechanical clutch is fully engaged and the zone lock device is fully cleared. -

Page 69: Door Stall Force Measurement

DOOR STALL FORCE MEASUREMENT The most practical way to measure the approximate magnitude of the door stall force is to use a spring gauge as shown in the picture below. Stall force is the static force to prevent the door from further moving. Stop the door anywhere from one-third to two-thirds of the door travel. -

Page 70: Code Distance Closing Time Setup

CODE DISTANCE CLOSING TIME SETUP (ACTUAL VALUE) To measure the Code Distance Closing Time, flip the 1 switch to SETUP. Press the . Physically move the door to the fully closed position. Record the count as VOLT PULSE Count1. Move the door in the Open direction, away from DCL, 1 inch for Center Parting doors, 2 inches for a Side Opening door. - Page 71 NOTES: MINIMUM CLOSING CODE TIME (ECI REFERENTIAL VALUE) Minimum closing code times are obtainable from the LCD keypad by entering the followings: DOOR TYPE SELECTION (HARMONIC, STRAIGHT LINEAR, OR GEARED LINEAR) ENTER BY ECI DEFAULTS. PAR. 52 (READ ONLY) 0: HARMONIC, S/O 1: HARMONIC, C/P 2: LINEAR STRAIGHT, S/O 3: LINEAR STRAIGHT, C/P...

-

Page 72: Checking Procedure For The Closing Code Times

CHECKING PROCEDURE FOR THE CLOSING CODE TIMES. NARROWER (NORMAL/HEAVY) DOOR (NORMAL/HEAVY) DOOR NARROWER DOOR NUDGING REGULAR SPEED REGULAR CLOSING SPEED NUDGING SPEED DECREASE (HSC) PAR. 141 NORMAL DOOR CHECK AGAIN HEAVIER DOOR D21 < CD CLOSING TIME IN LCD DISPLAY ITEM #10 NORMAL DOOR DECREASE (HEAVY HSC) PAR. - Page 73 INTE RFACING BET TWEEN ECI CE ERTIFIED INF RARED LIGHT T CURTAIN AN ND VFE2500 (OPTIONAL) Unde erstanding th he RE OPEN r elay: The R RE OPEN rela y can be activ vated by any of the follow wing detection Over Torque Controlled b by Par.

-

Page 74: Test The Infrared Detector Edges

Test the Infrared Detector Edges: - Obstruct the Infrared Detector Edges. The DETECTOR EDGES LED should be ON. - The RE-OPEN relay should be activated to send the RE-OPEN signal to the elevator controller. - The elevator controller will send the Door Open command signal back to the VFE- 2500 to OPEN the door. The LED of the Open Input module should be ON. - Page 75 Infra red Detector r Edges conne e ction nfrared Edges trigger OPEN relay IN NSTANTLY INFRARED DETECTOR EDGES E OPEN Signa To E levator Contr roller vator Contro ller sends Do or Open com mmand sign nal to the VFE E2500 to RE O OPEN the doo...

-

Page 76: Infrared Detector Edges Application Flowchart

INFRARED DETECTOR EDGES APPLICATION FLOWCHART MAKING SURE THAT PAR. 197 & PAR. 206 HAVE NON ZERO VALUES. PAR. 207 = 0 FOR THE FOLLOWING PROCEDURE. INFRARED EDGES HARDWARE SELECTION: IF THE INFO OF THE OUTPUT TYPE, NPN OR PNP, OF THE INFRARED EDEGS IS UNOBTAINABLE, SET SW8 TO EITHER NPN OR PNP. - Page 77 HEAV VY DOOR APP PLICATION (O OPTIONAL) In the e same eleva tor, the door operator ma ay operate tw wo different h oist way doo rs with one d door heavier t than the othe r. As a result, , the settings of Torque an nd Speed of o...

-

Page 78: Narrower Door

NARR ROWER DOO OR APPLICATI ON (OPTIONA In the e same eleva tor, the door operator ma ay operate tw wo different h oist way doo rs with one d door narrowe r than the othe r. As a result, , the settings of Torque, Sp peed, and the... -

Page 79: Narrower Door Application Flowchart

NARROWER DOOR APPLICATION FLOWCHART (OPTIONAL) No (PAR. 199 = 1) NARROWER DOOR Yes (PAR. 199 = 0) RETURN TO MAIN DO NOT DETECT AUX SENSOR DETECT AUX SENSOR DOES AUX SENSOR FAIL? AUX (OUT) = AUX (IN) AUX (OUT) = PAR. 65 DOOR COUNT >... -

Page 80: Nudging

GING APPLIC CATION (OPTI IONAL) For t he NUDGING G application, users need to o order an Ad dditional boar rd, 2500 3055 5. The obstru ction of the I nfrared Dete ctor Edges w will trigger the e EDGES TIME E OUT relay a fter a DELAY set by Par. -

Page 81: Nudging Application Flowchart

NUDGING APPLICATION FLOWCHART Note! Nudging application is subject to the Fire Service Codes, if applicable. INFRARED DETECTOR EDGES ARE OBSTRUCTED BUZZER EDGES TIME OUT IS REACHED DELAY TIMER (PAR. 198) DELAY TIMER (PAR. 197) EXPIRED? EXPIRED? DOOR OPEN TURN ON EDGES TIMEOUT INPUT BUZZER PAR. - Page 82 SERIA AL COMMUN NICATION N Bus is cur rrently use ed to comm municate be etween the e elevator cont troller and the VFE25 500. To s setup CAN bus comm unication, Flip the 1 itch to SET TUP. Set Par.15 = 6301 (password). Par.

- Page 83 PART TS LIST The f following part ts can be pur chased from ECI. Note e: ECI reserves s the right to replace any i items in this list at any tim m e without no o tice. Descri iption Picture ECI Part No.

- Page 84 PCB, A Additional I/O O board 2500 3055 Conne ector, Power c connector 2500 3082 (Green n color) Conne ector, 16 posi ition inputs 2500 3081 and ou utputs conne ctor Conn nector, 3 posi ition infrared CN4 , 895-7013 etector edges connector Conne...

- Page 85 Conn ector, 3 pos c connector for 2500 3077 heav vy and narrow w door input IC, Ena able IC 2500 3076 Relay, 24VDC coil v voltage, 2500 2011 10Am p, 250VAC re elay Modu le, Galvanic is solation 2500 1003 encod der module Modu...

- Page 86 Edges, , Janus infrare ed detector 906 3013 edges Edges, , Tritronics in frared 906 3020 detect tor edges Edges , Formula Sys stems infrare 906 3030 detector e edges 80 0...

- Page 87 Cable, , 14 pin ribbo on cable for 2500 3073-1 the ad dditional I/O b board Cabl e, 10 pin ribb bon cable for 2500 3073 he signal trans sfer board Cable e, 7 ft Cable fo or Parameter 2500 2026 Unit Cable, 7 ½...

- Page 88 Motor r, 91W 3 phas se 230VAC 2500 2016 L Geare ed Motor – Le eft hand Motor r, 91W 3 phas se 230VAC 2500 2016 R Geare ed Motor – Rig ght hand Transf former, 500V VA 110/220 2500 2017 Cam, P Plastic Cam 2500 1010...

- Page 89 Manu al, Hard copy y of the 2500 3069 VFE25 500 electrical manual Quick setup brochu 2500 3066 Bracke et, Hall effect t sensor 2500 5019 83 3...

- Page 90 Cover, , Plastic cove r for the 2500 3052 VFE25 500 drive Cover, , Plastic cove r for the 2500 3052-1 VFE25 500 drive 84 4...

- Page 91 Rev 10/20...

Need help?

Do you have a question about the MOVFE 2500 and is the answer not in the manual?

Questions and answers