Table of Contents

Advertisement

Quick Links

INSTALLATION AND OPERATING INSTRUCTIONS

Translation of the original operating instructions

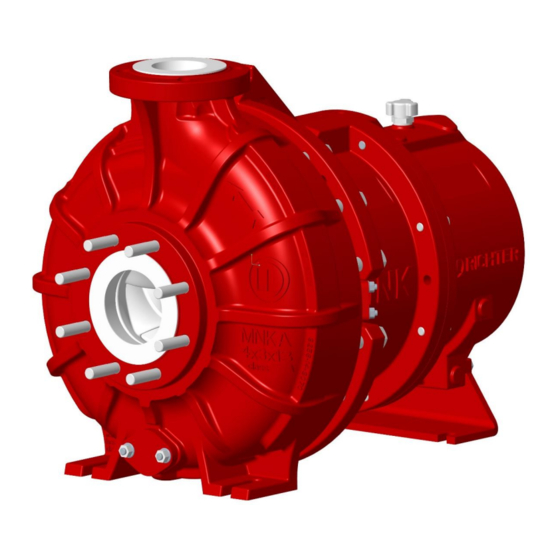

Series MNKA according to ASME

Sealless

chemical magnetic process pump

Bearing lubrication:

Long-life grease and oil bath

Bearing pedestal assembly: 4

Keep for future use! Read these operating instructions carefully before transport, installation,

operation and maintenance!

Subject to change without prior notice.

Reprinting is generally permitted provided that the source is credited.

© Richter Chemie-Technik GmbH.

9250-003-en Revision 01 Published 06/2022

Advertisement

Table of Contents

Summary of Contents for Richter MNKA Series

- Page 1 Keep for future use! Read these operating instructions carefully before transport, installation, operation and maintenance! Subject to change without prior notice. Reprinting is generally permitted provided that the source is credited. © Richter Chemie-Technik GmbH. 9250-003-en Revision 01 Published 06/2022...

-

Page 2: Table Of Contents

Series MNKA bearing pedestal assembly 4 Page 2 Contents Contents 2 6.1.2 Startup ..........14 Associated documents ..........3 6.2 Operating limits ..........14 Technical data ............3 6.2.1 Abrasive media ........14 1.1 Tightening torques .......... 4 6.2.2 Minimum/maximum flow rate ..... 14 1.2 Type plate, dry running, ATEX and housing 6.3 Shutdown ............ -

Page 3: Associated Documents

(Sichere Betriebsweise von Kreisel- pumpen) Technical data Manufacturer: Materials: Pressurized parts: Richter Chemie-Technik GmbH Ductile iron ASTM A395 / 5.3103 Otto-Schott-Str. 2 Carbon fiber composite CFRP D-47906 Kempen, Germany Parts in contact with medium: Phone: +49 2152 146 0... -

Page 4: Tightening Torques

[mm] [ASME] [in-lb] [Nm] 4 x ½“ 1½ Year of manufacture / 4 x ⅝“ Richter factory no. 4 x ⅝“ 8 x ⅝“ Dry running: 8 x ¾“ Flange according to ASME cl 300 Number x size Tightening torque... -

Page 5: Safety Instructions

Series MNKA bearing pedestal assembly 4 Page 5 Safety instructions ♦ Failure of electronic devices and measuring in- These operating instructions contain basic information that must be observed during struments due to magnetic fields. ♦ Danger to persons and their personal property installation, operation and maintenance. -

Page 6: Safety Instructions For Operating Company/Operator

Series MNKA bearing pedestal assembly 4 Page 6 health and the safety of workers that could be at All safety and protective facilities are to be risk from an explosive atmosphere. reinstalled and made functional immediately on completion of work. This unit must not be operated above the values specified in the data sheet When the safety instructions are observed... -

Page 7: Special Operating States

Series MNKA bearing pedestal assembly 4 Page 7 When mounting pump with non-Ex 2.6.2 Special operating states components (e.g. motor, shaft coupling), it is recommended to remove or obscure the Ex In the standard version, the plain marking on the pump part and, if applicable, other bearing is lubricated and cooled by the attachments. -

Page 8: Temperature Limits

Series MNKA bearing pedestal assembly 4 Page 8 Operating the pump outside the permissible operating range can also lead to dry running 2.6.8 Maintenance (e.g. due to evaporation in the interior). For safe and reliable operation, en- sure that the unit is properly main- 2.6.7 Temperature limits tained and kept in technically perfect condition by means of regular inspec-... -

Page 9: Transportation And Storage

Series MNKA bearing pedestal assembly 4 Page 9 Transportation and storage The pump or pump unit must be Elastomers must be protected against UV transported properly. Ensure that the radiation. pump/unit remains in a horizontal po- As a general rule, do not exceed a storage period sition during transportation and does of 10 years. -

Page 10: Product Description

Series MNKA bearing pedestal assembly 4 Page 10 Product description The housing dimensions, nominal outputs and Plain bearing pedestal 339 separates the hydrau- technical requirements of the MNKA bearing lic part of the pump from the can area. Both pedestal assembly 4 comply with ASME B73.3M, spaces are connected by flushing holes in the ISO 15783 / DIN ISO 5199. -

Page 11: Pipelines

Series MNKA bearing pedestal assembly 4 Page 11 Pipelines 5.4.2 Nozzle loading The pump can be nozzle loaded according to Before installing the pump, clean both the suction ANSI/HI 9.6.2. For values see installation plan. line and supply line as well as the discharge line. To prevent soiling or damage to the sealing sur- Temperature-related changes in the length of the faces, leave the flange covers on the flanges until... -

Page 12: Ventilation And Drainage

A vent line can also be a bypass, evacuation or ment is recommended. flushing line. Richter will provide information about and supply The pump housing is equipped with a drain port the following on request: as standard. Optionally, the drain bore can be ♦... -

Page 13: Coupling

EN 13463 without impairment. Richter offers both variants. The operator must ensure that the re- quirements Machinery Directive are met after installation of the coupling guard. -

Page 14: Commissioning/Shutdown

Series MNKA bearing pedestal assembly 4 Page 14 Commissioning/shutdown 6.1.2 Startup First commissioning ♦ Check that the drive shaft can be Normally, the pumps have already been test-run turned easily by hand. with water. Unless special agreements have ♦ Check the direction of rotation of the motor with been made, there could still be small amounts of residual water in the pump. -

Page 15: Shutdown

Series MNKA bearing pedestal assembly 4 Page 15 Pump is started up without liquid: Shutdown ♦ The plain bearing in the pump can be de- ♦ Close the discharge valve to the “minimum flow stroyed. ♦ Overheating can destroy other pump parts. rate”... -

Page 16: Maintenance

Series MNKA bearing pedestal assembly 4 Page 16 Maintenance 7.2.2 Oil bath lubrication Housing screw connections We recommend a mineral oil with the following characteristics for an expected bearing pedestal After initial loading by the operating pressure and temperature of up to 158 °F (70 °C): operating temperature, the tightening torques of Viscosity index: Approx. -

Page 17: Standby Pumps

Series MNKA bearing pedestal assembly 4 Page 17 Hold the individual parts of the magnetic Standby pumps couplings firmly or secure them. Otherwise they could be attracted, for example, by a vice: Risk of If a pump is on standby, it must be started up from accident! time to time. -

Page 18: Dismantling The Drive Unit And Long-Life Lubrication System

330 in the direction of the motor. ♦ To replace the rolling bearings 321/1 and ♦ An appropriate Richter device can be used to 321/2, push them off the drive shaft 213. remove the 545/1 and 545/2 bearing bushes. -

Page 19: Instructions For Assembly

Series MNKA bearing pedestal assembly 4 Page 19 7.8.2 Assembly of the drive unit and oil Instructions for assembly bath lubrication system ♦ Use original spare parts. See also section 2.4. ♦ Never use faulty parts. ♦ Screw hexagon screw 901/4 into bearing ped- ♦... -

Page 20: Assembly Of The Slide-In Unit

Series MNKA bearing pedestal assembly 4 Page 20 7.8.4 Assembly of the slide-in unit ♦ Mount plain bearing pedestal 339 and bearing bushes 529/x and apply corrosion protection CRC-SP 400II to plain bearing pedestal 339. ♦ Insert bearing sleeve 545/x on the impeller side. ♦... - Page 21 Series MNKA bearing pedestal assembly 4 Page 21 ♦ Screw the eye bolts into the holes on plain bearing pedestal 339. ♦ Lift plain bearing pedestal 339 together with im- peller 230 using the 3-strand sling chain and make sure that the square engages in the seat of plain bearing bush 545/x.

- Page 22 Series MNKA bearing pedestal assembly 4 Page 22 ♦ Lower bearing pedestal 339 together with impeller 230 above pump rotor 859. 9250-003-en Revision 01 TM 10458 Published 06/2022...

-

Page 23: Final Assembly

Series MNKA bearing pedestal assembly 4 Page 23 Z: Axial clearance of the plain bearing 0.016” to 0.051” (0.4 to 1.3 mm) These clearances must observed. The thickness of the housing gasket can be used to influence dimension Y. 7.8.5 Final assembly ♦... -

Page 24: Filling The Bearing Pedestal With Oil

Procedure for filling oil: 1) In-plant pumping station ♦ Pull the plastic container out of the holder. 2) Richter manufacturer ♦ Unscrew the plastic container and fill it with oil. or their local representative ♦ Screw the plastic container shut and insert it The following delivery data can be checked using into the holder. -

Page 25: Faults

Series MNKA bearing pedestal assembly 4 Page 25 Faults Faults can occur due to impermissible Flow rate too high: methods operation. Improper ♦ Is the geodetic head too low? methods of operation, even for short ♦ Are the pipe or nozzle resistances too low? periods, can result in serious damage ♦... -

Page 26: Exploded View Drawing

Series MNKA bearing pedestal assembly 4 Page 26 Exploded view drawing Long-life lubrication 9250-003-en Revision 01 TM 10458 Published 06/2022... -

Page 27: Oil Bath Lubrication

Series MNKA bearing pedestal assembly 4 Page 27 Oil bath lubrication 9250-003-en Revision 01 TM 10458 Published 06/2022... -

Page 28: Sectional Drawing

Series MNKA bearing pedestal assembly 4 Page 28 Sectional drawing 10.1 Legend Housing 529/x Bearing sleeve Cover flange 545/x Bearing bush 554/x Washer Support bracket 557/2 Contact washer Drive shaft Drive rotor Impeller Pump rotor 314/x Axial bearing 901/x Hexagon screw 321/x Radial ball bearing 902/x... -

Page 29: Sectional Drawing

Series MNKA bearing pedestal assembly 4 Page 29 10.2 Sectional drawing 9250-003-en Revision 01 TM 10458 Published 06/2022... -

Page 30: Sectional Drawing Of Oil Bath Lubrication

Series MNKA bearing pedestal assembly 4 Page 30 10.3 Sectional drawing of oil bath lubrication 9250-003-en Revision 01 TM 10458 Published 06/2022... -

Page 31: Assembly Aids

Series MNKA bearing pedestal assembly 4 Page 31 Assembly aids 11.1 Drilling template for housing drain Pump size ID no MNKA assembly 4 9217-89-1097 11.2 Puller for plain bearing bushes Pump size ID no MNKA assembly 4 9237-89-1138 Product description If the plain bearing bushes have to be removed from the plain bearing pedestal, we recommend using a special puller. - Page 32 Series MNKA bearing pedestal assembly 4 Page 32 Application ♦ Lower the rotor unit vertically into the device using a crane until the hub of the pump rotor rests on the base plate. ♦ Then tighten the 4 hexagon screws to a maximum of 60 Nm. For single and double-row pump rotors, tighten only the two lower screws.

- Page 33 Einsatzgrenzen / operating limits Baugröße / size: MNKA 6x4x13, MNKA 4x3x13, MNKA 3x2x13, MNKA 3x1.5x13 Mediumtemperatur ° ° medium temperature 1) Angelehnt an Flanschnorm ASME B16.42 / Based on ASME B16.42 flange standard Ⓒ Richter Chemie-Technik GmbH 9250-00-3046/4-00 TM 10432 31.03.22...

- Page 34 Drive magnet assembly with SmCo magnets Empfehlung: Lagerträger mit Ölschmierung Recommandation: Bearing pedestal witl oil bath lubrication Über 360 ° F / 180 ° C ohne ATEX Above 360 ° F / 180 ° C without ATEX Ⓒ Richter Chemie-Technik GmbH 9250-00-3046/4-00 TM 10432 31.03.22...

- Page 37 Waste Management Law (AbfG) and the Water Resources Act (WHG) An inspection/repair of Richter products and parts will only take place, if the attached explanation is filled out cor- rectly and completely by authorized and qualified technical personnel and is available.

- Page 38 Safety Information / Declaration of No Objection Concerning the Contamination of Richter-Pumps, -Valves and Components SCOPE AND PURPOSE Each entrepreneur (operator) carries the responsibility for the health and safety of his employees. This extends also to the personnel, who implements repairs with the operator or with the contractor.

- Page 39 for credit note Phone : Fax : End user : A. Details of Richter-product: Failure description: Classification: Article number: Serial number: B. Condition of the Richter- product: Contamination : Was it in operation ? toxic ...

- Page 40 Email: RichterCedarFalls-Info@idexcorp.com Email: RichterMumbai-Info@idexcorp.com Internet: www.richter-inc.com Internet: www.richter-ct.com © Richter Chemie-Technik GmbH 2022 Edition 06/2022 Revision 1.0 Subject to change without notice. 9250B003-en These installation and operating instructions must be kept! Richter™ = Richter Chemie-Technik GmbH; IDEX™ = IDEX Corporation...

Need help?

Do you have a question about the MNKA Series and is the answer not in the manual?

Questions and answers