Subscribe to Our Youtube Channel

Summary of Contents for Weishaupt WL30/1-C Z-1LN-A

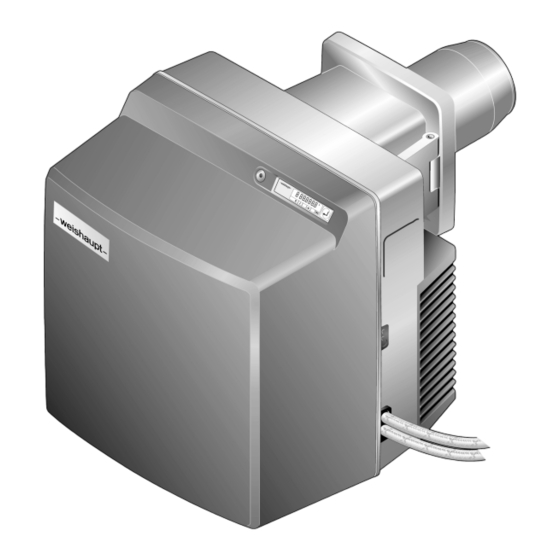

- Page 1 Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 83325802 1/2022-01...

-

Page 2: Table Of Contents

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A User instructions ...................... 5 1.1 Target group ........................ 5 1.2 Symbols .......................... 5 1.3 Guarantee and Liability .................... 6 Safety ............................. 7 2.1 Designated application .................... 7 2.2 Safety measures ...................... 7 2.2.1 Personal protective equipment (PPE) .............. 7 2.2.2 ... - Page 3 Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 6.2.4 Access level ...................... 35 Commissioning ...................... 36 7.1 Prerequisite ......................... 36 7.1.1 Connect measuring devices ................ 37 7.1.2 Set minimum oil pressure switch (optional) .......... 39 7.1.3 Setting values ...................... 40 7.2 ...

- Page 4 Installation and operating instruction Oil burner WL30/1-C Z-1LN-A Project planning ...................... 90 12.1 Oil supply ........................ 90 12.2 Continuous running fan or post-purge ............... 92 12.3 Additional requirements .................. 93 Spares .......................... 94 Notes .......................... 108 Key word index ...................... 109 4-112 83325802 1/2022-01 La...

-

Page 5: User Instructions

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 1 User instructions 1 User instructions This manual forms part of the equipment and must be kept on site. Translation of original Carefully read the manual prior to working on the unit. -

Page 6: Guarantee And Liability

Weishaupt parts, force majeure, unauthorised modifications made to the unit, the installation of additional components, which have not been tested with the... -

Page 7: Safety

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 2 Safety 2 Safety 2.1 Designated application The burner is suitable for operation on heat exchangers to EN 303 and EN 267. If the burner is not used on combustion chambers to EN 303 and EN 267, a safety... -

Page 8: Alterations To The Construction Of The Equipment

Oil burner WL30/1-C Z-1LN-A 2 Safety 2.3 Alterations to the construction of the equipment All conversions require written approval from Max Weishaupt GmbH. No additional components may be fitted, which have not been tested for use with the equipment. Do not use combustion chamber inserts, which hinder flame burnout. -

Page 9: Product Description

Type of control: two stage Mixing head: LowNO Mixing head version 3.2 Type and serial number The type and serial number on the type plate clearly identify the product. They are required by Weishaupt's customer service department. 1 Name plate Type: Ser. No.: 9-112... -

Page 10: Function

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 3 Product description 3.3 Function 3.3.1 Air supply Air damper The air damper regulates the air quantity required for combustion. The combustion manager drives the air damper via actuator. At burner shutdown the air damper closes automatically. -

Page 11: Oil Supply

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 3 Product description 3.3.2 Oil supply Oil pump The pump draws the oil through the supply line and carries it under pressure to the oil nozzle. The pressure regulating valve keeps the oil pressure constant. -

Page 12: Electrical Components

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 3 Product description 3.3.3 Electrical components Combustion Manager The combustion manager W-FM is the control unit of the burner. It controls the sequence of operation and monitors the flame. Operating panel The values and parameters of the combustion manager can be displayed and changed at the operating panel. - Page 13 Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 3 Product description W-FM 25 T1 T2 P11P13 1234 Flame sensor Operating point P0 (ignition position) Temperature or pressure regulator Operating point P1 (stage 1) Temperature or pressure regulator stage 2 Operating point P2 (solenoid valve stage 2) Temperature or pressure limiter Operating point P9 (stage 2)

-

Page 14: Inputs And Outputs

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 3 Product description 3.3.5 Inputs and outputs Observe wiring diagram supplied. TWI interface (VisionBox, accessory) sensor (accessory) Speed signal (Namur) Frequency converter Operating panel Air damper actuator Coded plug (black) Slot for analogue module EM3/3 or fieldbus module EM3/2 W-FM cover Stage 1 solenoid valve (K11) -

Page 15: Technical Data

Installation elevation max 2000 m With the relevant suitable fuel oil and layout of oil supply. Consultation with Weishaupt is required for higher installation elevation. 3.4.4 Fuels Fuel oil EL to DIN 51603-1 Fuel oil EL A Bio 10 to DIN 51603-6 Fuel oil EL to ÖNORM-C1109 (Austria) -

Page 16: Emissions

(temperature and humidity) medium temperature Combustion chamber dimensions, see Weishaupt Partner Portal / Documents and Applications / Online Applications / NO calculation for burners. Sound levels Dual number noise emission values... -

Page 17: Rating

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 3 Product description 3.4.6 Rating Combustion heat rating Combustion heat rating 72 … 300 kW 6.1 … 25.2 kg/h The oil throughput data relates to a calorific value of 11.9 kWh/kg for fuel oil EL. Capacity graph Capacity graph to EN 267. -

Page 18: Dimensions

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 3 Product description 3.4.7 Dimensions Burner 62 mm 420 mm 480 mm 620 mm 1 167 mm without combustion head extension 267 mm with combustion head extension (100 mm) 367 mm with combustion head extension (200 mm) 3.4.8 Weight... -

Page 19: Installation

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 4 Installation 4 Installation 4.1 Installation requirements Burner type and capacity graph Burner and heat exchanger must be matched. Check burner type and burner capacity. Installation location Prior to installation ensure that: sufficient space is available for normal and service position [ch. 3.4.7],... -

Page 20: Selecting A Nozzle

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 4 Installation 4.2 Selecting a nozzle Determine nozzle size. Load distribution The load distribution of the burner is made via a pressure change-over on the oil pump. Generally, stage 1 takes on approx. 65 % of the maximum oil throughput, a different distribution may be necessary. - Page 21 Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 4 Installation Nozzle selection table Different load values are possible due to tolerances. Stage 1 Burner capacity [kW] at pump pressure Nozzle size [gph] 9 bar 10 bar 11 bar 12 bar 1.65...

-

Page 22: Burner Installation

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 4 Installation 4.3 Burner installation Observe health and safety regulations for lifting and carrying loads [ch. 3.4.8]. Remove screws 1. Remove pin 4. Remove burner flange 3 from burner housing. It is possible to install the burner rotated by 180 if space is limited. This requires conversion measures [ch. 4.3.1]. -

Page 23: Rotate Burner By 180° (Optional)

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 4 Installation 4.3.1 Rotate burner by 180° (optional) Mount operating panel 1 on the opposite side of the housing. Mount fixing bracket 3 on the opposite side of the housing. Remove pressure hoses 6. Remove mixing head 4, see [ch. 9.7]. -

Page 24: Installation

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 5 Installation 5 Installation 5.1 Oil supply Observe EN 12514-2, DIN 4755, TRÖI and local regulations. Check conditions for oil pump Suction resistance max 0.4 bar Supply pressure max 2 bar Supply temperature max 60 °C... - Page 25 Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 5 Installation Connect oil supply and observe: do not twist oil hoses avoid mechanical tension consider length of hose required for the service position, do not kink oil hoses (curve radius 1 of 75 mm must be maintained).

-

Page 26: Electrical Connection

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 5 Installation 5.2 Electrical connection Risk of electric shock Working on the device when voltage is applied can lead to electric shock. Isolate the device from the power supply prior to starting any work. - Page 27 Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 5 Installation Separate supply line for burner motor (not with variable speed drive) Observe wiring diagram supplied. Plug supply line for burner motor into connection plug 1 of the contactor. External fuse of separate supply line:...

-

Page 28: Operation

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 6 Operation 6 Operation 6.1 Operating panel [–] Change values [L/A] Air Select air damper actuator [Enter] Reset burner: call up information press for approx. 0.5 seconds: Info level press for approx. 2 seconds: Service level... - Page 29 Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 6 Operation Operating status The exact operating status of the combustion manager can also be displayed. This simplifies determining the cause of a fault during troubleshooting [ch. 11.1]. Press and hold [–] and [+] simultaneously for approx. 3 seconds.

-

Page 30: Display

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 6 Operation 6.2 Display The display shows the current operating statuses and operating data. 1 Setting level activated 2 Start phase activated 3 Info level activated 4 Actuator runs CLOSED 5 Actuator runs OPEN... -

Page 31: Info Level

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 6 Operation 6.2.1 Info level Burner data can be interrogated in the Info level . Press [Enter] for approx. 0.5 seconds. The Info level is activated. Press [Enter] to reach the next information. -

Page 32: Service Level

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 6 Operation 6.2.2 Service level The service level gives information about: Actuator position of the individual operating points, the most recent fault, flame signal during burner operation. Press [Enter] for approx. 2 seconds. -

Page 33: Parameter Level

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 6 Operation 6.2.3 Parameter level The parameter level can only be called up in Standby (OFF) mode. Press [+] and [Enter] keys simultaneously for approx. 2 seconds. The parameter level is activated. - Page 34 Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 6 Operation Pno. Parameters Setting range Factory setting Display mode 0: E-parameter is not activated in the access level 1: E-parameter is activated in the access level Settings 2 and 3 are required for O trim, see supplementary sheet "O...

-

Page 35: Access Level

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 6 Operation 6.2.4 Access level In the access level, the configuration can be adapted relative to the burner type or version. In the parameter level, the display mode must be configured to 1, to enable access to parameters E0 … E4. -

Page 36: Commissioning

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 7 Commissioning 7 Commissioning 7.1 Prerequisite Commissioning must only be carried out by qualified personnel. Only correctly carried out commissioning ensures the operational safety. Do not operate the burner outside of the capacity graph [ch. 3.4.6]. -

Page 37: Connect Measuring Devices

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 7 Commissioning 7.1.1 Connect measuring devices Pressure measuring device for mixing pressure Open pressure test point for mixing pressure 1 and connect pressure measur- ing device. Oil pressure measuring devices on oil pump Vacuum gauge for suction resistance/supply pressure. - Page 38 Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 7 Commissioning Measuring device for sensor current (continuous operation only) Disconnect plug coupling on flame sensor LFS1. Connect current measuring device 1 in series. Flame signal flame sensor LFS1/RAR9 Extraneous light detection from 6.5 μA...

-

Page 39: Set Minimum Oil Pressure Switch (Optional)

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 7 Commissioning 7.1.2 Set minimum oil pressure switch (optional) Depending on the burner application, optional equipment may be required for op- timum operation [ch. 12.3]. Remove end cap. Set minimum oil pressure switch to 8 bar using the setting screw. -

Page 40: Setting Values

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 7 Commissioning 7.1.3 Setting values Set mixing head relative to the combustion heat rating required. For this, the dif- fuser setting and the air damper setting should be matched. Determine diffuser setting and air damper setting Do not operate the burner outside of the capacity graph [ch. 3.4.6]. - Page 41 Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 7 Commissioning Air damper default settings 1 Combustion heat rating [kW] 3 Stage 1 2 Air damper setting [°] 4 Stage 2 Set diffuser With dimension X = 0mm the indicating bolt is flush with nozzle assembly cover.

-

Page 42: Adjusting The Burner

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 7 Commissioning 7.2 Adjusting the burner 7.2.1 Burner without variable speed drive Risk of electric shock Touching the ignition device can lead to electric shock. Do not touch ignition device during the ignition process. - Page 43 Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 7 Commissioning Preset P1 Press [+] key. Factory setting operating point P1 (stage 1) is displayed. Press and hold [L/A] key and set air damper setting determined using the [–] or [+] key [ch. 7.1.3]. Preset P0 Press [+] key.

- Page 44 Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 7 Commissioning 2. Adjusting the operating points Open oil shut off devices. If a controlled shutdown or lockout occurs during setting: Briefly press [G] and [L/A] keys simultaneously. Press [+] key. Combustion manager changes to setting level.

- Page 45 Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 7 Commissioning Set pump pressure for stage 2 The pump pressure must be set according to the nozzle selected [ch. 4.2]. Check pump pressure at pressure gauge. Set pressure using pressure regulating screw 1: increase pressure: clockwise rotation, decrease pressure: anticlockwise rotation.

- Page 46 Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 7 Commissioning Adjust P0 Press [-] key. Burner drives to operating point P0 (ignition position). Press and hold [L/A] key and set P0 to the same value as P1 using the [-] or [+] key.

- Page 47 Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 7 Commissioning Adjust P2 and P3 Press [+] key. Switch off point stage 2 when running closed (P2) is displayed. Set switch off point stage 2 when running closed (P2) to approx. 1/3 of the setting movement between P1 and P9.

-

Page 48: Burner With Variable Speed Drive (Optional)

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 7 Commissioning 7.2.2 Burner with variable speed drive (optional) Risk of electric shock Touching the ignition device can lead to electric shock. Do not touch ignition device during the ignition process. DANGER During commissioning check: suction resistance or flow pressure of oil pump [ch. 5.1],... - Page 49 Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 7 Commissioning Preset P1 Press [+] key. Factory setting operating point P1 (stage 1) is displayed. Press and hold [L/A] key and set air damper setting determined using the [–] or [+] key [ch. 7.1.3]. Press [Enter] and [L/A] simultaneously.

- Page 50 Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 7 Commissioning Preset P2 and P3 Press [+] key. Factory setting operating point P2 (switch off point stage 2 when running closed) is displayed. Press and hold [L/A] key and set P2 approx. 3 … 8° above P1 using the [–] or [+] key.

- Page 51 Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 7 Commissioning 2. Adjusting the operating points Open oil shut off devices. If a controlled shutdown or lockout occurs during setting: Briefly press [G] and [L/A] keys simultaneously. Press [+] key. Combustion manager changes to setting level.

- Page 52 Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 7 Commissioning Set pump pressure for stage 1 The pump pressure must be set according to the nozzle selected [ch. 4.2]. Check pump pressure at pressure gauge. Set pressure using pressure regulating screw 1: increase pressure: clockwise rotation, decrease pressure: anticlockwise rotation.

- Page 53 Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 7 Commissioning Adjust P9 Select speed at full load as low as possible, but not less than 80 %. In doing so: - observe flame stability, - maintain mixing pressure required [ch. 7.1.3].

- Page 54 Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 7 Commissioning Adjust P0 The ignition speed should be 100 %. Press [-] key. Burner drives to operating point P0 (ignition position). Check mixing pressure The mixing pressure in ignition position must be between 3.0 5.0 mbar.

- Page 55 Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 7 Commissioning Adjust P2 and P3 A speed of 100% is recommended at the switch-off and switch-on point of stage 2. Press [+] key. Switch off point stage 2 when running closed (P2) is displayed.

- Page 56 Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 7 Commissioning 3. Check start behaviour and on/off switch points Switch off and restart burner. Check start behaviour Check on and off switch point stage 2: excess air phase (CO content) prior to switch over must not be too long, flame must not fail.

-

Page 57: Set Air Pressure Switch (Optional)

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 7 Commissioning 7.3 Set air pressure switch (optional) Depending on the burner application, optional equipment may be required for op- timum operation [ch. 12.3]. The switch point must be checked and if necessary adjusted during commission- ing. -

Page 58: Concluding Work

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 7 Commissioning 7.4 Concluding work Oil leakage from oil pressure measuring devices due to constant load Oil pressure measuring devices could be damaged and cause environmental pollu- tion through leakage. NOTICE Remove oil measuring devices once commissioning is complete. -

Page 59: Check Combustion

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 7 Commissioning 7.5 Check combustion Determine excess air Slowly close air damper(s) in the relevant operating point, until the combustion limit is reached (soot number approx. 1). Measure and document O content. -

Page 60: Subsequent Optimisation Of Operating Points

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 7 Commissioning 7.6 Subsequent optimisation of operating points If necessary, the combustion values can subsequently be corrected. Unplug bridging plug No. 7 on combustion manager. Combustion manager drives to Standby. Briefly press [–] and [+] simultaneously. -

Page 61: Shutdown

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 8 Shutdown 8 Shutdown For breaks in operation: Switch off burner. Close fuel shut off devices. 61-112 83325802 1/2022-01 La... -

Page 62: Servicing

The design lifespan of the components is listed in the service plan [ch. 9.2]. Weishaupt recommends a service contract is entered into to ensure regular in- spections. - Page 63 Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 9 Servicing Following servicing Risk of electric shock Touching the ignition device can lead to electric shock. Do not touch ignition device during the ignition process. DANGER Check tightness of oil carrying components.

-

Page 64: Service Plan

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 9 Servicing 9.2 Service plan Components Criteria / design lifespan Service procedure Fan wheel Soiling Clean Damage Replace Air duct Soiling Clean Air damper Soiling Clean Air pressure switch Switch point Check 250 000 burner starts or 10 years... -

Page 65: Hinge Open The Burner

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 9 Servicing 9.3 Hinge open the burner Observe notes on servicing [ch. 9.1]. Without combustion head extension Remove screws 1. Hinge open the burner. With combustion head extension Remove mixing head [ch. 9.7]. Remove screws 1. -

Page 66: Replace Nozzle

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 9 Servicing 9.4 Replace nozzle Observe notes on servicing [ch. 9.1]. Do not clean nozzles, always fit new nozzles. Hinge open the burner [ch. 9.3]. Unplug ignition cable 4. Undo screw 1 and remove diffuser. -

Page 67: Removing And Refitting Nozzle Shut Off

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 9 Servicing 9.5 Removing and refitting nozzle shut off Observe notes on servicing [ch. 9.1]. Removing Remove nozzle [ch. 9.4]. Counter-hold the nozzle assembly 4 using a spanner and remove nozzle holder Remove valve piston 2 and compression spring 3 using a suitable tool (e. g. -

Page 68: Removing The Mixing Head

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 9 Servicing 9.7 Removing the mixing head Observe notes on servicing [ch. 9.1]. Remove flame sensor QRB4 4 or flame sensor RAR9 (optional). Unplug ignition cable 1. Remove pressure hoses 3. Undo screws 2. Turn mixing head to the left up to the recess and remove. -

Page 69: Set Mixing Head

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 9 Servicing 9.8 Set mixing head Observe notes on servicing [ch. 9.1]. Set nozzle distance Hinge open the burner [ch. 9.3]. Insert setting gauge and check dimension A (4 … 5 mm). If the value measured deviates from dimension A: Undo screw 1. -

Page 70: Service Position

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 9 Servicing 9.9 Service position Observe notes on servicing [ch. 9.1]. Remove mixing head [ch. 9.7]. Unplug plug 4 from ignition unit. Remove cover 2 and remove plugs. Remove support 3 for oil hoses. Hold housing cover and remove screws 1. -

Page 71: Removing And Refitting Oil Pump

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 9 Servicing 9.10 Removing and refitting oil pump Observe notes on servicing [ch. 9.1]. Removing Close fuel shut off devices. Unplug plug 1. Remove oil hoses 5 and pressure hoses 4. Undo screws 2 and remove oil pump. -

Page 72: Removing And Refitting Fan Wheel

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 9 Servicing 9.11 Removing and refitting fan wheel Observe notes on servicing [ch. 9.1]. Removing Place housing cover into service position [ch. 9.9]. Remove grub screw 1 and remove fan wheel. Refitting Refit fan wheel in reverse order and ensure correct alignment of the spring washer 2,... -

Page 73: Removing And Refitting Oil Pump Filter

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 9 Servicing 9.13 Removing and refitting oil pump filter Observe notes on servicing [ch. 9.1]. Removing Close fuel shut off devices. Remove bolts 1. Remove pump cover. Replace filter 3 and gasket 2. -

Page 74: Removing And Refitting Air Damper Actuator

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 9 Servicing 9.14 Removing and refitting air damper actuator Observe notes on servicing [ch. 9.1]. Removing Remove actuator plug 4 from combustion manager. Remove screws 5. Remove actuator with fixing plate 3 and shaft 2. Refitting Damage to the actuator caused by turning the hub Actuator could be damaged. -

Page 75: Removing And Refitting Angle Drive

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 9 Servicing 9.15 Removing and refitting angle drive Observe notes on servicing [ch. 9.1]. Removing Remove air damper actuator [ch. 9.14]. Remove screws 2. Remove angle drive. Refitting Turn shaft 1 to its stop (air damper Open) and hold. -

Page 76: Replacing The Combustion Manager

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 9 Servicing 9.16 Replacing the combustion manager Observe notes on servicing [ch. 9.1]. Unplug all plugs. Undo screws 1. Push combustion manager upwards and replace. Connect all plugs again. Preset combustion manager Unplug bridging plug No. 7 on combustion manager. - Page 77 Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 9 Servicing Press [+]. Setting level (parameter E0) is displayed. Adopt value 0 (single fuel burner), if necessary adjust using [ENTER] and [-] key. Press [+]. E1 is displayed. The value of parameter E1 can not be altered.

- Page 78 Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 9 Servicing Adopt value 0 (no ignition delay), if necessary set using [Enter] and [-]. Press [+]. Combustion manager changes into the setting level for step points. Determine the operating points from the sticker 1.

-

Page 79: Replacing The Fuse

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 9 Servicing 9.17 Replacing the fuse Observe notes on servicing [ch. 9.1]. Unplug connection plug from combustion manager. Replace fuse (T6,3H, IEC 127-2/5). 1 Replacement fuse 9.18 Set flame senor RAR9 (optional) Only in conjunction with continuous operation. -

Page 80: Troubleshooting

Top up water. changer has triggered Reset low water safety interlock on heat exchanger. Notify your heating contractor or Weishaupt Customer Service if the problem occurs repeatedly. 10.1.2 Display OFF The following faults may be corrected by the operator: Fault... -

Page 81: Display Flashes

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 10 Troubleshooting 10.1.3 Display flashes A burner fault has occurred. The burner is in lockout. The error code is displayed flashing. Read error code, e. g. A7h. Rectify cause of fault [ch. 10.2]. -

Page 82: Detailed Fault Codes

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 10 Troubleshooting 10.1.4 Detailed fault codes Additional information, which breaks down the error in more detail, can be dis- played by pressing a button. The first detailed fault code and the second detailed fault code are only relevant for... -

Page 83: Rectifying Faults

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 10 Troubleshooting 10.2 Rectifying faults The following faults must only be rectified by qualified personnel: Fault codes Cause Rectification 01h … 02h Internal unit fault Interrupt the voltage supply temporarily Reset the burner, if fault reoccurs replace the 05h …... - Page 84 Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 10 Troubleshooting The following faults must only be rectified by qualified personnel: Fault codes Cause Rectification Switch off via PC Software – Second detailed fault code: A1h Check Bus address Invalid Bus address...

- Page 85 Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 10 Troubleshooting The following faults must only be rectified by qualified personnel: Fault codes Cause Rectification Tolerance fault actuator Check freedom of movement of air damper and / or angle drive Replace actuator [ch. 9.14]...

- Page 86 Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 10 Troubleshooting The following faults must only be rectified by qualified personnel: Fault codes Cause Rectification Switch contact of air pressure switch not in Check air pressure influences Standby Check air pressure switch setting...

-

Page 87: Operating Problems

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 10 Troubleshooting 10.3 Operating problems The following faults must only be rectified by qualified personnel: Observation Cause Rectification Poor start behaviour of burner Mixing pressure too high Correct mixing pressure in ignition... -

Page 88: Technical Documentation

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 11 Technical documentation 11 Technical documentation 11.1 Program sequence The exact operating status of the combustion manager can also be displayed. Ac- tivate operating status [ch. 6]. Operating phase Operating status Condition / function Fault present F .. -

Page 89: Conversion Table Unit Of Pressure

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 11 Technical documentation 11.2 Conversion table unit of pressure Pascal 0.1 mbar 0.01 0.00001 1 mbar 0.0001 10 mbar 1 000 0.001 100 mbar 10 000 0.01 1 bar 100 000 1 000... -

Page 90: Project Planning

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 12 Project planning 12 Project planning 12.1 Oil supply Observe EN 12514-2, DIN 4755, TRÖI and local regulations. General information relating to the oil supply Do not use cathode protection system with steel tanks. - Page 91 Two pipe system In a two pipe system the oil pump is vented automatically. Ring main operation Weishaupt recommends the use of a ring main when operating several burners. 91-112 83325802 1/2022-01 La...

-

Page 92: Continuous Running Fan Or Post-Purge

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 12 Project planning 12.2 Continuous running fan or post-purge Fire hazard due to failure of the combustion air fan Failure of the combustion air fan (e.g. due to a power failure or defective motor) -

Page 93: Additional Requirements

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 12 Project planning 12.3 Additional requirements Additional requirements for burners for liquid and gaseous fuels to EN 267: the pressure equipment operates in accordance with the Pressure Equipment Directive 2014/68/EU, as components of industrial thermal process plants in accordance with EN 746-2,... -

Page 94: Spares

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 13 Spares 13 Spares 1.01 1.22 1.21 1.23 1.25** 1.16 1.24 1.18 1.02 1.26** 1.15 1.17 1.18 1.23 1.19 1.20 1.18 1.10 1.11 1.05 1.03 1.12 1.09 1.07 1.10 1.08 1.13 1.04 1.05... - Page 95 Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 13 Spares Pos. Description Order No. 1.01 Cover 241 310 01 112 1.02 Screw M8 x 16 DIN 7991 404 412 1.03 Burner housing 241 310 01 017 1.04 Intake housing complete 241 310 01 082 –...

- Page 96 Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 13 Spares Burner without variable speed drive 2.09 2.08 2.10 2.07 2.05 2.11 2.15 2.13 2.23* 2.12 2.24* 2.18 2.20* 2.22* 2.17 2.06 2.03 2.16 2.02 2.14 2.21* 2.19* 2.23* 2.01 2.04...

- Page 97 Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 13 Spares Pos. Description Order No. 2.01 Motor ECK05/A-2 230 V / 50 Hz 240 310 07 032 2.02 Screw M8 x 20 DIN 912 402 511 2.03 Shaft key 4 x 5 DIN 6888 490 154 2.04...

- Page 98 Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 13 Spares Burner with variable speed drive 3.09 3.08 3.10 3.07 3.05 3.11 3.15 3.13 3.12 3.18 3.17 3.06 3.03 3.16 3.02 3.04 3.14 3.01 3.19 3.20 98-112 83325802 1/2022-01 La...

- Page 99 Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 13 Spares Pos. Description Order No. 3.01 Motor DK05/A-2 3~ 230 V / 50 Hz 230 310 07 032 3.02 Screw M8 x 20 DIN 912 402 511 3.03 Shaft key 4 x 5 DIN 6888 490 154 3.04...

- Page 100 Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 13 Spares 4.10 4.10 4.02 4.01 4.08 4.09 4.05 4.07 4.06 4.05 4.03 4.04 4.03 4.11* 4.23* 4.19* 4.21* 4.23* 4.22* 4.12* 4.22* 4.21* 4.22* 4.20* 4.13* 4.10* 4.22* 4.23* 4.14* 4.15* 4.19*...

- Page 101 Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 13 Spares Pos. Description Order No. 4.01 Pump AT2V55CK 9605 4P0700 601 866 – Solenoid coil T80 Suntec 220-240 V 50-60 Hz 604 495 – Filter set with cover seal 601 107 4.02...

- Page 102 Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 13 Spares 5.08 5.06 5.07 5.04 5.05 5.09 5.01 5.10 5.02 5.03 5.12 5.11 5.15 5.17 5.14 5.13 5.16 5.20 5.20 5.18 5.21 5.22 5.26 5.19 5.28 5.25 5.24 5.27 5.30 5.31 5.29...

- Page 103 5.01 Diffuser WL30/1-C Z-1LN-A 241 310 14 232 5.02 Aperture WL30/1-C Z-1LN-A 241 310 14 237 5.03 Ignition electrode holder WL30/1-C Z-1LN-A 241 310 14 222 5.04 Screw M4 x 6 Torx-Plus 20IP 409 226 or 409362 5.05 Ignition electrode 241 300 10 187 5.06...

- Page 104 Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 13 Spares 5.08 5.06 5.07 5.04 5.05 5.09 5.01 5.10 5.02 5.03 5.12 5.11 5.15 5.17 5.14 5.13 5.16 5.20 5.20 5.18 5.21 5.22 5.26 5.19 5.28 5.25 5.24 5.27 5.30 5.31 5.29...

- Page 105 Oil burner WL30/1-C Z-1LN-A 13 Spares Pos. Description Order No. 5.16 Nozzle assembly complete WL30/1-C Z-1LN-A – Standard 241 310 10 010 – extended by 100 mm* 240 310 10 070 – extended by 200 mm* 240 310 10 080 5.17...

- Page 106 Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 13 Spares 6.18 6.19 6.03 6.01 6.16 6.17 6.08 6.22* 6.07 6.21* 6.02 6.04 6.05 6.20* 6.06 6.09 6.11 6.10 6.12 6.14 6.13 6.15 6.24*** 6.25*** 6.23** 6.26**** 106-112 83325802 1/2022-01 La...

- Page 107 Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 13 Spares Pos. Description Order No. 6.01 Combustion manager W-FM 25 / 230 V – intermittent operation without O trim 600 487 – intermittent operation with O2 trim 600 491 – Continuous operation / O...

-

Page 108: Notes

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 14 Notes 14 Notes 108-112 83325802 1/2022-01 La... -

Page 109: Key Word Index

Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 15 Key word index 15 Key word index Disposal .................. 8 Drilling diagram.............. 19 Access level .............. 29, 35 Ducted air intake ............ 7, 17 Actuator................. 74 Adjustment ................ 60 Air damper ............. 10, 40, 74 Air damper setting .............. 41... - Page 110 Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 15 Key word index Indicating bolt .............. 41, 69 Info key .................. 28 Pa.................... 89 Info level ................ 31 Parameter level .............. 33 Initialisation time .............. 13 Pascal .................. 89 Inputs .................. 14 Personal protective equipment .......... 7 Installation................ 19 Post-purge time.............. 13...

- Page 111 Installation and operating instruction Oil burner WL30/1-C Z-1LN-A 15 Key word index Stage 2................ 11, 41 Standards ................ 15 Starts .................. 31 Sticker ................... 78 Storage.................. 15 Suction resistance ............ 24, 90 Supply.................. 24 Supply pressure ........... 24, 37, 90 Supply temperature ............ 24 Temperature ................. 15 Transport................ 15...

- Page 112 Max Weishaupt GmbH · 88475 Schwendi Weishaupt close by? Addresses, telephone numbers etc. can be found at www.weishaupt.de We reserve the right to make changes. All rights reserved. The complete program: Reliable technology and prompt, professional service W Burners up to 700 kW...

Need help?

Do you have a question about the WL30/1-C Z-1LN-A and is the answer not in the manual?

Questions and answers