Summary of Contents for DeZurik KGC-MC

- Page 1 DeZURIK KGC-MC METAL CUTTING KNIFE GATE VALVES D11060 Instruction November 2020 DeZURIK, Inc. Sartell, Minnesota USA | Phone: 320-259-2000 | www.dezurik.com | info@dezurik.com...

- Page 2 Safety label(s) on the product indicate hazards that can cause injury or death. If a safety label becomes difficult to see or read, or if a label has been removed, please contact DeZURIK for replacement label(s). Personnel involved in the installation or maintenance of valves should be constantly alert to potential emission of pipeline material and take appropriate safety precautions.

-

Page 3: Table Of Contents

DeZURIK KGC-MC METAL CUTTING KNIFE GATE VALVES Table of Contents Description ................................... 4 Handling ..................................4 Installation ..................................6 Cyclone or Gravity (Dry) Service Installations ................... 6 Other Installations ............................. 6 General Guidelines ........................... 6 Operation ..................................7 Lubrication ................................... 7 Packing.................................. -

Page 4: Description

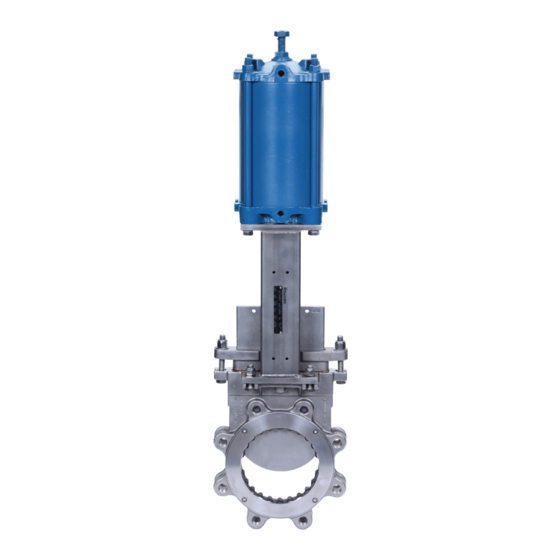

DeZURIK KGC-MC METAL CUTTING KNIFE GATE VALVES Description KGC-MC metal cutting knife gate valves have a stainless steel body and gate, and an all-metal or metal/resilient seat. The KGC-MC metal cutting knife gate valve is available in 3-24" sizes. Handling WARNING! A potential hazard exists with handling valves. - Page 5 DeZURIK KGC-MC METAL CUTTING KNIFE GATE VALVES Handling continued Suggested lifting option is as shown below to lift valve assemblies that are in a vertical orientation. For valves with pneumatic cylinder actuators, wrap slings around the top of each leg. Use caution to not bump, dent or damage the cylinder tube and avoid any side load on the cylinder piston rod.

-

Page 6: Installation

DeZURIK KGC-MC METAL CUTTING KNIFE GATE VALVES Installation Install the valve between ASME Class 125 or Class 150 pipeline flanges, or other flanges that match valve end connection. Flange gaskets are required. Before installation, remove foreign material such as weld spatter, oil, grease, and dirt from the valve and pipeline. -

Page 7: Operation

DeZURIK KGC-MC METAL CUTTING KNIFE GATE VALVES Installation continued Note: The packing gland is slightly loosened prior to shipping. This is done to increase the life of the packing during extended storage. After installing the valve, pressurize pipeline and ensure the packing is not leaking. If the packing leaks, adjust the packing as described below. -

Page 8: Drawings

DeZURIK KGC-MC METAL CUTTING KNIFE GATE VALVES Drawings Figure 4 - Component Identification D11060 Page 8 November 2020... -

Page 9: Packing Replacement

DeZURIK KGC-MC METAL CUTTING KNIFE GATE VALVES Packing Replacement Removing the Old Packing WARNING! Pipeline pressure can cause personal injury or equipment damage. Relieve pipe- line pressure before removing gate stem and packing gland nuts. 1. Relieve the pressure in the pipeline and close the valve. -

Page 10: Installing The New Packing

DeZURIK KGC-MC METAL CUTTING KNIFE GATE VALVES Installing the New Packing Table B: Packing Rings and Scraper Rings The CW2 packing option scraper ring Length and Quantity (A2) and packing (A8) ring length and quantity are shown in Table B. -

Page 11: Reassembling Valve

DeZURIK KGC-MC METAL CUTTING KNIFE GATE VALVES Reassembling Valve 1. Replace the packing gland (A4), screws (A5), washer (A6) and nuts (A7). Tighten the nuts evenly and finger tight, plus 1/2 turn. 2. Reconnect the stem to the gate with the two screws and nuts. -

Page 12: Reassembling The Valve

3. Pressurize the pipeline and inspect the valve for leaks. Replacing the Gate Note: If the gate is for a KGC-MC metal cutting valve with a pneumatic cylinder actuator, the clip and gate are match drilled to handle high frequency cycling. In this case, refer to the Replacing the Clip section and drill out the gate holes that align with the clip. -

Page 13: Replacing The Clip

Replacing the Clip For KGC-MC metal cutting valves with a pneumatic cylinder actuator, the clip and gate are match drilled to handle high frequency cycling. If the clip needs to be replaced, the following steps would be necessary to achieve a proper fit between the clip, gate and shoulder bolts: 1. -

Page 14: Purge Port Option

DeZURIK KGC-MC METAL CUTTING KNIFE GATE VALVES Replacing the Clip continued 8. Thread the clip into the pneumatic actuator’s piston rod up to the jam nut but also ensure that the clip opening lines up to the gate. 9. Extend the actuator to the gate, align the clip and gate holes and install the shoulder bolts. Tighten the nuts onto the shoulder bolts and tighten the jam nut. - Page 15 DeZURIK KGC-MC METAL CUTTING KNIFE GATE VALVES Purge Port Options continued VALVE SIZE Purge Port INCHES 1/4” 3/8” 1/2” 3/4” Figure 8 - Purge Port Sizes and Locations November 2020 Page 15 D11060...

-

Page 16: Troubleshooting

DeZURIK KGC-MC METAL CUTTING KNIFE GATE VALVES Troubleshooting Condition Possible Causes Corrective Action Packing leaks, with no evidence of Packing is loose Adjust packing gland galling on gate Packing is worn or torn Replace packing Packing leaks and gate is galled... - Page 17 If you use metric fasteners with ASME Class 150/300 bolt holes and flange bolt patterns, you do so at your sole risk and any liability associated with such use shall not be the responsibility of DeZURIK, Inc. In addition to the foregoing, DeZURIK’s Manufacturer’s Conditions apply.

Need help?

Do you have a question about the KGC-MC and is the answer not in the manual?

Questions and answers