Table of Contents

Advertisement

Quick Links

Operation, Installation & Maintenance Manual

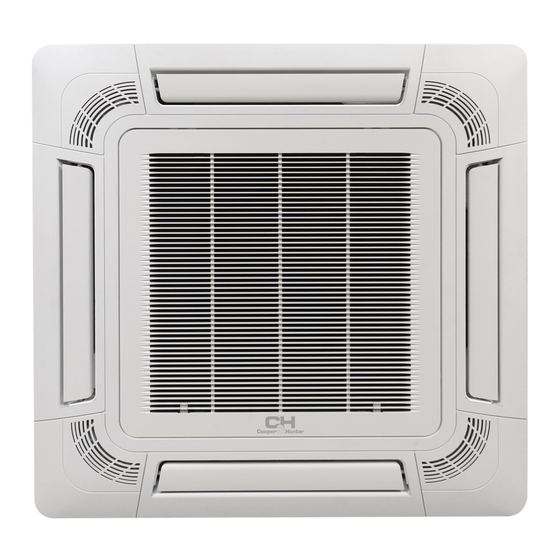

4-WAY CASSETTE TYPE

THANK YOU FOR PURCHASING

THIS CENTRAL AIR CONDITIONER.

PLEASE READ AND UNDERSTAND

THIS MANUAL BEFORE USING THE

AIR CONDITIONER. KEEP THIS

MANUAL FOR FUTURE

REFERENCE.

CHV-09SCC4W

CHV-12SCC4W

CHV-15SCC4W

CHV-19SCC4W

CHV-22SCC4W

CHV-24SCC4W

CHV-27SCC4W

CHV-30SCC4W

CHV-38SCC4W

CHV-48SCC4W

CHV-54SCC4W

ORIGINAL INSTRUCTIONS

Advertisement

Table of Contents

Summary of Contents for Cooper & Hunter CHV-09SCC4W

- Page 1 Operation, Installation & Maintenance Manual 4-WAY CASSETTE TYPE CHV-09SCC4W CHV-12SCC4W CHV-15SCC4W CHV-19SCC4W CHV-22SCC4W CHV-24SCC4W CHV-27SCC4W CHV-30SCC4W CHV-38SCC4W CHV-48SCC4W CHV-54SCC4W THANK YOU FOR PURCHASING THIS CENTRAL AIR CONDITIONER. PLEASE READ AND UNDERSTAND THIS MANUAL BEFORE USING THE AIR CONDITIONER. KEEP THIS...

-

Page 3: Important Notice

Dear user: Thank you for choosing and using our product. To better understand and use this product, please be sure to read and observe the following related issues before use. IMPORTANT NOTICE Signal words (DANGER, WARNING and CAUTION) are used to indicate hazard seriousness. Definitions of the hazard levels are provided below with respective signal words. - Page 4 DANGER Please don't perform installation works such as refrigerant piping connection, drain pipe connection, and wiring connection. Violations may result in system leakage, electrical failure or fire. In the case of fire, please turn off the power immediately; please don't touch electrical parts with the hands, or electric shock may arise. Do not pour water into the indoor or outdoor unit.

-

Page 5: Correct Disposal Of This Product

Correct Disposal of this product This marking indicates that this product should not be disposed with other household wastes. To prevent possible harm to the environment or human health from uncontrolled waste disposal, recycle it responsibly to promote the sustainable reuse of material resources. To return your used device, please use the return and collection systems or contact the retailer where the product was purchased. - Page 7 1.Safety Precautions Tools & Instruments for Installation Transportation & Handling 3.1 Transportation 3.2 Handling of Indoor Unit Installation of Indoor Unit 4.1 Factory-Supplied Accessories 4.2 Initial Check 4.3 Installation Refrigerant Piping Work 5.1 Piping Materials 5.2 Piping Connection 6.Drain Pipe Electrical Wiring 7.1 General Check 7.2 Wiring...

- Page 9 Do not install the indoor unit, outdoor unit, Do not perform installation work, refrigerant piping remote control switch and cable work, drain piping and electrical wiring connection within approximately 9.8ft.(3m) from strong without referring to the installation manual. electromagnetic wave radiators such as Check that the ground wire is securely connected.

-

Page 10: Initial Check

The indoor unit must be installed at an appropriate 4.2 Initial Check location so that the indoor temperature can be evenly distributed. Install the indoor unit in a space for easy operation and maintenance as shown in Fig. 4.1. There should be no obstruction of air flow at the vent. Provide a service access door near the unit Do not install the indoor unit in a machinery shop piping connection area on the ceiling. - Page 11 4.3.3 Mounting the Indoor Unit For Steel Beam For Concrete Slab Mount the indoor unit as shown in Fig. 4.6. 5-29/32~6-19/64in.(150~160mm) Screw in Mount field-supplied parts 220~331lbs(100~150kg) Suspension bolt 4-M10 or W3/8 Concrete 8-M10 or W3/8 Suspension Bolt Washer 8-M10 or W3/8 Fixing Point Beam (W3/8 or M10)

- Page 12 4.3.4 Adjust the Distance between Indoor Unit (b) For ceiling without panel and Ceiling Please cover the machine with plastic cloth to keep it clean during installation. Check the level of water pan using a water level to avoid incorrect installation of drain discharge mechanism.

-

Page 13: Piping Connection

(2) As shown in Fig. 5.4, two spanners shall be used for 5.2 Piping Connection (1) The connection point and diameter of piping are shown in Figs. 5.1 and 5.2. Unit: in.(mm) 33-5/64( 0) ( Pipe Size .(mm) Tightening Torque ft· (N.m) 6-19/64(160) (Liquid Pipe) 1/4(Φ6.35) - Page 14 (1) The position of the drain pipe Where the relative humidity of air inlet or connection is shown ambient air exceeds 80%, an auxiliary water pan t in.(mm) shall be fabricated at installation site and placed under the indoor unit, as shown in Fig. 6.2. Connected to Drain Pipe 3-15/64(82) Indoor Unit...

- Page 15 7.2 Wiring The electrical wiring connection for indoor unit is shown in Fig. 7.1. Turn OFF the main power switches to the indoor (1) Connect transmission wiring to the PBC unit and outdoor unit before electrical wiring or in electrical box through the connection hole periodical check, and wait for at least three on electrical box.

- Page 16 7/8 in.(22.2mm) Conduit Hole CAUTION ● Connecting Hole for Connecting Hole for Communication Cables and Power Supply Wiring Wire Controller Cables Fig. 7.1 Electrical Wiring Connection for Indoor Unit Units Power supply Fan motor Power supply Communication wiring size Cable Size Voltage Model (kBtu/h) Volts...

- Page 17 Test run should be performed according to the Installation & Maintenance Manual. Pay attention to the following items while the system Do no operate the system until all the check points are cleared. is running. (A) Do not touch any of the parts by hand at the (A) Check to ensure the electrical resistance between discharge gas side, since the temperatures of terminal and ground is more than 1 MΩ.

- Page 18 10.1 Setting of D Switches (c) Safety reset (DSW7) Factory settings (1) DIP switch must be set with power sources of the indoor and outdoor units in OFF state. Otherwise, the settings are invalid. Once strong current is (2) The DIP switches are located as shown in the accidentally connected to figure below.

- Page 20 Remarks Details 1 Set Indoor Unit: Operation Installation & Maintenance Manual: 1 pc 1 pc 1 pc 6 pcs 2 pcs 1 pc 1 pc Pipe Clamp: 1 pc 08.20...

Need help?

Do you have a question about the CHV-09SCC4W and is the answer not in the manual?

Questions and answers